System for replacing steam internally blowing hot-dip galvanized steel pipe equipment

A hot-dip galvanizing and steam technology, applied in hot-dip galvanizing process, metal material coating process, coating and other directions, can solve the problems of increasing production cost, being subject to pot inspection, low utilization value, etc., and saving production. The effect of low cost, low production cost and high utilization value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

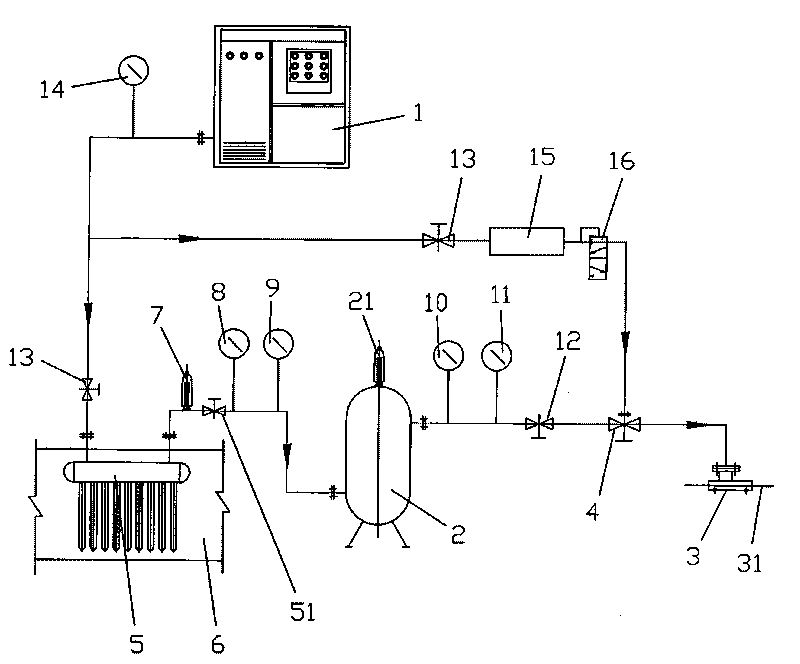

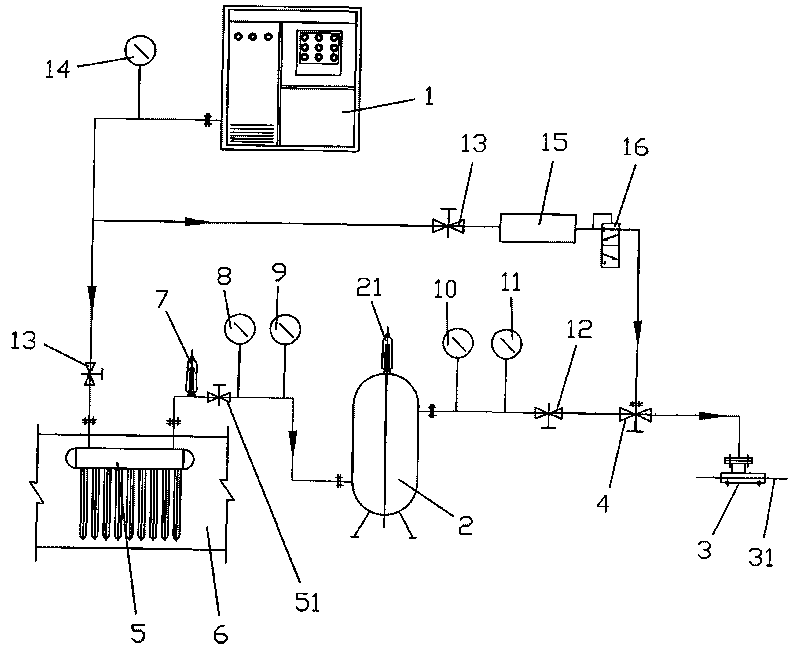

[0010] Reference figure 1 , The present invention is an alternative steam internal blowing hot-dip galvanized steel pipe equipment system, including an air compressor 1, a steam drum 2, an internal blowing device 3 connected to the steam drum 2, and the steam drum 2 and the internal blowing device 3 are also connected There is a pneumatically controlled membrane valve 4, the control end of the pneumatically controlled membrane valve 4 is in communication with the air path of the air compressor 1, the steam drum 2 is in air path communication with an air preheater 5, the air preheater 5 is in communication with the air compressor The machine 1 is connected with the air path, and the air preheater 5 is arranged in the flue 6 of the galvanizing pot heating furnace.

[0011] The above technical solution can also have the following improvement solutions: a safety valve 7, a temperature gauge 8 and a pressure gauge 9 are also provided between the steam drum 2 and the air preheater 5.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com