Automatic control system used for rolling force of burring roller and control method thereof

An automatic control system and deburring technology, applied in the direction of rolling force/roll gap control, etc., can solve the problems of poor adjustment accuracy, small range and inability to adapt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

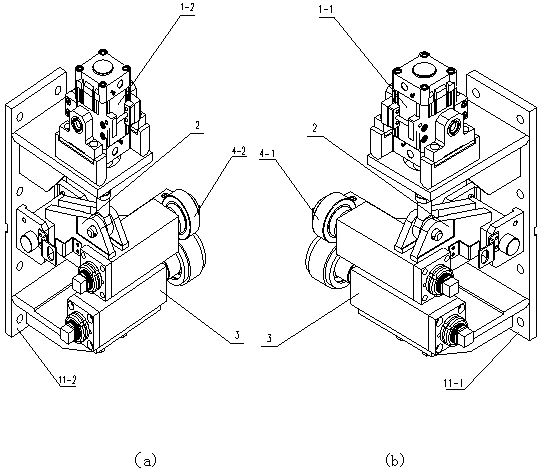

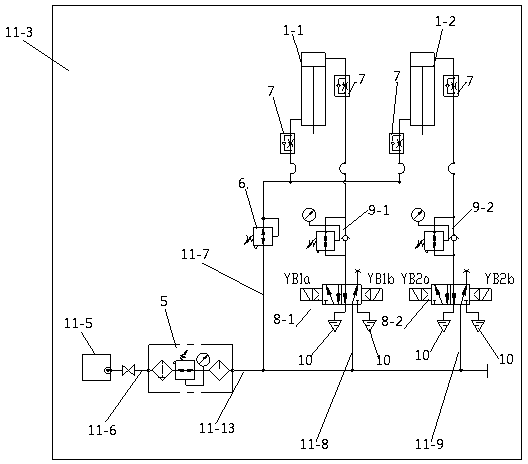

[0032] Embodiment 1, in conjunction with attached Figure 1-3 describe.

[0033] An automatic control system for the rolling force of a deburring roll, including a left deburring device 11-1 and a right deburring device 11-2 arranged in mirror images; (the left deburring device includes a swing frame 2 fixed on a frame The upper part of the swing frame 2 is equipped with a first cylinder 1-1 connected thereto, the lower part of the swing frame 2 is equipped with a movable pressure roller 4-1 fixed thereto, and a fixed support frame 3 at the lower part of the movable pressure roller 4-1 ; The structure of the right deburring device is consistent with that of the left deburring device) The right deburring device 11-2 includes a second cylinder 1-2, and the left deburring device 11-1 includes a first cylinder 1-1, so The automatic control system also includes a pneumatic control unit; the first cylinder 1-1 and the second cylinder 1-2 are connected with the pneumatic control ...

Embodiment 2

[0036] Embodiment 2, in conjunction with attached Figure 1-3 describe.

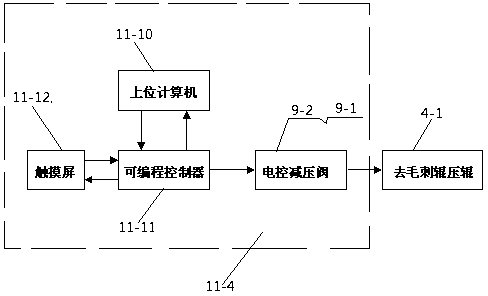

[0037] On the basis of the foregoing embodiments, the control system 11-4 includes a host computer 11-10, a programmable controller 11-11 connected to the host computer 11-10, a touch screen 11 connected to the programmable controller 11-11 -12 and electric control pressure relief valve (electric control pressure relief valve one 9-1, electric control pressure relief valve two 9-2);

[0038] Input the physical parameters and processing instructions of the workpiece to the programmable controller 11-11 through the touch screen 11-12;

[0039] Described programmable controller 11-11 receives touch screen 11-12 to execute command and physical parameter and model it; Control force, and converted to the electrical signal input of the electronically controlled pressure reducing valve (electrically controlled pressure reducing valve 1 9-1, electronically controlled pressure reducing valve 2 9-2), the electr...

Embodiment 3

[0042] Embodiment 3, in conjunction with attached Figure 1-3 describe.

[0043] On the basis of the foregoing embodiments, one-way throttle valves 7 are respectively provided between the pressure reducing valve 6 and the rod chambers of the first cylinder 1-1 and the second cylinder 1-2.

[0044] A one-way throttle valve 7 is arranged between the first cylinder 1-1 and the rodless cavity of the first cylinder 1-1; One-way throttle valve 7 is arranged between the rodless cavity of 2.

[0045] A muffler 10 is respectively installed on the two-position five-way reversing valve two 8-2 and the two-position five-way reversing valve one 8-1.

[0046] In this scheme, one-way throttle valves are arranged on the first air path, the second air path, and the third air path near the gas ports of the first cylinder and the second cylinder to ensure the speed of the adjustment cylinder. The preferred design of the muffler makes the The exhaust sound is reduced to a minimum d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com