Blowing tube type inner blower

A tube type, transmission mechanism technology, applied in metal material coating process, hot dip plating process, coating and other directions, can solve the problems of high noise, increased production cost, harsh working environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The specific implementation, structure, features and effects provided by the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

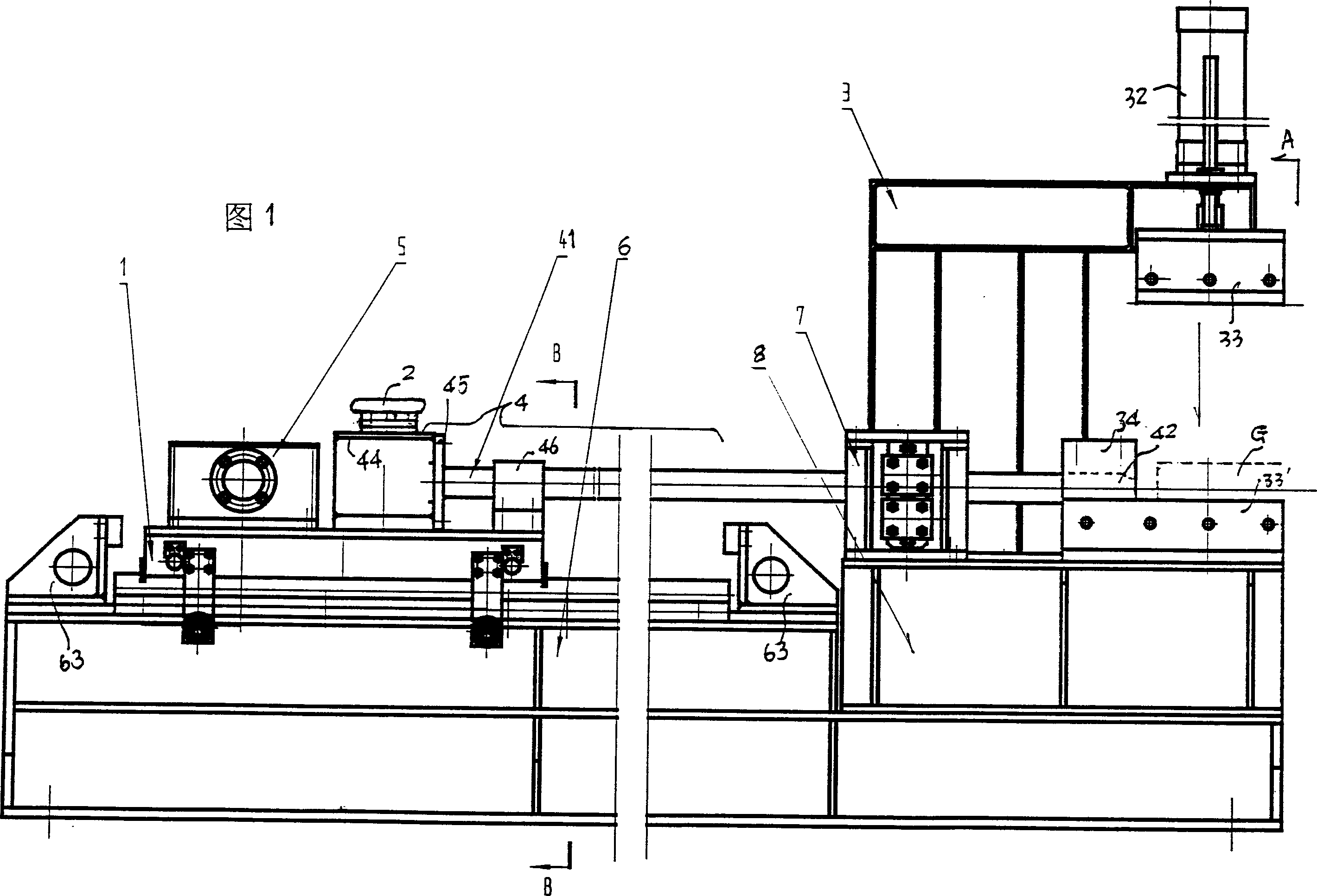

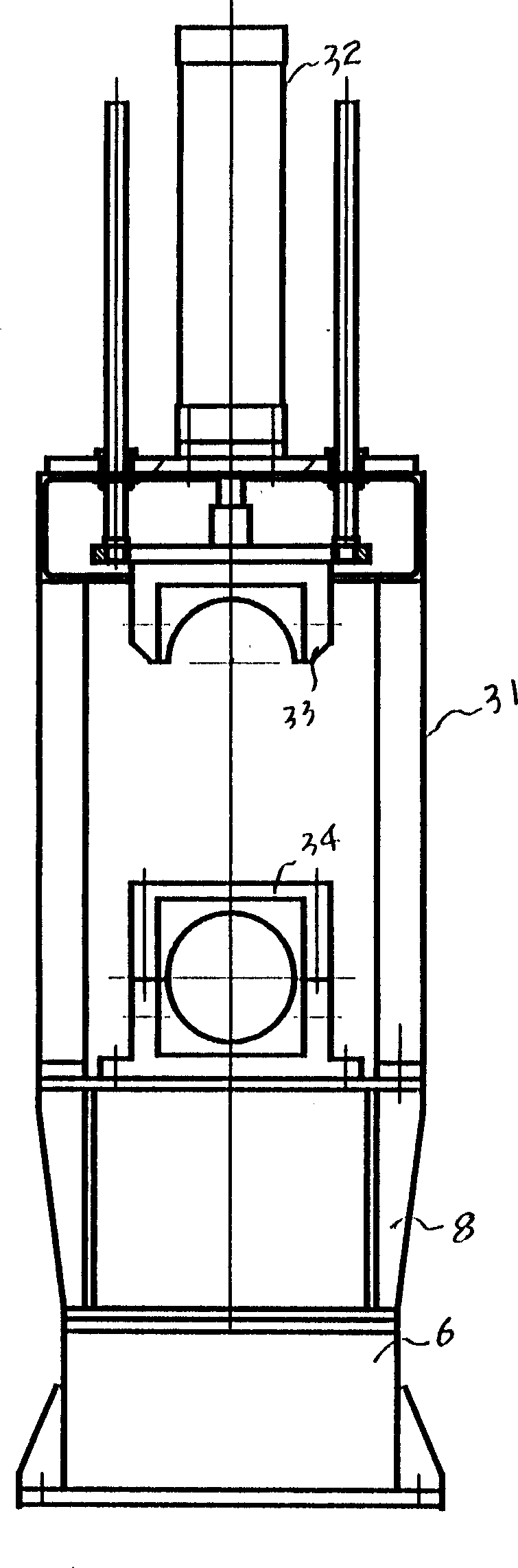

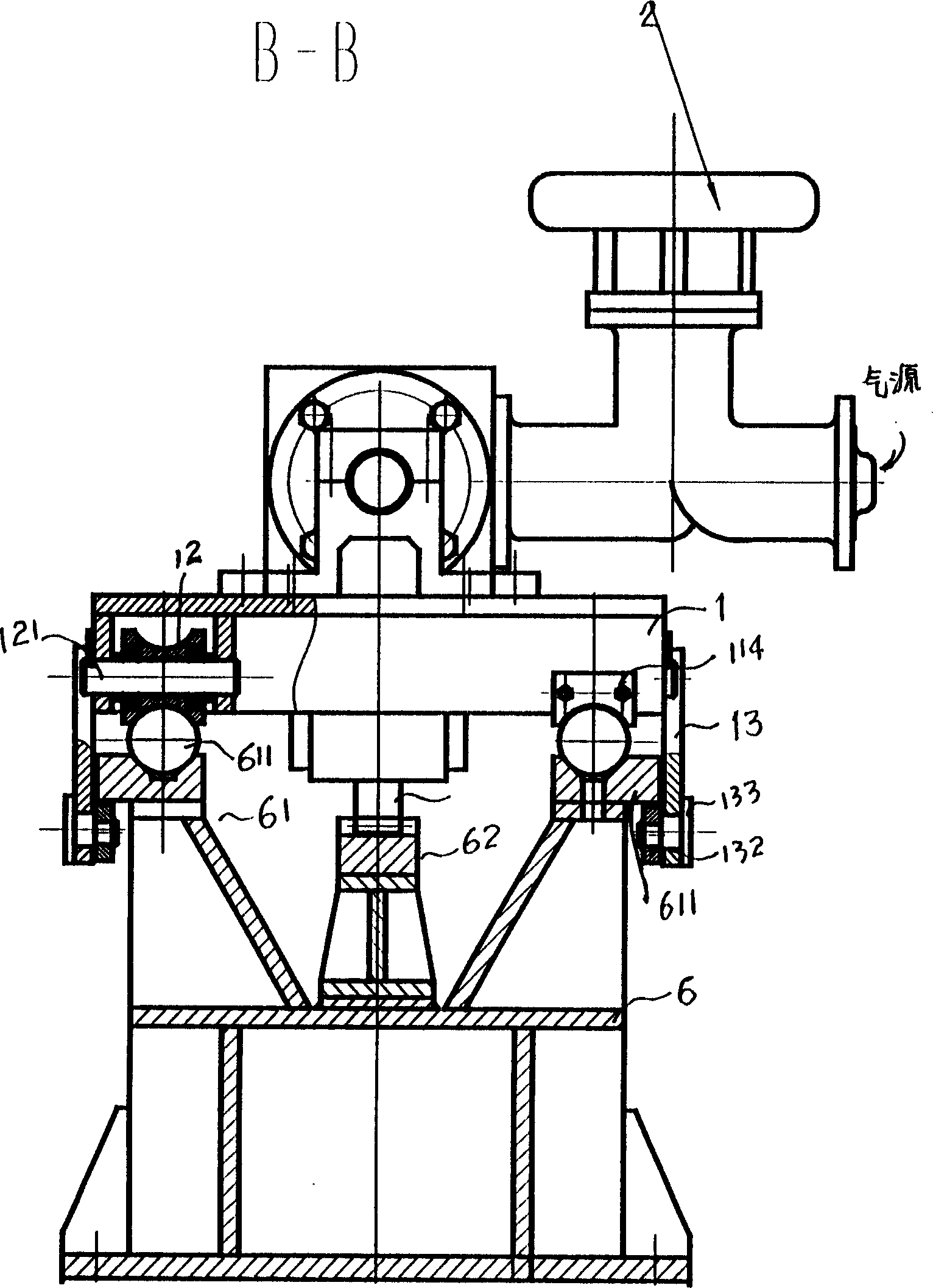

[0036] Please refer to Fig. 1, a kind of blowpipe type internal blowing machine, drives with servo motor (51), erects on the track of bed (6) and carries transmission mechanism (5), internal blowing valve (2) and blowing nozzle blowpipe ( 4) The internal blowing trolley (1) is equipped with a clamping guide block (3) and a guide device (7) on the bed through the machine base (8),

[0037] Wherein the lathe bed (6) is referring to Fig. 6, 6A, 6B and Fig. 1, 1B, and the double track (61) that circular guide rail (611) is housed is set on the lathe bed, is provided with the suitable length of circular guide rail between this double track Rack (62), the rack should be matched with the drive gear in the transmission mechanism, and a buffer block (63) is fixed at both ends of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com