Patents

Literature

65results about How to "There will be no disconnection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

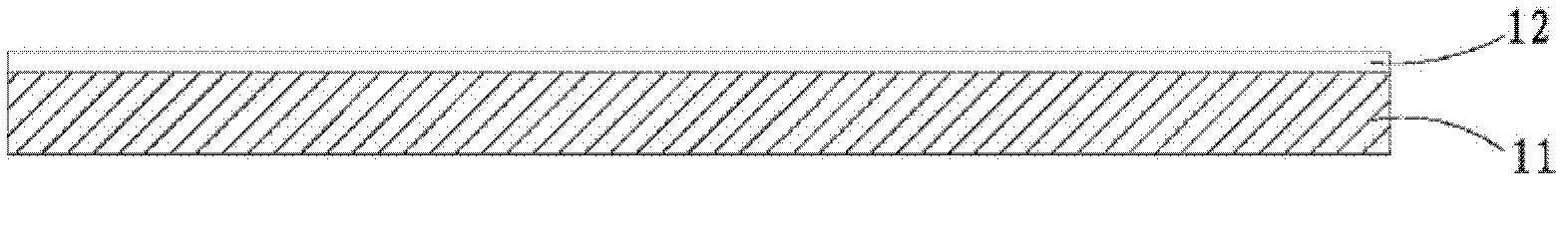

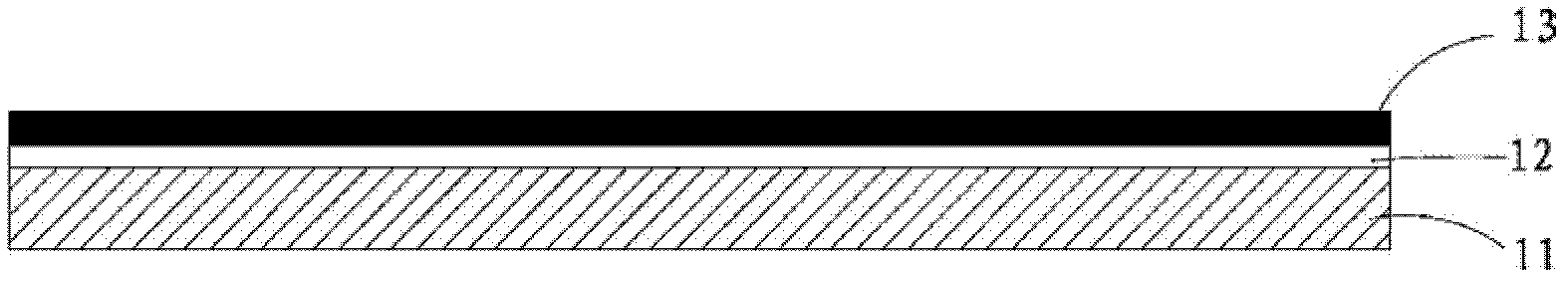

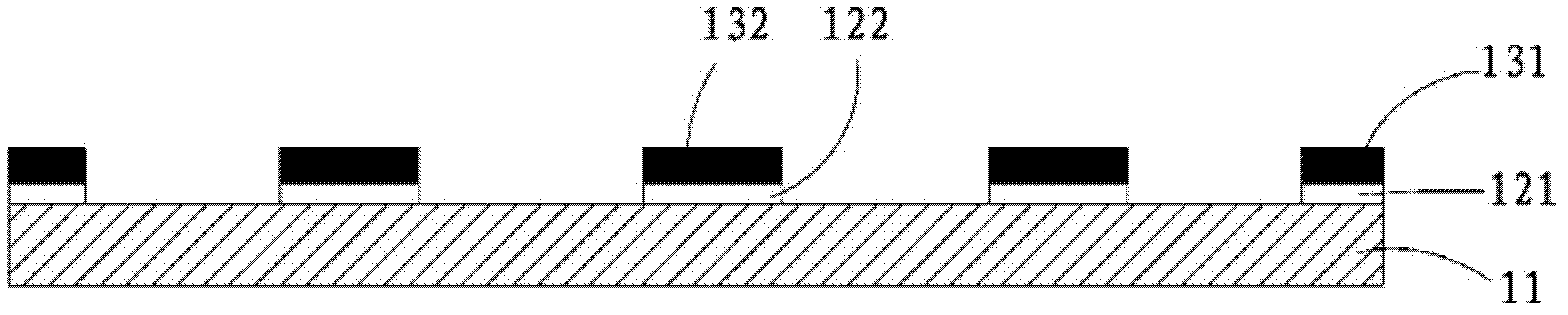

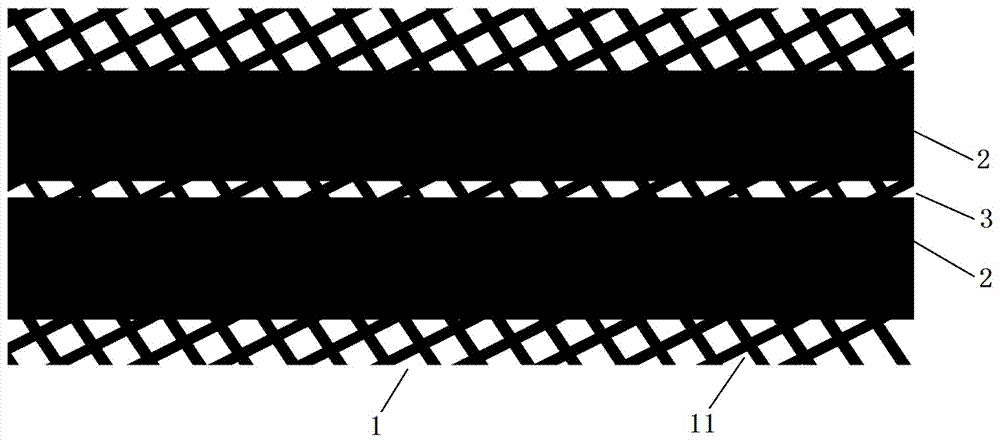

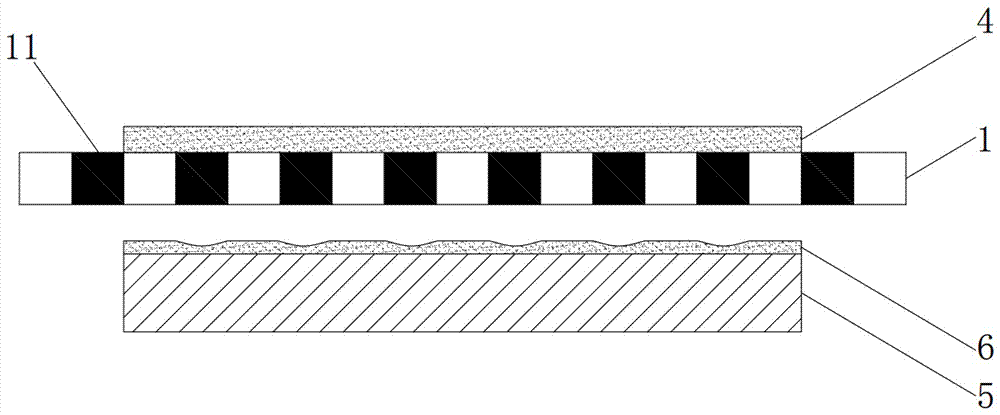

Novel electrode lead capacitive screen manufacturing method and its product and touch screen terminal

ActiveCN102279684AThere will be no disconnectionPrecise thickness controlInput/output processes for data processingPolyesterCapacitance

The invention is applicable to the technical field of touch screen production and provides a method for manufacturing a novel electrode lead capacitive screen, the novel electrode lead capacitive screen and a touch screen terminal. The method comprises the following steps of: (1) preparing an indium tin oxide (ITO) conductive film on a polyester (PET) base film; (2) preparing a copper film on the ITO conductive film by using a magnetically-controlled splutter coating method; (3) manufacturing ITO patterns, and forming an edge copper electrode lead at one time; (4) selectively etching the copper film on the middle ITO pattern, and reserving the ITO pattern to obtain PET thin film structures; and (5) sequentially adhering two PET thin film structures which are obtained in the step (4) and a piece of panel glass by using an optical adhesive to obtain the novel electrode lead capacitive screen. In the method for manufacturing the novel electrode lead capacitive screen provided by the invention, the magnetically-controlled splutter coating method is adopted to replace a silk-screening silver paste process to manufacture an electrode lead of a capacitive screen with mature technical means; and by the method, the good rate for manufacturing the capacitive screen having a film-film structure can be greatly improved, so that the manufacturing cost of the capacitive screen is saved.

Owner:深圳豪威显示科技有限公司

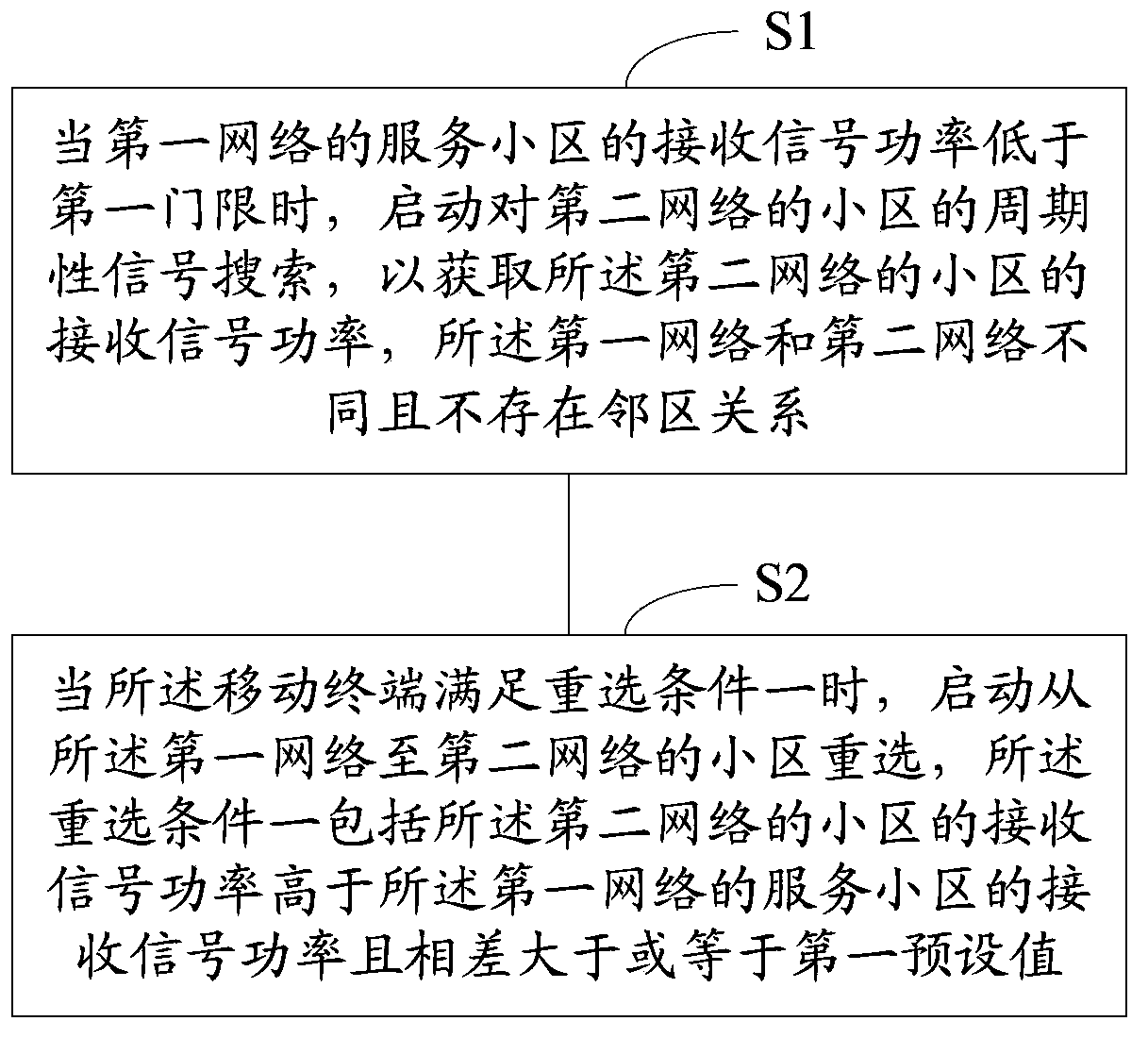

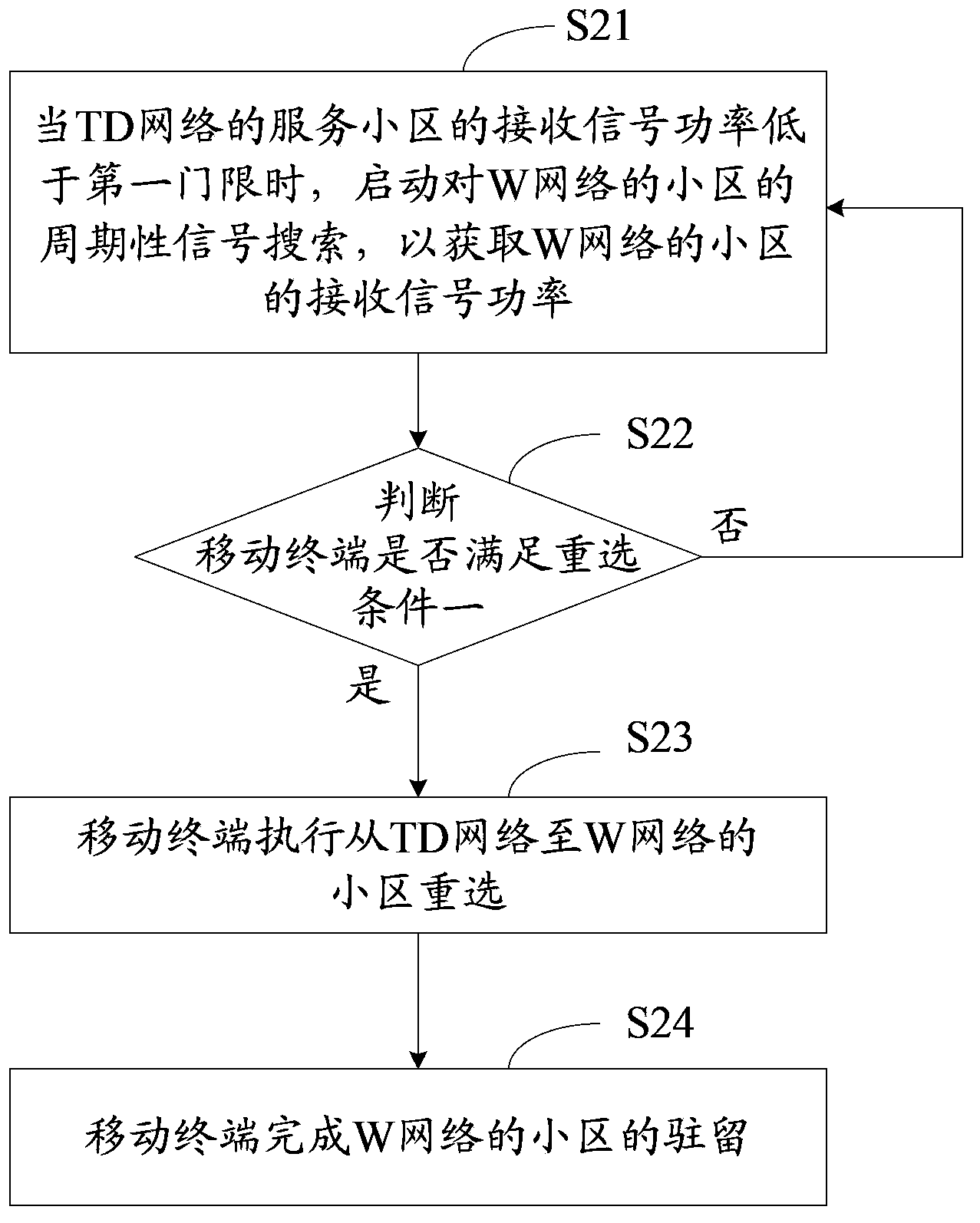

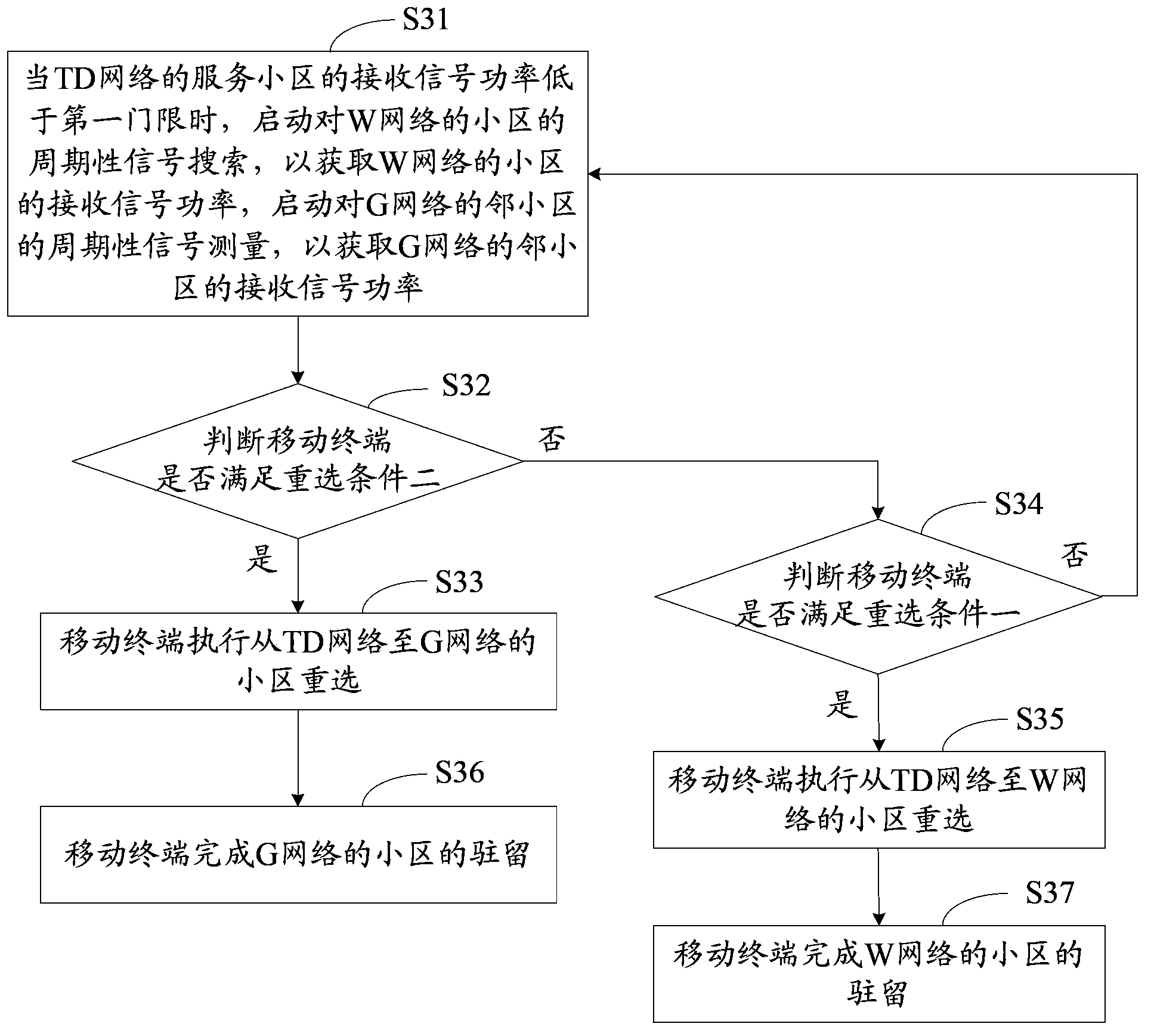

Mobile terminal and different system cell reselection method thereof

ActiveCN103916921AThere will be no disconnectionGuaranteed continuityWireless communicationTelecommunicationsAir interface

The invention discloses a mobile terminal and a different system cell reselection method thereof. The different system cell reselection method comprises: when the receiving signal power of a service cell of a first network is smaller than a first threshold, starting periodical signal search for a cell of a second network to obtain the receiving signal power of the cell of the second network, the first network and the second network being different and having no neighborhood relations; and when a mobile terminal satisfies a first reselection condition, starting cell reselection from the first network to the second network, the first reselection condition comprising that the receiving signal power of the cell of the second network is higher than the receiving signal power of the service cell of the first network and a difference is greater than or equal to a first preset value. By using the technical scheme provided by the invention, smooth cell reselection between two networks which do not have neighborhood configuration relations can be realized, and network disconnection is not generated. The technical scheme does not relate to modification of a mobile terminal air interface protocol and realization of a network side, and rapid disposition and realization are facilitated.

Owner:SPREADTRUM COMM (SHANGHAI) CO LTD

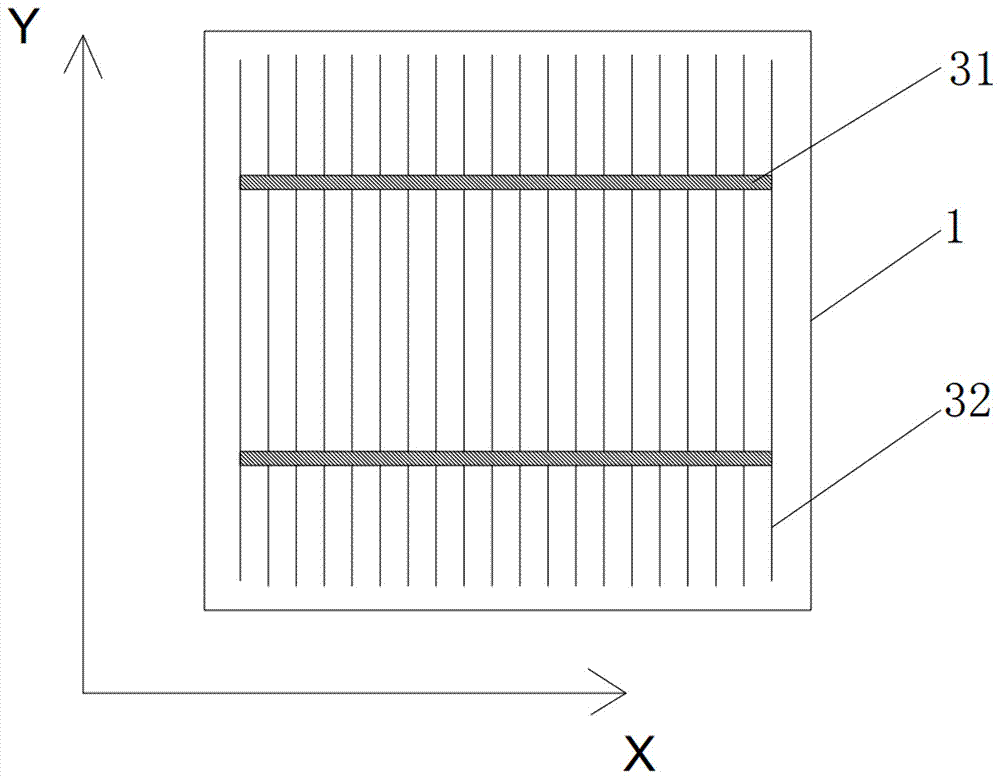

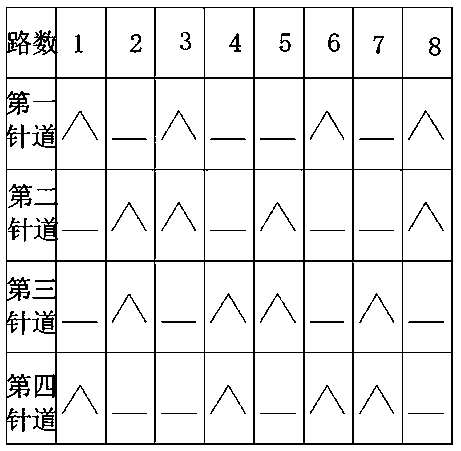

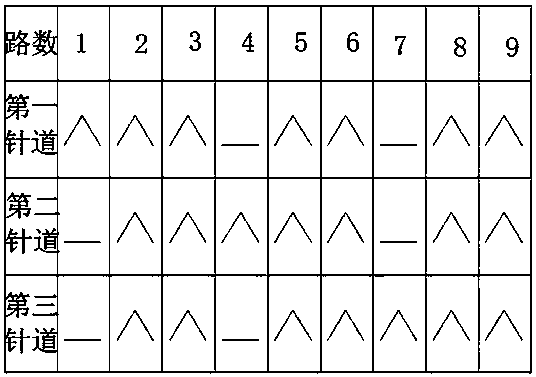

Silk-screen printing method of solar cell grid line electrode

ActiveCN106926598AThere will be no disconnectionQuality improvementFinal product manufactureOther printing apparatusScreen printingEngineering

The invention relates to the technical field of production of solar cells, and in particular, discloses a silk-screen printing method of a solar cell grid line electrode. The method comprises the following steps: a halftone is set with a certain offsets in the gird line direction for two times of silk-screen printing, so that screen knots of screen cloth are staggered from corresponding cells during moving of the screen cloth to prepare the rid line electrode. The method can effectively improve the false printing phenomenon caused by printing of the screen knot parts to improve the printing quality, in particular, is suitable for preparation of a thin grid line, is simple and feasible in operation, and is low in implementation cost.

Owner:YINGLI ENERGY CHINA

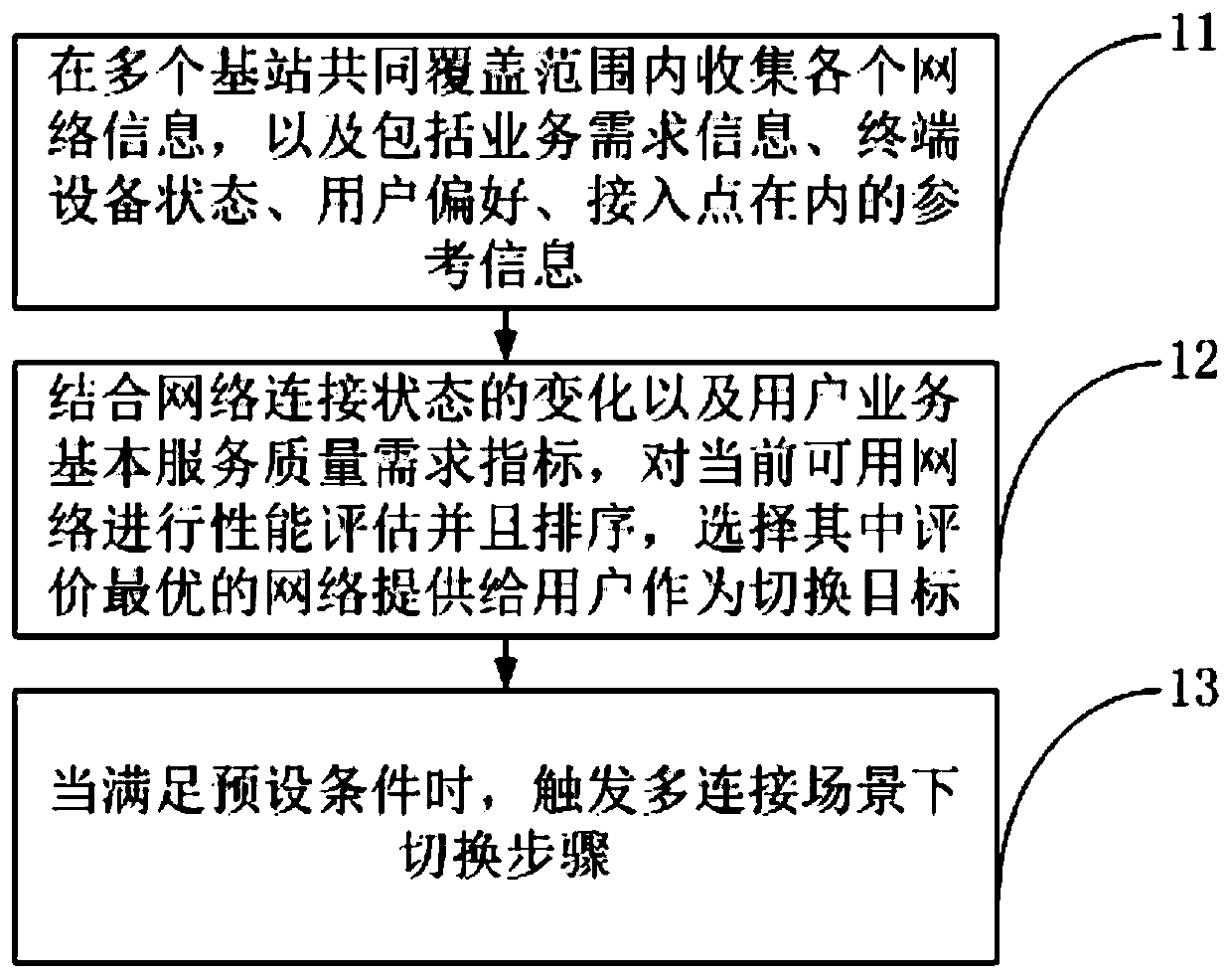

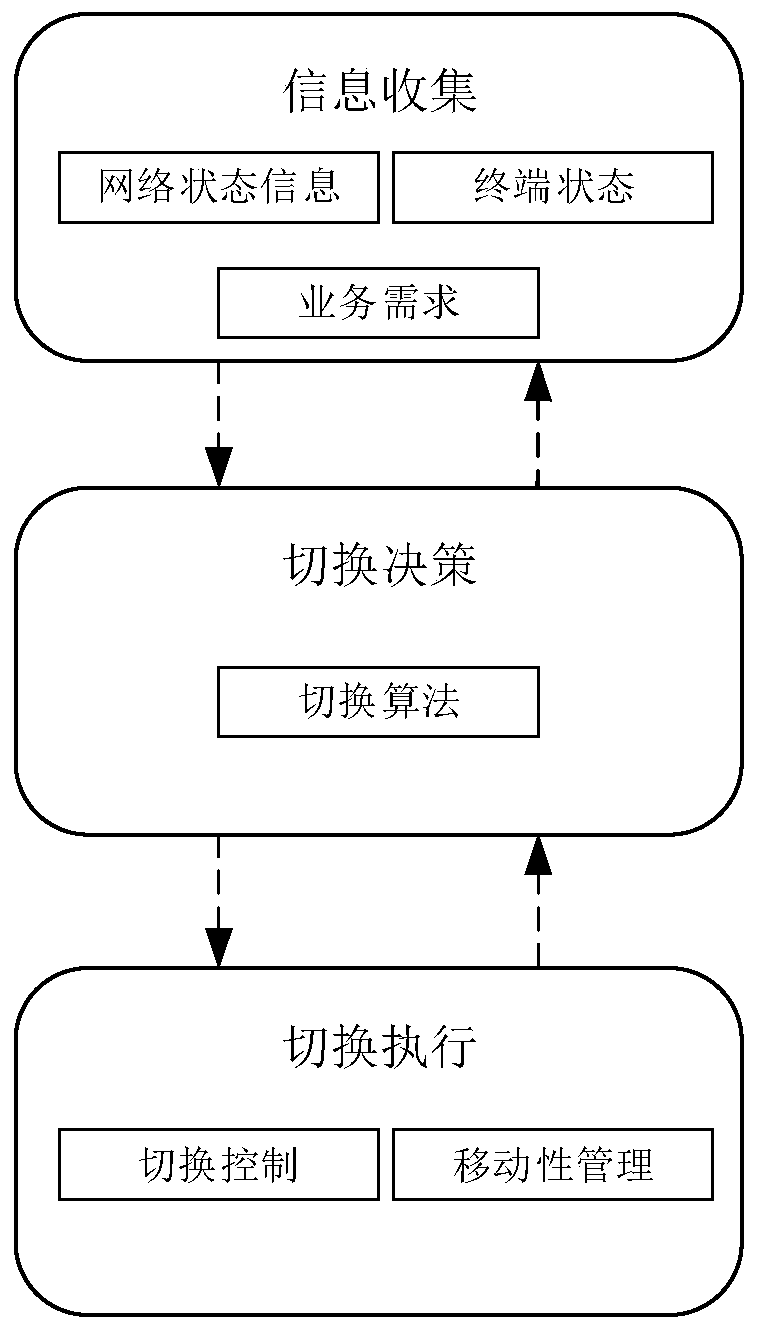

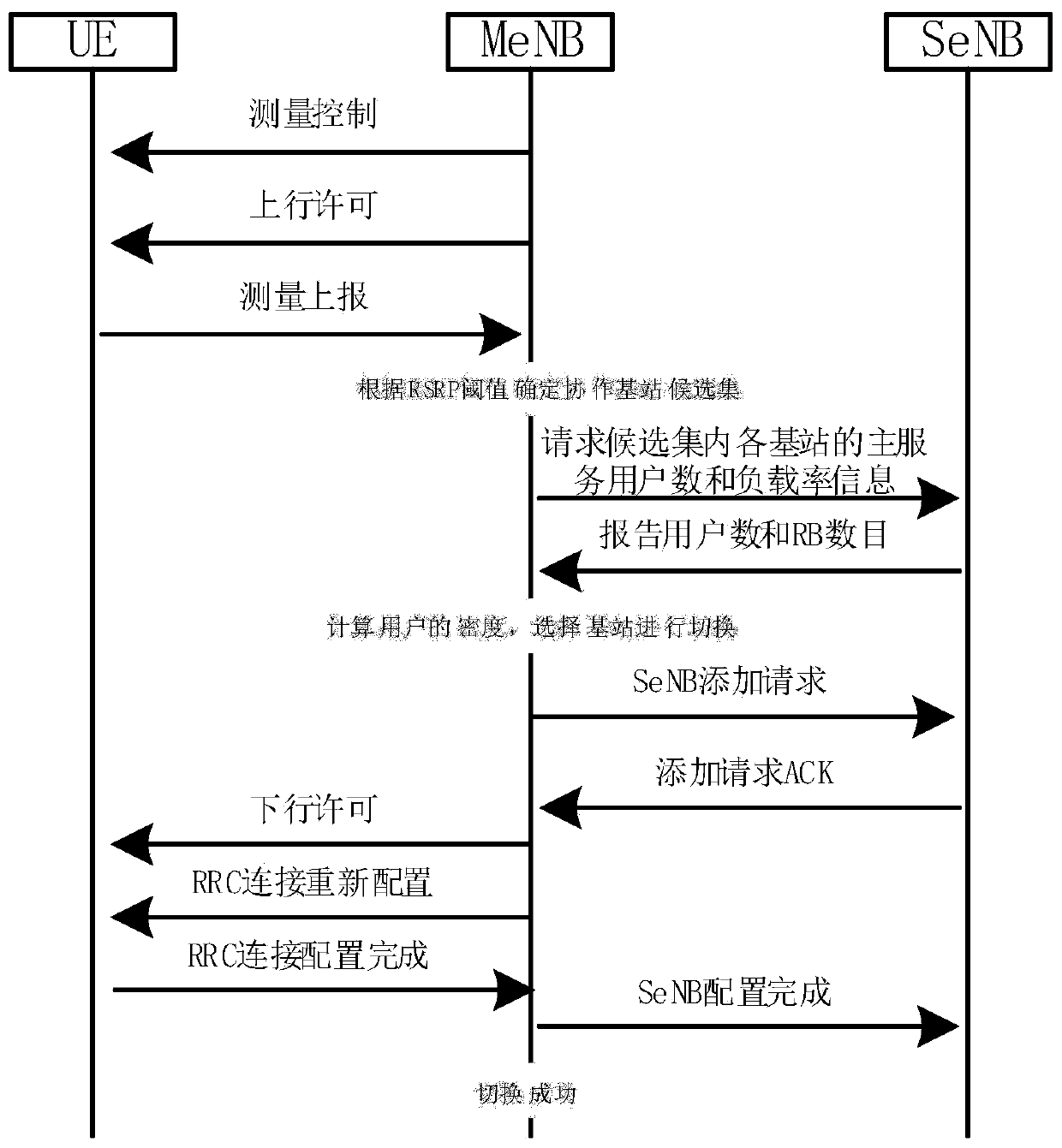

Network selection and mobility management method for power Internet of Things multi-connection technology

InactiveCN111465066AGuaranteed service qualityEasy to detectNetwork topologiesQuality of serviceAccess network

The embodiment of the invention provides a network selection and mobility management method for an electric power Internet of Things multi-connection technology, and the method comprises the steps: collecting all pieces of network information and reference information including business demand information, terminal equipment states, user preferences and access points in a common coverage range ofa plurality of base stations; in combination with the change of the network connection state and the basic service quality demand index of the user service, performing performance evaluation and sorting on the currently available networks, and selecting the network with the optimal evaluation as a switching target for the user; and when a preset condition is satisfied, triggering a switching stepin the multi-connection scene. In a multi-connection scene of the electric power Internet of Things, the connection between the Internet of Things terminal and the access network is not limited by a single base station any more, but a cluster of base stations cooperating with each other, and a larger service base station selection space is provided for the terminal by a mechanism of simultaneouslyconnecting with a plurality of base stations. Reasonable multi-connection network selection is carried out, so that the performance of the multi-connection system can be further improved.

Owner:ZHEJIANG HUAYUN INFORMATION TECH CO LTD

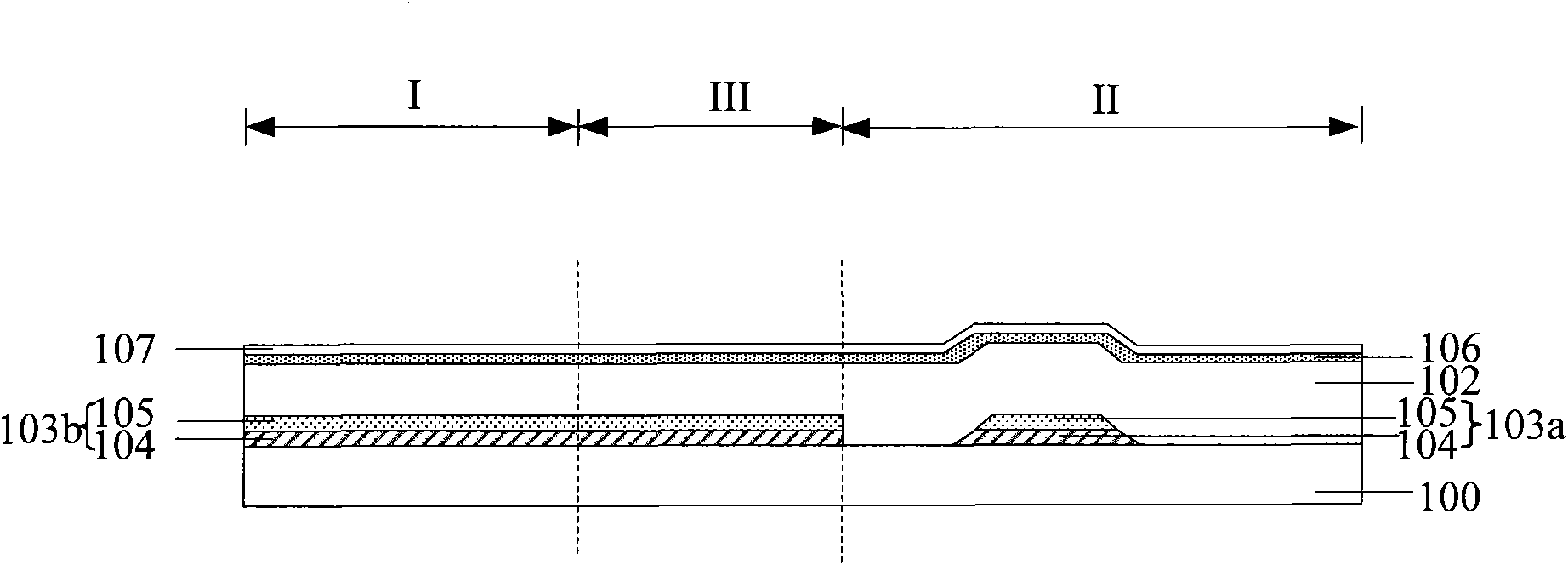

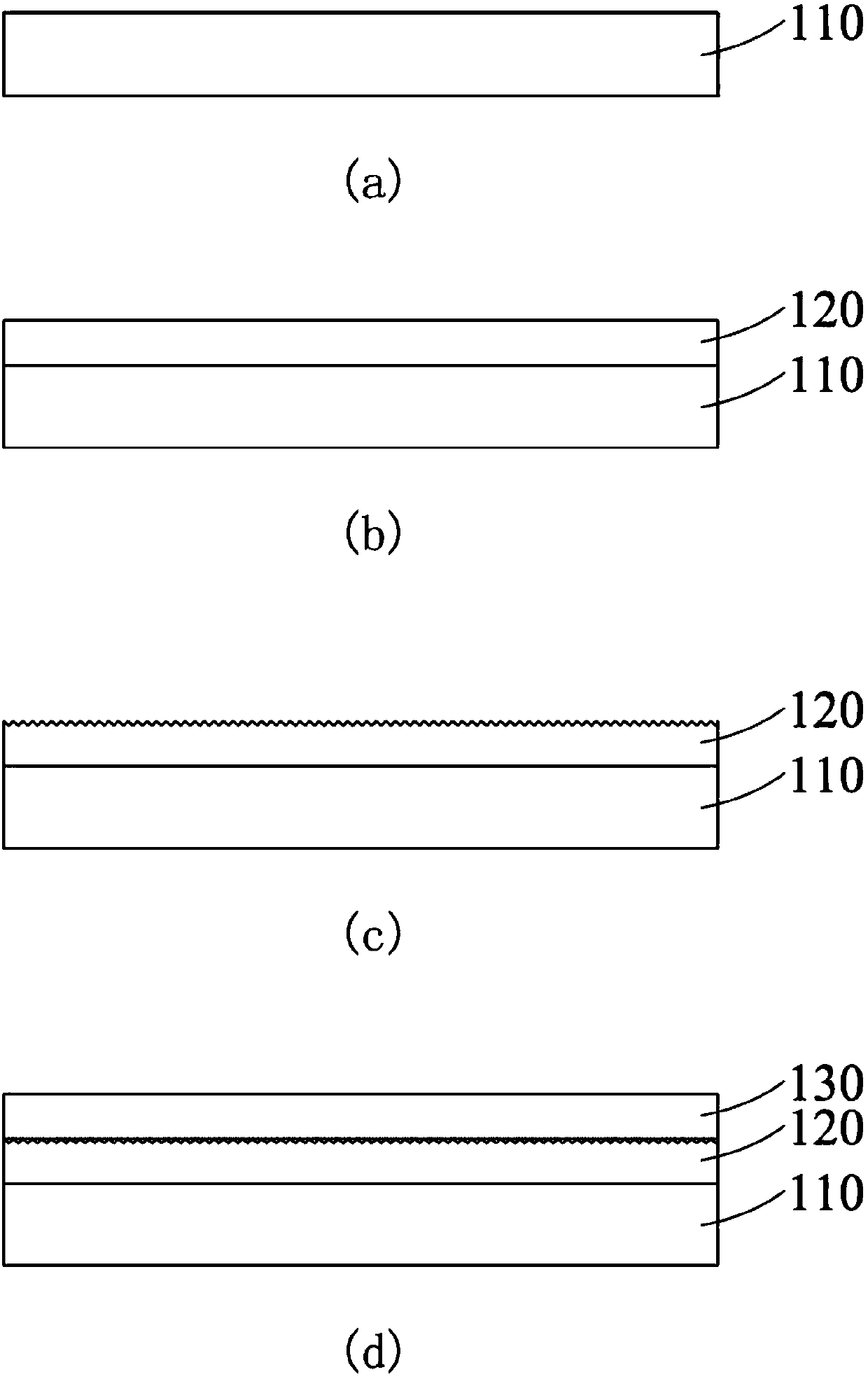

Liquid crystal display, liquid crystal display substrate and formation method thereof

ActiveCN101770982AAvoid corrosionImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesInsulation layerLiquid-crystal display

The invention relates to a liquid crystal display, a liquid crystal display substrate and a formation method thereof. The method for forming the liquid crystal display substrate comprises the following steps: forming a gate metal layer in a short-circuiting bar area and a pad area on a substrate and forming a gate electrode in a pixel unit area; sequentially forming a gate electrode insulation layer and an amorphous silicon composite layer which cover the gate metal layer and the gate electrode on the substrate; etching the amorphous silicon composite layer and the gate electrode insulation layer in the short-circuiting bar area and the pad area until the gate metal layer is exposed to form a short-circuiting bar area contact hole and a pad area contact hole; etching the amorphous siliconcomposite layer and reserving the amorphous silicon composite layer at a position corresponding to the gate electrode in the pixel unit area; forming a source / drain electrode metal layer on the gate electrode and the amorphous silicon composite layer and in the short-circuiting bar area contact hole and the pad area contact hole; and etching the source / drain electrode metal layer to form a source / drain electrode and a conducting channel in the pixel unit area and electrically connect the gate electrode metal layer with the source / drain electrode metal layer in the short-circuiting bar area. The liquid crystal display and the liquid crystal display substrate and the formation method thereof improve the reliability of a device and the efficiency of product quality analysis.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

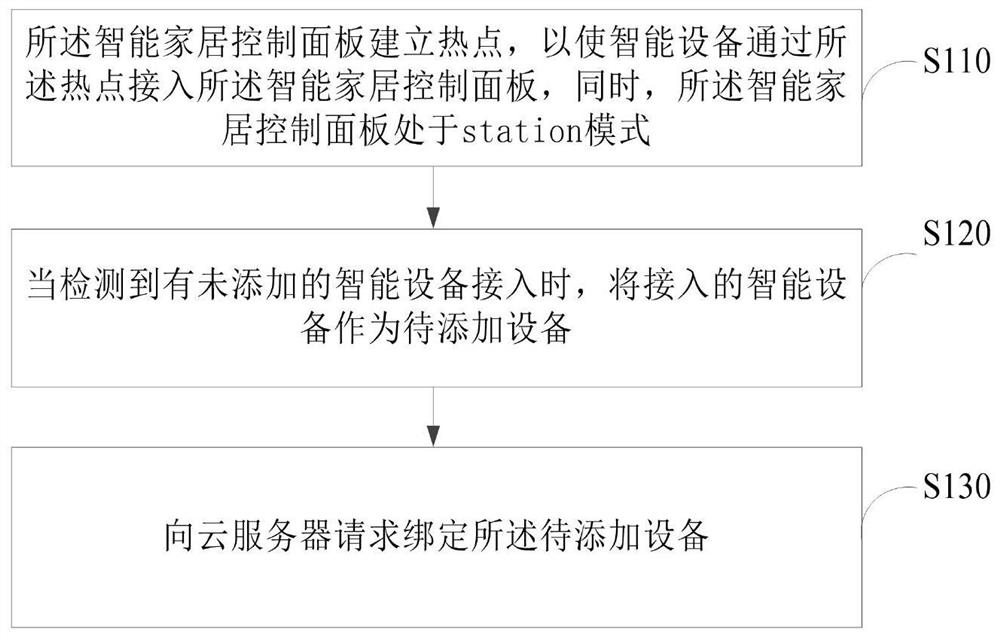

Smart device adding method and device, smart home control panel and storage medium

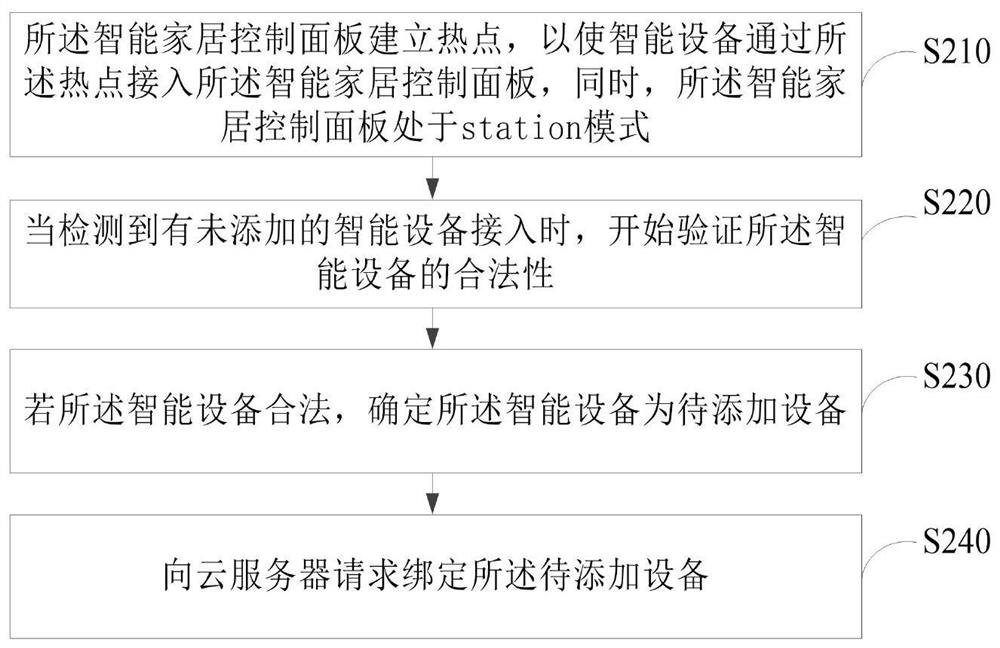

ActiveCN111865731AThere will be no disconnectionImprove efficiencyTotal factory controlHome automation networksComputer hardwareHome control

The embodiment of the invention discloses a smart device adding method and device, a smart home control panel and a storage medium. The method comprises the steps that a smart home control panel establishes a hot spot, so that the smart device is connected to the smart home control panel through the hot spot, and meanwhile, the smart home control panel is in a station mode; when it is detected that unadded smart device is accessed, the accessed smart device is taken as to-be-added equipment; and requesting to bind the to-be-added device is performed to a cloud server. Through adoption of the above method, a plurality of smart devices can access the smart home control panel through hot spots at the same time. The smart home control panel only needs to verify whether a plurality of accessedsmart devices are added or not, the smart devices which are not added in the multiple accessed smart devices are determined as the to-be-added equipment, the multiple to-be-added smart devices can bebound at the same time, the smart devices do not need to be connected one by one by searching hot spots of the smart devices, and therefore the efficiency of adding the smart devices is improved.

Owner:SHENZHEN OURUIBO ELECTRONICS

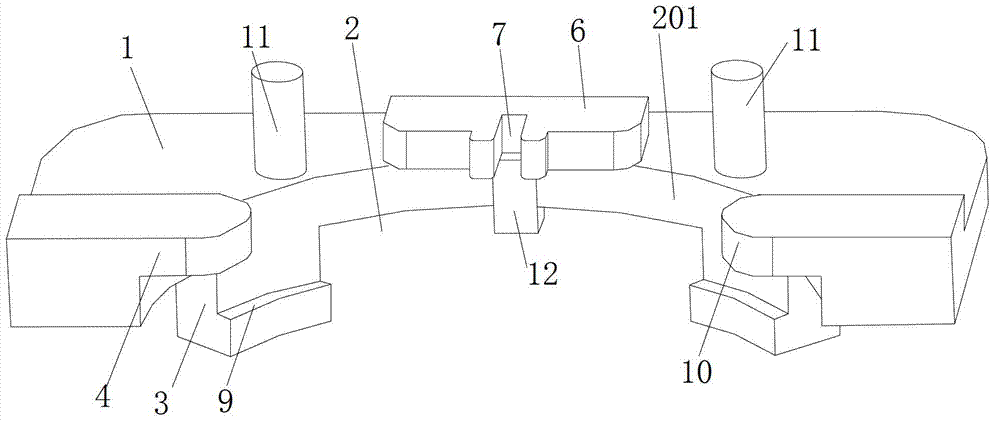

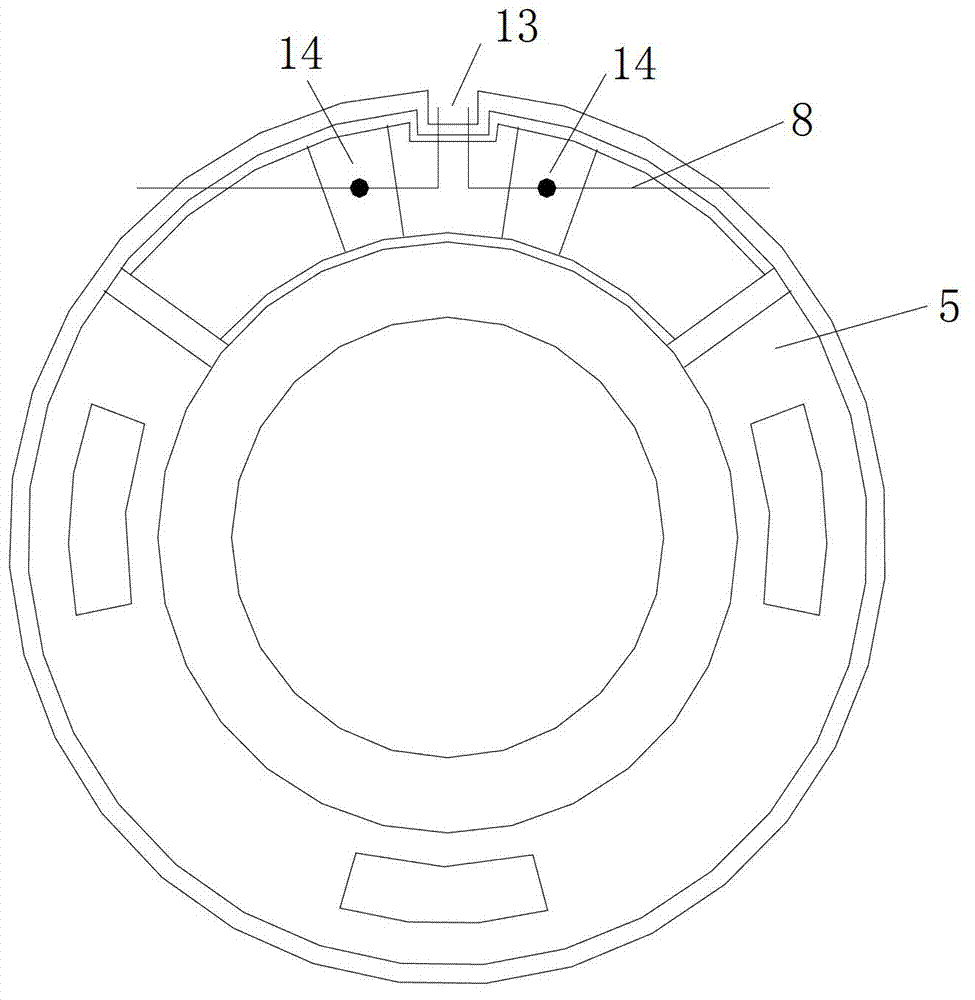

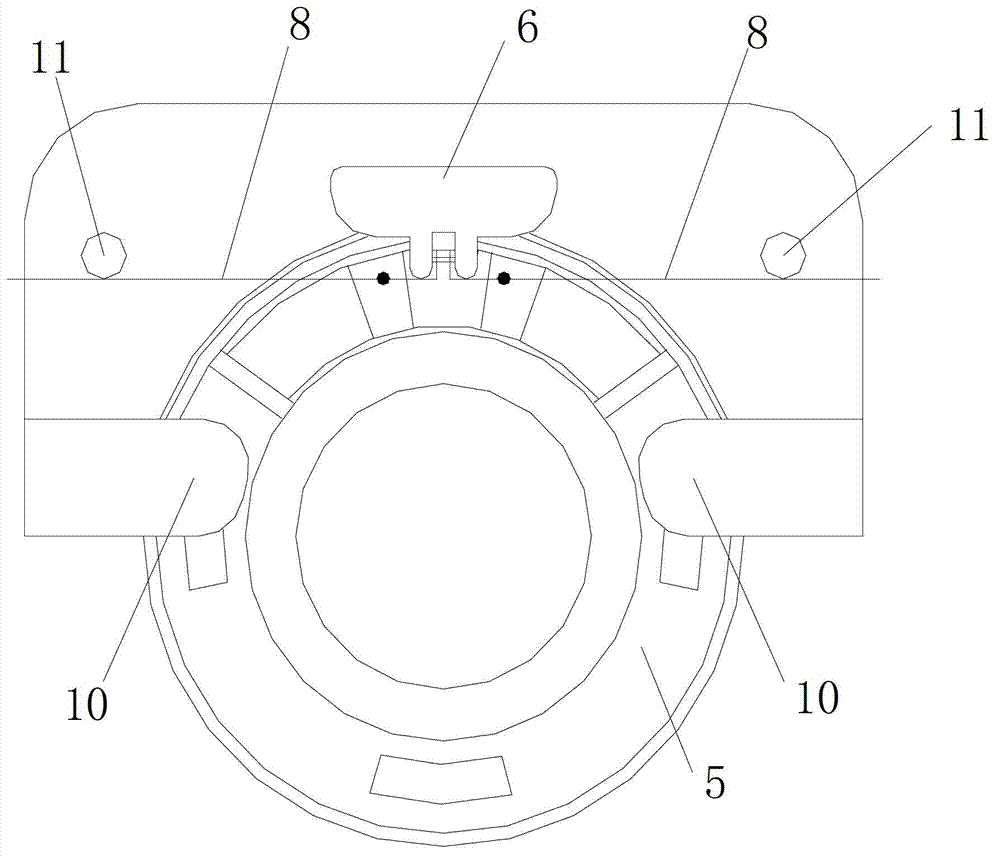

Tool and method for spot-welding loose wires of frame of loudspeaker

ActiveCN102825409AEnsure consistencyGuaranteed reliabilityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSpot welding

The invention relates to a tool and a method for spot-welding loose wires of a frame of a loudspeaker. The tool comprises a tool base plate; a notch which is sunk towards the middle of the tool base plate is arranged on one side of the tool base plate; a supporting portion is arranged on the tool base plate and is positioned below the notch; a limiting portion which is matched with the supporting portion is arranged on the tool base plate and above the notch; limiting space is formed among the supporting portion, the limiting portion and the wall of the notch; a wire crossing block is arranged on the upper end surface of the tool base plate and is positioned on one side of the center of the wall of the notch; one end of the wire crossing block extends to the middle of the notch; and a wire crossing groove opening is arranged at the extending end of the wire crossing block. Wires welded by the tool and the method are loose, and the phenomenon that the wires are pulled manually, are quite tight and even can be broken is avoided. In addition, because the wires cannot be tight, the anti-impact ability of welding points of the wires is increased, the quality of products is improved, and risks of customer complaint are reduced.

Owner:BESTAR HLDG

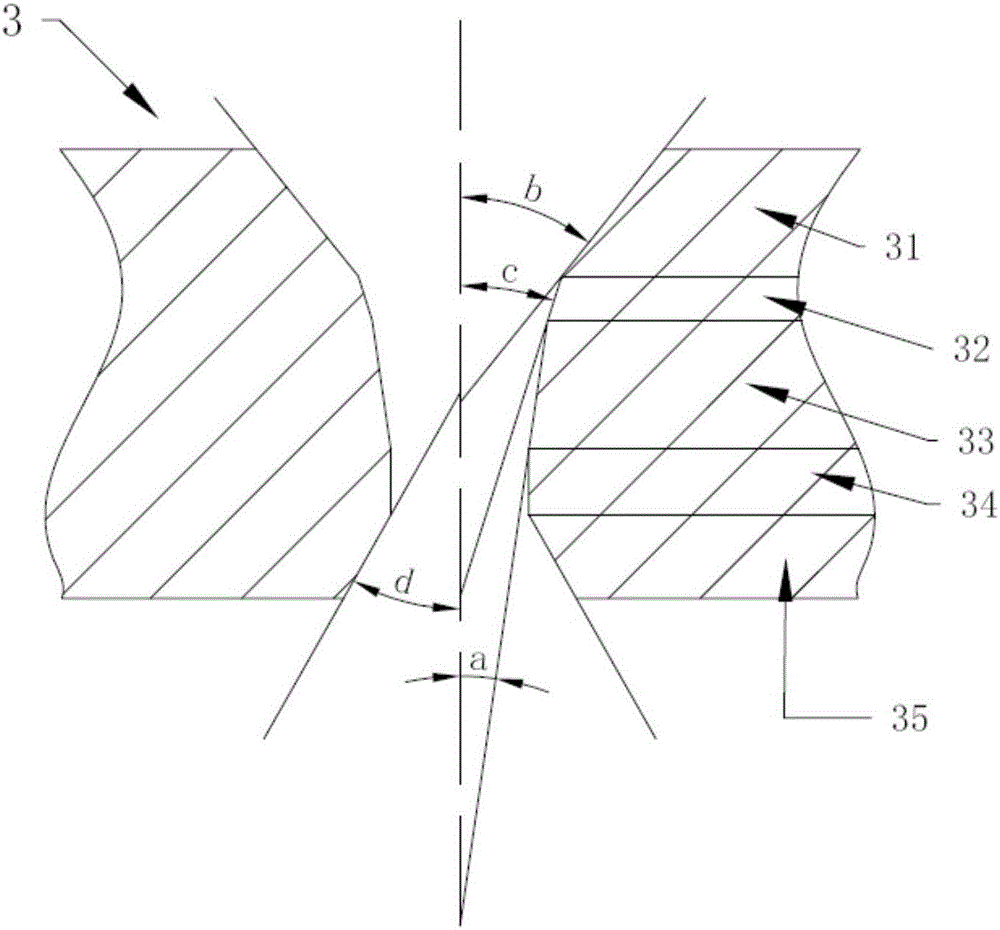

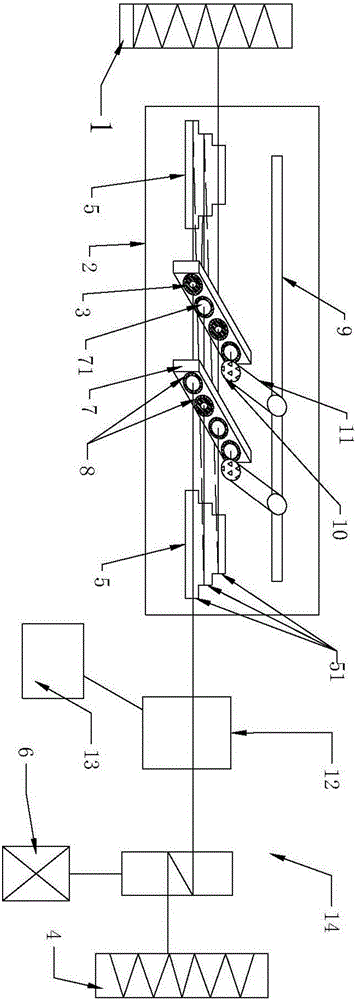

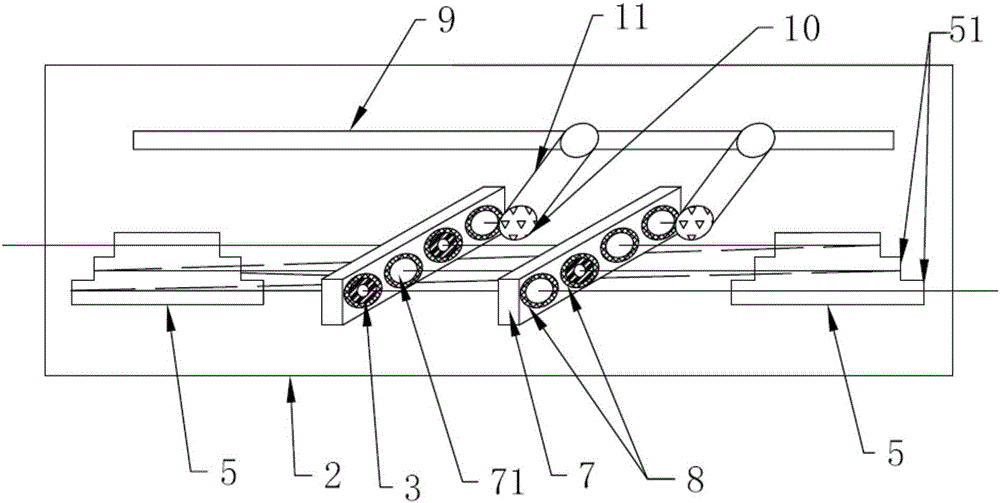

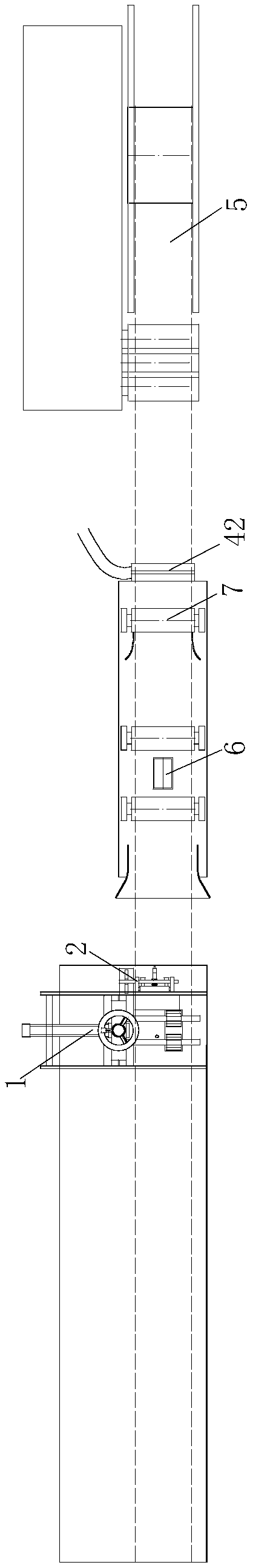

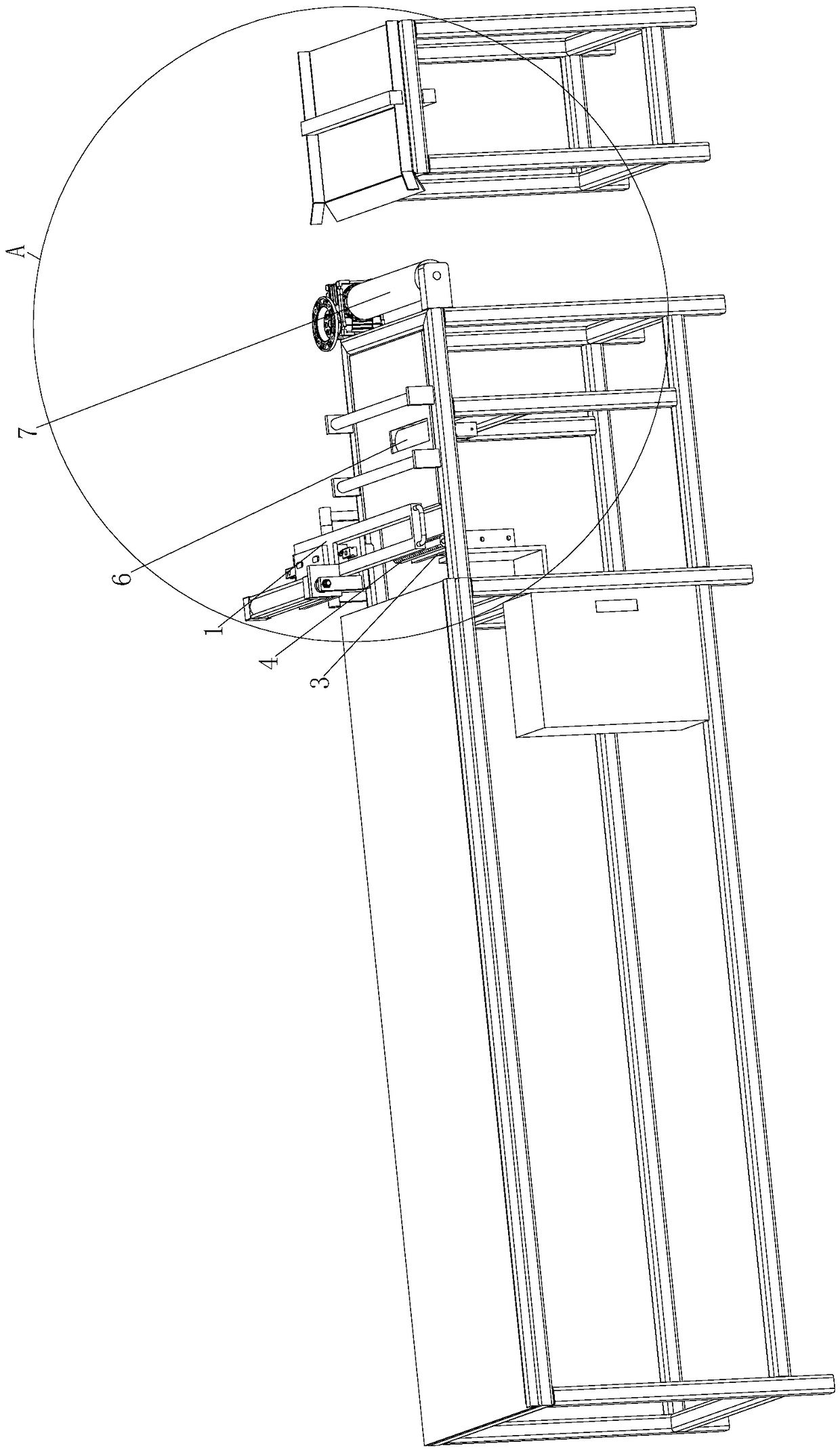

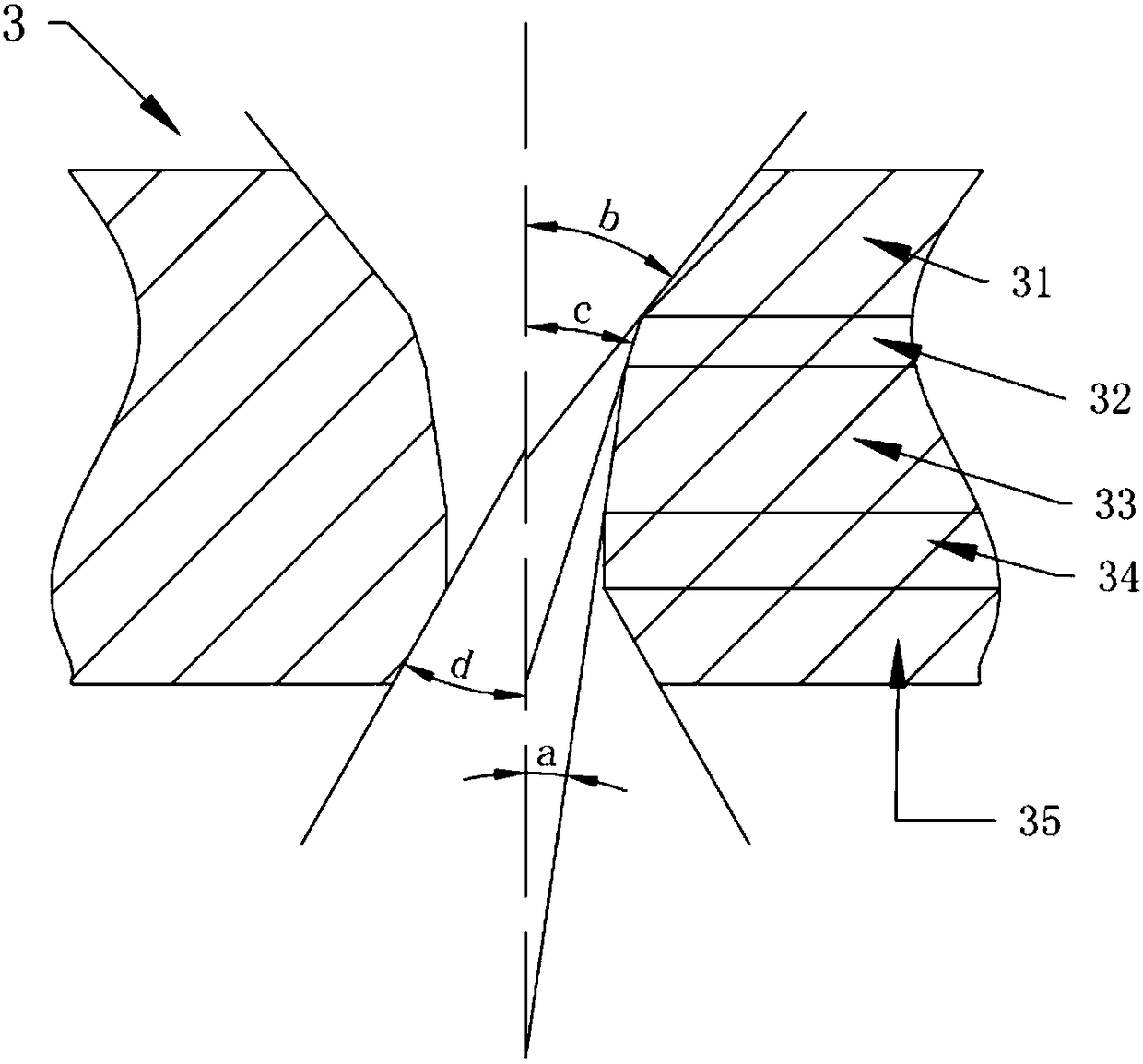

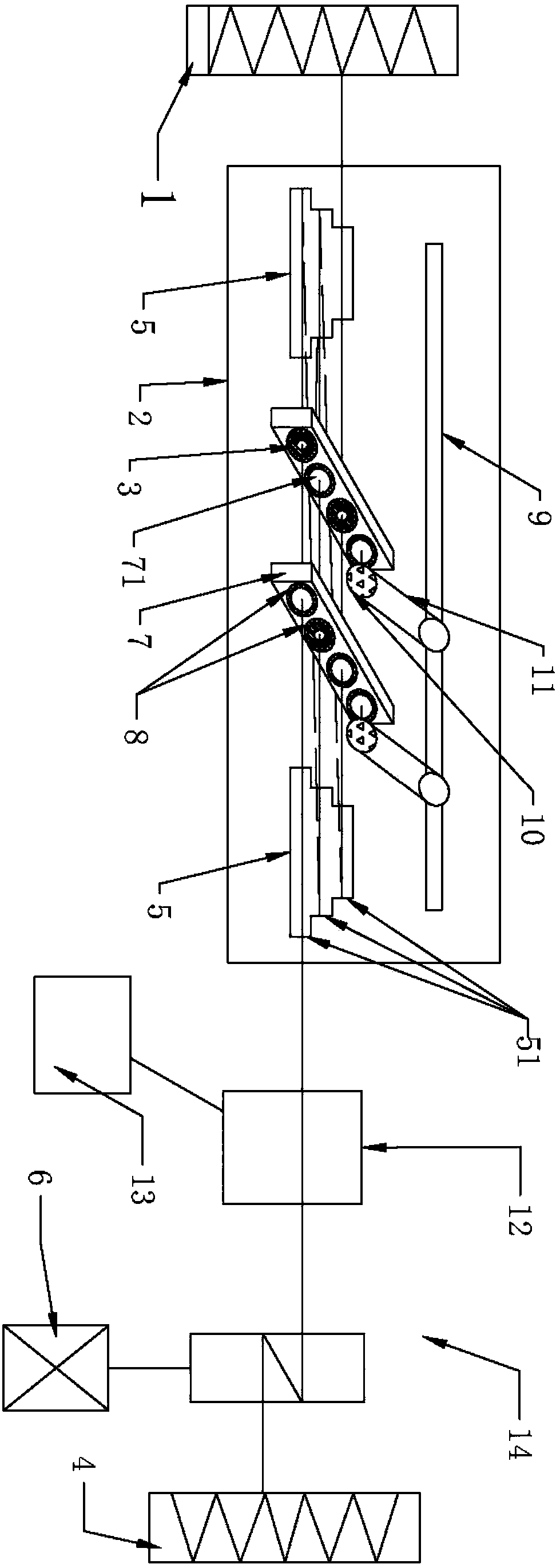

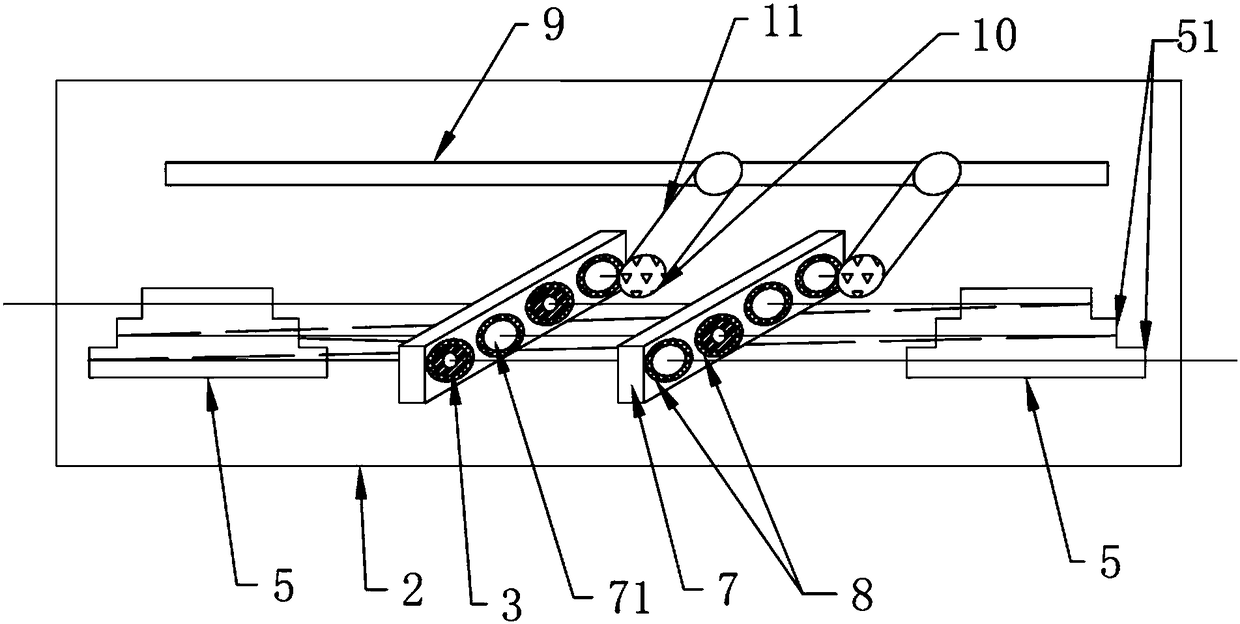

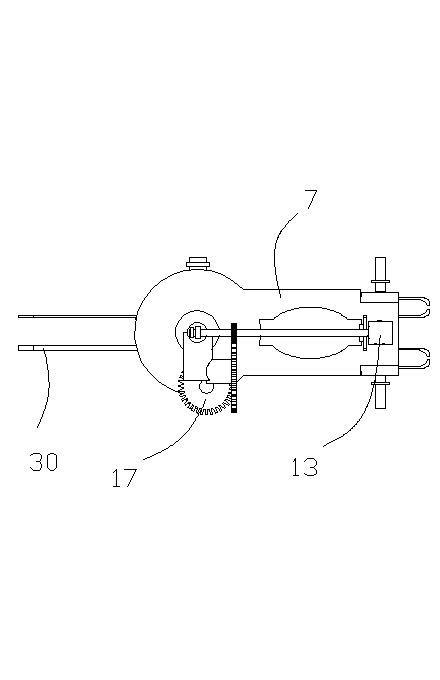

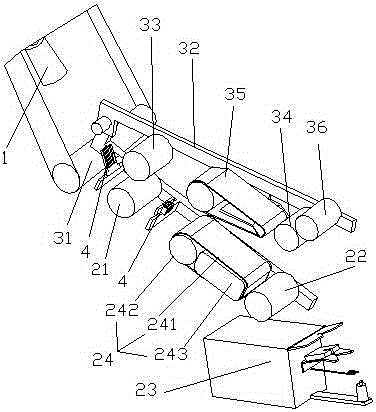

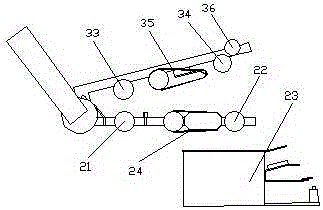

Drawing die and drawing system for metal wire

The invention discloses a drawing die and a drawing system for a metal wire. The drawing die comprises a tapered inlet region, a lubricating region, a tapered compression region, a cylindrical sizing region and a tapered outlet region which are sequentially connected through a circular arc transition portion; and the angle of the taper angle of the die decreases gradually from the tapered inlet region to the compression region, and the angle of the taper angle of the compression region ranges from 5 degrees to 12 degrees. The drawing system comprises a pay-off device, a drawing box body, at least one supporting seat, a traction device and a take-up device. The supporting seats are obliquely arranged on the inner wall of the drawing box body. The drawing die is mounted in mounting holes of the supporting seats. When the metal wire passes the compression region of the drawing die, compared with a drawing die in the prior art, by the adoption of the drawing die and the drawing system, if the same metal wire compression rate and the small reduction of the area are reached, the required traction force provided by the traction device is minimum, the loss of the internal gold phase structure of the metal wire material is small, a die core is not destroyed, the service life of the drawing die is prolonged, and the surface of the drawn metal wire is smooth.

Owner:NANTONG HUIFENG ELECTRONICS TECH

Method for preparing labor protection gloves from needling non-woven fabrics of imitating leather

A stream production line method for making the labor-protecting gloves with punched non-woven fabric simulating leather includes such steps as dipping the punched non-woven fabric in resin, overlaying two layers of said fabric, installing a hand-shaped die set to the pressing head of a hot press, heating it to a predefined temp, hot die pressing to adhere said overlayed two layers of fabric, turning on the constant-temp baking over to heat its internal temp to a predefined temp, putting the semi-finished gloves along with its die set in the baking oven, baking, and separating the finished gloves from its die set.

Owner:姜涛

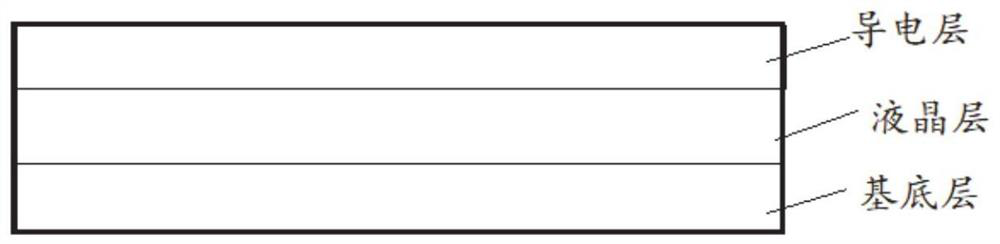

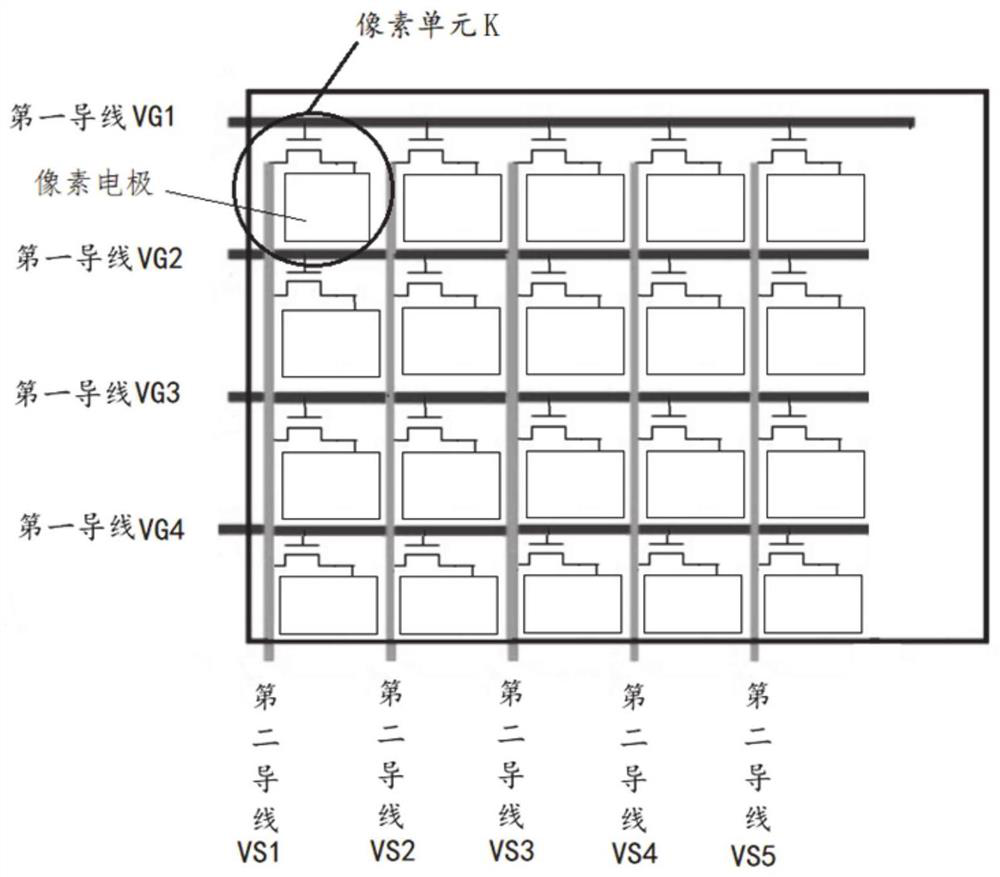

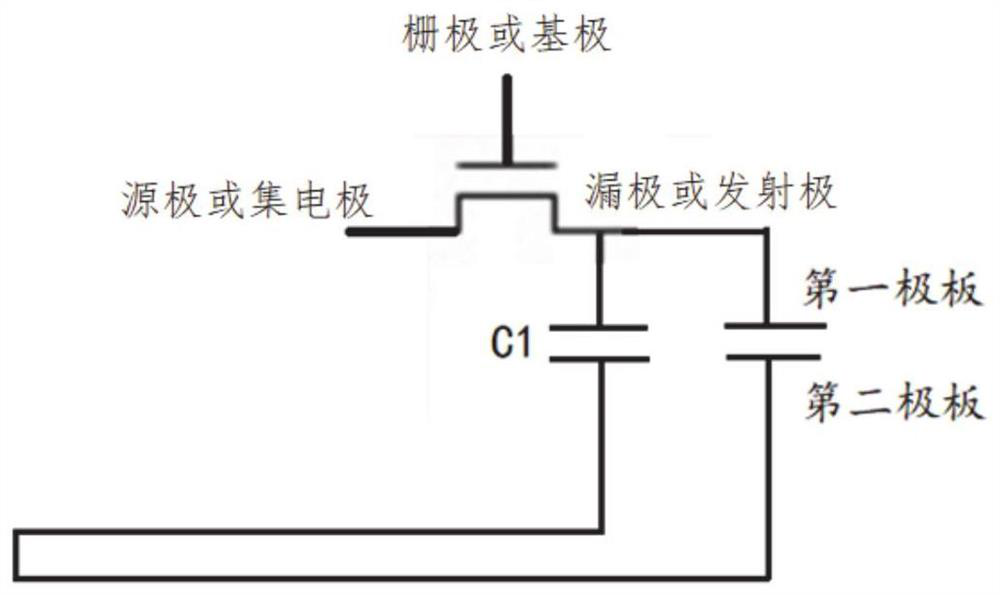

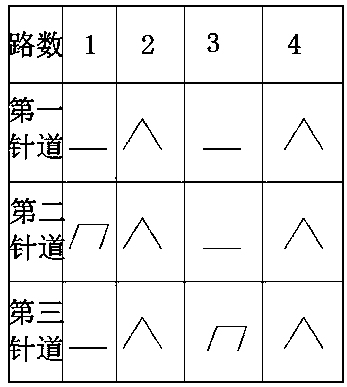

Bistable liquid crystal writing device and method with electric drive display and pressure display

ActiveCN112711151AThere will be no disconnectionReduce processStatic indicating devicesElectrical appliancesMaterials scienceLiquid crystal

The invention discloses a bistable liquid crystal writing device and method with electric drive display and pressure display. The bistable liquid crystal writing device comprises a conducting layer, a bistable liquid crystal layer and a substrate layer, which are arranged in sequence. The substrate layer integrats: a plurality of pixel units arranged in an array mode, wherein each pixel unit is internally provided with a pixel electrode and a switch tube connected with the pixel electrode. a control unit, which is configured to adopt a row-by-row / column-by-column driving mode, based on the display position in each row / column, set voltage is input to the corresponding pixel electrodes by controlling the conduction and input voltage of the switching tubes set in each row / column in sequence, so that the pixel electrodes and the conductive layer form a set electric field at the spatially overlapped position, and the pixel electrodes and the conductive layer form a display area, and finally, the display of the to-be-displayed content is realized. According to the liquid crystal writing device, set content can be displayed, meanwhile, some complex content can be presented on the writing device, and a large amount of writing time is saved.

Owner:SHANDONG LANBEISITE EDUCATIONAL EQUIP GRP

Manufacturing method for silver French terry

InactiveCN108193357AGood air permeabilityBreathable and beautifulWeft knittingGrip property fibresAfter treatmentYarn

The invention discloses a manufacturing method for a silver French terry. The method comprises the steps of 1, manufacturing raw materials of a veil and a reverse side looped yarn; 2, weaving the veiland the reverse side looped yarn into a gray cloth on a circular knitting machine; 3, performing after-treatment. In the fabric manufacturing process, no broken yarn phenomenon is caused, and the terry woven by triangular cloth arrangement on the circular knitting machine is good in breathability and attractive in appearance.

Owner:JIANGYIN DELAI NEW FABRICS CO LTD

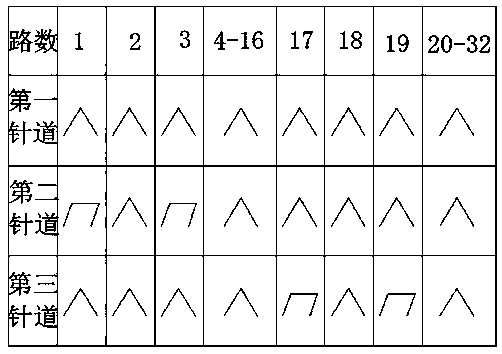

Manufacture method for square point jacquard weave undershirt cloth

InactiveCN108385255AGood air permeabilityBreathable and beautifulWeft knittingSynthetic fibresLine BreakYarn

The invention discloses a manufacture method for square point jacquard weave undershirt cloth. The manufacture method comprises the following steps: (1) preparing raw materials including Modal, terylene and spandex; (2) weaving yarns prepared in (1) into gray cloth on a circular knitting machine; (3) carrying out after treatment. According to the manufacture method, a situation of line breaking ina shell fabric manufacture process is avoided, and in addition, the woven shell fabric has good gas permeability and is attractive due to the triangular arrangement in the circular knitting machine.

Owner:JIANGYIN DELAI NEW FABRICS CO LTD

Manufacturing method of sectionally dyeing undershirt cloths

InactiveCN108193358AImprove breathabilityThere will be no disconnectionWeft knittingGrip property fibresYarnEngineering

The invention discloses a manufacturing method of sectionally dyeing undershirt cloths. The method includes the steps of 1, preparing modal blended yarn and spandex as raw materials; 2, weaving yarn prepared in step 1 into blank cloths on a circular knitting machine; 3, conducting after-finishing. In the manufacturing process of a fabric, threads cannot be broken, and the woven fabric is great inair permeability and attractive in appearance by triangularly arranging the cloths in the circular knitting machine.

Owner:JIANGYIN DELAI NEW FABRICS CO LTD

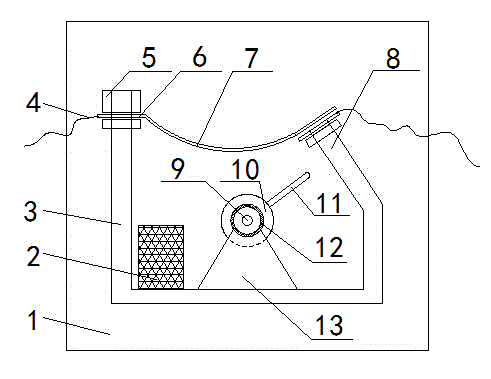

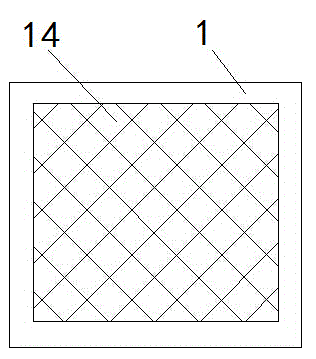

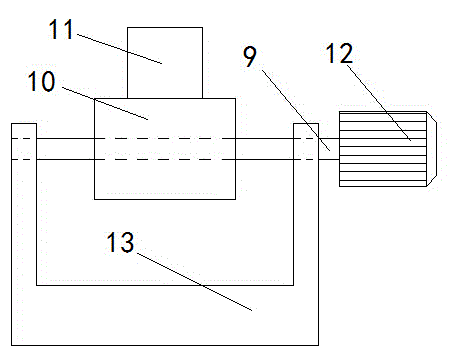

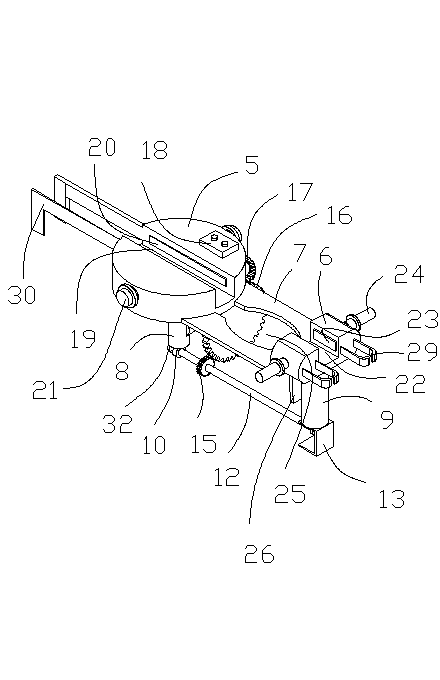

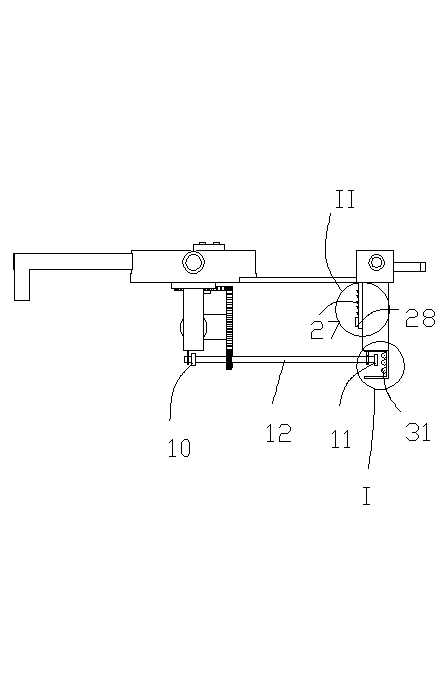

Automatic control power switch used outdoors

InactiveCN104952647ANo leakageThere will be no disconnectionSwitch power arrangementsContact electric connectionAutomatic controlStructural engineering

The invention discloses an automatic control power switch used outdoors. The power switch comprises a box, a storage battery, an insulation post I, a circuit, insulation nuts, conductive pieces, a memory alloy, an insulation post II, a central shaft, a roller, a scraper, a motor, a support and a solar cell panel, wherein the insulation post I and the insulation post II which are integrated are arranged in the box, the insulation nuts are arranged at top ends of the insulation post I and the insulation post II, the conductive piece clamped between two insulation nuts on the insulation post I is connected with the memory alloy, the memory alloy is also attached to the conductive piece at the top end of the insulation post II, the support is arranged in the box, the central shaft is placed on the support and sleeved with the roller, the scraper is arranged on the roller, one end of the central shaft is connected with the motor, and the motor is connected with the storage battery through a lead. The automatic control power switch used outdoors can connect and disconnect a line automatically and adjust connection and disconnection time of the line as required.

Owner:PENGLAI POWER SUPPLY CO OF STATE GRID SHANDONG ELECTRIC POWER CO

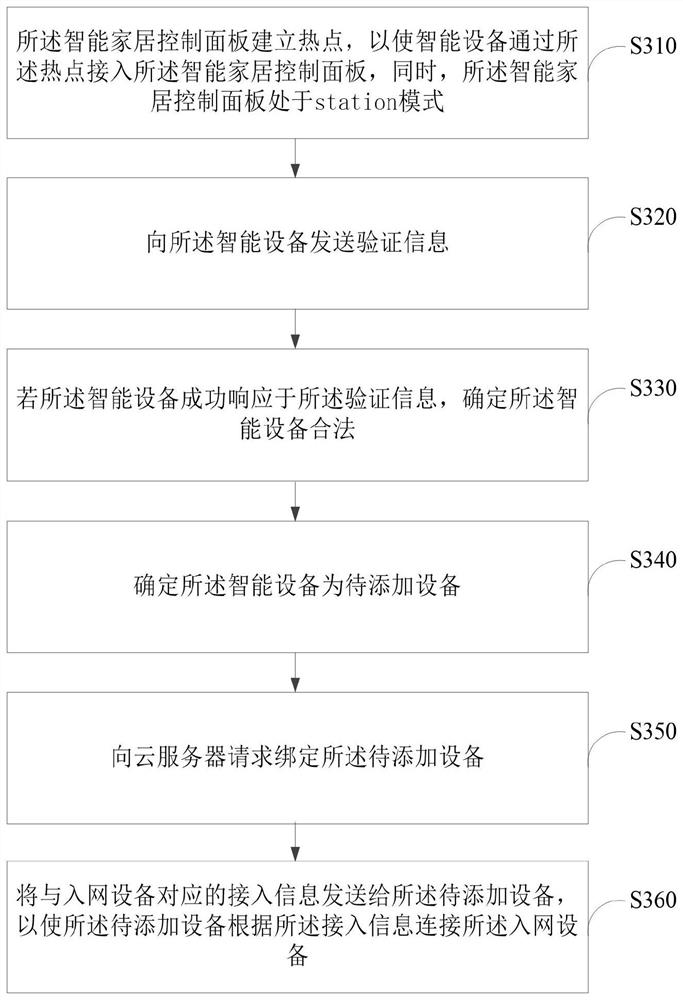

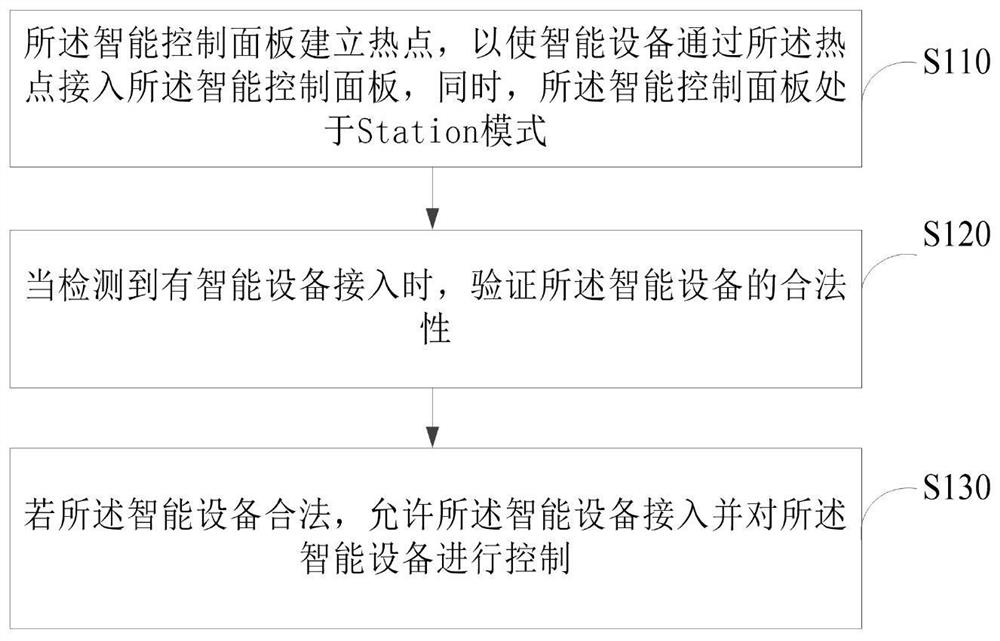

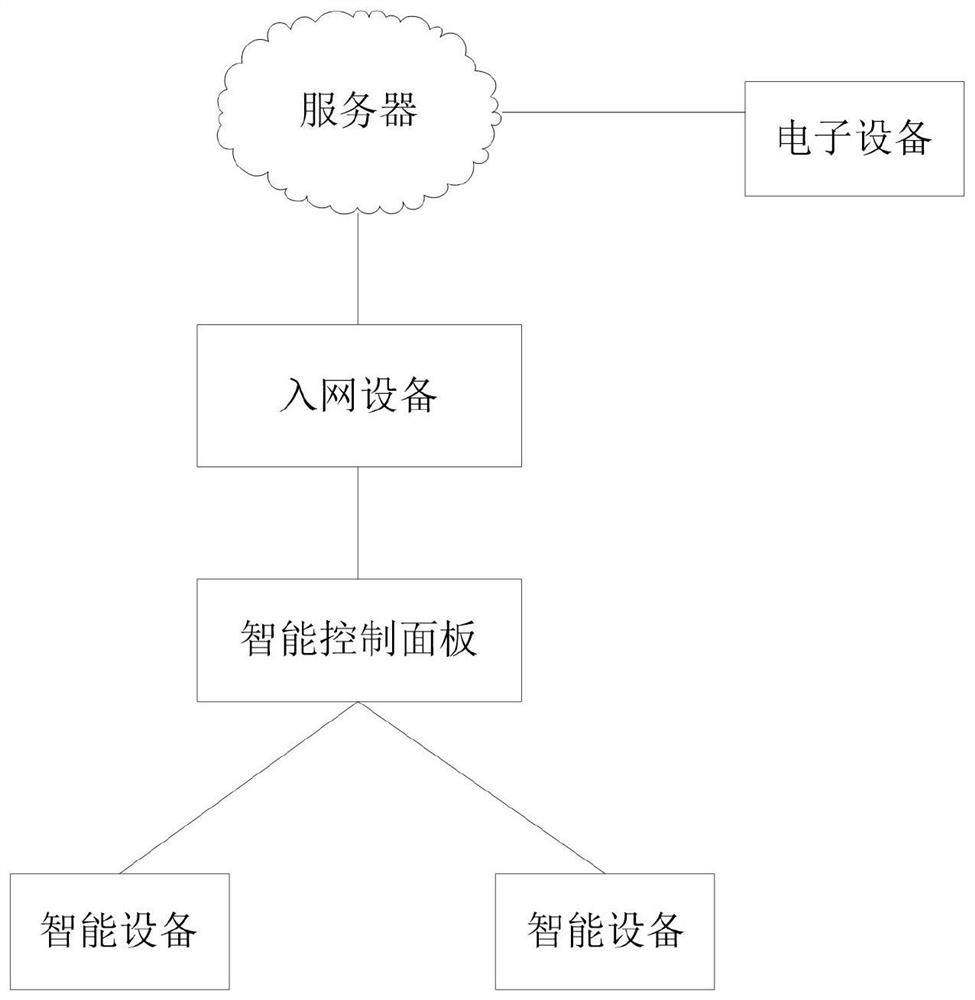

Intelligent equipment control method and device, intelligent control panel and storage medium

InactiveCN111901208AVerify legitimacyThere will be no disconnectionHome automation networksIntelligent equipmentEmbedded system

The embodiment of the invention discloses an intelligent equipment control method and device, an intelligent control panel and a storage medium. The method comprises the steps that the intelligent control panel establishes a hot spot, so that intelligent equipment is connected to the intelligent control panel through the hot spot, and meanwhile, the intelligent control panel is in a Station mode;when it is detected that the intelligent equipment is accessed, the legality of the intelligent equipment is verified; and if the intelligent equipment is legal, the intelligent equipment is allowed to access and controlled. Through the above method, the intelligent control panel can be in the Station mode and the AP mode at the same time, therefore, in the process that the intelligent device is connected to the intelligent control panel through the hotspot, the intelligent control panel cannot be disconnected from the network, and in addition, the intelligent device can be controlled throughthe intelligent control panel even if the network access device is disconnected from the network or powered off.

Owner:SHENZHEN OURUIBO ELECTRONICS

Manufacturing method of herringbone looped pile fabric

InactiveCN108486751AImprove breathabilityThere will be no disconnectionWeft knittingVegetal fibresWoven fabricYarn

The invention discloses a manufacturing method of herringbone looped pile fabric. The manufacturing method comprises the steps of 1, preparing the raw materials of cotton modal blended yarn and spandex; 2, weaving the yarn prepared in step 1 into gray cloth on a circular knitting machine; 3, conducting after-finishing. According to the manufacturing method of the herringbone looped pile fabric, inthe process of manufacturing the fabric, the situation of thread breaking cannot occur; meanwhile, through the triangular distribution in the circular knitting machine, the woven fabric is good in breathability and attractive.

Owner:JIANGYIN DELAI NEW FABRICS CO LTD

Production method of hoodie silver yarn terry fabric

InactiveCN108385253AImprove breathabilityThere will be no disconnectionGrip property fibresCircular knitting machinesYarnEngineering

The invention discloses a production method a hoodie silver yarn terry fabric. The method comprises the following steps: (1) preparing raw materials including surface yarns, silver yarns and back sideterry yarns; (2) knitting the surface yarns, the silver yarns and the back side terry yarns into a gray cloth on a circular knitting machine; and (3) carrying out after-finishing. Through the production method of the hoodie silver yarn terry fabric, the situation of breakage of yarns is avoided in the production process of the fabric; through triangular arrangement of the cloth in the circular knitting machine, the knitted fabric is high in breathability and attractive in appearance.

Owner:JIANGYIN DELAI NEW FABRICS CO LTD

Production method of unequally-spaced yarn-dyed undershirt cloth

The invention discloses a production method of unequally-spaced yarn-dyed undershirt cloth. The method comprises the steps that (1), raw materials of cotton modal blended yarn and spandex are prepared; (2) yarns prepared in step (1) are woven into gray cloth on a circular knitting machine; (3) after treatment is carried out. The production method of the unequally-spaced yarn-dyed undershirt clot has the advantages that a situation of line breakage during the production of the fabric, and the triangular configuration in the circular knitting machine makes the woven fabric have air permeability,good comfort and attractive appearance.

Owner:JIANGYIN DELAI NEW FABRICS CO LTD

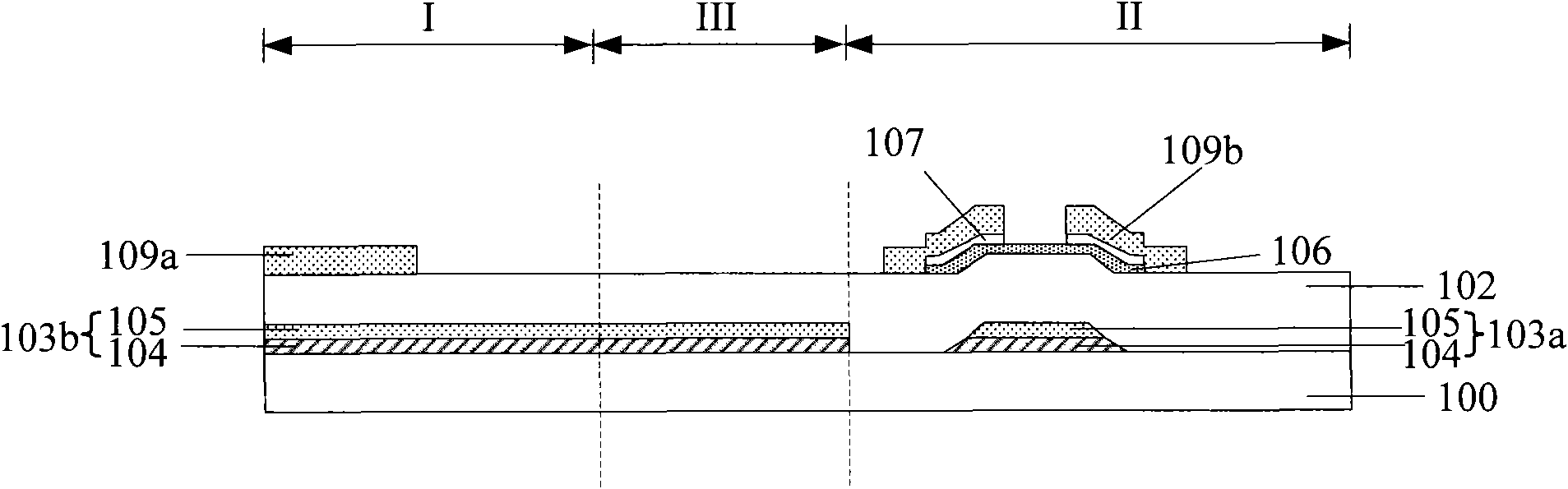

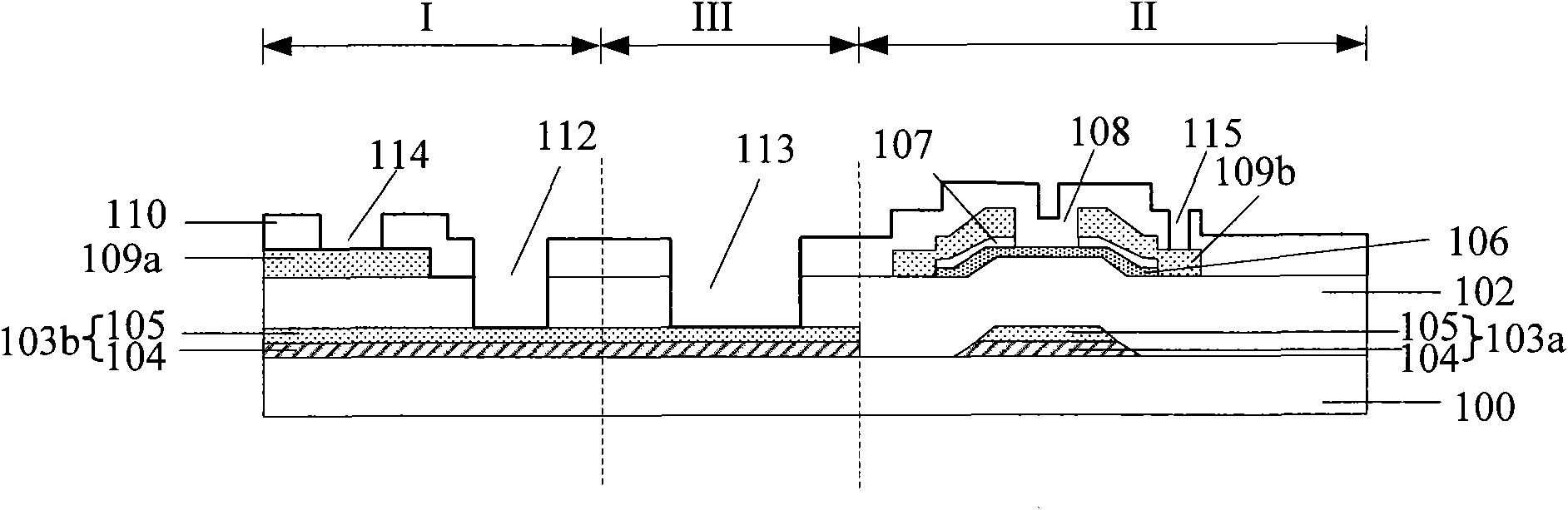

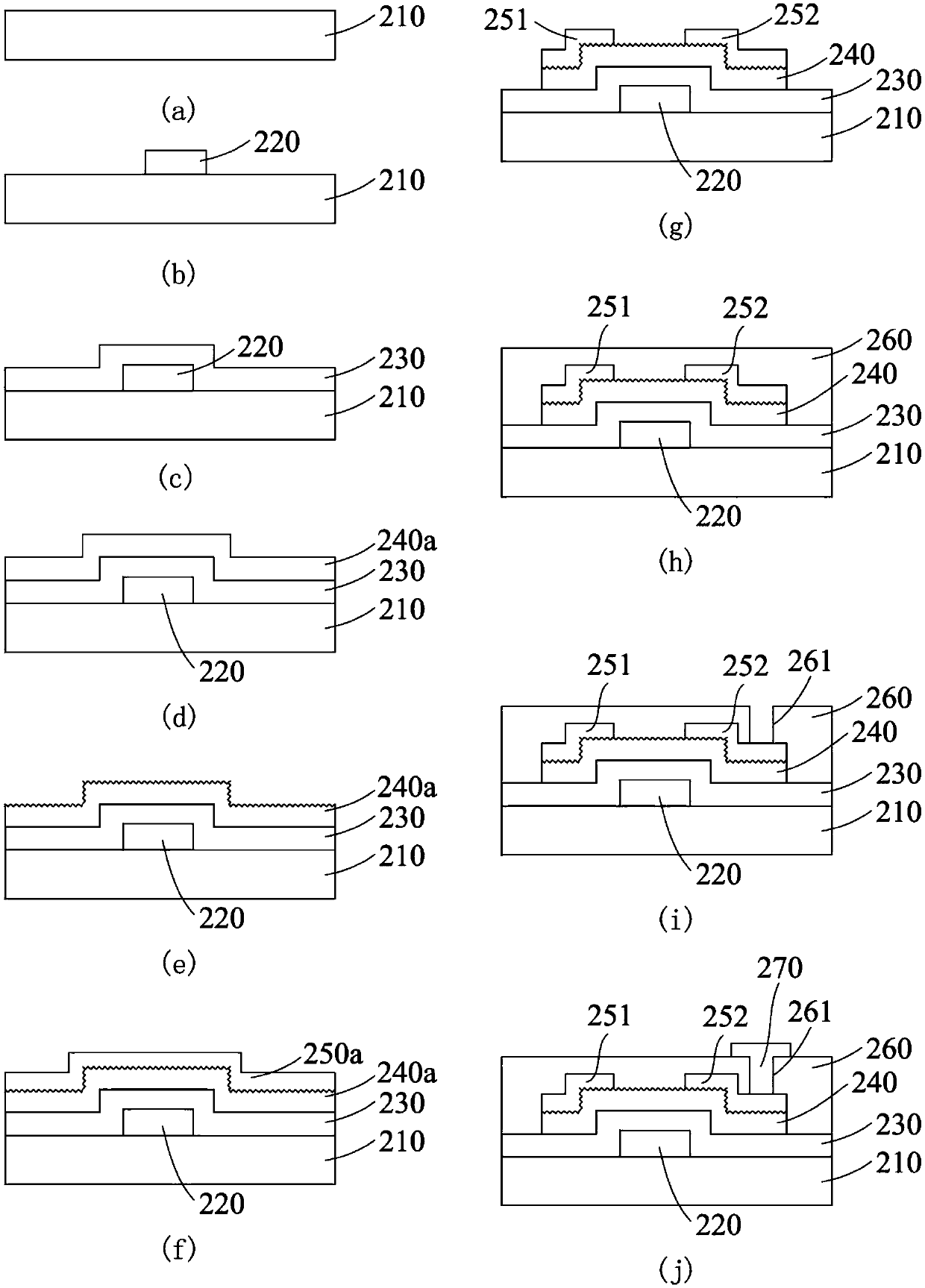

Array substrate and method for manufacturing the same, and method for improving adhesiveness between film layers

InactiveCN107591359AImprove adhesionImprove yieldSolid-state devicesSemiconductor/solid-state device manufacturingSemiconductor materialsActive layer

The invention provides a method for manufacturing an array substrate. The method comprises: providing a substrate; forming a gate on the substrate; forming a gate insulating layer on the substrate andthe gate; forming a semiconductor material layer on the gate insulating layer; carrying out roughening processing on the surface of the semiconductor material layer; forming source-drain metal layeron the semiconductor material layer; carrying out exposing, developing, and etching on the source-drain metal layer and the semiconductor material layer so as to form an active layer on the gate insulating layer and form a source and a drain that are spaced from each other on the active layer and the gate insulating layer; forming a passivation layer on the active layer, the gate insulating layer,the source and the drain; forming a via hole exposing the drain electrode; and forming a pixel electrode in contact with the drain through the via hole on the passivation layer. According to the invention, because roughening processing is carried out on the surface of the active layer, the adhesive forces of the source, the drain, and the active layer are strengthened, thereby avoiding line breaking and improving the yield of the array substrate.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

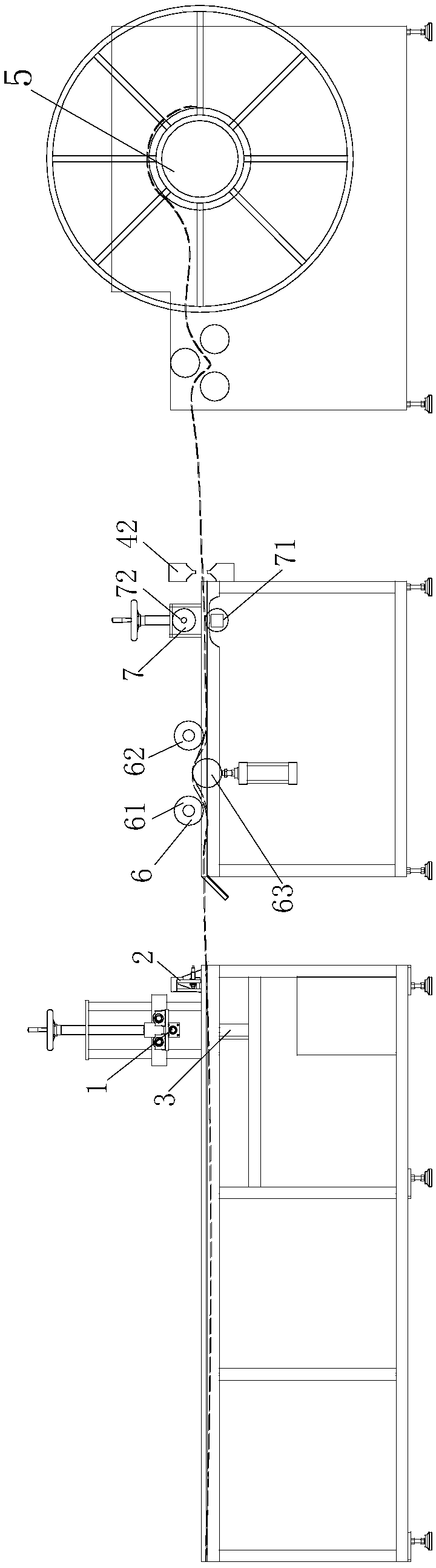

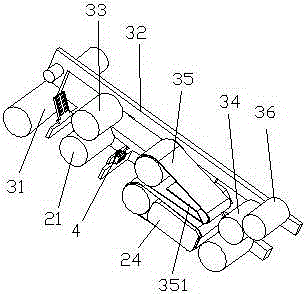

Processing and production method and equipment special for bamboo split rolls

PendingCN109016039AReduce investmentThere will be no disconnectionAdhesive application devicesAgricultural engineeringLap joint

The invention relates to a processing and production method and equipment special for bamboo split rolls and belongs to the field of bamboo split roll processing. A front bamboo split curtain and a rear bamboo split curtain are connected in a stitching mode and lines may break in the prior art. The processing and production method special for the bamboo split rolls comprises the following steps of(1) applying glue to the tail section of the front bamboo split curtain, specifically, the glue is used for bonding the tail section of the front bamboo split curtain to the head section of the rearbamboo split curtain; (2) connecting the head section of the rear bamboo split curtain to the tail section of the front bamboo split curtain in a lapping mode; (3) applying pressure to the lap joint portion of the head section of the rear bamboo split curtain and the tail section of the front bamboo split curtain; (4) cooling the glue for bonding the head section of the rear bamboo split curtain to the tail section of the front bamboo split curtain; and (5) conveying and winding the front bamboo split curtain and the rear bamboo split curtain after the front bamboo split curtain and the rear bamboo split curtain are bonded. By means of the method, the front bamboo split curtain and the rear bamboo split curtain can be bonded more firmly, and debonding is avoided.

Owner:ZHEJIANG GUANGXIN BAMBOO BASED MATERIALS CO LTD

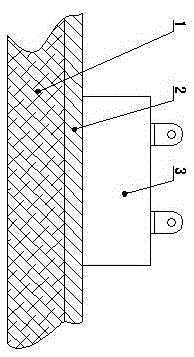

Heatable mirror

InactiveCN105657884ASolution to short lifeRealize the requirements of automatic constant temperature controlTransparent/reflecting heating arrangementsTemperature controlCopper

The invention provides a heatable mirror. According to the heatable mirror, a heat conduction layer (2) produced from aluminum, copper and the like with very good thermal conductivity is arranged on the back of a lens (1), a PTC heating body (3) is attached to the back of the heat conduction layer, and heat emitted by the PTC heating body (3) can be uniformly conducted to the lens by virtue of the heat conduction layer, so as to realize functions of deicing, defrosting, demisting and the like. Furthermore, the temperature regulation of the PTC heating body is decided by the material characteristics of the PTC heating body, and a temperature sensor and a temperature control circuit are saved, so that the number of electrical apparatus elements is greatly reduced, and the fault rate of the heatable mirror is greatly reduced. Compared with traditional heating elements, the heatable mirror has incomparable advantages that the constant temperature heating is realized, the heating body does not become red, the influence caused by supply voltage is extremely low, and the like; and when reaching a set temperature, the power is automatically decreased to be below 1% of the original power, and the temperature does not need to be maintained by switching on or off a power supply like general heating elements, so that the energy consumption is saved, and meanwhile, the service life of the heatable mirror is greatly prolonged.

Owner:姚胜南

Method for preparing labor protection gloves from needling non-woven fabrics of imitating leather

A stream production line method for making the labor-protecting gloves with punched non-woven fabric simulating leather includes such steps as dipping the punched non-woven fabric in resin, overlaying two layers of said fabric, installing a hand-shaped die set to the pressing head of a hot press, heating it to a predefined temp, hot die pressing to adhere said overlayed two layers of fabric, turning on the constant-temp baking over to heat its internal temp to a predefined temp, putting the semi-finished gloves along with its die set in the baking oven, baking, and separating the finished gloves from its die set.

Owner:姜涛

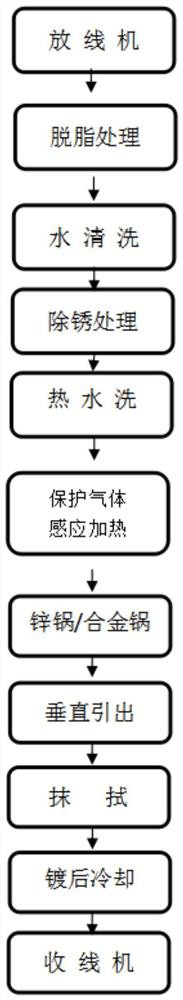

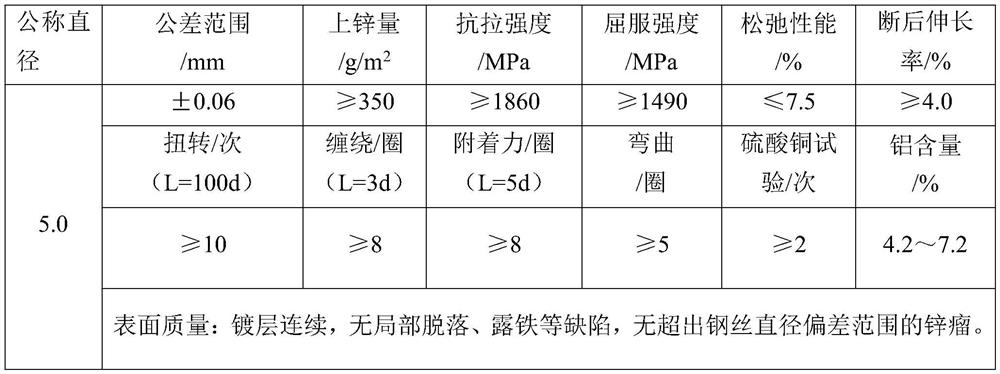

Process method for obtaining steel wire hot galvanizing and alloy thick plating layer

PendingCN112921261AMeet production requirementsGuaranteed binding requirementsHot-dipping/immersion processesFurnace typesShielding gasAlloy

The invention relates to a process method for obtaining a steel wire hot galvanizing and alloy thick plating layer. The process method comprises the following steps: performing oil and rust removal treatment on the surface of a steel wire at a wiring speed in a range of 150-500 m / min, putting the treated steel wire into an induction heating furnace, and performing induction heating on the steel wire under the action of protective gas at the induction heating temperature 0-70 DEG C lower than a plating solution temperature, wherein the plating solution temperature is 420-520 DEG C, and the induction heating time is 0.5-2 seconds; and discharging the steel wire out of the induction heating furnace, entering a zinc pot from a closed steel pipe, vertically leading out a plating solution through a ceramic wire pressing shaft, entering a wiping device, and finally cooling to obtain the thick-plated steel wire. According to the method, the steel wire subjected to surface treatment can enter the zinc pot after being subjected to induction heating by protective gas of which the temperature is equal to or lower than the hot plating temperature at a relatively high wiring speed, namely in a range of 150-500 m / min, and then is vertically led out of a liquid surface to be wiped, so that a high-binding-force thick plating layer meeting the strength requirement is obtained.

Owner:TIANJIN GONGDA GALVANIZING EQUIP CO LTD

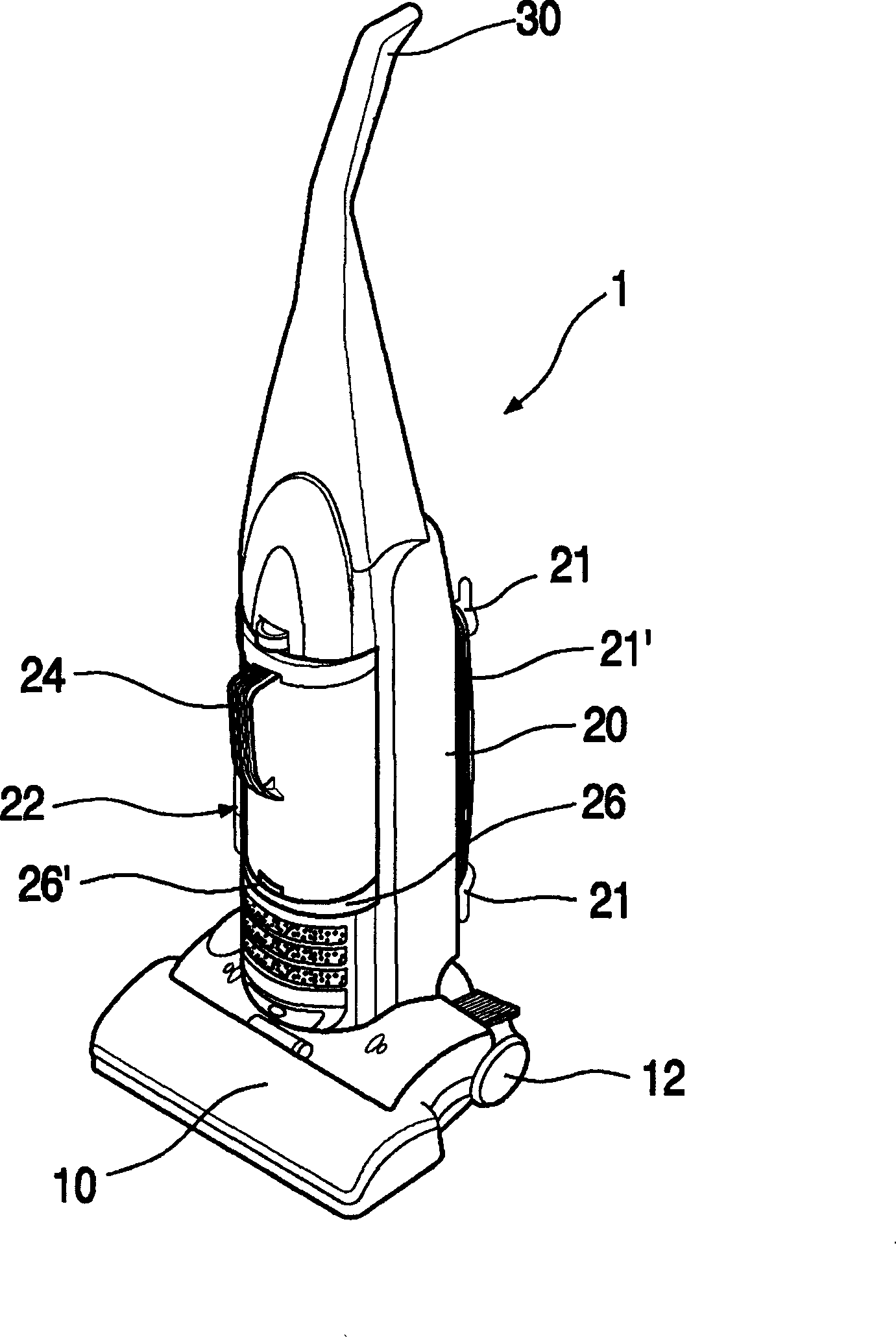

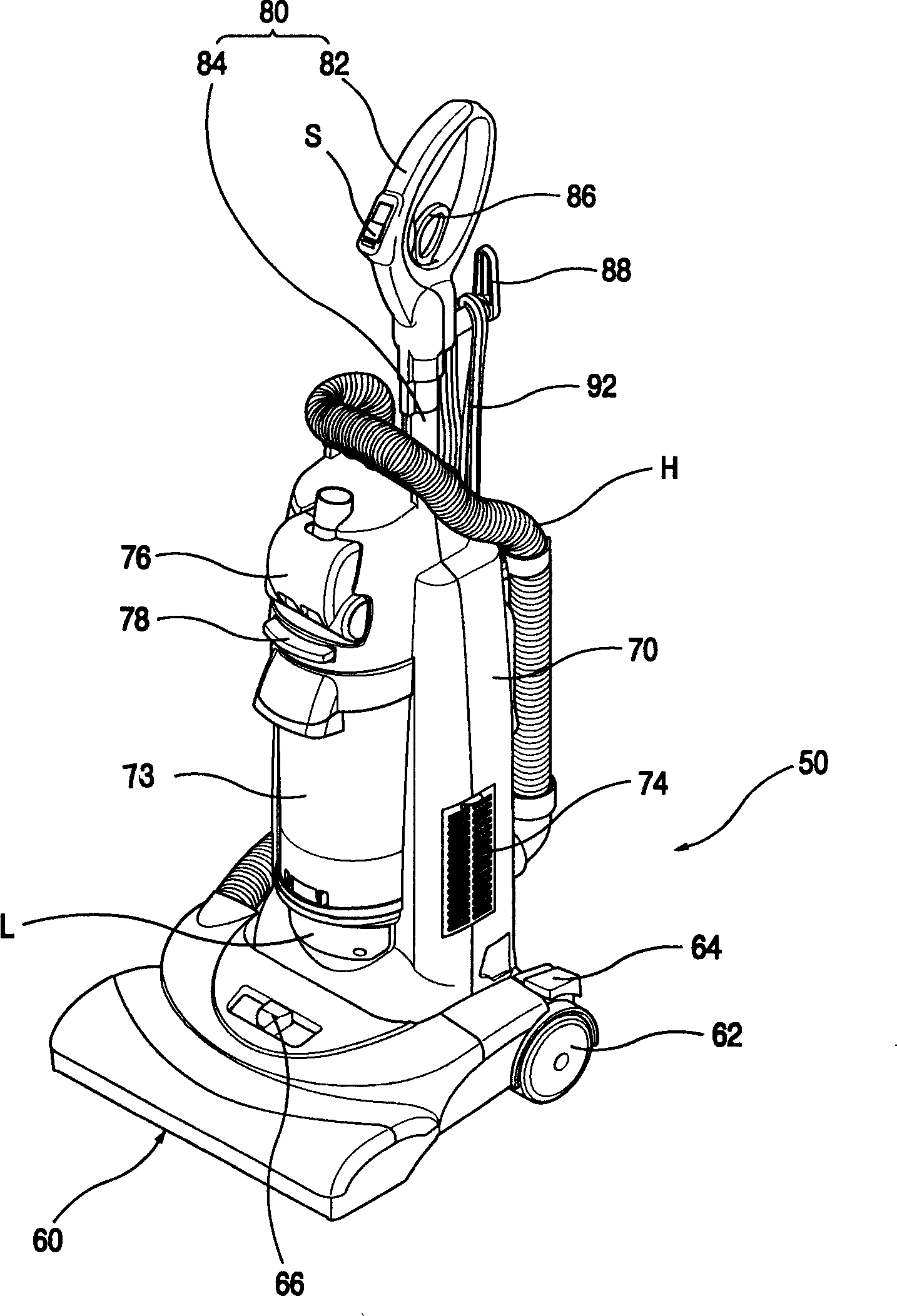

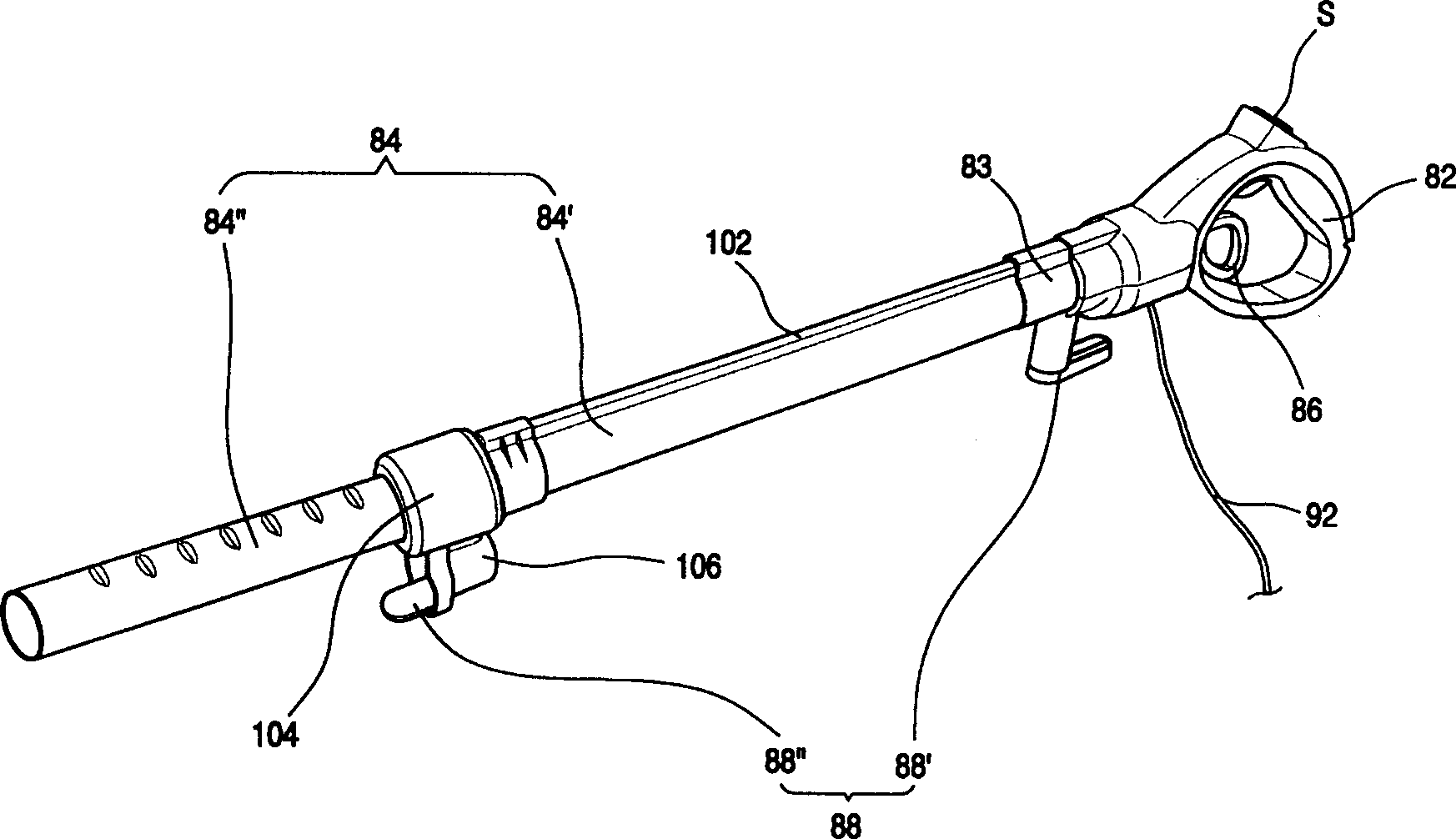

Vacuum cleaner grip

The invention relates to a handle of vacuum dust-collector with a channel for fixing power cord and a fixing rib, which comprises a handle (82) of user and a handle pipe (84) connected on one side of handle (82). Wherein, the handle (82) is formed by the handle main body (82') for guiding the power cord (92) which inputs the outer power, and a handle cover (82'') for shading one side of the handle main body (82'); and the handle pipe (84) is formed by a outer pipe (84') for forming the appearance, and a inner pipe (84'') sliding along the inner side of outer pipe (84'). The inner part of handle (82) has a channel (94) to contain a part of power cord (92). The channel (94) is in the Z shape on the handle main body (82'). The inner part of handle (82) has several fixing ribs (108) to fix power cord (92). Said invention can avoid the separation of power cord.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

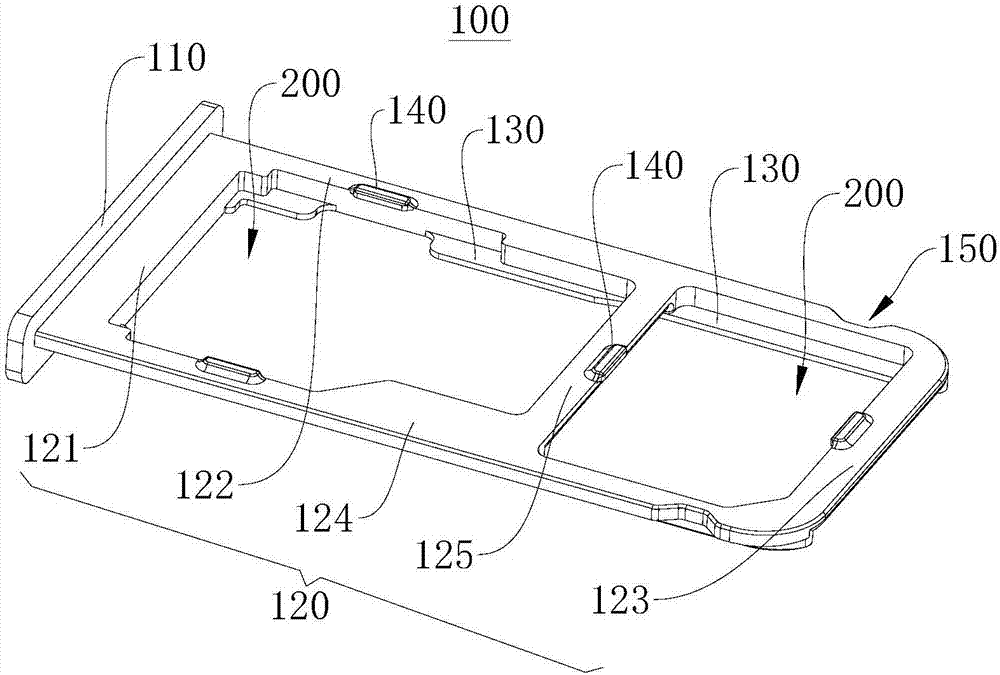

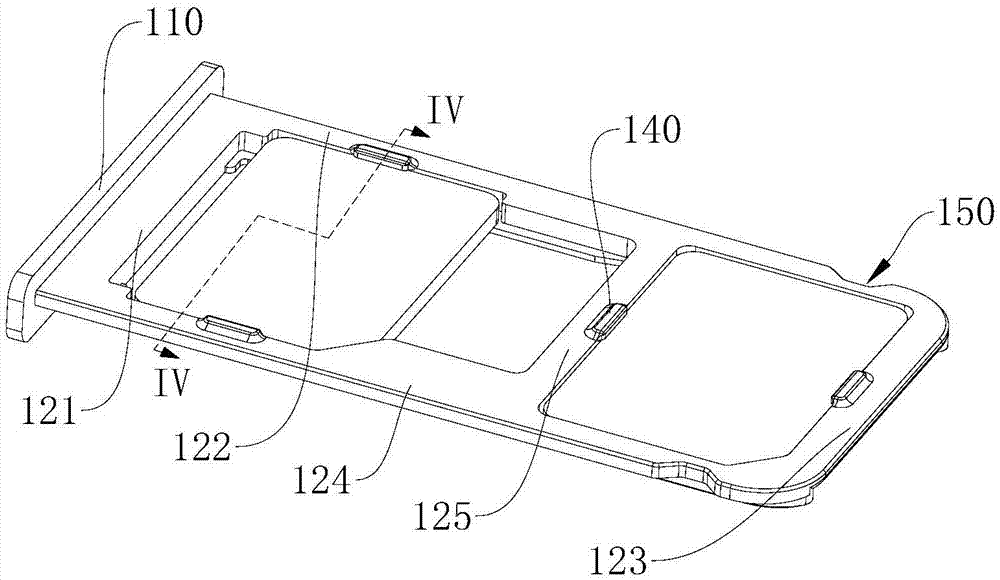

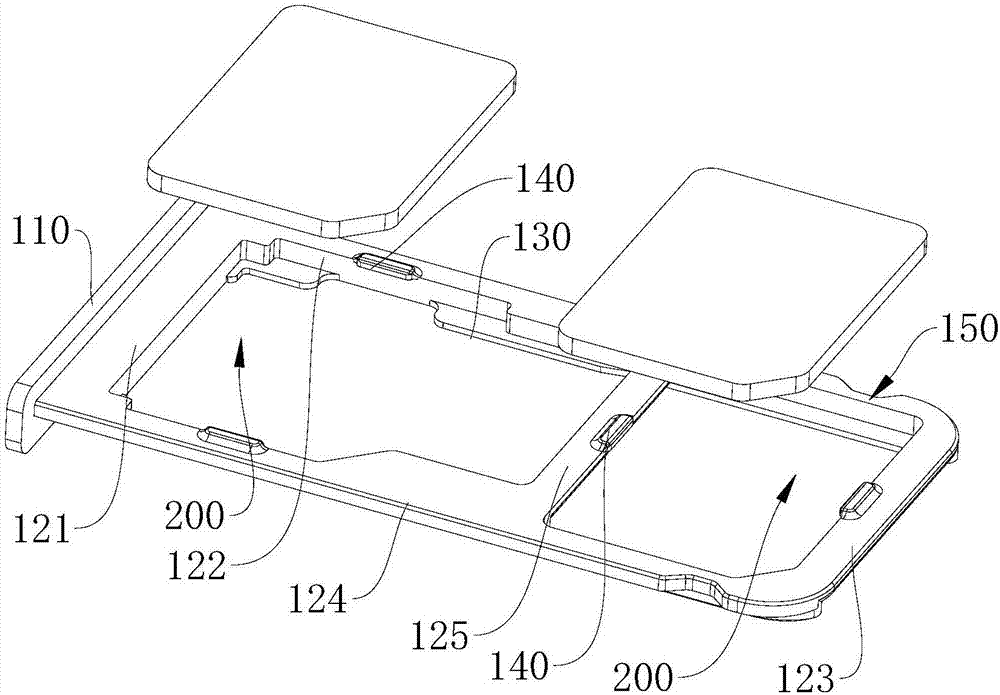

Card tray structure and electronic device

InactiveCN107134681APrevent fallingInhibit sheddingCoupling device detailsTransmissionEngineeringElectronic equipment

The invention provides a card tray structure and electronic equipment, and relates to the technical field of electronic equipment. The card holder structure 100 is used in electronic equipment, and the card holder structure 100 includes a card holder door plate 110 , a card limiting plate 120 , a card bearing portion 130 and a card buckle 140 . One end of the card limiting plate 120 is connected to the card tray door 110 , and at least one card placement position 200 matching the shape of the card is opened through the card limiting plate 120 . The card bearing part 130 is arranged on the card placement position 200 and is located at one side of the card placement position 200, and the card bearing part 130 is used to prevent the card from falling. The card buckle 140 is disposed on the card placement position 200 and is located on the other side of the card placement position 200 opposite to the card bearing portion 130 , and the card buckle 140 and the card bearing portion 130 are used to clamp on both sides of the card. The card is clamped between the card buckle 140 and the card bearing part 130 , so that the card cannot move freely in the thickness direction and prevents the card from accidentally falling off the card limiting plate 120 .

Owner:QIKU INTERNET TECH SHENZHEN CO LTD

A kind of drawing die and the drawing system of metal wire

The invention discloses a drawing die and a drawing system for a metal wire. The drawing die comprises a tapered inlet region, a lubricating region, a tapered compression region, a cylindrical sizing region and a tapered outlet region which are sequentially connected through a circular arc transition portion; and the angle of the taper angle of the die decreases gradually from the tapered inlet region to the compression region, and the angle of the taper angle of the compression region ranges from 5 degrees to 12 degrees. The drawing system comprises a pay-off device, a drawing box body, at least one supporting seat, a traction device and a take-up device. The supporting seats are obliquely arranged on the inner wall of the drawing box body. The drawing die is mounted in mounting holes of the supporting seats. When the metal wire passes the compression region of the drawing die, compared with a drawing die in the prior art, by the adoption of the drawing die and the drawing system, if the same metal wire compression rate and the small reduction of the area are reached, the required traction force provided by the traction device is minimum, the loss of the internal gold phase structure of the metal wire material is small, a die core is not destroyed, the service life of the drawing die is prolonged, and the surface of the drawn metal wire is smooth.

Owner:NANTONG HUIFENG ELECTRONICS TECH

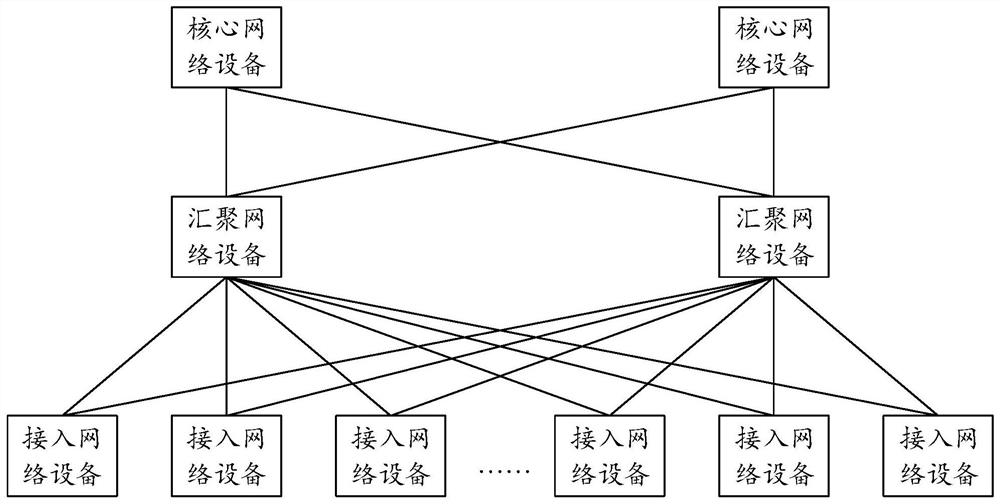

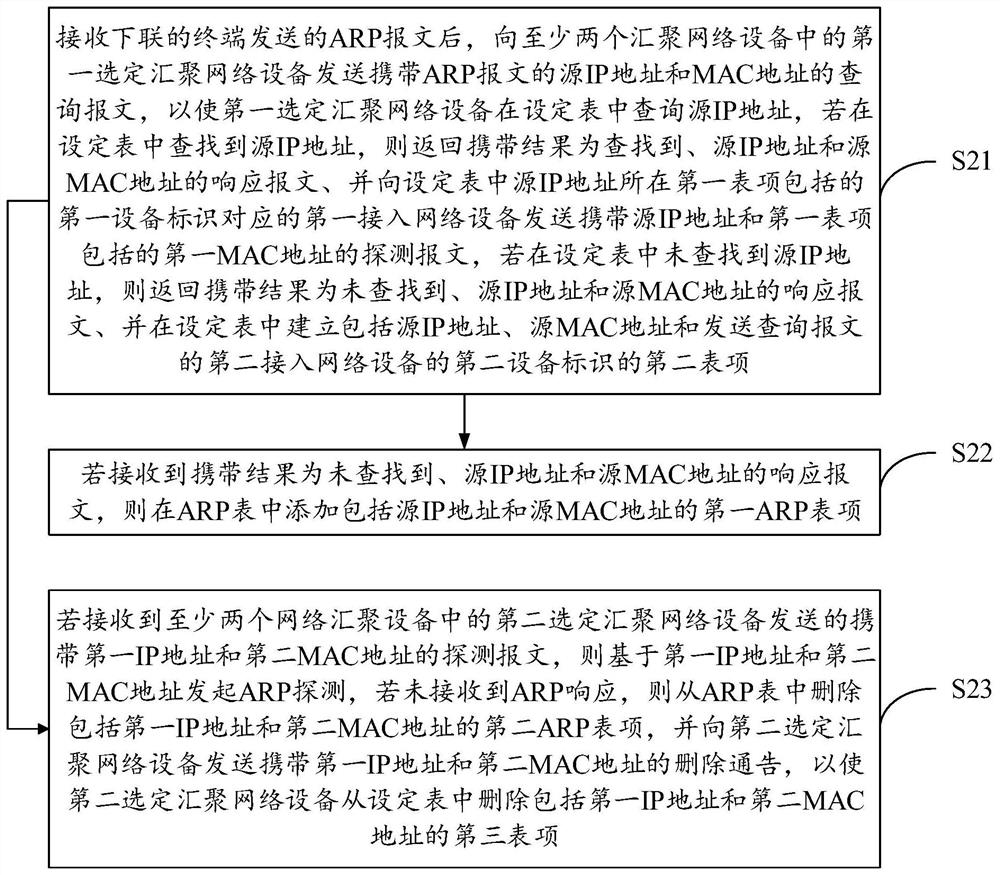

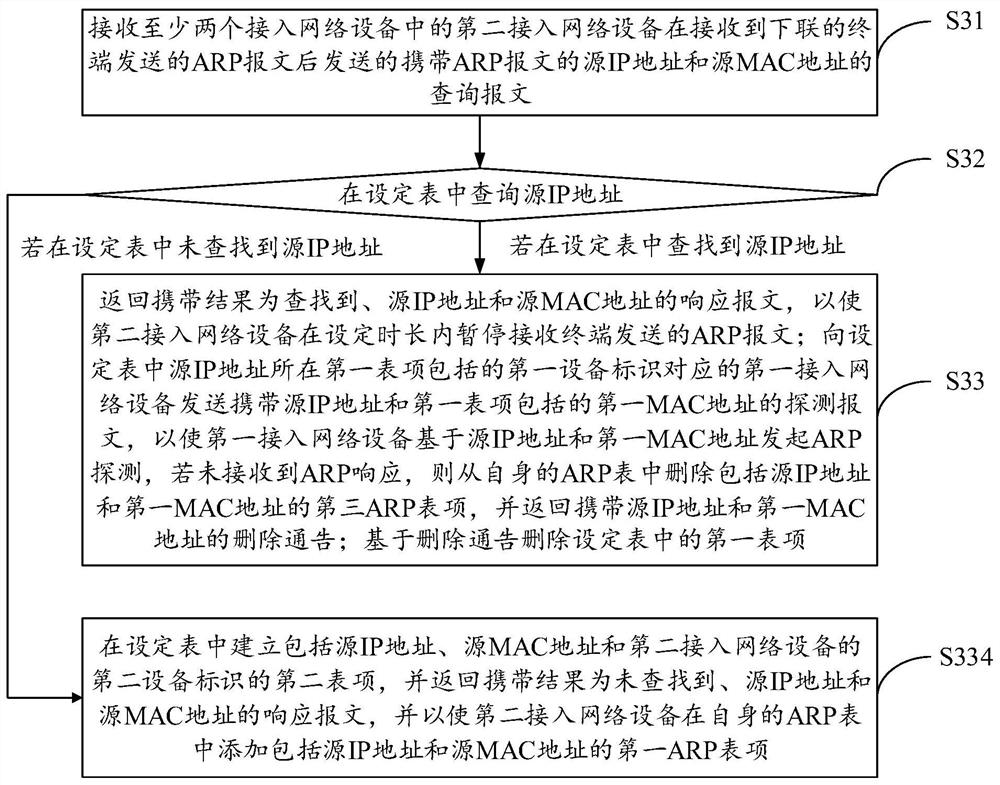

ARP table updating method and device

PendingCN113810511AReduce delete timeThere will be no disconnectionTransmissionIp addressEngineering

The invention discloses an ARP table updating method and device, and the method comprises the steps: transmitting a query message carrying a source IP address and a source MAC address of an ARP message to first selected convergence network equipment after receiving the ARP message transmitted by a downlink terminal; if a response message carrying the result of "not found", the source IP address and the source MAC address is received, adding a first ARP table item comprising the source IP address and the source MAC address in an ARP table; if a detection message carrying a first IP address and a second MAC address sent by second selected convergence network equipment is received, initiating ARP detection based on the first IP address and the second MAC address, and if an ARP response is not received, deleting a second ARP table item comprising the first IP address and the second MAC address from the ARP table, and sending a deletion notification carrying the first IP address and the second MAC address to the second selected convergence network equipment. According to the scheme, the deletion time of the ARP table item can be shortened.

Owner:RUIJIE NETWORKS CO LTD

Shelf for placing cutting torch conveniently

InactiveCN103056481AFlat surfaceThere will be no disconnectionGas flame welding apparatusIndustrial engineeringPulley

The invention discloses a shelf for placing a cutting torch conveniently. The shelf comprises a supporting seat, a supporting rod is arranged on the supporting seat, one end of the supporting rod is provided with a clamping plate for clamping a workpiece, the supporting rod is further provided with a pulley, the pulley is arranged in the clamping plate, and the supporting seat is provided with a control device for controlling the pulley to roll. The workpiece is cut after the shelf is utilized to fix the cutting torch, the surface of the workpiece is smooth after the workpiece is cut, heated degrees of cut positions are consistent during cutting, and the problem that the workpiece is not cut off is solved.

Owner:NINGBO JIANGBEI XINGDA WELDING CUTTING REGULATING METER FACTORY

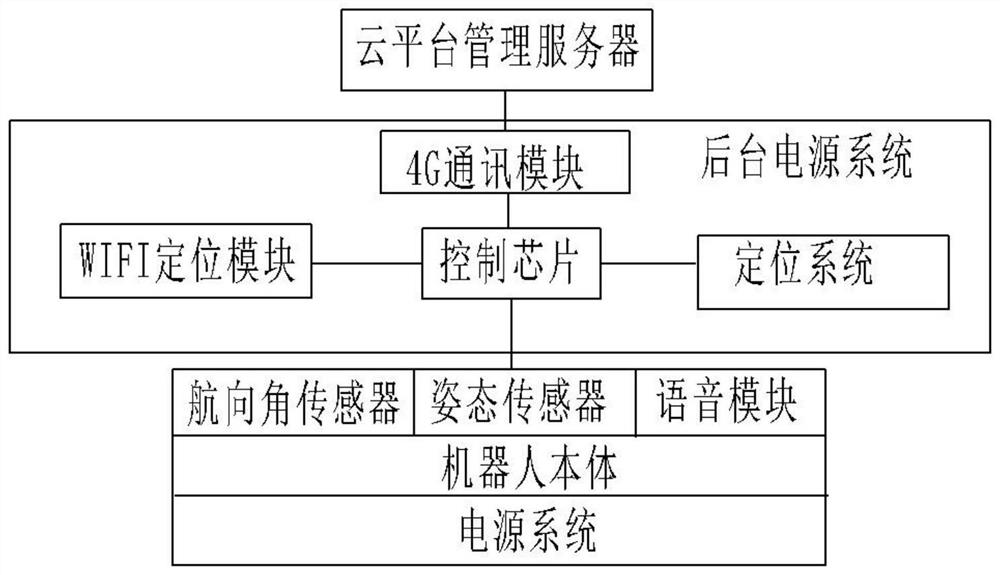

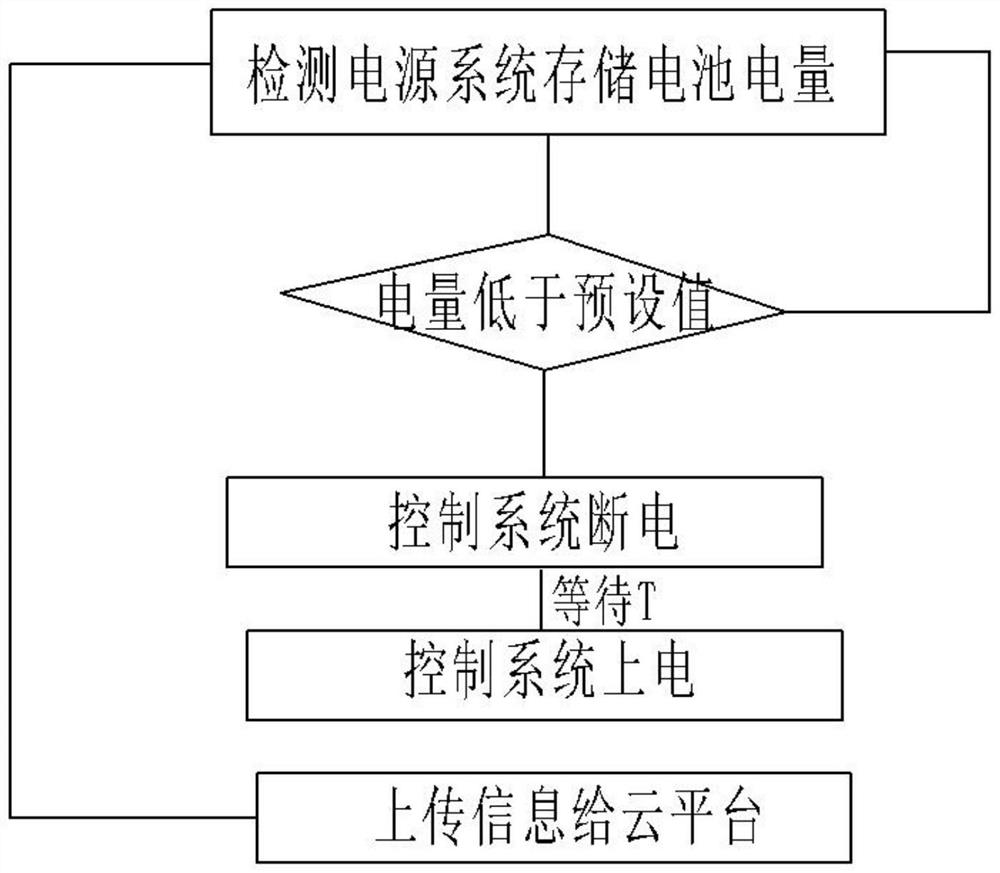

Robot power management system and method

PendingCN114142599AThere will be no disconnectionWill not lose contactBatteries data exchangeCircuit monitoring/indicationControl systemControl engineering

The invention relates to the field of robot battery management, in particular to a robot power management system and method.The robot power management system comprises a robot body and a power system for supplying power to the robot body, the robot body further comprises a control system, and the control system comprises a control chip, a positioning system, a WIFI positioning module, a voice module and a 4G communication module which are integrated; the control chip is connected with the cloud platform through the 4G communication module; and when the power supply system works abnormally, the background power supply system provides auxiliary voltage to supply power to the control system. According to the invention, the robot can keep in contact with the background under the condition that the robot loses power, so that the condition of losing contact is avoided.

Owner:山东新坐标智能装备有限公司

Improved spinning frame

The invention belongs to the field of spinning and relates to an improved spinning frame which comprises a roving roller and a spinning structure arranged below the roving roller. The improved spinning frame is characterized in that the spinning structure comprises a first roller, a second roller and a winding component which are sequentially arranged in the yarn moving direction. A yarn pressing structure is arranged above the spinning structure. The yarn pressing structure comprises a fixed rod arranged at the rear of the first roller in the yarn moving direction, a yarn pressing frame rotatably fixed to the fixed rod and a pressing wheel movably arranged on the yarn pressing frame. The pressing wheel comprises a first pressing wheel acting on the first roller and a second pressing wheel acting on the second roller. The improved spinning frame is simple in structure, the tension is controlled appropriately, line breakage does not occur, the twisting efficiency is high, the yarn quality is guaranteed, extra energy consumption is not needed neither, and the production cost is reduced.

Owner:ZHEJIANG ZHONGXIN WOOL TEXTILE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com