Heatable mirror

A heating body and lens technology, applied in ohmic resistance heating, transparent/reflective heating devices, electric heating devices, etc., to achieve uniform heating, enhanced overall performance, and fewer components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

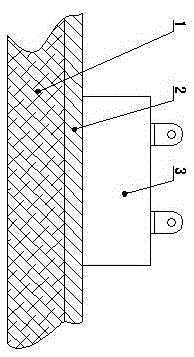

[0016] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

[0017] In the figure, when there is frost, water mist or even ice on the surface of the mirror, turn on the power, at this time the heat conductor 3 starts to generate heat, and the heat it emits is quickly and evenly transferred to the lens 1 through the heat conduction layer 2, so that The temperature of the mirror surface rises, so as to achieve the purpose of eliminating water mist and icing on the mirror surface, so that it can be used normally. Since the PTC heating body has the characteristics of self-temperature control, there is no need to add additional temperature control devices to the heating device, which reduces the hidden danger of increased failures caused by the increase in the period.

[0018] This electric heating mirror can not only be used on bathroom mirrors, but also can be used on rearview mirrors of motor vehicles. In the cold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com