Blade of mud stirring machine

A mixer and blade technology, which is applied in the field of mud mixing equipment, can solve the problems of poor adjustment of the blade gap, blade jamming, and motor damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

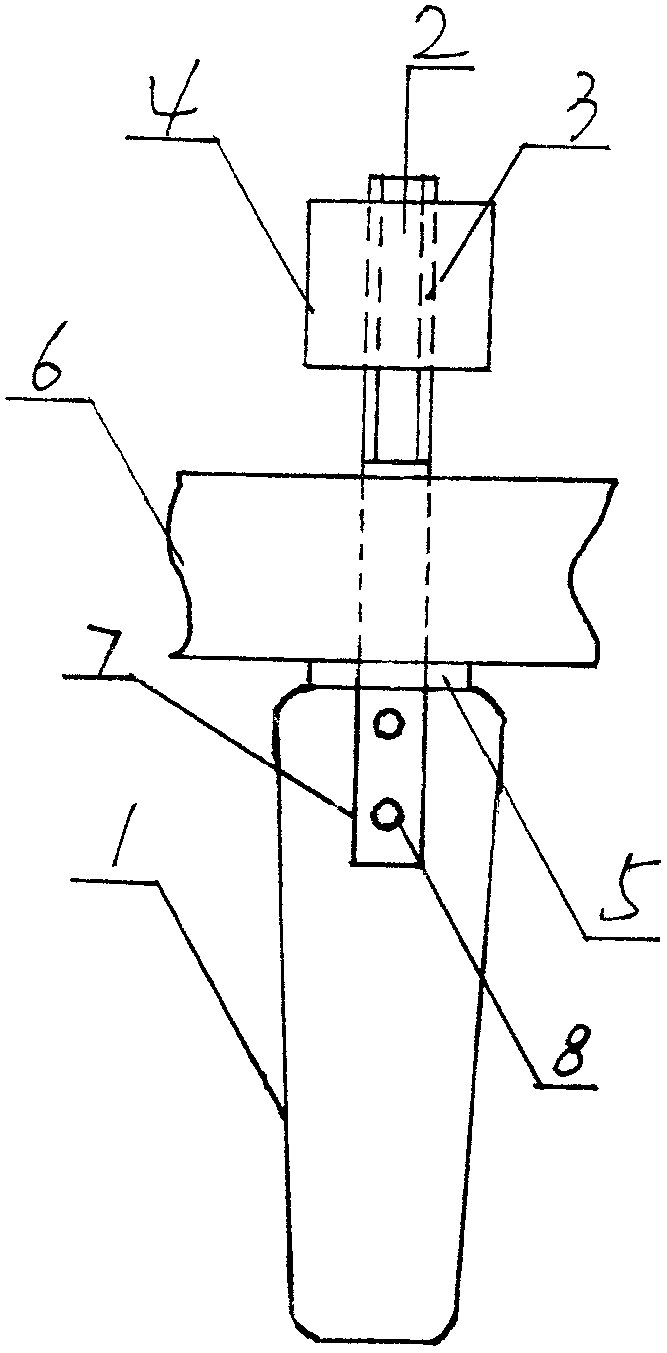

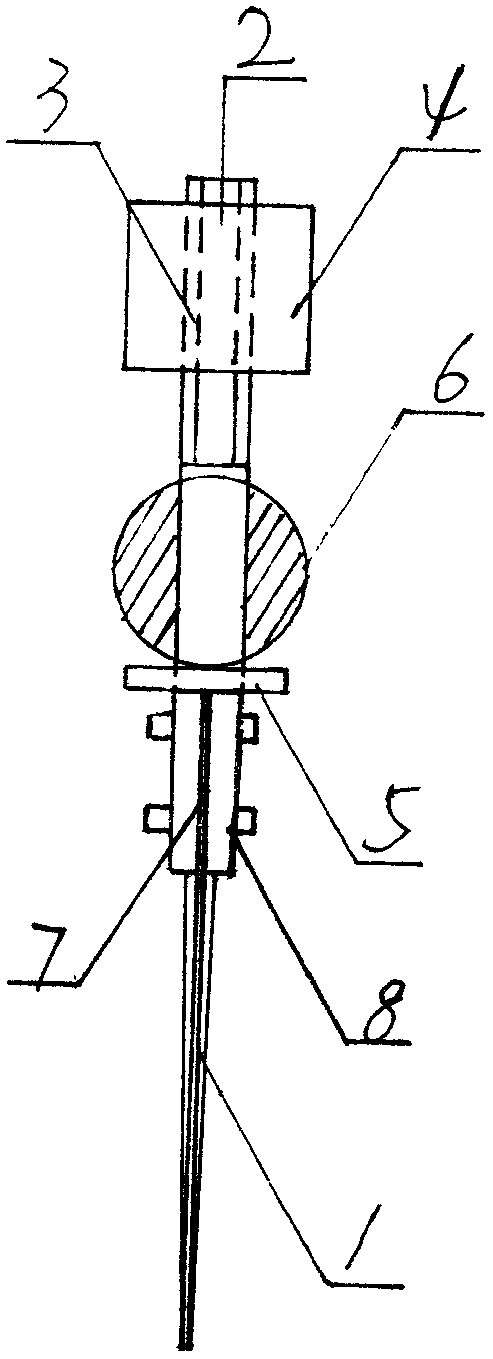

[0008] Such as figure 1 , 2 As shown, the structure of the blade of the mud mixer is composed of a blade surface 1, a petiole 2 and a nut 3 connected. The blade surface 1 of the blade is made of elastic steel plate (the kind of automobile steel plate), the front shape of the blade surface 1 is an isosceles trapezoid with rounded corners, the middle of the blade surface 1 is thick, the periphery is thin and the steel is tough and sharp, and the elasticity is good. In this way, the shear force of the blades during stirring is increased, thereby improving the working efficiency of the mixer. At the big end of the blade surface 1, a row (several) of thread holes 8 are arranged along the middle longitudinal axis of the blade surface 1 for use in connection with the petiole 2.

[0009] The petiole 2 is a section of cylinder, the diameter of the petiole 2 is greater than the middle thickness of the blade surface 1, and a section of a slot 7 is longitudinally provided in the middle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com