System for industrial waste gas treatment and salt regeneration

A technology of industrial waste gas and regeneration system, applied in chemical instruments and methods, preparation of chlorides, separation of dispersed particles, etc., can solve problems such as pollution and achieve the effect of increasing added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

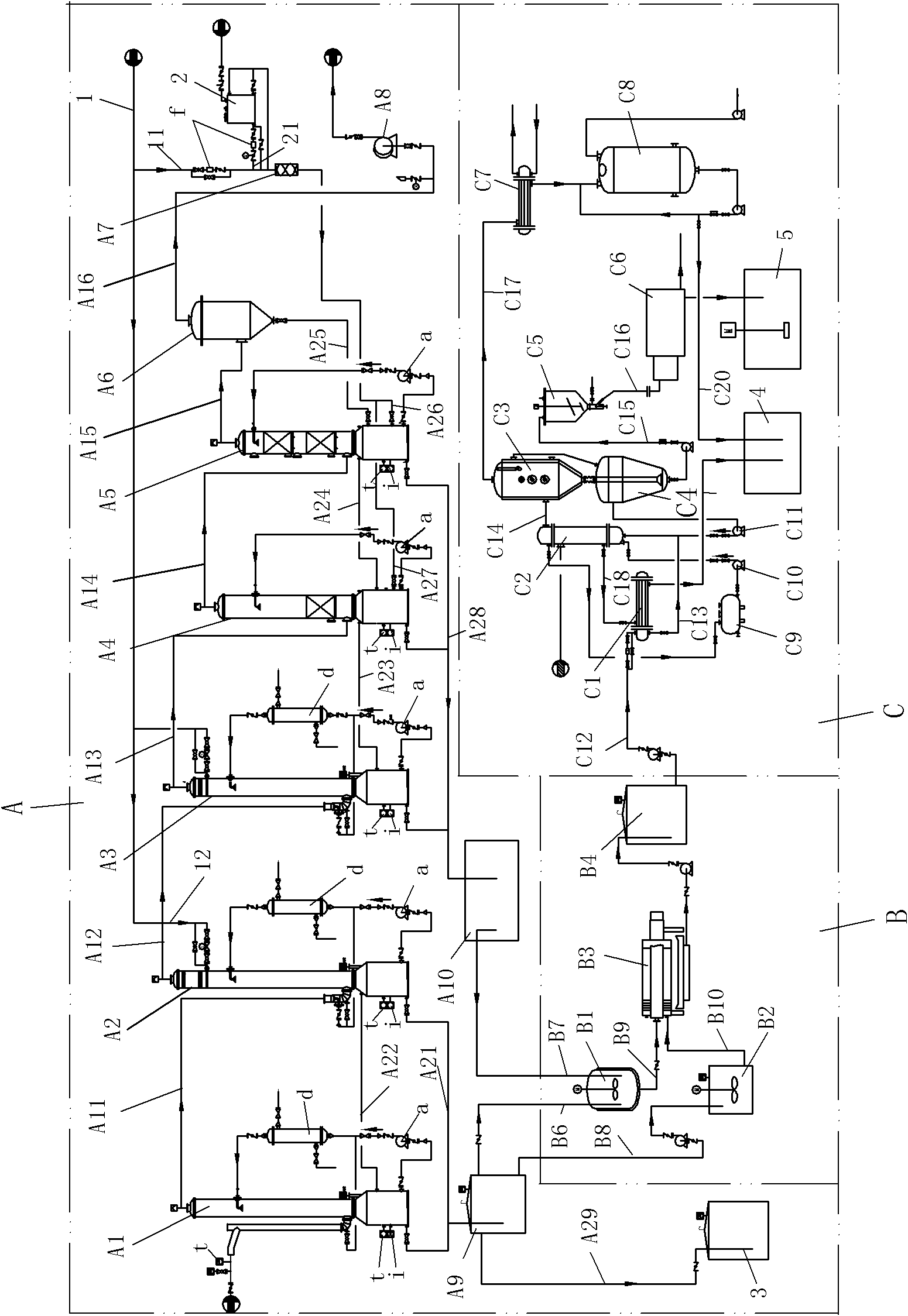

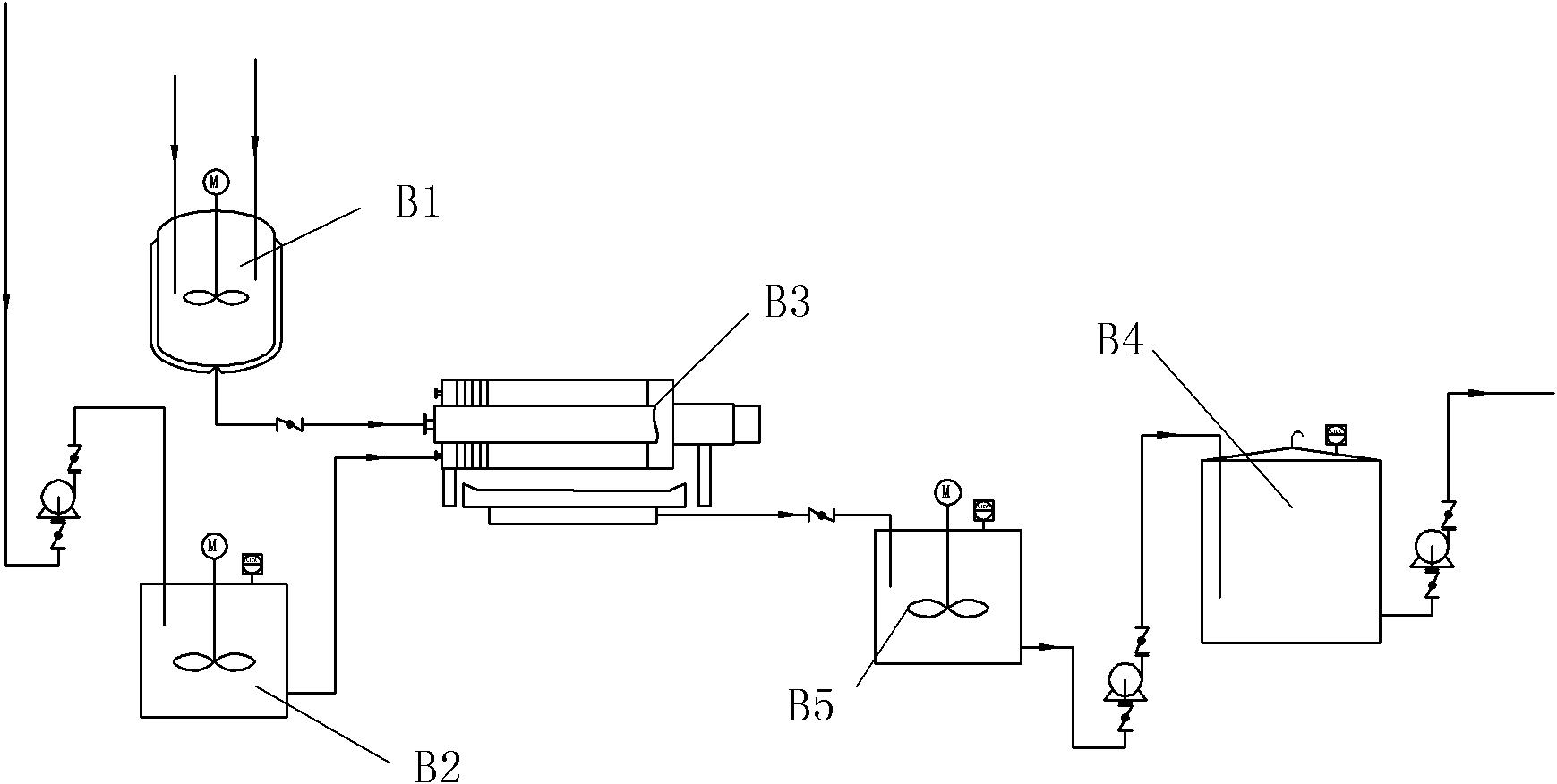

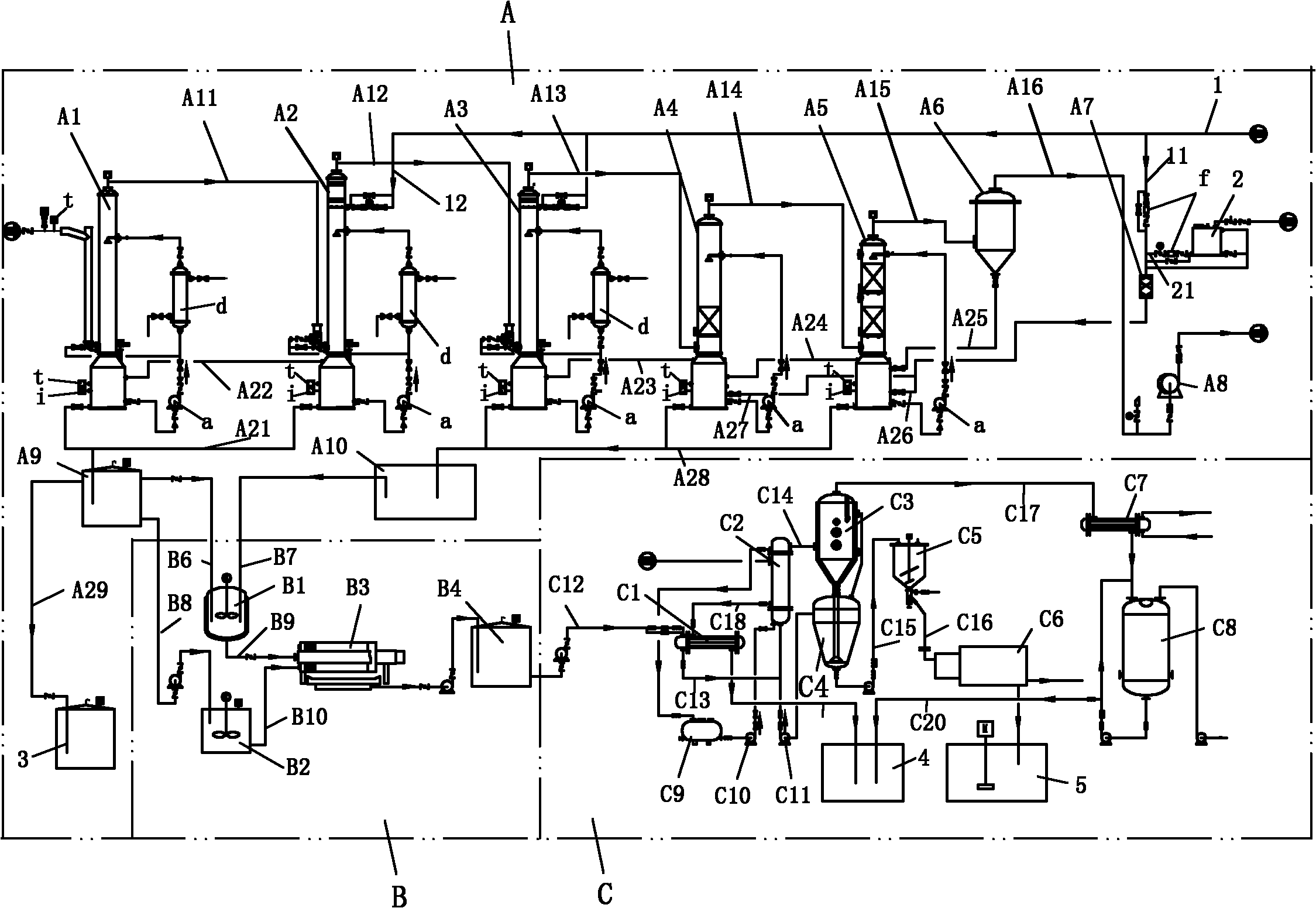

[0011] Example 1 see figure 1 , This embodiment includes waste gas treatment device A, neutralization and deslagging device B, salt solution concentration device C, water supply main pipe 1, lye supply tank 2, hydrochloric acid storage tank 3, water collection tank 4 and filtrate storage tank 5. The neutral water of the main water supply pipe 1 is jointly provided by external industrial water and condensed water produced by the system.

[0012] The exhaust gas treatment device A has No. 1 absorption tower A1, No. 2 absorption tower A2, No. 3 absorption tower A3, No. 4 absorption tower A4, No. 5 absorption tower A5, aerosol separator A6, mixer A7 and acid liquid clarification Tank A9 and lye transfer tank A10. The above No. 1 absorption tower A1 is a spray absorption tower, No. 2 absorption tower A2 and No. 3 absorption tower A3 are turbulent spray absorption towers. No. 4 absorption tower A4 and No. 5 absorption tower A5 are packed absorption towers. The upper part of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com