Electromagnetic cleaning means for hot galvanizing liquid

A technology of electromagnetic purification and hot-dip galvanizing, which is applied in the field of metal smelting and can solve problems such as weak magnetism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

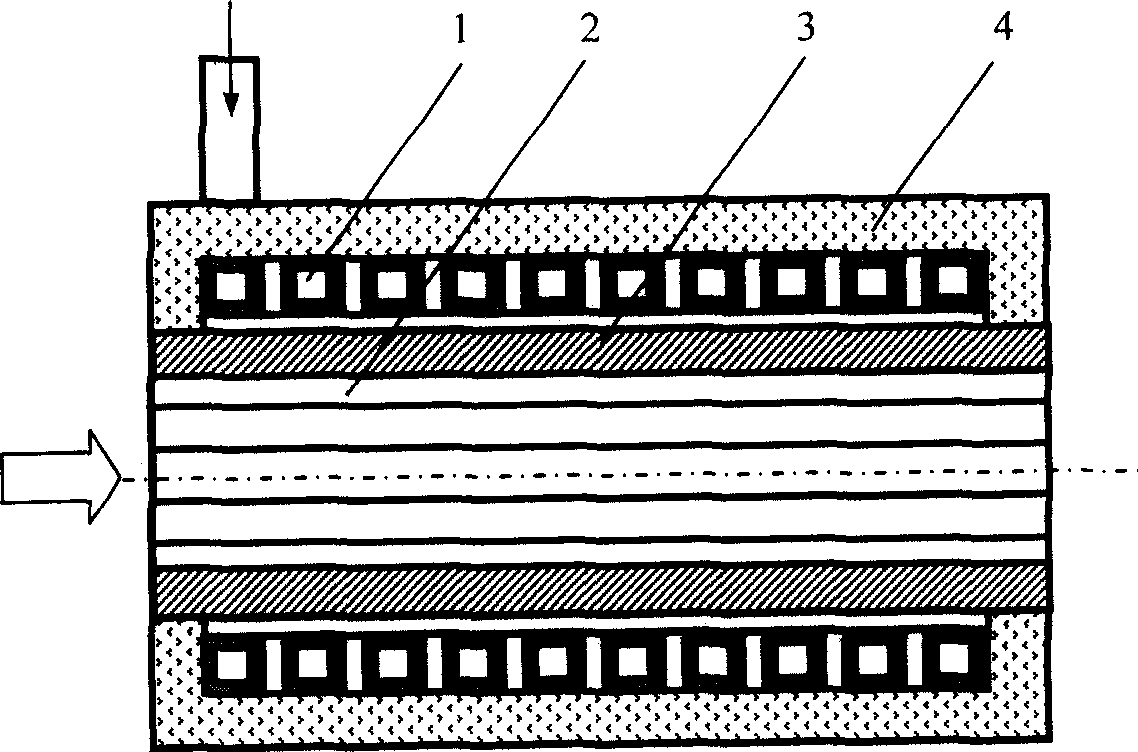

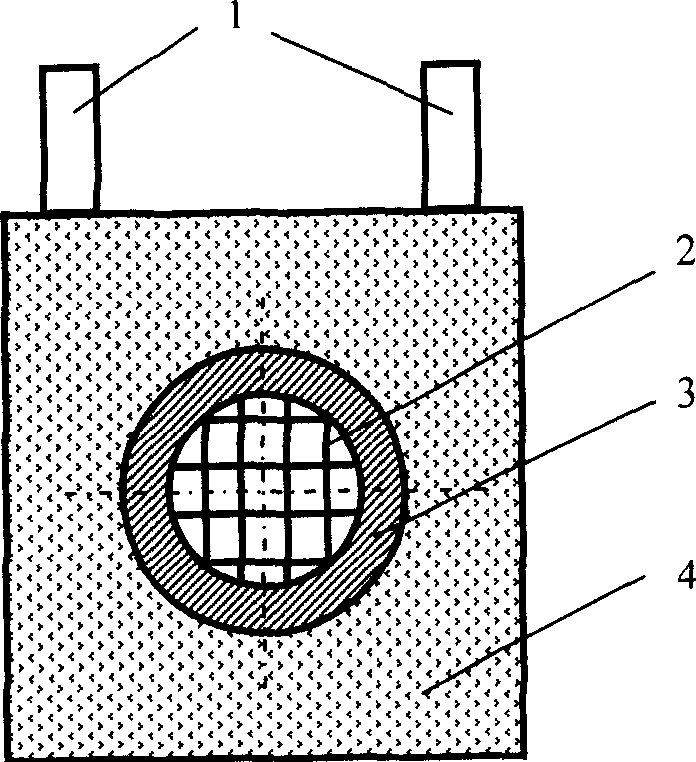

[0011] Such as figure 1 , figure 2 As shown, the present invention includes: induction coil 1 , ceramic tube 2 , heat insulation sleeve 3 and refractory shell 4 . The ceramic tube 2 is placed inside the induction coil 1 , the heat insulation sleeve 3 is arranged between the induction coil 1 and the ceramic tube 2 , and the induction coil 1 , the ceramic tube 2 and the heat insulation sleeve 3 are all placed in the refractory shell 4 .

[0012] The ceramic tube 2 is a honeycomb-shaped ceramic tube with square holes, which is formed by extruding ceramic slurry and then sintering.

[0013] The induction coil 1 is wound by a copper tube, and circulating water flows through the inside of the copper tube.

[0014] The heat insulating sleeve 3 is formed by pressing calcium-silicon plate material with excellent heat insulating performance.

[0015] The present invention can be placed individually or in multiples in the hot-dip galvanizing pot, especially in the position where ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com