Electric wheel assembly tool and assembly method

A technology for assembling tooling and electric wheels, applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve the problems of heavy weight of reducers and motors, troublesome assembly of electric wheels, limiting assembly efficiency, etc., and achieves low cost and structure. The effect of simplicity and improved assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

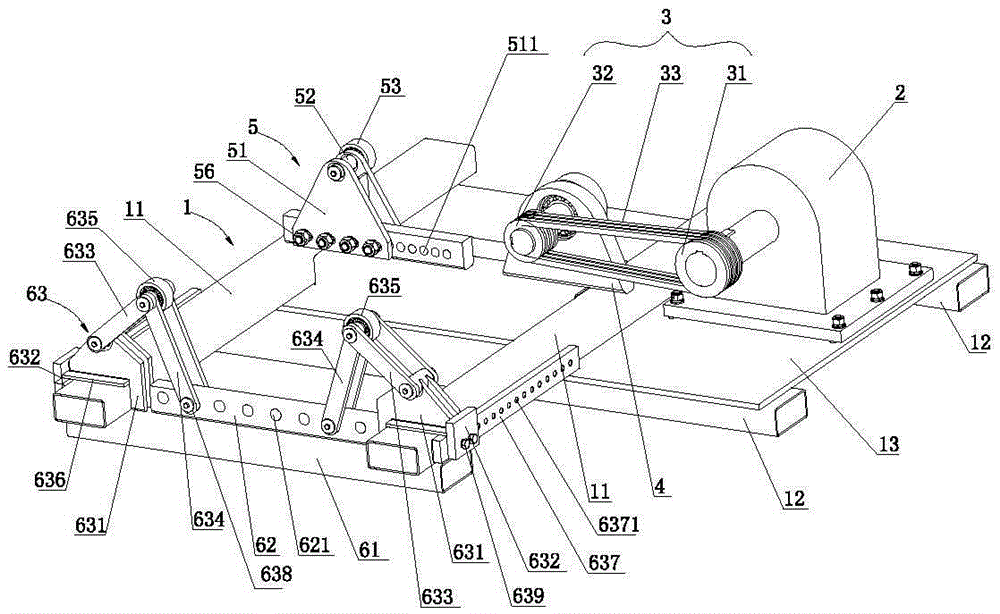

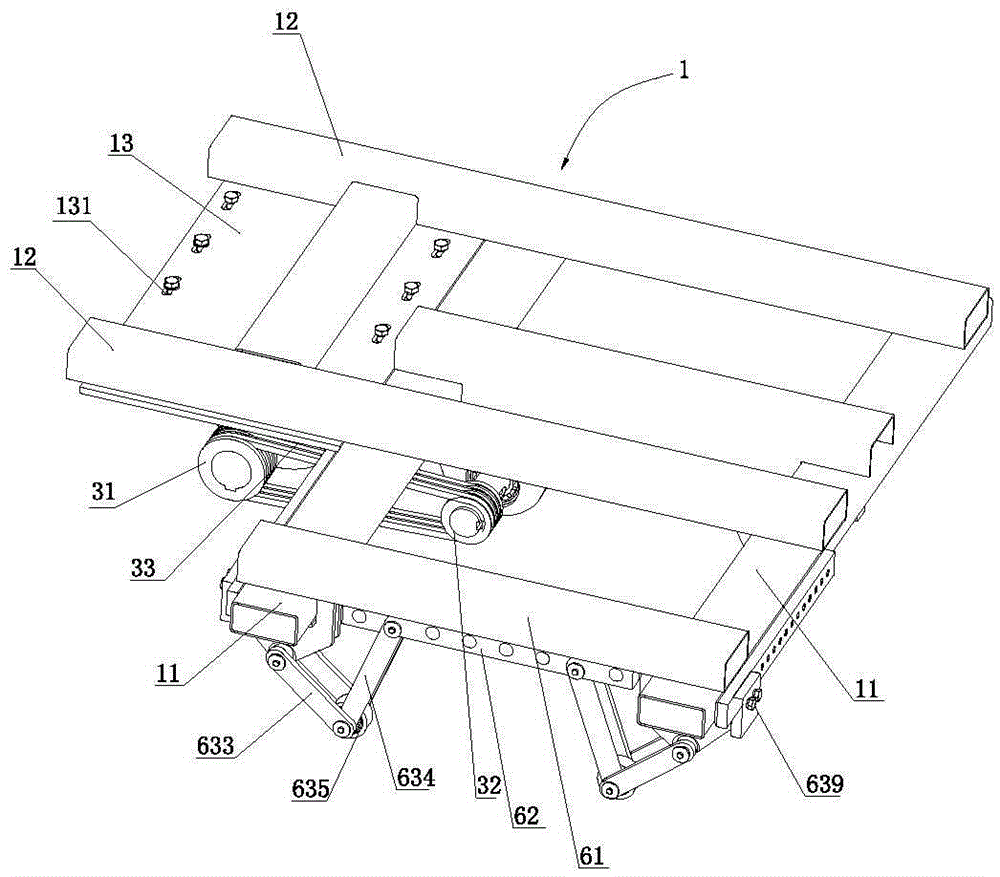

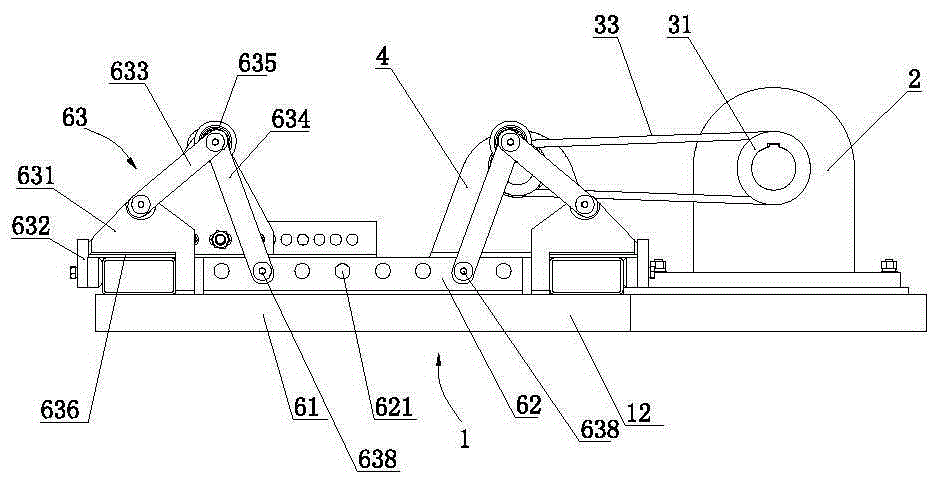

[0023] like Figure 1 to Figure 4 As shown, the electric wheel assembly tool includes an underframe 1 , a driving device 2 , a transmission system 3 , a fixing seat 4 , a first adjusting device 5 and a second adjusting device 6 .

[0024] The underframe 1 includes a longitudinal beam 11 and a cross beam 12; the longitudinal beam 11 is composed of a plurality of cross beams 12; the longitudinal beam 11 is welded on the cross beam 12, and one end of the two cross beams 12 extends out of one The beam 11 is equipped with a fixed plate 13 at the protruding end of the crossbeam 12, and is provided with a mounting hole 131 on the fixed plate 13. The mounting hole 131 is a waist-shaped hole, and the driving device 2 is installed on the fixed plate 13. The waist-shaped hole is set, so it is convenient to adjust the position of the driving dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com