A kind of electroplating sludge chromium element extraction device and method equipped with ultrasonic generator

A technology of ultrasonic generator and electroplating sludge, which is applied in the direction of improving process efficiency, etc., can solve the problems of low processing efficiency, long reaction time, low extraction rate of chromium element, etc., and achieve improved processing efficiency, high-purity extraction, and shortened reaction time the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

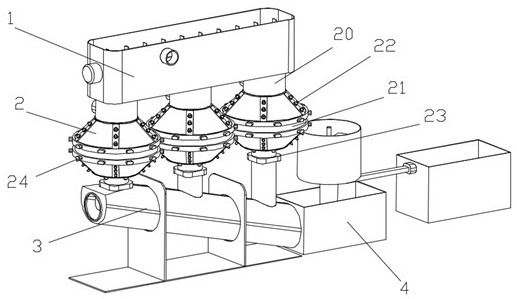

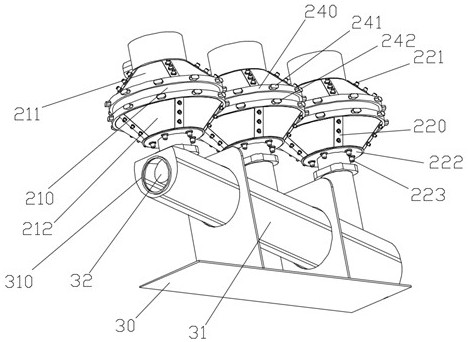

[0044] like figure 1 An electroplating sludge chromium element extraction device equipped with an ultrasonic generator as shown includes an electroplating sludge pretreatment tank 1, three ultrasonic cavitation reactors 2 arranged below the electroplating sludge pretreatment tank 1, and A separation assembly 3 for separating sludge at the lower end of the ultrasonic cavitation reactor 2, and a reaction extraction device 4 communicating with one end of the separation assembly 3;

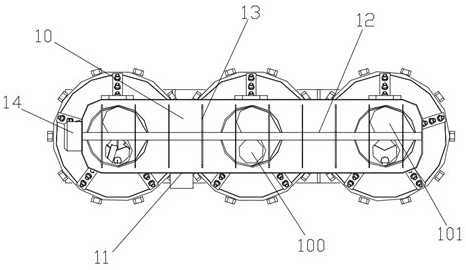

[0045] like figure 2 As shown, the electroplating sludge pretreatment tank 1 includes a horizontally disposed treatment tank body 10, a water inlet pipe 11 arranged on the treatment tank body 10, and a first stirring shaft 12 arranged inside the treatment tank body 10 , the first stirring blade fan 13 evenly arranged on the first stirring shaft 12, and the drive motor 14 arranged on the treatment tank body 10 for driving the first stirring shaft 12;

[0046] The lower end surface of the treatment t...

Embodiment 2

[0061] The difference with embodiment 1 is:

[0062] The cone angles of the upper cone surface 211 and the lower cone surface 212 are both 55°.

[0063] like Figure 5 The ultrasonic cavitation reaction chamber 21 is provided with a vibrating diaphragm assembly 25 inside;

[0064] like Figure 5 , Image 6 As shown, the vibrating diaphragm assembly 25 includes a first fixed plate 250 evenly arranged on the inner wall of the upper conical surface 211 and a second fixed plate 251 evenly arranged on the inner wall of the lower conical surface 212. The first vibrating membrane 252 on the plate 250, and the second vibrating membrane 253 arranged on the second fixed plate 251 and extending in the horizontal direction.

[0065] A rotating connecting ring 213 is disposed inside the lower conical surface 212; a mud scraper 214 is movable on the rotating connecting ring 213.

[0066] Wherein, the first vibrating membrane 252 and the second vibrating membrane 253 are both made of sp...

Embodiment 3

[0069] Adopt the electroplating sludge chromium element extracting device carrying ultrasonic generator of embodiment 1 to carry out the method for chromium element extraction, comprise the following steps:

[0070] S1, adjust the water content

[0071] First add electroplating sludge into the electroplating sludge pretreatment tank 1, then add clear water into the treatment tank body 10 through the water inlet pipe 11, so that the liquid-solid ratio in the electroplating sludge pretreatment tank 1 is 4ml: 1g, the first stirring Blade fan 13 stirs;

[0072] S2. Ultrasonic cavitation

[0073] Open the sealing cover plate 101 to allow the electroplating sludge to enter the ultrasonic cavitation reaction chamber 21, spray a sodium hydroxide solution with a mass concentration of 35% into the electroplating sludge through the first nozzle 241, and start the first ultrasonic generator 221 and the second ultrasonic generator simultaneously. Two ultrasonic generators 223; when the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com