Process method for obtaining steel wire hot galvanizing and alloy thick plating layer

A process method and hot-dip galvanizing technology, applied in hot-dip plating process, metal material coating process, improvement of process efficiency, etc., can solve the problems of pollution in the production process, high production cost, difficult to increase DV value, etc. The effect of increasing the output, reducing the number of lines, and shortening the production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

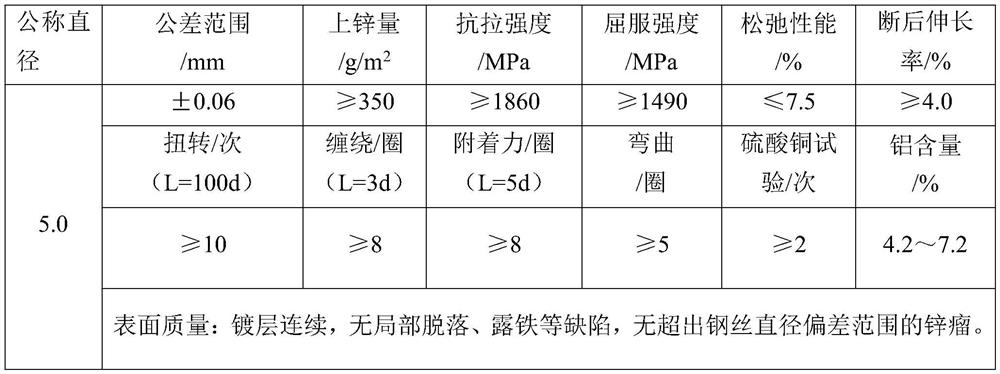

[0036] Adopt the method of the present invention to implement the production of hot-dip galvanized aluminum alloy steel wire: material 82B, hot-dip Galfan (Zn-5%Al-RE) alloy, diameter 5.0mm, production capacity requirement 30,000 tons / year. See Table 1 for technical requirements:

[0037] Table 1 Technical requirements of 5.0mm Galfan-plated steel wire

[0038]

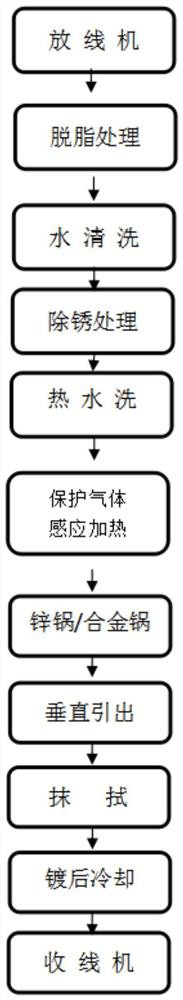

[0039] go through figure 1 The process of completing the hot-dip Galfan alloy process of steel wire. The specific process parameters are as follows: DV=1000mm·m / min, wire speed 200m / min, number of wires 2, induction heating temperature 400°C, hot-dip temperature 440°C, air knife pressure 1.0kg. After production, two galvanized wires were taken, and the wire diameter, zinc content, aluminum content, mechanical properties and surface quality were tested respectively, and the experimental data and conclusions in the following table 2 were obtained.

[0040] Table 2 Measured results of 5.0mm Galfan-coated steel wire...

Embodiment 2

[0044] Adopt the method of the present invention to implement the production of galvanized steel wire for galvanized steel strands: hot-dip galvanized with a material of 65#, a diameter of 3.20mm, and a production capacity requirement of 24,000 tons / year. See Table 3 for technical requirements:

[0045] Table 3 3.20mm galvanized steel wire technical requirements

[0046]

[0047] go through figure 1 The process of completing the hot-dip galvanizing process of steel wire. The specific process parameters are as follows: DV=640mm·m / min, wire speed 200m / min, number of wires 4, induction heating temperature 450°C, hot-dip temperature 465°C, air knife pressure 0.3kg. After production, four galvanized wires were taken, and the wire diameter, zinc content, mechanical properties and surface quality were tested respectively, and the experimental data and conclusions in Table 4 below were obtained.

[0048] Table 4 3.20mm galvanized steel wire measured results

[0049]

[0050]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com