Calcium sulfate whisker and production method of raw material calcium sulfate thereof

A technology of calcium sulfate whisker and production method, applied in the directions of polycrystalline material growth, crystal growth, single crystal growth, etc., can solve the problems of intractable processing, low aspect ratio, difficult to carry out acid leaching, etc., and achieve significant economic benefits, The effect of low production cost and improved aspect ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

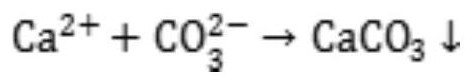

Method used

Image

Examples

Embodiment 1

[0039] Calcium sulfate whiskers are produced as follows:

[0040] (1) Dilute the filtered calcium carbide slag with water to the Ca(OH) in the slurry 2 The mass concentration of the solution is 260g / L, and the surplus chlorine gas in the chlor-alkali industry is passed into until the pH of the solution=4, the chlorine gas is stopped, and the first solution is obtained after a full reaction; the reaction temperature is 50°C, and Ca(ClO) 2 The concentration is 0.86mol / L, and the available chlorine content is 97g / L.

[0041] (2) adding NaOH to the first solution until the pH=7 of the solution stops adding NaOH to obtain the second solution;

[0042] (3) filtering the second solution to obtain the third solution;

[0043] (4) adding Glauber's salt to the third solution for full reaction, and obtaining a fourth solution after the reaction is completed; the reaction temperature is 60°C.

[0044] (5) filter the fourth solution to obtain calcium sulfate solid phase and supernatant...

Embodiment 2

[0050] Calcium sulfate whiskers are produced as follows:

[0051] (1) Dilute the calcium carbide slag (same batch as in Example 1) with water to the Ca(OH) in the slurry after pressure filtration 2 The mass concentration of the solution is 200g / L, and the excess chlorine gas in the chlor-alkali industry is passed into until the pH of the solution=6.5, the chlorine gas is stopped, and the first solution is obtained after a full reaction; Ca(ClO) 2 The concentration is 1.12mol / L, and the available chlorine content is 147g / L.

[0052] (2) adding NaOH to the first solution until the pH=9 of the solution stops adding NaOH to obtain the second solution;

[0053] (3) filtering the second solution to obtain the third solution;

[0054] (4) adding Glauber's salt to the third solution for full reaction, and obtaining a fourth solution after the reaction is completed; the reaction temperature is 50°C.

[0055] (5) filter the fourth solution to obtain calcium sulfate solid phase and s...

Embodiment 3

[0061] Calcium sulfate whiskers are produced as follows:

[0062] (1) Dilute the calcium carbide slag (same batch as in Example 1) with water to the Ca(OH) in the slurry after pressure filtration 2 The mass concentration of the solution is 300g / L, and the excess chlorine gas in the chlor-alkali industry is passed into until the pH of the solution=5, the chlorine gas is stopped, and the first solution is obtained after sufficient reaction; Ca(ClO) 2 The concentration is 0.66mol / L, and the available chlorine content is 105g / L.

[0063] (2) adding NaOH to the first solution until the pH=8 of the solution stops adding NaOH to obtain the second solution;

[0064] (3) filtering the second solution to obtain the third solution;

[0065] (4) adding Glauber's salt to the third solution for full reaction, and obtaining a fourth solution after the reaction is completed; the reaction temperature is 40°C.

[0066] (5) filter the fourth solution to obtain calcium sulfate solid phase and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com