Liquid crystal display, liquid crystal display substrate and formation method thereof

A liquid crystal display and substrate technology, applied in the direction of instruments, semiconductor devices, electric solid devices, etc., can solve problems such as abnormal signals, water stains on the display, etc., to reduce static electricity or contact resistance, avoid burning phenomena, and avoid corrosion problems Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

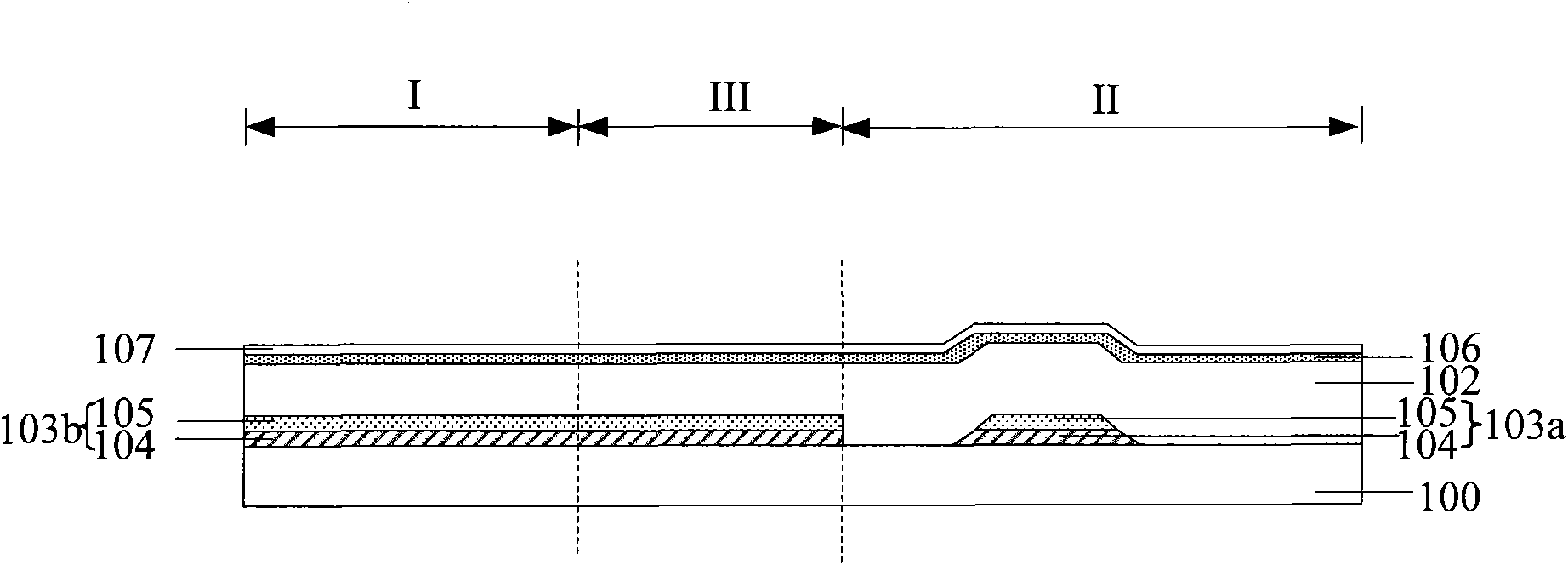

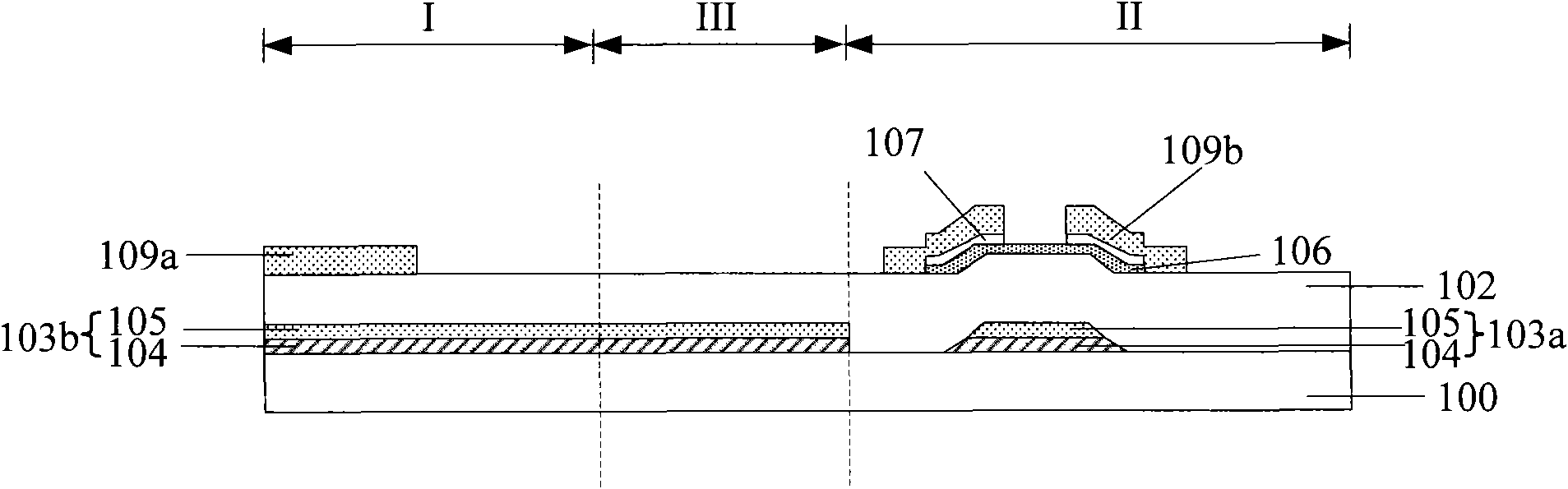

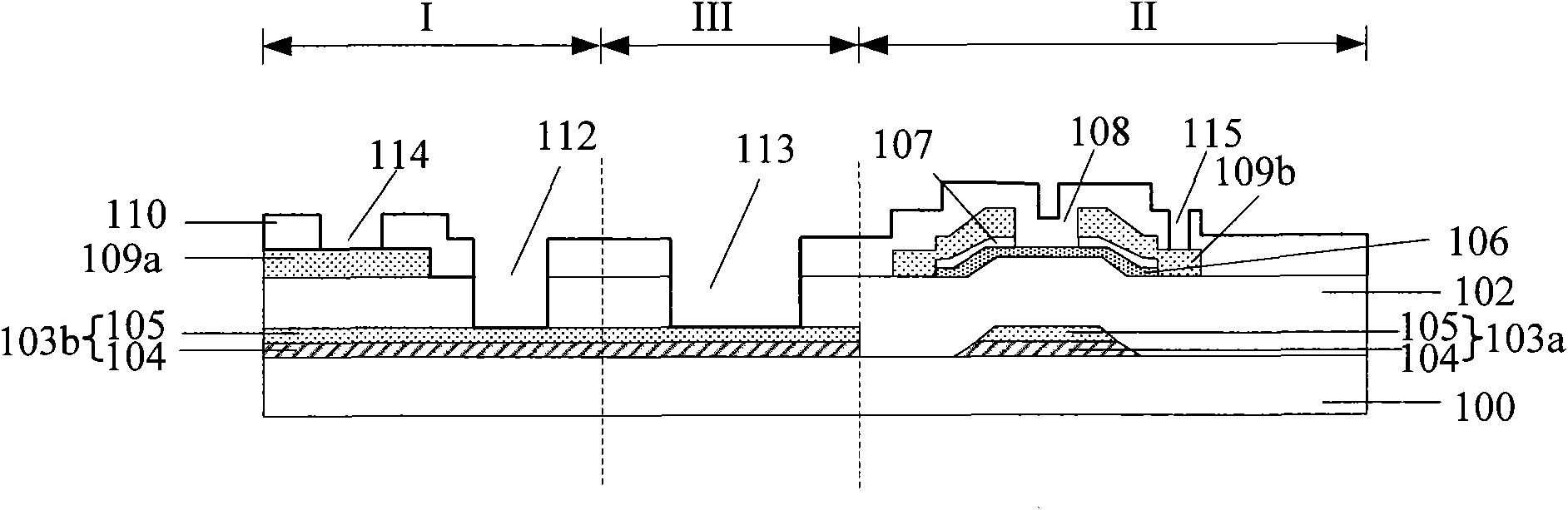

[0023] The invention adopts a single layer of aluminum or aluminum alloy as the material of the grid and the grid metal layer, which reduces the deposition steps, improves the production capacity, and effectively solves the problem that the use of two layers of metal film will produce a primary battery when the grid is formed by wet etching. The reaction leads to corrosion and the phenomenon of water marks caused by uneven brightness of the display.

[0024] After the source / drain metal layer is connected to the gate metal layer, a passivation layer is deposited, and only the passivation layer is etched during the etching process, which can avoid the source / drain contact holes with different depths caused by etching in the prior art. The problem of over-etching of the drain metal layer; the surface of the source / drain metal layer connected to the gate metal layer in the present invention is flat, without damage caused by the etching problem, and improves the reliability of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com