Rotary kiln surface residual heat utilization device

A rotary kiln and waste heat technology, applied in waste heat treatment, indirect heat exchangers, heat exchanger types, etc., can solve the waste of waste heat resources, the waste heat of the rotary kiln can not be effectively used and other problems, and achieve the effect of temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Describe the present invention in detail below in conjunction with accompanying drawing and embodiment.

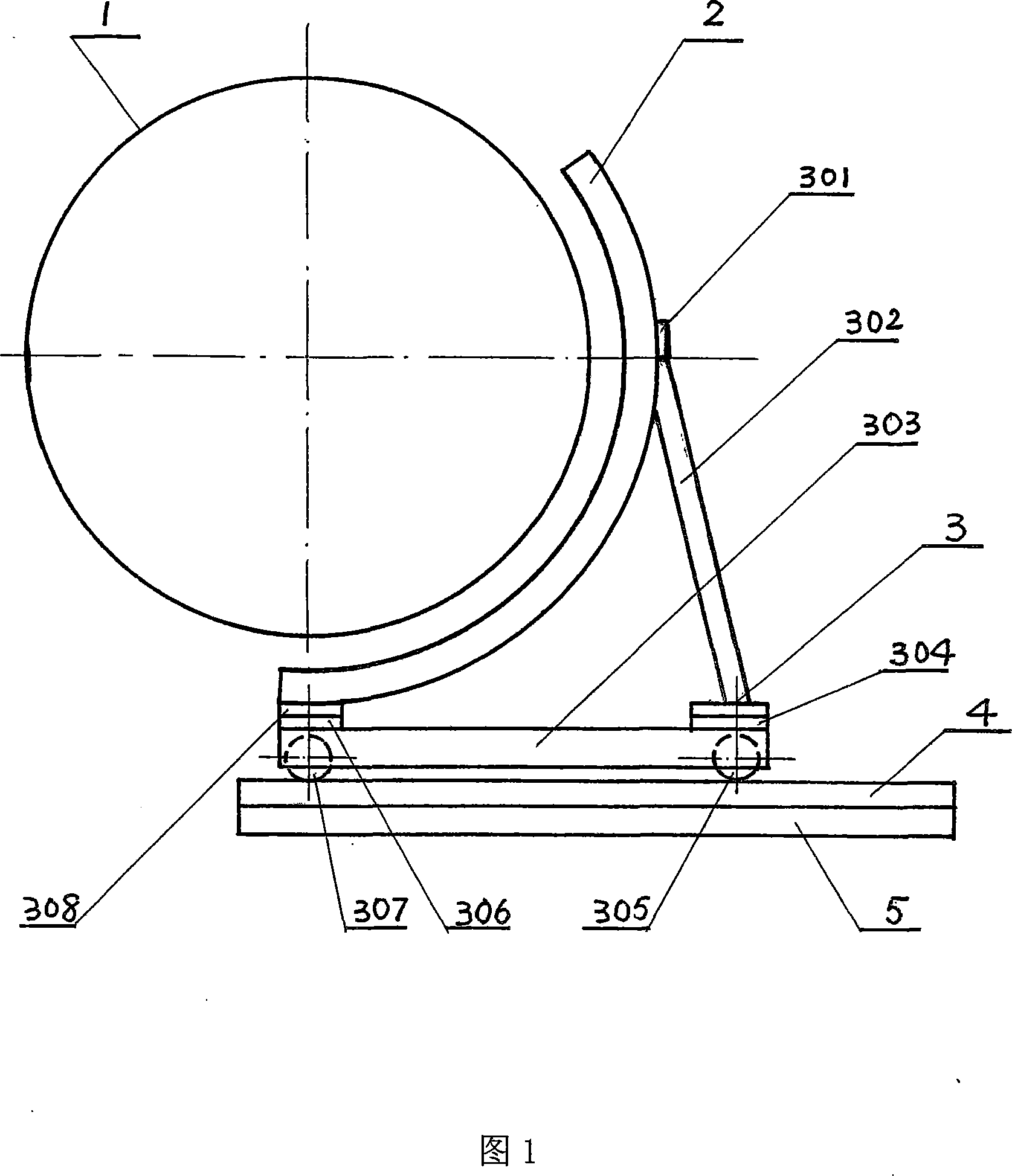

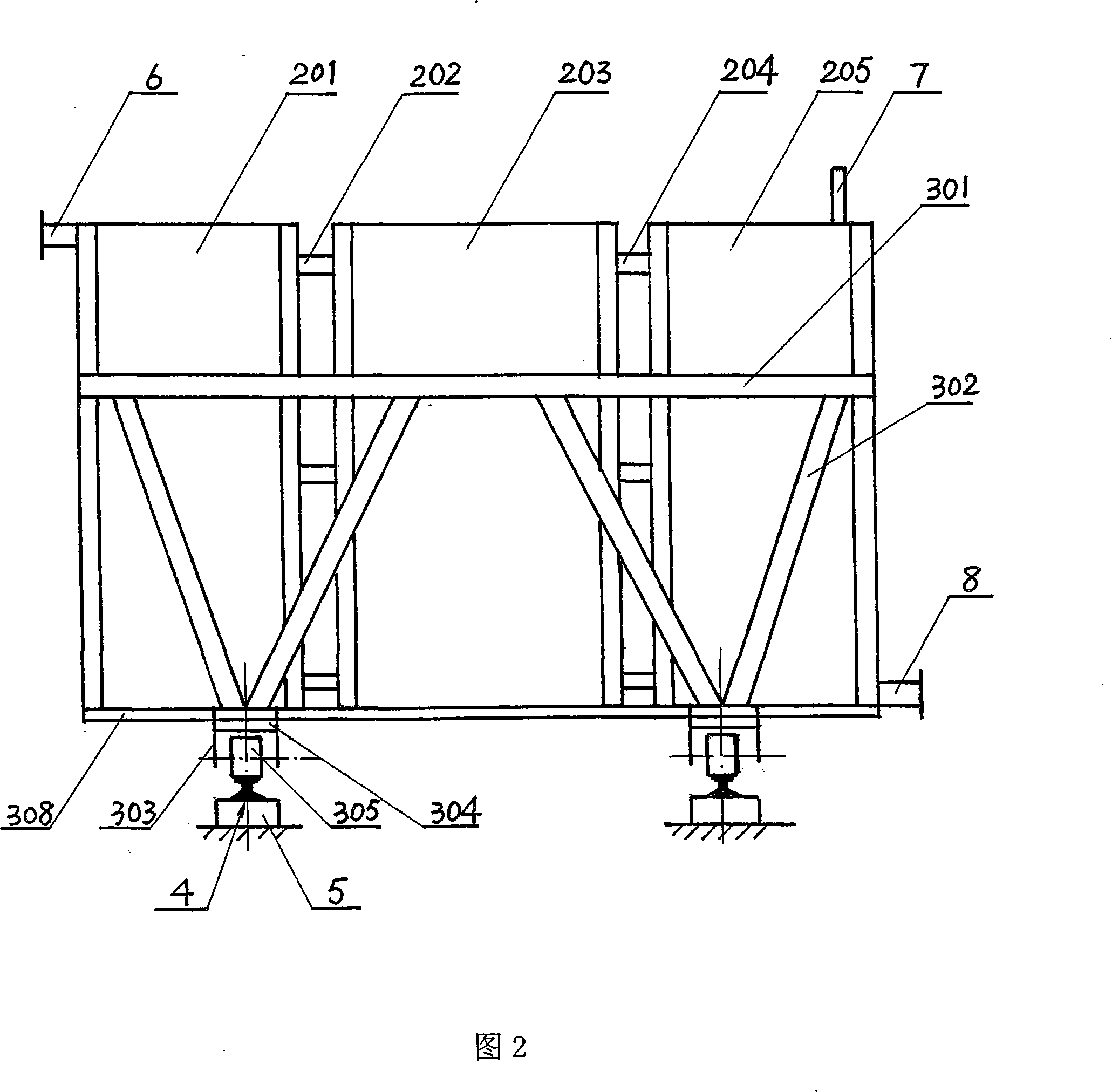

[0020] As shown in Figure 1 and Figure 2,

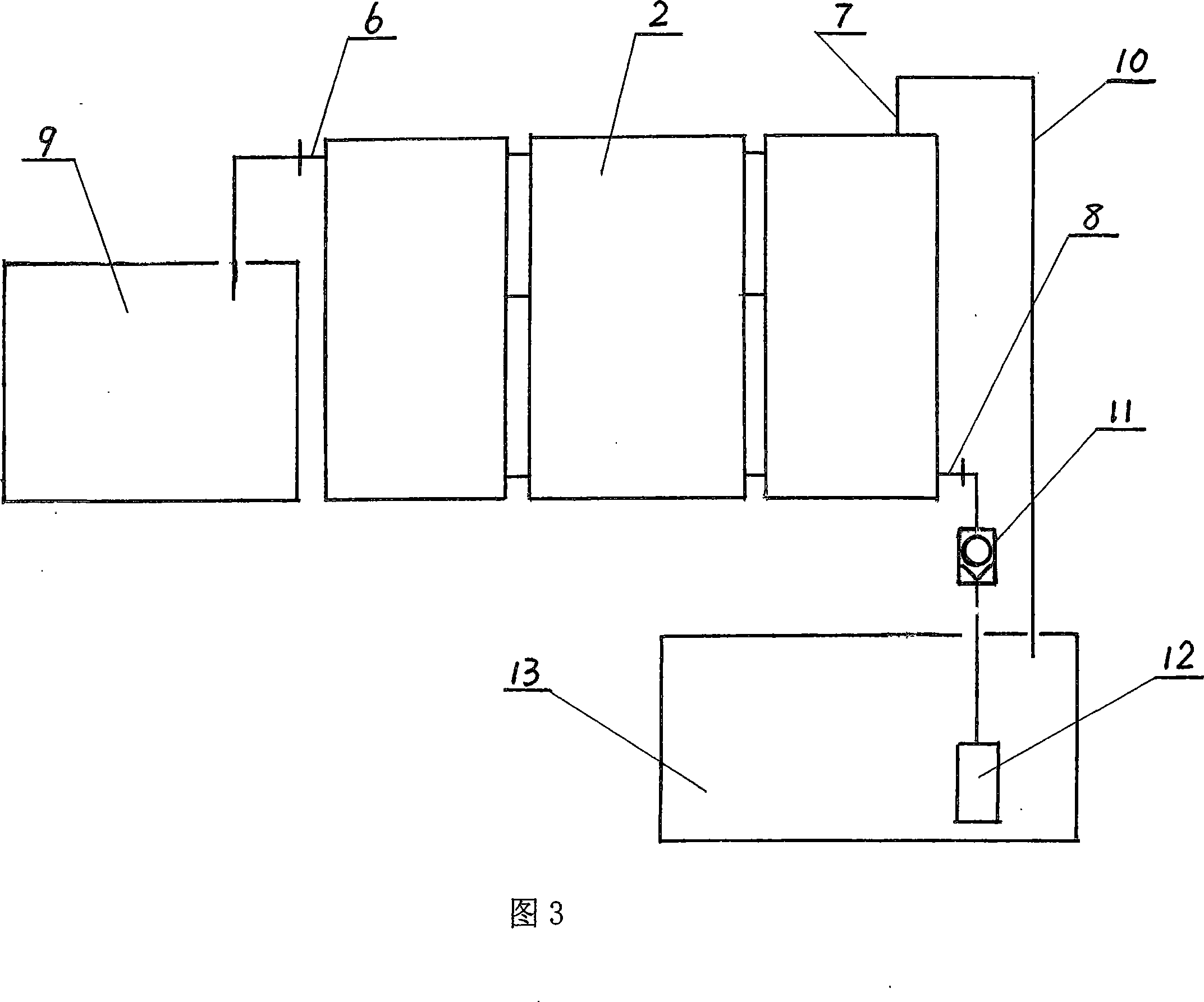

[0021] The waste heat utilization device on the surface of the rotary kiln includes a heat exchanger 2 arranged outside the surface of the rotary kiln body 1. The heat exchanger 2 has a heat-absorbing surface adapted to the surface shape of the rotary kiln body 1. The cross section of the rotary kiln body 1 is It is circular, and the heat-absorbing surface of the heat exchanger 2 is an arc surface concentric with the cross-section of the rotary kiln body 1, that is, the heat exchanger 2 is an arc-shaped plate sandwich structure, and the heat-absorbing surface faces the surface of the rotary kiln body 1, It is used to absorb the heat emitted from the surface of the rotary kiln body 1. The heat exchanger 2 has three heat exchanger units 201, 203 and 205, and the connecting pipes 202 and 204 are used to connect the heat excha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com