Wear-resistant piston head

A technology of piston head and piston skirt, applied in the field of internal combustion engine, can solve the problems of piston head contacting the cylinder wall, cylinder eccentric wear, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

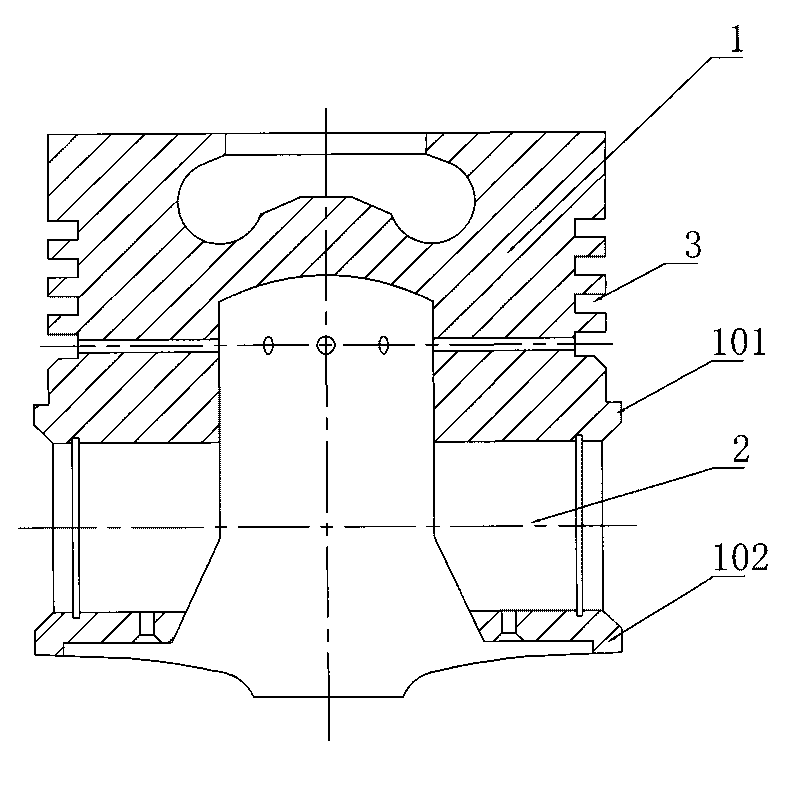

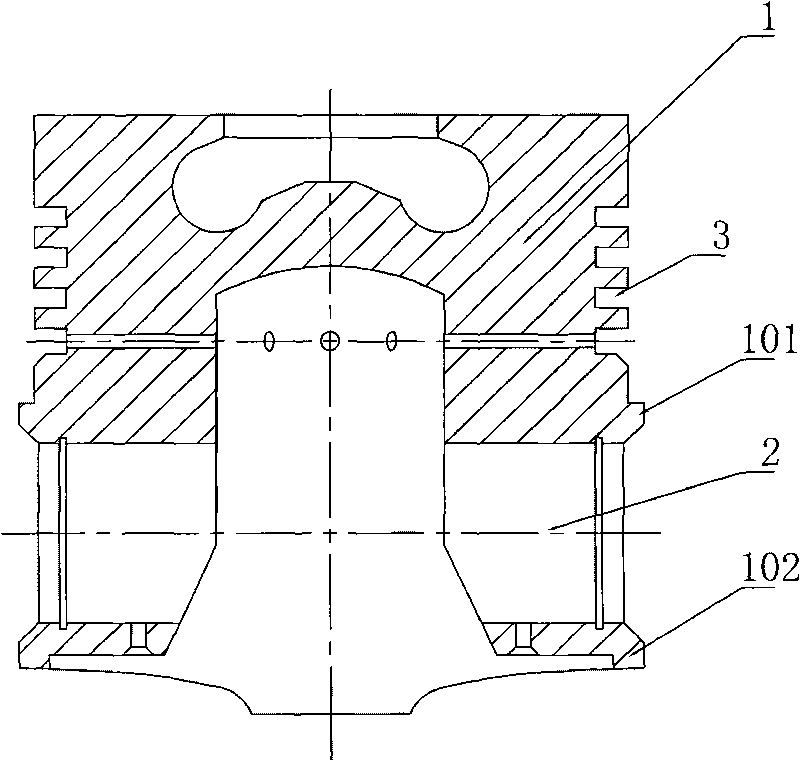

[0008] Such as figure 1 , in order to avoid wear and tear of the piston head, the piston head 1 is provided with a pin shaft hole 2 that runs through the piston head transversely, above the pin shaft hole 2 there are multiple piston ring grooves 3, and below the pin shaft hole 2 is the piston skirt 102 A radially protruding step 101 is provided above the pin shaft hole 2 and between the bottommost piston ring groove, and the diameter of the step 101 is equal to the diameter of the piston skirt 102 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com