Device and method for removing slag on surface of plating liquid

A plating solution and liquid slag technology, applied in hot dip plating process, coating, metal material coating process, etc., can solve the problems of poor personnel operation safety, high cost, low efficiency, etc., to improve surface quality and strong products. Applicability, the effect of reducing the leakage point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

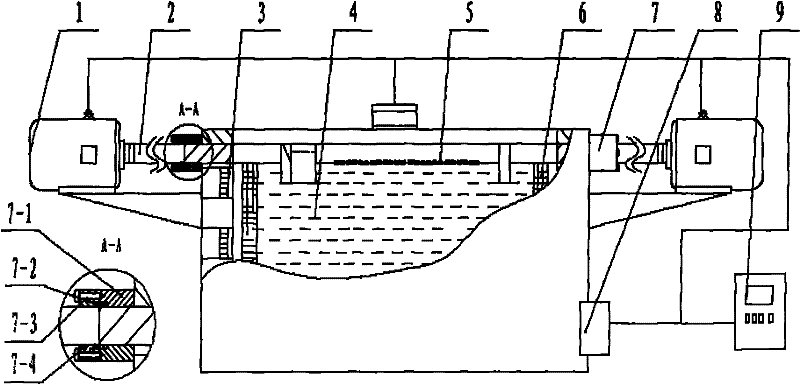

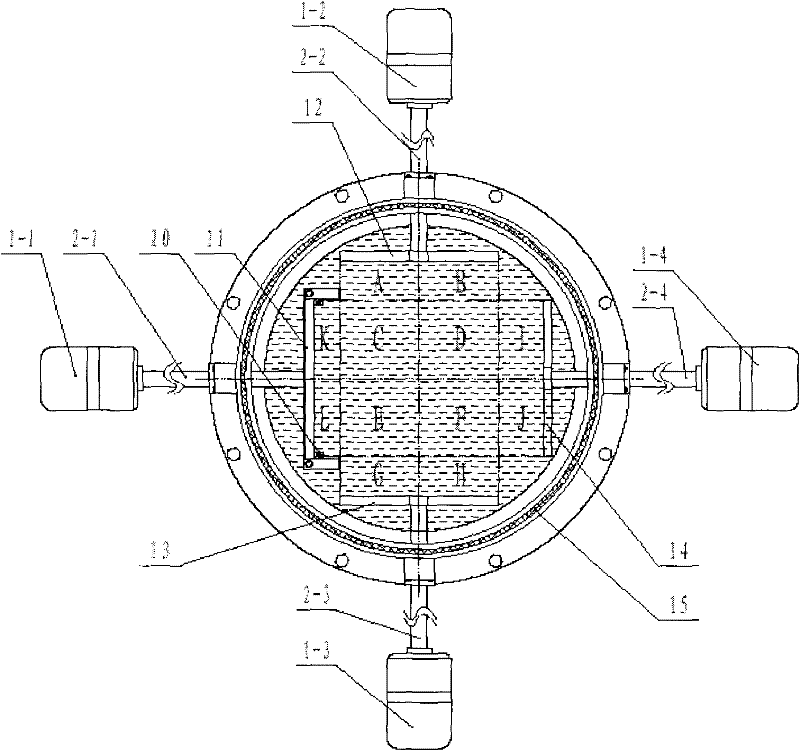

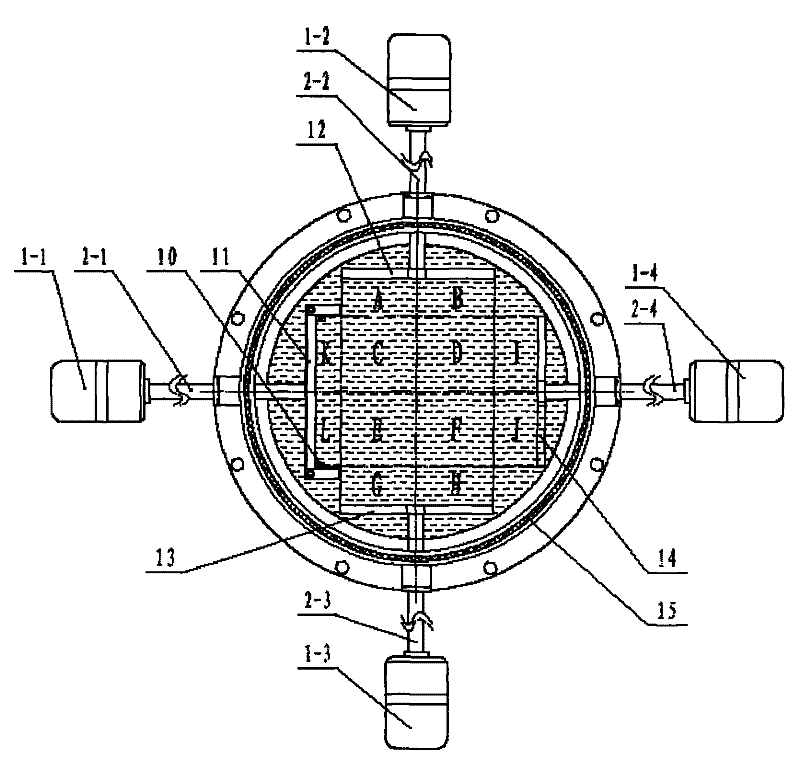

[0031] Further illustrate the present invention below in conjunction with accompanying drawing.

[0032] As shown in the figure, four motors 1-1, 1-2, 1-3, 1-4 are symmetrically distributed outside the crucible furnace 3, and each motor is respectively connected to a driver 2-1, 2-2, 2-3, 2 -4, the driver enters the crucible furnace 3 through the sealing device 7, and reciprocates in the plating solution 4 of the crucible furnace 3. The sealing device 7 is composed of a lower flange 7-1, a silicone ring 7-2, a screw 7-3 and an upper flange 7-4. The plating solution 4 is contained in a crucible 6 , and a certain amount of plating slag 5 exists on the surface of the plating solution 4 .

[0033] Drivers 2-1, 2-2, 2-3, and 2-4 are respectively connected to the slag stopper 11, the first side slag pusher 12, the second side slag pusher 13, the opposite slag pusher 14, the motor 1-2, 1-3 and 1-4 respectively drive the first side slag pusher 12 , the second side slag pusher 13 , a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com