A hot-dip galvanizing bath and hot-dip galvanizing process

A hot-dip galvanizing and hot-dipping technology, applied in hot-dip plating process, metal material coating process, coating and other directions, to achieve the effect of formula optimization, reducing surface defects and reducing the amount of zinc slag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

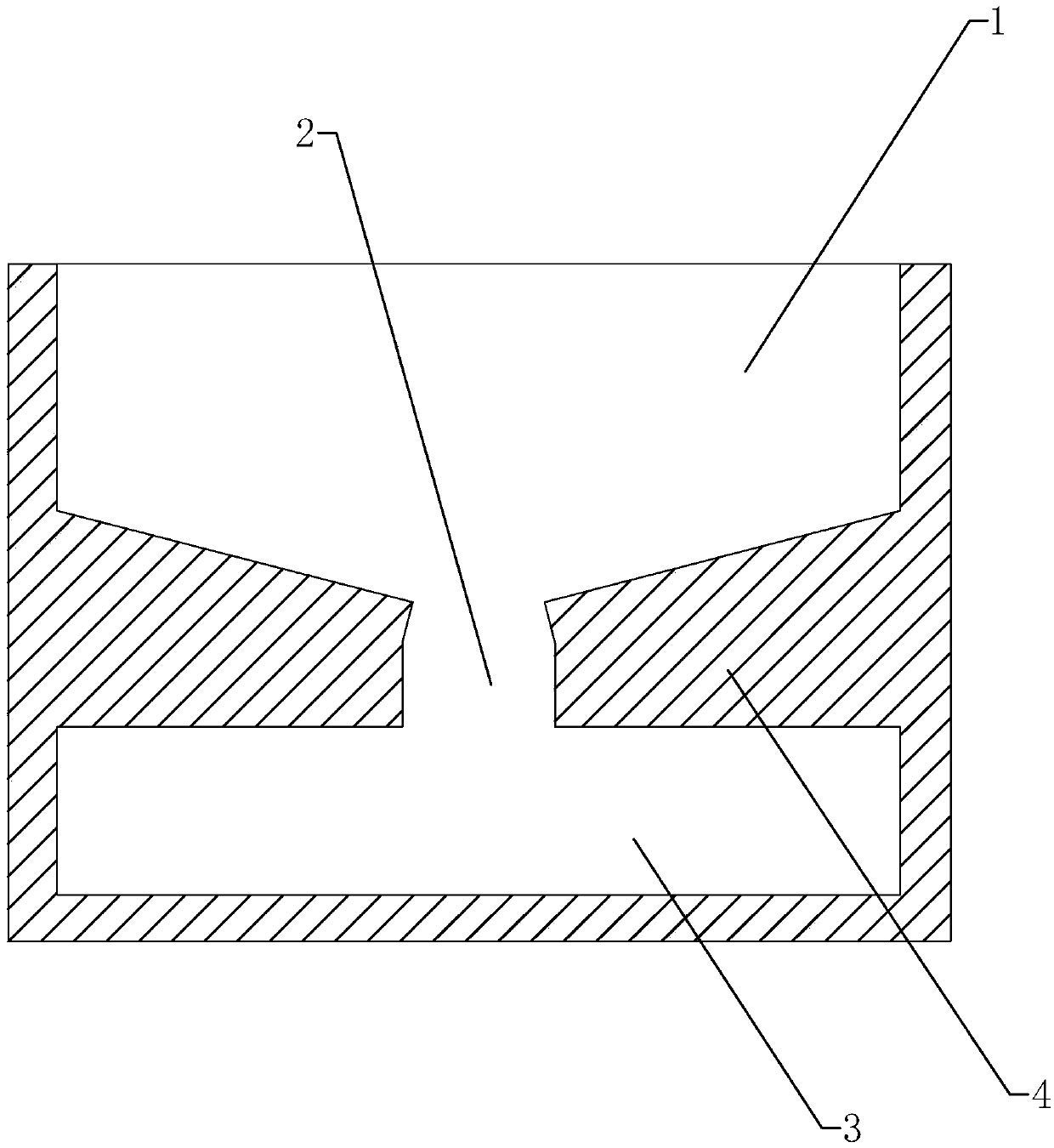

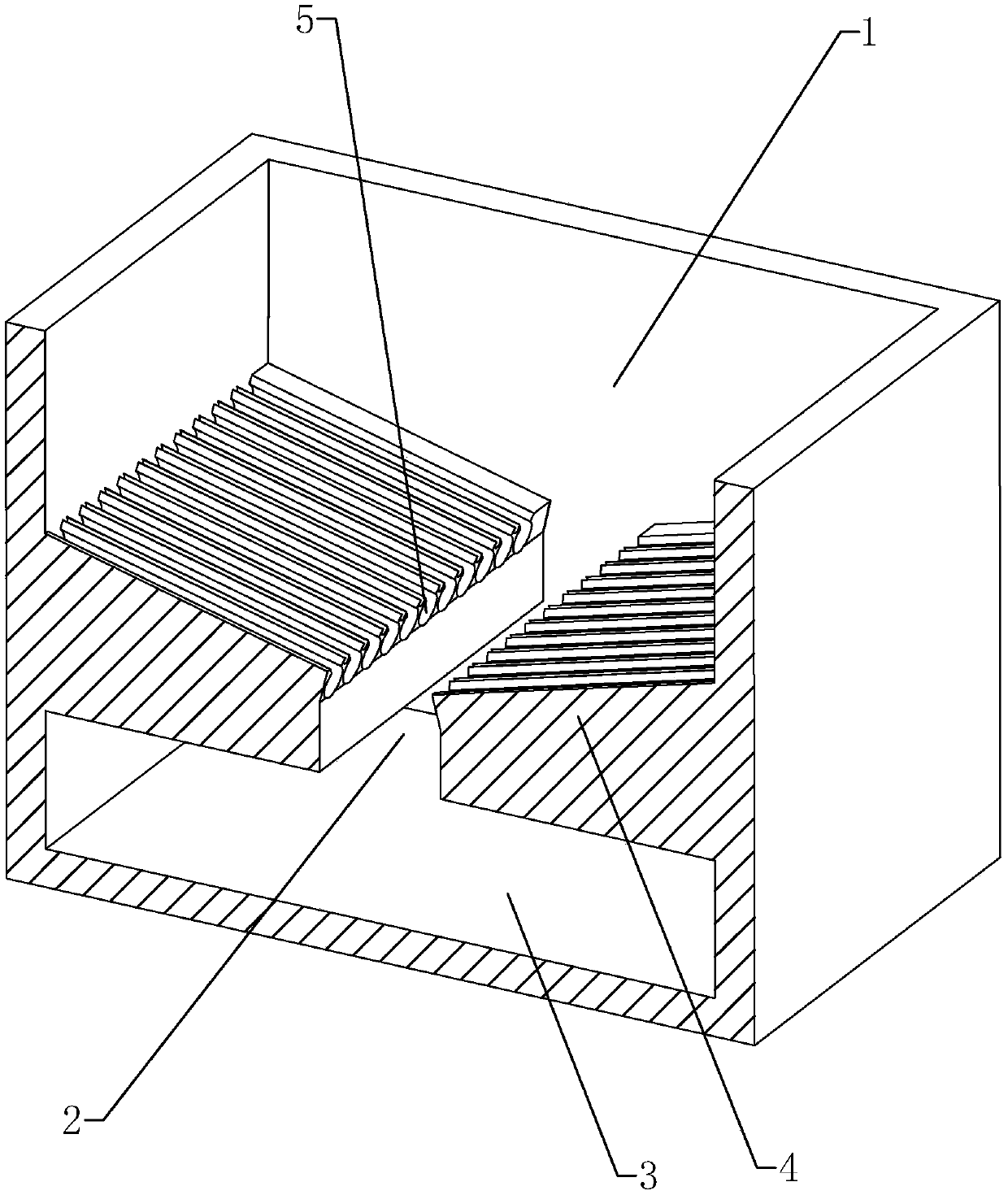

[0039] Embodiment 1: a kind of hot-dip bath for hot-dip galvanizing process, in conjunction with figure 1 with figure 2 , including an active pool 1, a connection part 2 and a sedimentation tank 3 arranged in sequence from top to bottom, and the active pool 1 and the sedimentation tank 3 are cuboids. The connecting part 2 is arranged vertically and connects the middle part of the active pool 1 and the sedimentation tank 3. The bottom of the active pool 1 is a receiving part 4, and the receiving part 4 continuously descends from both sides of the active pool 1 to the connecting part 2.

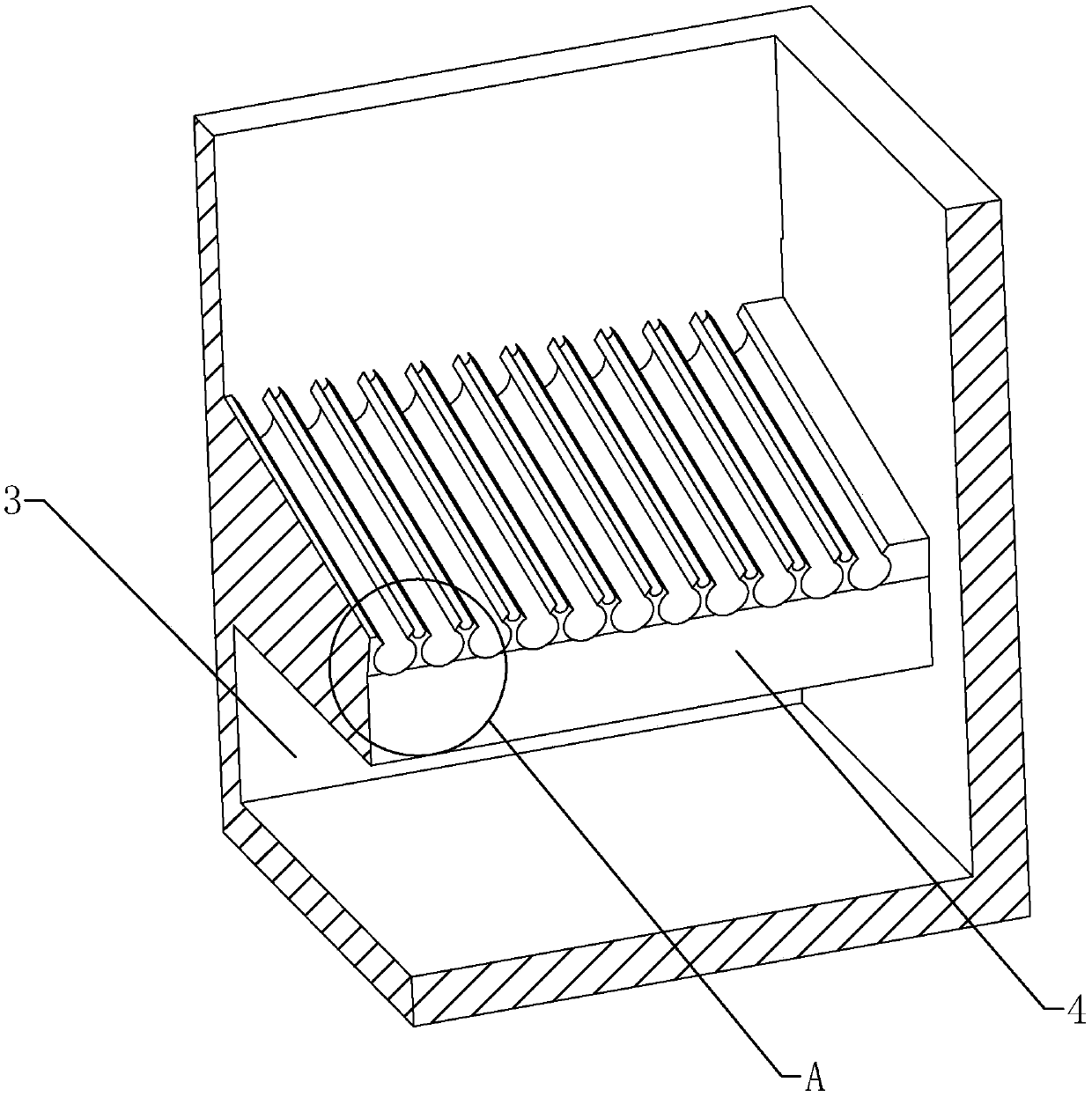

[0040] combine image 3 with Figure 4 , The receiving portion 4 is provided with a plurality of first receiving cavities 5 for receiving zinc slag. The first receiving cavity 5 is a cylindrical cavity, the axial direction of the first receiving cavity 5 is arranged along the inclined direction of the receiving part 4, and one end close to the connecting part 2 in the axial direction is ope...

Embodiment 2

[0042] Embodiment 2: a kind of hot-dip bath for hot-dip galvanizing process, contrast Figure 5 and Image 6 , the difference from Embodiment 1 is that the cross-sections of the first receiving cavity 5 and the second receiving cavity 6 are both elliptical arcs, and the elliptical arc is larger than a semi-ellipse, and the short distance between the first receiving cavity 5 and the second receiving cavity 6 The axis is perpendicular to the receiving part 4 , the long axis is parallel to the receiving part 4 , and the opening is located directly above the first receiving cavity 5 .

Embodiment 3

[0043] Embodiment 3: a kind of hot-dip galvanizing process, comprises the steps:

[0044] S1: Put steel components in an acid pool to remove surface rust, and rinse in water to remove acid;

[0045] S2: Transfer the steel components to the fluxing solution in the fluxing bath, soak for 10-120 minutes at 65-68°C, and adjust the soaking time according to the amount of rust;

[0046] S3: Transfer the steel member to the top of the hot-dip bath in Example 2, control the temperature in the hot-dip bath to 440°C, remove the scum in the hot-dip bath with a slag scoop, and put the steel member into the hot-dip bath Hot-dip in the molten zinc bath for 30-200s (adjust the time according to the required thickness), and at the same time turn on the fan to blow off the smoke above the hot-dip pool, then take the steel member out of the hot-dip pool and remove it by tapping Unformed zinc droplets on the surface of steel components;

[0047] S4: Put the steel components into the cooling po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com