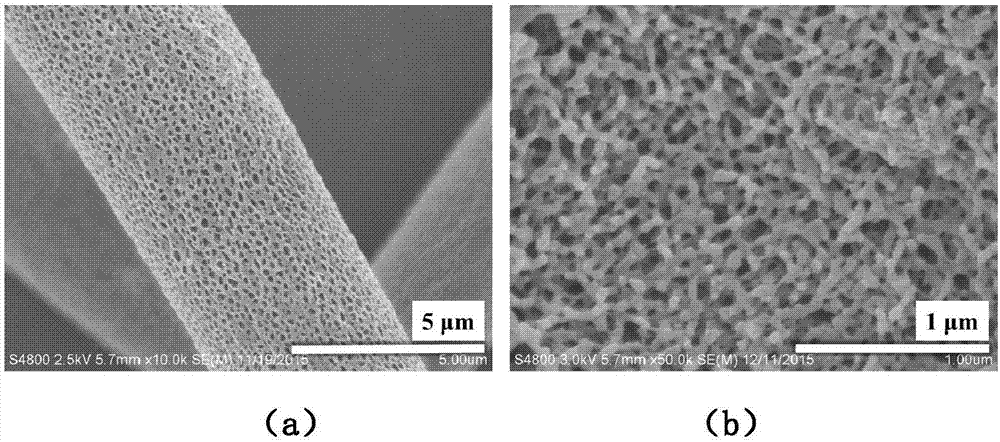

Thin film composed of polylactic acid fibers in nano-continuous porous structure and preparation method thereof

A polylactic acid fiber, porous structure technology, applied in the direction of fiber type, fiber processing, chemical instruments and methods, etc., can solve the problems of limitation and single pore size, and achieve the effect of good mechanical properties and good ductility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

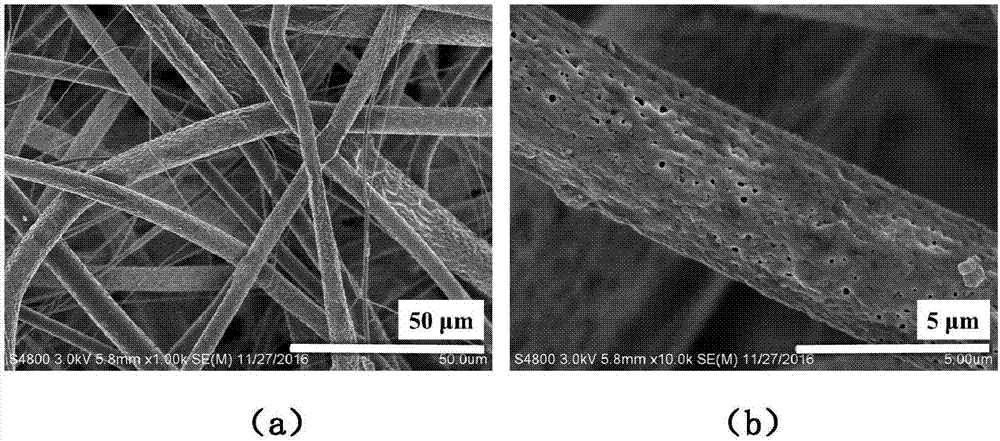

[0038] Dissolve 0.5 gram of polylactic acid and 1.5 gram of polyethylene oxide in chloroform and stir for 6 hours to form a 10% chloroform solution with a mass fraction of 1 / 3 of the mass ratio of polylactic acid / polyethylene oxide; Under the same electrospinning conditions, the spinning environment temperature is 10-35°C, and a polylactic acid / polyethylene oxide film with an average diameter of about 6 microns and a fiber-integrated thickness of 200 microns is prepared.

Embodiment 2

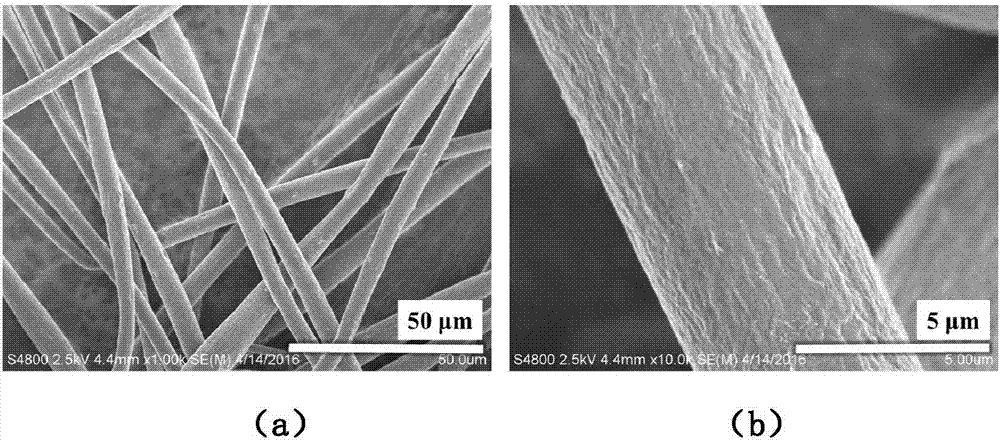

[0040] 0.67 grams of polylactic acid and 1.33 grams of polyethylene oxide were dissolved in chloroform and stirred for 6 hours to form a 10% chloroform solution with a mass fraction of 1 / 2 of the mass ratio of polylactic acid / polyethylene oxide; Under the same electrospinning conditions, the spinning environment temperature is 10-35°C, and a polylactic acid / polyethylene oxide film with an average diameter of about 6 microns and a fiber-integrated thickness of 200 microns is prepared.

Embodiment 3

[0042] Dissolve 1 gram of polylactic acid and 1 gram of polyethylene oxide in chloroform and stir for 6 hours to form a 10% chloroform solution with a mass fraction of 1 / 1 in the mass ratio of polylactic acid / polyethylene oxide; Under the same electrospinning conditions, the spinning environment temperature is 10-35°C, and a polylactic acid / polyethylene oxide film with an average diameter of about 6 microns and a fiber-integrated thickness of 200 microns is prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com