Continuous and electromagnetic separating method for zinc slag in heat galvanizing liquid

An electromagnetic separation and hot-dip galvanizing technology, which is applied in hot-dip galvanizing process, process efficiency improvement, coating, etc., can solve potential safety hazards, insufficient purification efficiency and effect of zinc pot, inability to purify zinc liquid in zinc pot, etc. problem, to achieve the effect of reducing zinc consumption and zinc slag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

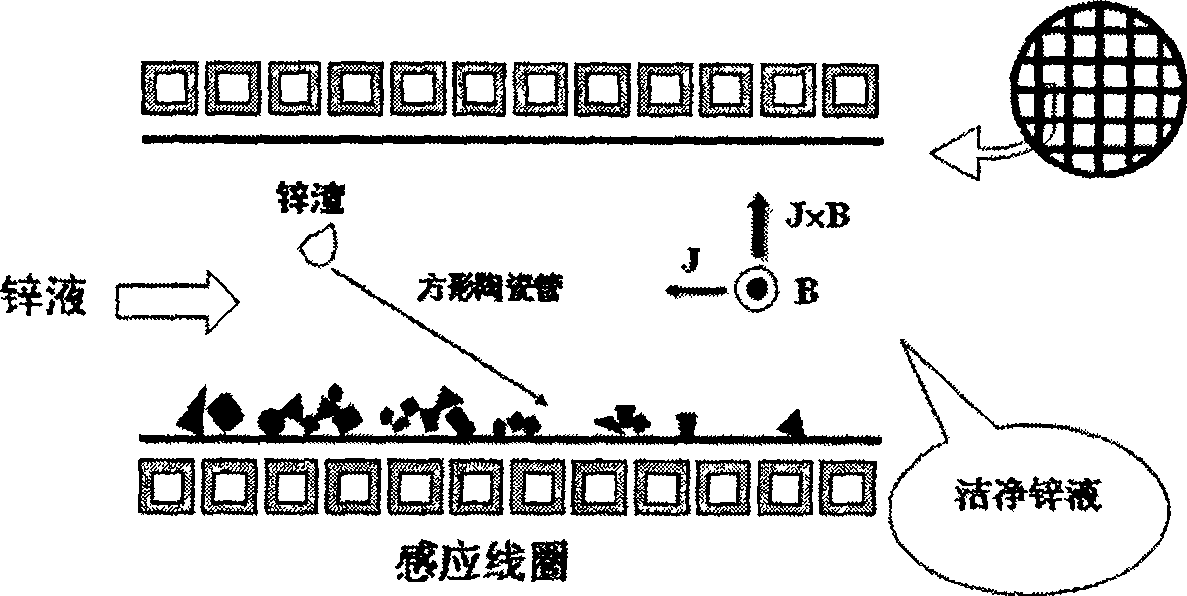

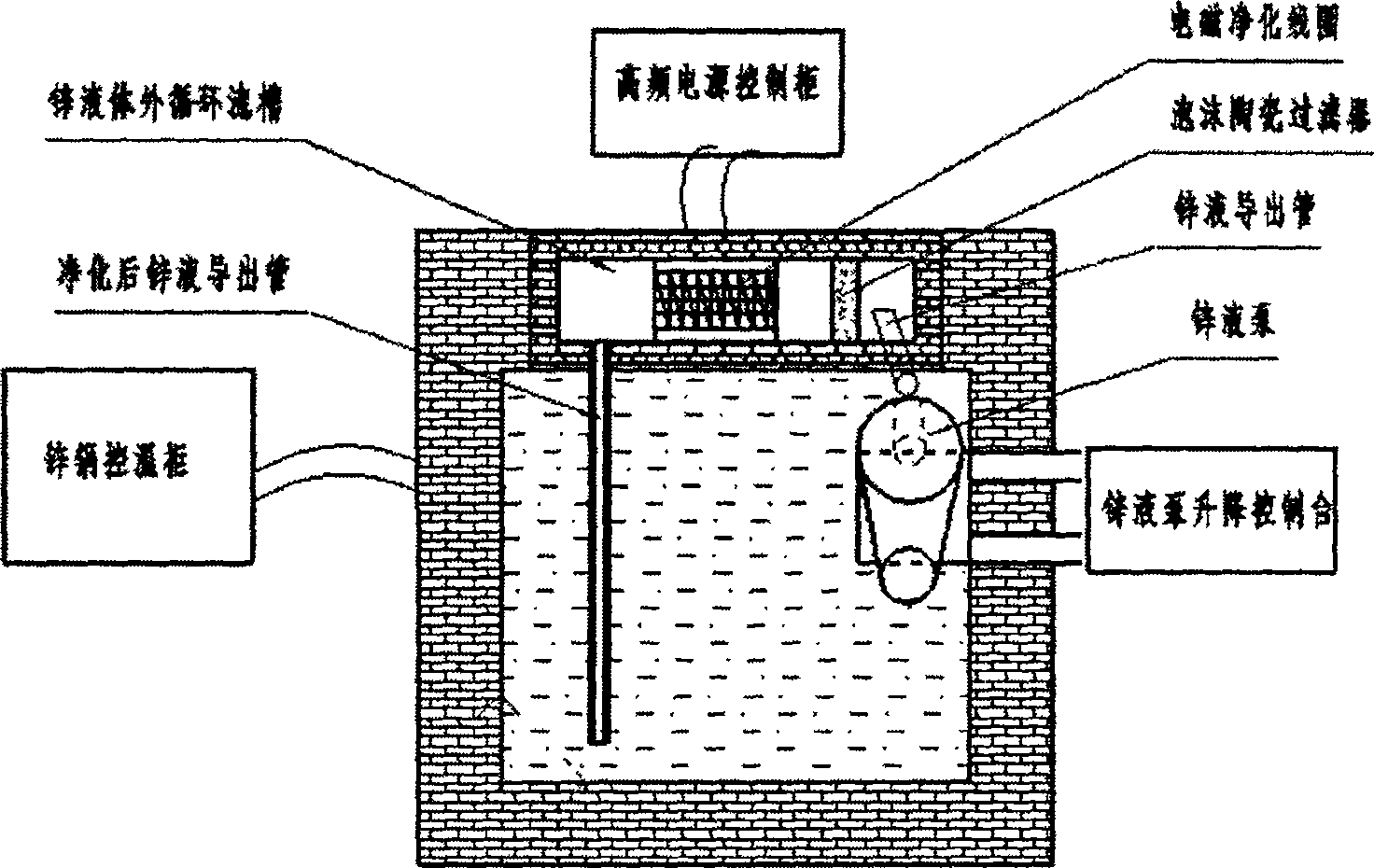

[0025] In this embodiment, a continuously working zinc liquid pump is used to extract the zinc liquid from the zinc pot, so that the zinc liquid flows into an electromagnetic purification flow tank placed outside the zinc pot. The separation process of zinc dross from zinc liquid is all carried out in the launder. The separation process consists of two parts: primary filtration and secondary filtration. In the primary filtration, a ceramic foam filter is used to remove zinc slag with a particle size greater than 40μm. The alternating magnetic field is applied through the coaxial solenoid coil, the magnetic field frequency is 20kHz, the effective value of the magnetic induction intensity B is 0.03T, the cross-sectional dimension is 10mm×10mm, the length is 200mm square hole ceramic tube, the zinc liquid flow speed is 50mm / s, after purification, zinc dross larger than 20μm can be basically removed. After the zinc liquid flows out of the electromagnetic purification device, it flows...

Embodiment 2

[0027] In this embodiment, a continuously working zinc liquid pump is used to extract the zinc liquid from the zinc pot, so that the zinc liquid flows into an electromagnetic purification flow tank placed outside the zinc pot. The separation process of zinc dross from zinc liquid is all carried out in the launder. The separation process consists of two parts: primary filtration and secondary filtration. In the primary filtration, a ceramic foam filter is used to remove zinc slag with a particle size greater than 40μm. The alternating magnetic field is applied through the coaxial solenoid coil, the frequency of the magnetic field is 20kHz, the effective value of the magnetic induction intensity B is 0.06T, the cross-sectional dimension is 10mm×10mm, the length is 300mm square hole ceramic tube, the zinc liquid flow speed is 40mm / s, after purification, zinc slag larger than 15μm can be basically removed. After the zinc liquid flows out of the electromagnetic purification device, it...

Embodiment 3

[0029] In this embodiment, a continuously working zinc liquid pump is used to extract the zinc liquid from the zinc pot, so that the zinc liquid flows into an electromagnetic purification flow tank placed outside the zinc pot. The separation process of zinc dross from zinc liquid is all carried out in the launder. The separation process consists of two parts: primary filtration and secondary filtration. In the primary filtration, a ceramic foam filter is used to remove zinc slag with a particle size greater than 40μm. The alternating magnetic field is applied through the coaxial solenoid coil, the magnetic field frequency is 20kHz, the effective value of the magnetic induction intensity B is 0.10T, the cross-sectional dimension is 10mm×10mm, the length is 300mm square hole ceramic tube, the zinc liquid flow speed is 35mm / s, after purification, zinc slag larger than 10μm can be basically removed. After the zinc liquid flows out of the electromagnetic purification device, it flows ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com