Silk-screen printing method of solar cell grid line electrode

A solar cell, screen printing technology, applied in printing, circuit, photovoltaic power generation and other directions, can solve the problems of short service life, increased equipment, grid line disconnection, etc., to improve quality and yield, improve work efficiency, The effect of improving print quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

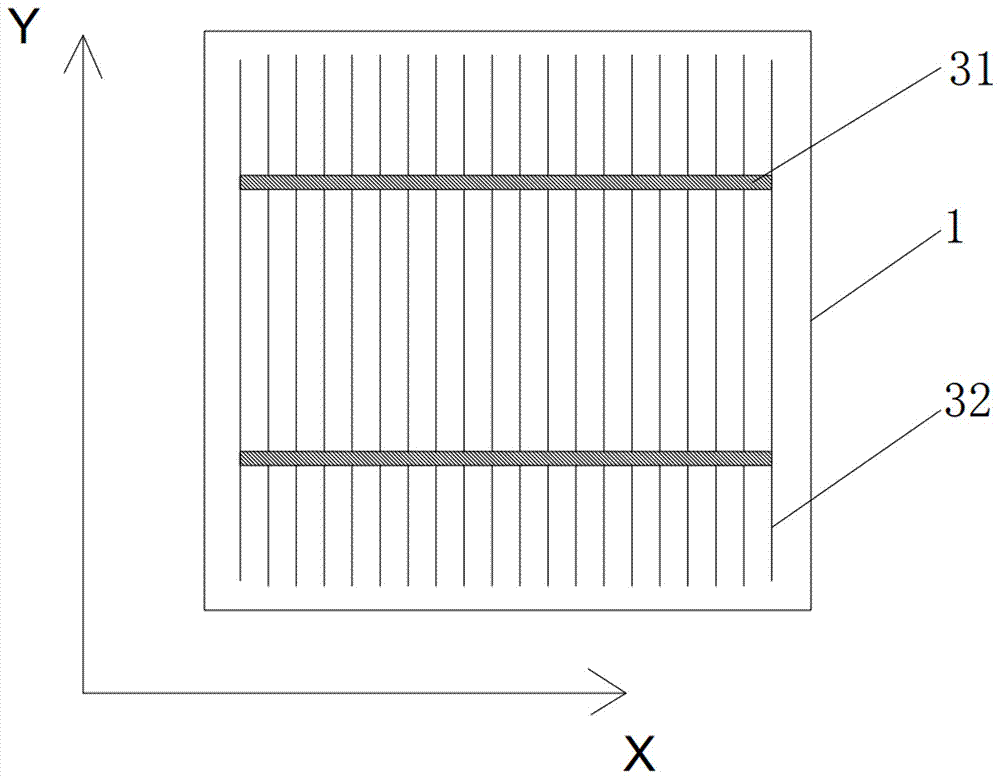

[0025] In the design of the front grid lines of solar cells, in order to improve the conversion efficiency of solar cells, the grid lines that collect charges on the front side need to be designed as thin as possible, which can effectively increase the surface area for receiving sunlight and improve cell efficiency.

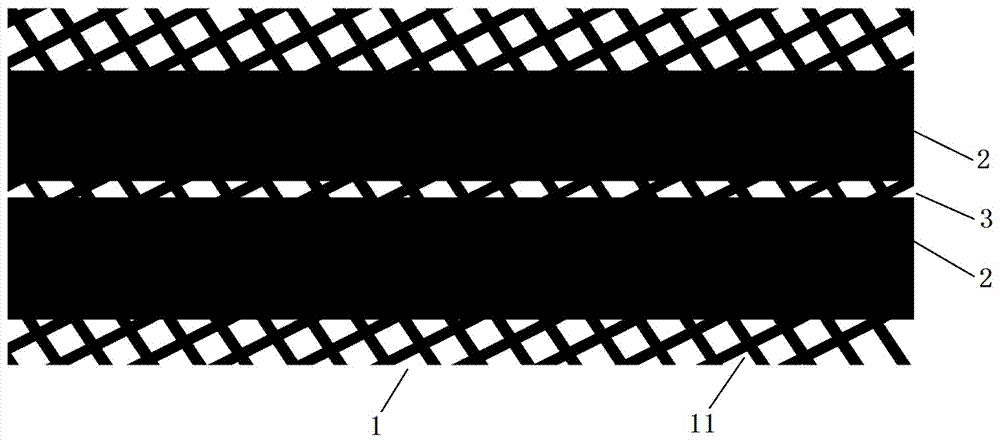

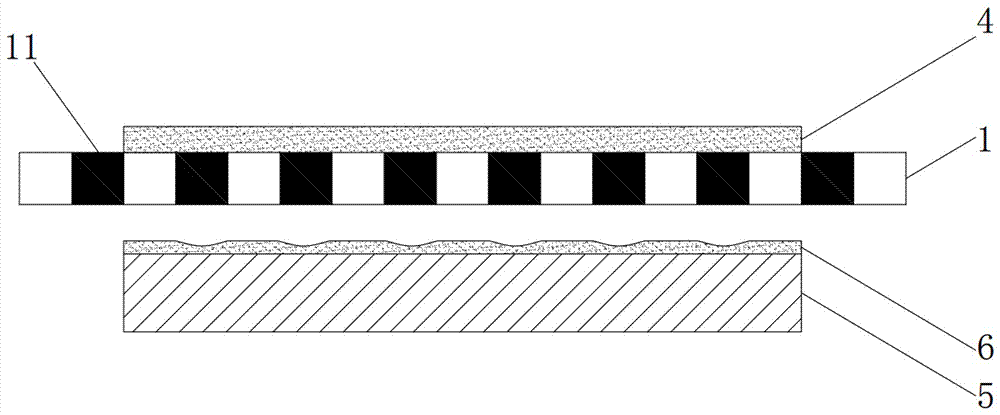

[0026] The relatively mature technology in the production of front grid lines is the production of front electrodes by screen printing. This technology is cheap, mature and reliable. However, as the grid line becomes thinner, the influence of the mesh part of the mesh in screen printing becomes greater and greater. Through technological progress, the silk thread used to weave the mesh has dropped below 20 μm, but the warp in the mesh weaving process The knot formed at the intersection with the weft is inevitable, forming a bottleneck in the further thinning process of the grating. In order to further reduce the line width of the gate lines, many methods have been...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com