System and method for preparing erythritol and polydextrose from corn starch

A technology of polydextrose and erythritol, which is applied in the field of sugar alcohol preparation, can solve the problems of increasing the added value of raffinate, low utilization rate of high value, etc., and achieves the effect of reducing processing cost and realizing high value utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

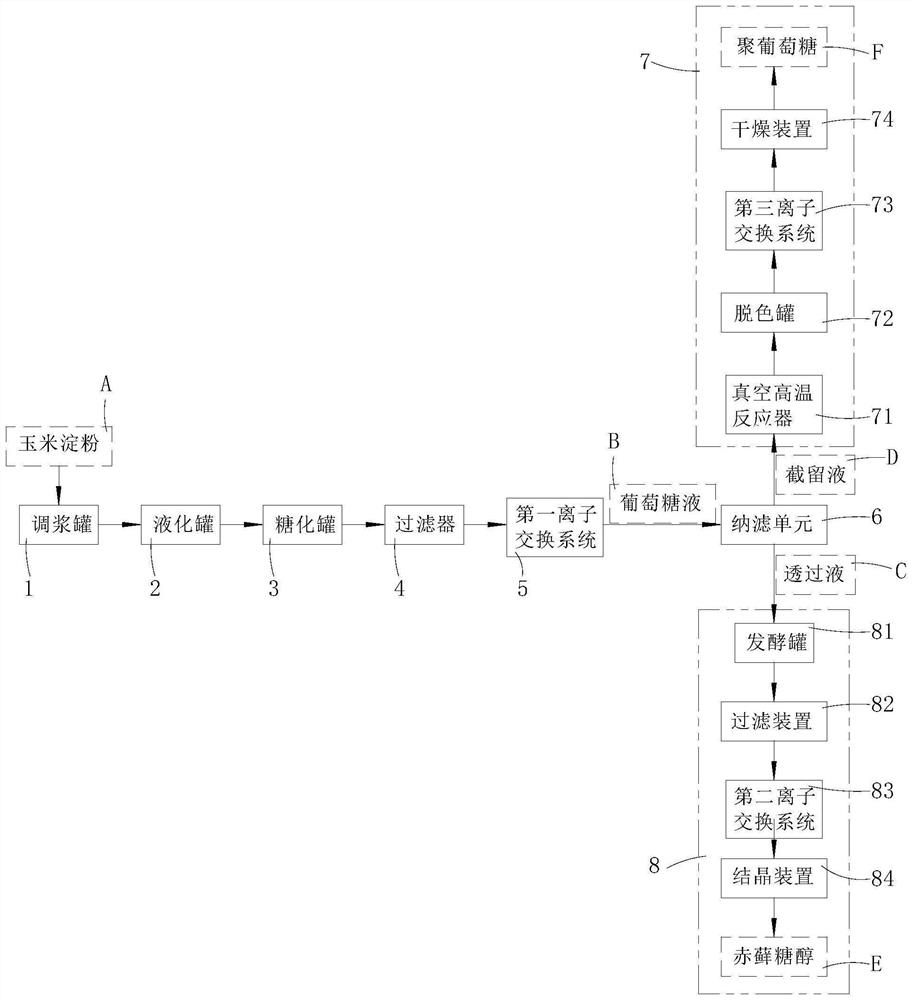

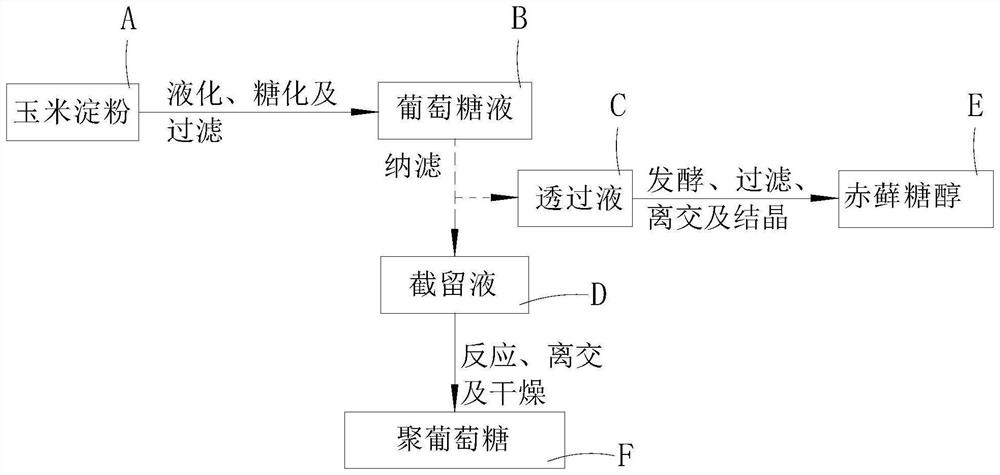

[0043] The first embodiment of the method utilizing cornstarch to prepare erythritol and polydextrose of the present invention, comprises the steps:

[0044] Step 11: After mixing cornstarch A with water to make cornstarch milk, add high temperature resistant α-amylase and glucoamylase in sequence to liquefy and saccharify the cornstarch to obtain a saccharification solution. The filter 4 is used to remove impurities such as macromolecular protein and fat in the saccharification liquid, and then the ion exchange resin of the first ion exchange system 5 is passed through to obtain the glucose liquid B with a conductivity of 1.696 μs / cm and a purity of 96%.

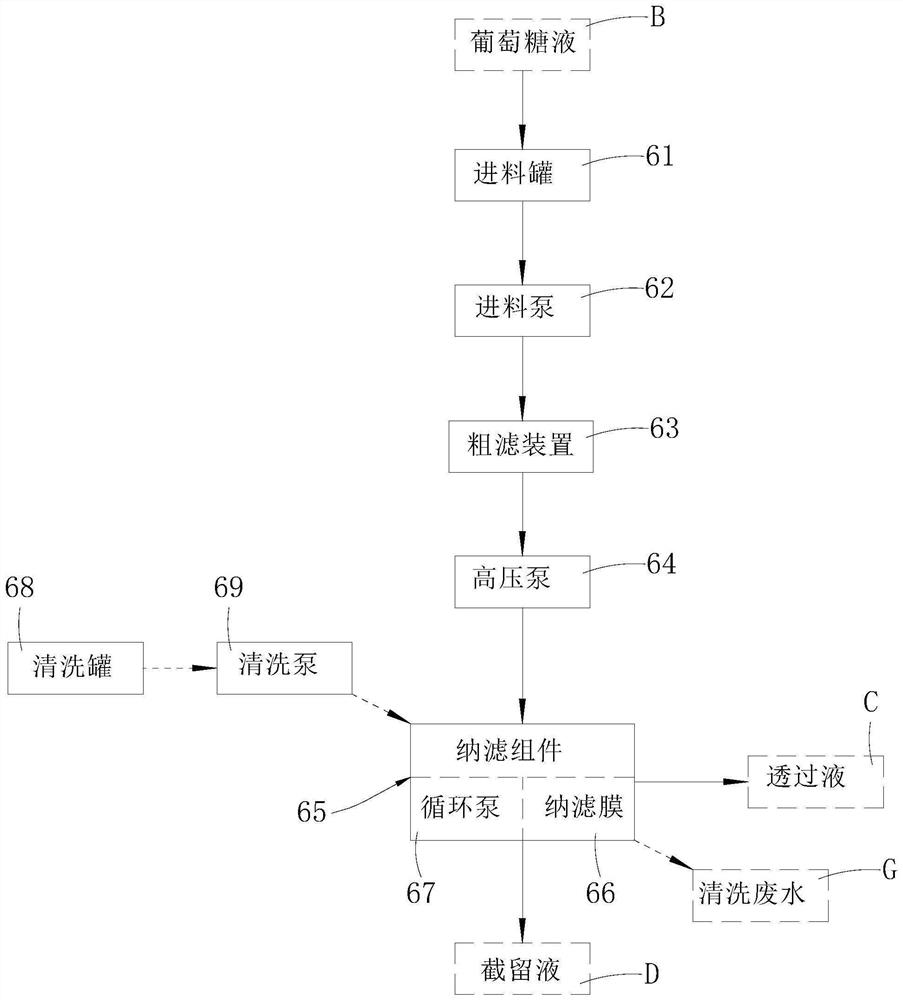

[0045] Step 12: Take glucose solution B with a dry weight of 1 ton and perform nanofiltration treatment to obtain permeate C with a dry weight of 0.79 tons and a glucose purity of 99.2% and a dry weight of 0.21 tons with a glucose purity of 84.0% respectively. % of retentate D. In the retentate D, in addition to glucose, i...

Embodiment 2

[0052] The second embodiment of the method utilizing cornstarch to prepare erythritol and polydextrose of the present invention comprises the following steps:

[0053] Step 21: After mixing cornstarch A with water to make cornstarch milk, add high-temperature resistant α-amylase and glucoamylase in sequence to liquefy and saccharify the cornstarch to obtain a saccharification solution. The filter 4 is used to remove impurities such as macromolecular protein and fat in the saccharification liquid, and then the ion exchange resin of the first ion exchange system 5 is passed through to obtain the glucose liquid B with a conductivity of 1.914 μs / cm and a purity of 95.8%.

[0054] Step 22: Take glucose liquid B with a dry weight of 1 ton and perform nanofiltration to obtain permeate C with a dry weight of 0.78 tons and a glucose purity of 99.4% and a dry weight of 0.22 tons with a glucose purity of 83.1% respectively. The retentate D. In the retentate D, in addition to glucose, it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refraction | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com