Manufacturing method for silver French terry

A production method and a technology for fish scale cloth, applied in the field of textiles, can solve the problems of not beautiful enough, the air permeability of the fabric is not good enough, the yarn is disconnected, etc., and the effect of beautiful air permeability and good air permeability can be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0019] A method for making silver fish scale cloth, comprising:

[0020] (1) Steps of preparing raw material veil and reverse pile yarn;

[0021] (2) The step of weaving the veil and reverse terry yarns into gray cloth on a circular knitting machine;

[0022] (3) The steps of finishing.

[0023] The veil in step (1) includes cotton-spandex blended yarn and silver spandex blended yarn, and the reverse terry yarn is cotton-polyester blended yarn.

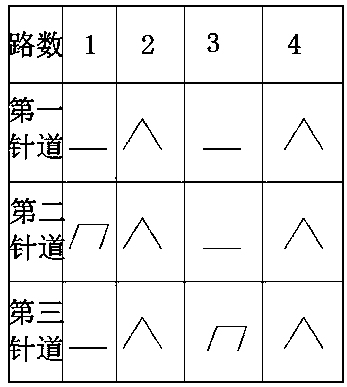

[0024] Step (2) includes: arranging needles→triangular typesetting→covering the triangular seat→hanging the three kinds of threads on the creel→threading the yarn to the yarn feeder and yarn feeder→hanging the need...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com