A kind of preparation method of L-glucosone

A technology of L-glucosone and cellulose, which is applied in the field of preparation of high-yield L-glucosone, can solve the problems of waste of concentrated sulfuric acid, unfavorable environmental protection, pollution, etc., achieves significant economic and social benefits, is beneficial to environmental protection, and has large applications. Foreground effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

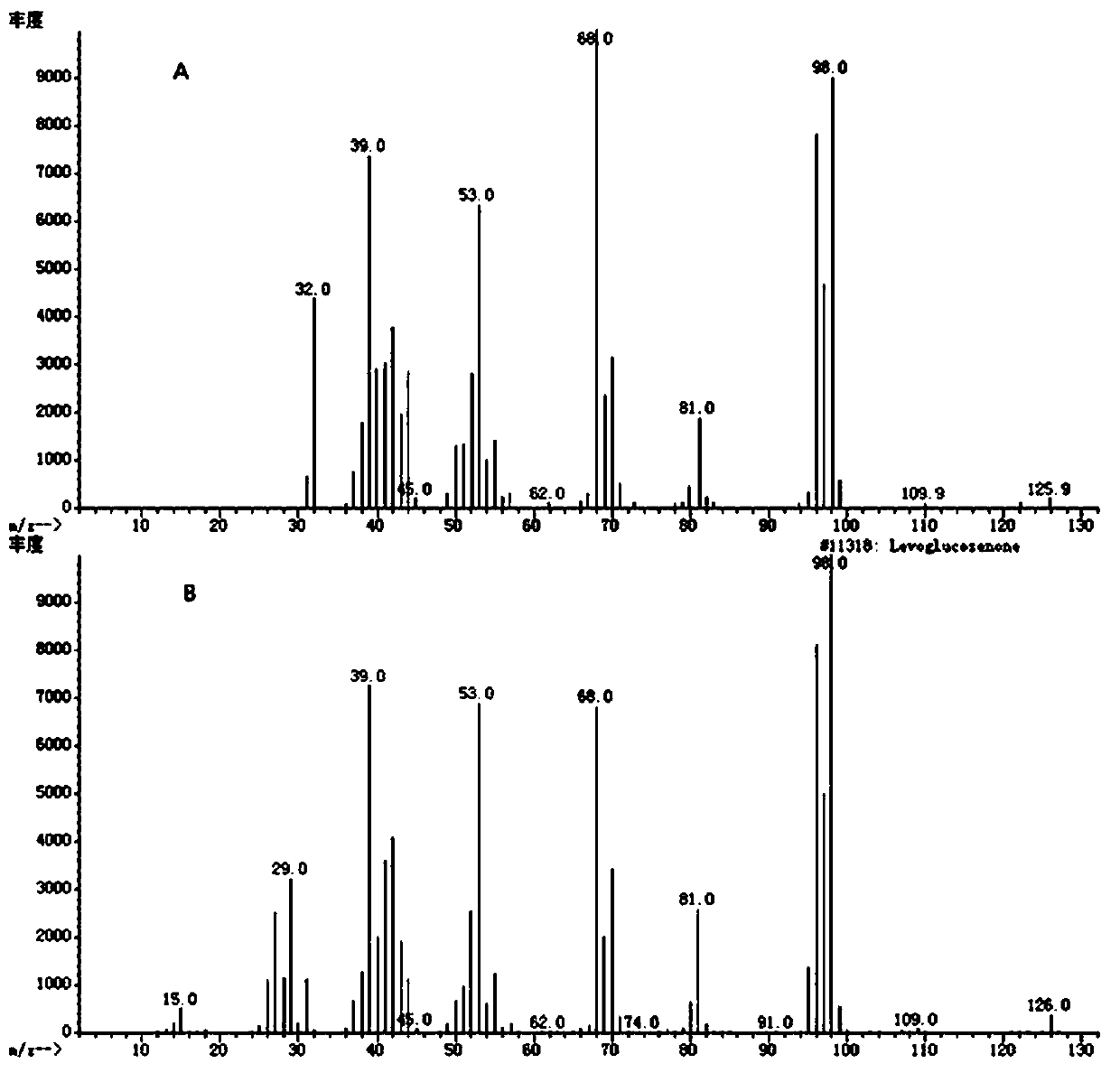

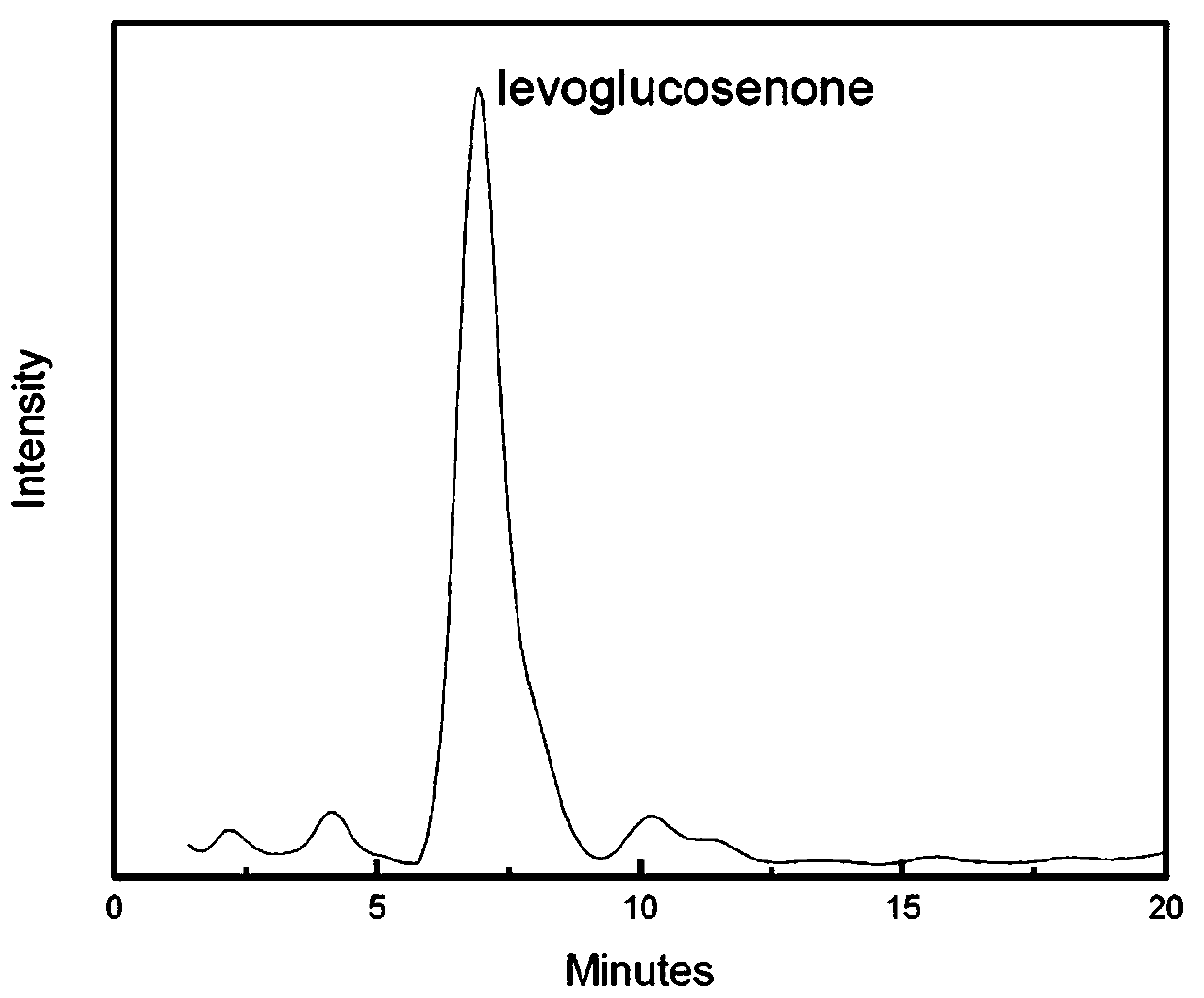

Image

Examples

Embodiment 1

[0030] The preparation method of L-glucosone of the present invention, the detailed steps of this preparation method are as follows:

[0031] a. First, dissolve phosphoric acid in water to form 100mL of 2.0mol / L phosphoric acid solution, then add 10g of microcrystalline cellulose to the obtained phosphoric acid solution, mix thoroughly after adding, and soak for 10min;

[0032] b. Filter the material after soaking (by filtering to remove most of the liquid absorbed in the microcrystalline cellulose after soaking), and then put the obtained filter cake in a pyrolysis furnace under vacuum (5mmHg) and 200°C. Pyrolysis pretreatment for 10 minutes to obtain a dehydrated intermediate product;

[0033] c. Cool the obtained dehydrated intermediate product to room temperature, place it in 100 mL, 0.05 mol / L sodium hydroxide aqueous solution after cooling, mix well, and soak for 10 min;

[0034] d. Filter the product obtained in step c (remove most of the liquid adsorbed in the product...

Embodiment 2

[0038] The preparation method of L-glucosone of the present invention, the detailed steps of this preparation method are as follows:

[0039] a. First, dissolve phosphoric acid in water to form 100 mL of 1.5 mol / L phosphoric acid solution, then add 10 g of microcrystalline cellulose to the obtained phosphoric acid solution, mix thoroughly after adding, and soak for 20 minutes;

[0040] b. Filter the material after soaking (by filtering to remove most of the liquid absorbed in the microcrystalline cellulose after soaking), and then put the obtained filter cake in a pyrolysis furnace under vacuum (5mmHg) and 150°C. Pyrolysis pretreatment for 30 minutes to obtain the dehydrated intermediate product;

[0041] c. Cool the obtained dehydrated intermediate product to room temperature, place it in 100 mL, 0.03 mol / L sodium hydroxide aqueous solution and mix thoroughly after cooling, and soak for 20 min;

[0042] d. Filter the product obtained in step c (remove most of the liquid adso...

Embodiment 3

[0045] The preparation method of L-glucosone of the present invention, the detailed steps of this preparation method are as follows:

[0046] a. First, dissolve phosphoric acid in water to form 100mL of 2.2mol / L phosphoric acid solution, then add 10g of microcrystalline cellulose to the obtained phosphoric acid solution, mix thoroughly after adding, and soak for 10min;

[0047] b. Filter the material after soaking (by filtering to remove most of the liquid absorbed in the microcrystalline cellulose after soaking), and then put the obtained filter cake in a pyrolysis furnace, in a vacuum (vacuum degree of 5mmHg), 220 ℃ Perform pyrolysis pretreatment for 10 minutes under the same conditions to obtain a dehydrated intermediate product;

[0048] c. Cool the obtained dehydrated intermediate product to room temperature, place it in 100mL, 0.08mol / L sodium hydroxide aqueous solution and mix thoroughly after cooling, and soak for 10min;

[0049] d. Filter the product obtained in step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com