Method for calculating strip steel entering zinc pot temperature

A calculation method, zinc pot technology, applied in calculation, computer-aided design, design optimization/simulation, etc., can solve the problem of large fluctuations in the temperature detection value of the strip steel entering the zinc pot, the inability to realize precise control of the strip steel entering the zinc pot, and the inability to Accurately detect the temperature of the strip steel entering the zinc pot, etc., to achieve the effect of solving large temperature errors, satisfying precise control, and avoiding large temperature measurement errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

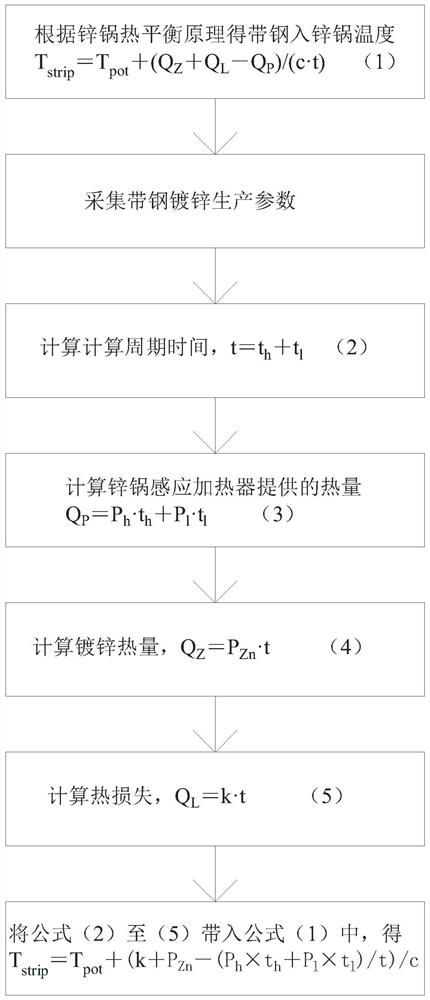

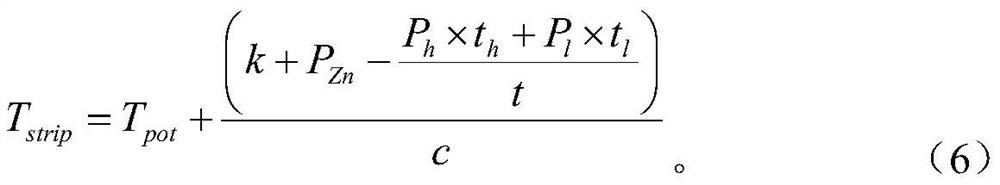

Method used

Image

Examples

Embodiment 1

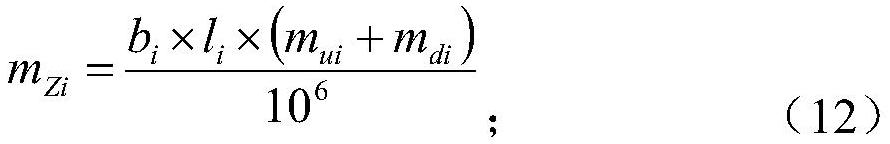

[0095] Collect strip galvanizing production parameters: temperature T of zinc bath in zinc pot pot =455℃, high power value P of zinc pot induction heater h =800kW, low power value P of zinc pot induction heater l = 248kW, high power single run time t h = 29min, low power single run time t l =92min; collect and calculate the number of steel coils produced in the cycle time t n=6, that is, i takes 1,2,...,6, wherein, the weight m of the 6 coils produced i , entrance width b i , the length of the entrance coil l i , Coating weight on the upper surface of the outlet m ui , Coating weight on the lower surface of the outlet m di and production time t i As shown in Table 1.

[0096] Table 1 Calculate the information table of 6 coils of steel strip produced in the cycle time t

[0097]

[0098] Calculation cycle time t=t h +t l =29+92=121 min.

[0099] According to the formulas (7)-(10), (11) and (12), calculate the line mass ratio f of the i-th coil strip i , line area ...

Embodiment 2

[0110] Collect strip galvanizing production parameters: temperature T of zinc bath in zinc pot pot =452℃, high power value P of zinc pot induction heater h =681kW, zinc pot induction heater low power value P l = 227kW, high power single run time t h = 25min, low power single run time t l =19min; Collect and calculate the number of steel coils produced within the cycle time t n=2, i.e. take 1,2 for i, where the weight m of the 2 coils of strip steel produced i , entrance width b i , the length of the entrance coil l i , Coating weight on the upper surface of the outlet m ui , Coating weight on the lower surface of the outlet m di and production time t i as shown in Table 3.

[0111] Table 3 Calculate the information table of 2 coils of strip steel produced in the cycle time t

[0112]

[0113] Calculation cycle time t=t h +t l =25+19=44min.

[0114] According to the formulas (7)-(10), (11) and (12), calculate the line mass ratio f of the i-th coil strip i , line...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific heat capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com