Tool sharpener

A knife grinder and grinding wheel technology, applied in grinding/polishing equipment, grinding/polishing safety devices, other manufacturing equipment/tools, etc., can solve problems such as difficult to master, complex structure of knife grinder, easy to be injured, etc. To achieve the effect of preventing splashing around

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

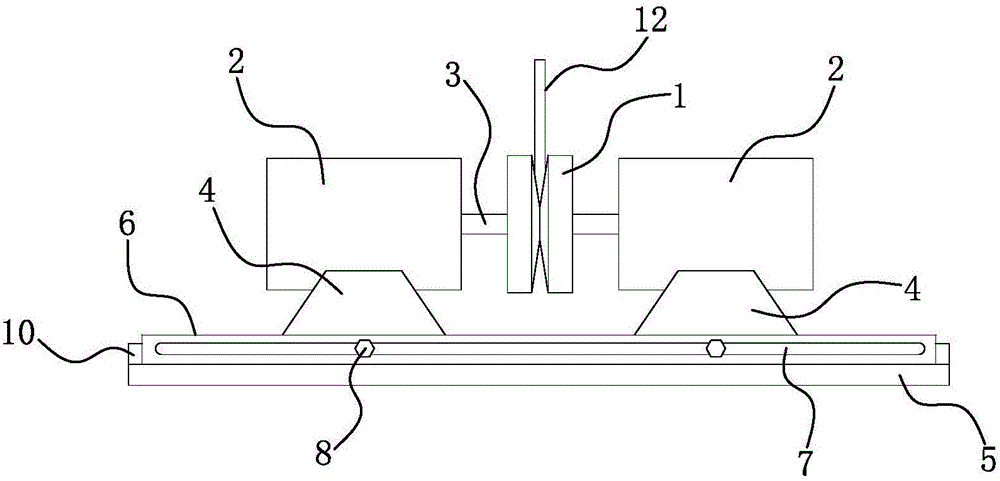

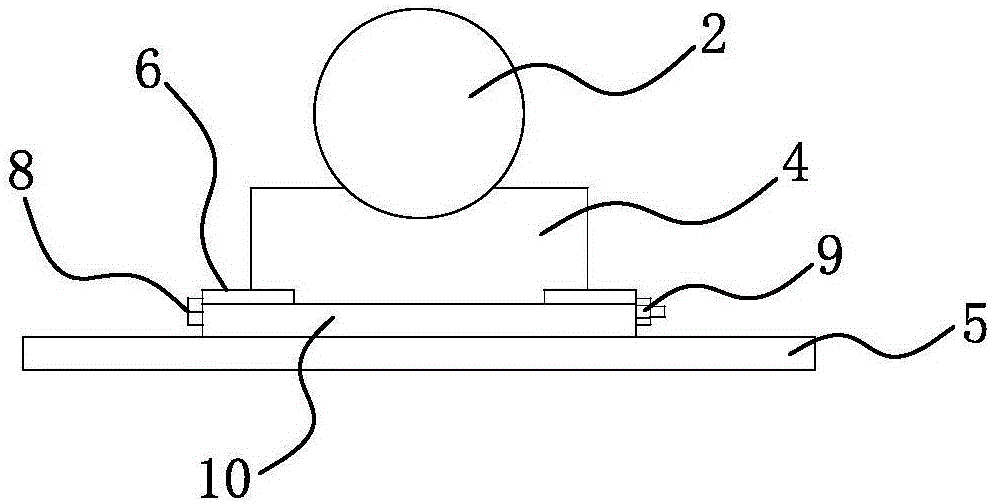

[0023] like figure 1 shown, combined with figure 2 As shown, the knife grinder of the present invention comprises two oppositely arranged emery wheels 1, and the opposite wheel surfaces of the two emery wheels 1 are conical, and the two emery wheels 1 are respectively driven by a motor 2, and when the motor 2 drives the emery wheel 1 to rotate, the two emery wheels The rotation direction of grinding wheel 1 is opposite. When in use, the cutting edge of the cutter 12 is placed between the conical surfaces of the two grinding wheels 1. Since the rotation directions of the two grinding wheels 1 are opposite, the cutter 12 is simultaneously subjected to the frictional force applied by the grinding wheels 1 in two opposite directions. Now the cutter 12 is force-balanced in the horizontal direction, and the cutter 12 can be sharpened as long as the cutter 12 is reciprocated two or three times along a straight line by hand.

[0024] The specific way that the motor 2 drives the gri...

Embodiment 2

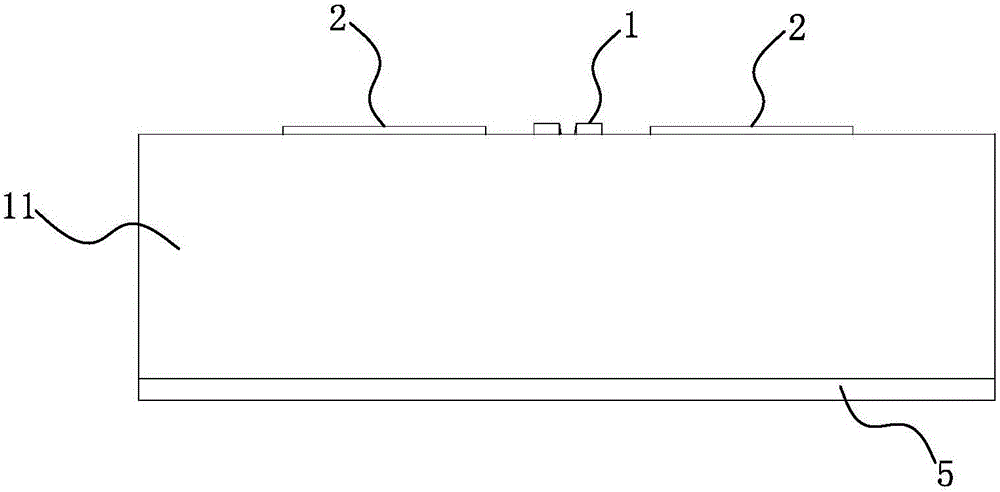

[0032] The difference between the present embodiment and the first embodiment is that an arc-shaped baffle 11 is provided on both sides of the slide rail 6, and this embodiment will be described in detail below.

[0033] like image 3 shown, combined with Figure 4 , 5 As shown, the knife grinder of the present invention comprises two oppositely arranged emery wheels 1, and the opposite wheel surfaces of the two emery wheels 1 are conical, and the two emery wheels 1 are respectively driven by a motor 2, and when the motor 2 drives the emery wheel 1 to rotate, the two emery wheels The rotation direction of grinding wheel 1 is opposite. When in use, the cutting edge of the cutter 12 is placed between the conical surfaces of the two grinding wheels 1. Since the rotation directions of the two grinding wheels 1 are opposite, the cutter 12 is simultaneously subjected to the frictional force applied by the grinding wheels 1 in two opposite directions. Now the cutter 12 is force-ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com