Water-resistant waterborne polyurethane ink vehicle and preparation method thereof

A technology of water-based polyurethane and ink connecting material, which is applied in the direction of ink, household appliances, application, etc., can solve the problem of insufficient water resistance of water-based polyurethane ink connecting material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

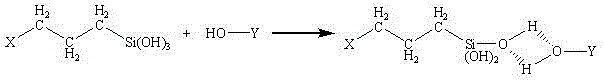

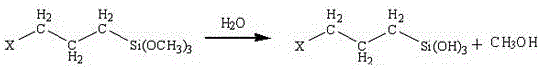

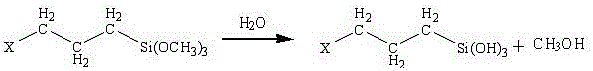

Method used

Image

Examples

Embodiment 1

[0029] The preparation method of a kind of water-resistant type water-based polyurethane ink binder of the present embodiment is as follows:

[0030] (1) Take 200ml of absolute ethanol, add hydrochloric acid dropwise to it to adjust the pH value to 3~4, then take 25ml of 3-methacryloxypropyltrimethoxysilane and add it to the ethanol-hydrochloric acid system for 30min Hydrolyze thoroughly until the mixed solution is clear and transparent, and let it stand at room temperature for later use;

[0031] (2) Weigh 1.0g of bacterial cellulose and 100.0g of thoroughly hydrolyzed silanol and ethanol-hydrochloric acid mixed solution and place it in a conical flask. The surface modification process of bacterial cellulose requires a reaction temperature of 60°C and a reaction time of 2h , the mechanical stirring speed is 60r / min, after the modification reaction is finished, the bacterial cellulose is vacuum-filtered and washed 3 times with absolute ethanol to prepare 1.06g of modified bact...

Embodiment 2

[0037] The preparation method of a kind of water-resistant type water-based polyurethane ink binder of the present embodiment is as follows:

[0038] (1) Take 300ml of absolute ethanol, add hydrochloric acid dropwise to it to adjust the pH value to 3~4, then take 34ml of 3-(2,3-glycidoxy)propyltrimethoxysilane and add it to the above ethanol- Carry out hydrolysis in the hydrochloric acid system for 30 minutes until the mixed solution is clear and transparent, and let it stand at room temperature for later use;

[0039] (2) Weigh 2.0g of bacterial cellulose and 200.0g of thoroughly hydrolyzed silanol and ethanol-hydrochloric acid mixed solution and place it in a conical flask. The surface modification process of bacterial cellulose requires a reaction temperature of 60°C and a reaction time of 2h , the mechanical stirring speed is 60r / min, after the modification reaction is finished, the bacterial cellulose is vacuum filtered and washed 3 times with absolute ethanol to prepare ...

Embodiment 3

[0045] The preparation method of a kind of water-resistant type water-based polyurethane ink binder of the present embodiment is as follows:

[0046] (1) Take 200ml of absolute ethanol, add hydrochloric acid dropwise to it to adjust the pH value to 3~4, then measure 20ml of 3-(2,3-glycidoxy)propyltrimethoxysilane and add it to the above ethanol- Carry out hydrolysis in the hydrochloric acid system for 30 minutes until the mixed solution is clear and transparent, and let it stand at room temperature for later use;

[0047] (2) Weigh 1.5g of bacterial cellulose and 150.0g of thoroughly hydrolyzed silanol and ethanol-hydrochloric acid mixed solution and place it in a conical flask. The surface modification process of bacterial cellulose requires a reaction temperature of 60°C and a reaction time of 2h , the mechanical stirring speed is 60r / min, after the modification reaction is finished, the bacterial cellulose is vacuum filtered and washed 3 times with absolute ethanol to prepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com