Carbon-silicon composite material, preparation method thereof, and lithium ion battery containing carbon-silicon composite material

A composite material, carbon-silicon technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as volume effect and capacity fading that cannot be fundamentally suppressed, and achieve improved specific capacity and cycle performance, and high lithium storage capacity Characteristics, the effect of high discharge specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

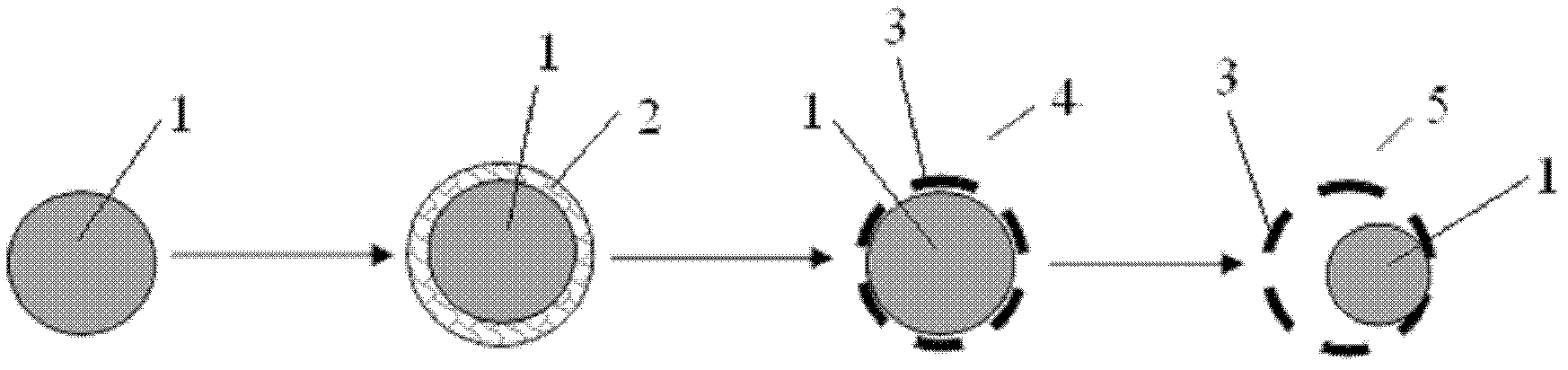

[0031] This embodiment provides a method for preparing a carbon-silicon composite material, which includes the following steps:

[0032] (1) Mixing: polyvinyl chloride and silicon powder with a particle size of 1.5 μm are mixed and ball-milled according to a mass ratio of 1:1 to obtain a mixture of polyvinyl chloride and silicon powder;

[0033] (2) Coating: transfer the mixture into a porcelain boat, heat up to 950°C under the protection of argon, keep it warm for 5 hours, take it out after cooling, and obtain a composite material in which the porous carbon layer is tightly coated with silicon;

[0034] (3) Corrosion: Add the composite material of the porous carbon layer tightly coated with silicon into the corrosion solution, the mass ratio of the two is 1:200, and stir continuously for 24 hours, and the composite material of the porous carbon layer tightly coated with silicon Part of the silicon in the carbon is corroded, and the resulting suspension is filtered, fully wash...

Embodiment 2

[0038] This embodiment provides a method for preparing a carbon-silicon composite material, which includes the following steps:

[0039] (1) Mixing: Dissolve phenolic resin in a mixed solvent of ethanol and distilled water to obtain a solution of phenolic resin, add 0.05 μm silicon powder to the solution, the mass ratio of phenolic resin to silicon powder is 1:10, and ultrasonically disperse at 120 Minutes, and then by spray drying to obtain a mixture of phenolic resin and silicon powder, the organic carbon precursor is evenly distributed on the surface of the silicon;

[0040] (2) Coating: Transfer the mixture into a porcelain boat, heat up to 650°C under the protection of nitrogen, keep it warm for 6 hours, take it out after cooling, and obtain a composite material in which the porous carbon layer is tightly coated with silicon;

[0041](3) Corrosion: Add the composite material of the porous carbon layer tightly coated with silicon into the etching solution, the mass ratio o...

Embodiment 3

[0044] This embodiment provides a method for preparing a carbon-silicon composite material, which includes the following steps:

[0045] (1) Mixing: the styrene-butadiene rubber latex and the silicon powder whose particle size is 2.5 μm are mixed and ground according to the ratio of 4: 1 according to the mass ratio, so as to obtain the mixture of styrene-butadiene rubber latex and silicon powder;

[0046] (2) Coating: Transfer the mixture into a porcelain boat, raise the temperature to 1100°C under the protection of argon and hydrogen mixed gas, keep it warm for 2 hours, take it out after cooling, and obtain a composite of porous carbon layer tightly coated with silicon. Material;

[0047] (3) Corrosion: Add the composite material of the porous carbon layer tightly coated with silicon into the etching solution, the mass ratio of the two is 1:10, and stir continuously for 13 hours, the porous carbon layer tightly coated with silicon composite material Part of the silicon in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com