A kind of preparation of organic vegetable dye and dyeing method thereof

A plant dye and dyeing method technology, applied in the field of dye extraction and dyeing, can solve the problems of large environmental pollution, high production cost, complex dye synthesis process, etc., and achieve the effects of reducing energy consumption, reducing energy consumption and accelerating extraction speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

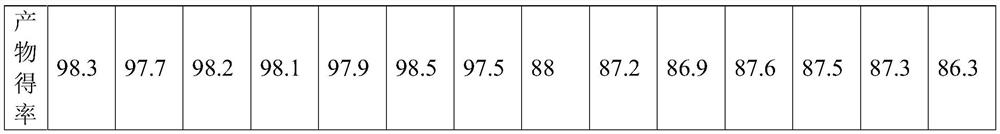

Examples

Embodiment 1

[0035] The preparation method of organic vegetable dye:

[0036] (1) Mix the plant leaves and ethanol with a mass ratio of 1:3 in a countercurrent extraction equipment, then heat up to 70 ° C for 1 hour, and then perform countercurrent extraction to obtain the initial extract; the plant leaves are selected from tea leaves or holly leaves or Mulberry leaves or pine needles, etc.;

[0037] (2) Centrifuging the initial extract to obtain a first filtrate and a first filter residue, and subjecting the first filtrate to an adsorption treatment by a first solid-phase extraction column under an ultrasonic state to obtain a first effluent;

[0038](3) return the first filter residue and the first effluent to the countercurrent extraction equipment respectively, carry out countercurrent extraction again at 70° C., and then process according to the method of step (2) to obtain the second filter residue and the second effluent. In the step, the second solid phase extraction column is use...

Embodiment 2

[0045] The preparation method of organic vegetable dye:

[0046] (1) Mix the plant fruit and deionized water with a mass ratio of 1:3 in a countercurrent extraction equipment, then heat up to 60°C for 1 hour, and then carry out countercurrent extraction to obtain the initial extract; the plant fruit is selected from pomegranate peel or persimmon or dragon fruit peel, etc.;

[0047] (2) Centrifuging the initial extract to obtain a first filtrate and a first filter residue, and subjecting the first filtrate to an adsorption treatment by a first solid-phase extraction column under an ultrasonic state to obtain a first effluent;

[0048] (3) return the first filter residue and the first effluent to the countercurrent extraction equipment respectively, carry out countercurrent extraction again at 60° C., and then process according to the method of step (2) to obtain the second filter residue and the second effluent. In the step, the second solid phase extraction column is used for...

Embodiment 3

[0054] The preparation method of organic vegetable dye:

[0055] (1) Mix mahogany sawdust with a mass ratio of 1:3 and sodium bicarbonate solution with a concentration of 0.5g / L in a countercurrent extraction equipment, then heat up to 50°C for 1 hour, and then carry out countercurrent extraction to obtain the initial extract;

[0056] (2) Centrifuging the initial extract to obtain a first filtrate and a first filter residue, and subjecting the first filtrate to an adsorption treatment by a first solid-phase extraction column under an ultrasonic state to obtain a first effluent;

[0057] (3) return the first filter residue and the first effluent to the countercurrent extraction equipment respectively, carry out countercurrent extraction again at 50° C., and then process according to the method of step (2) to obtain the second filter residue and the second effluent. In the step, the second solid phase extraction column is used for adsorption treatment;

[0058] (4) The second ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com