Swinging strip steel guiding conveying device

The technology of a conveying device and a guiding device is applied in the field of conveying to a coiler and guiding, which can solve the problems of disrupted production rhythm, complicated maintenance, and high consumption of spare parts, so as to reduce waste, avoid fire accidents, spare parts and other problems. Low consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

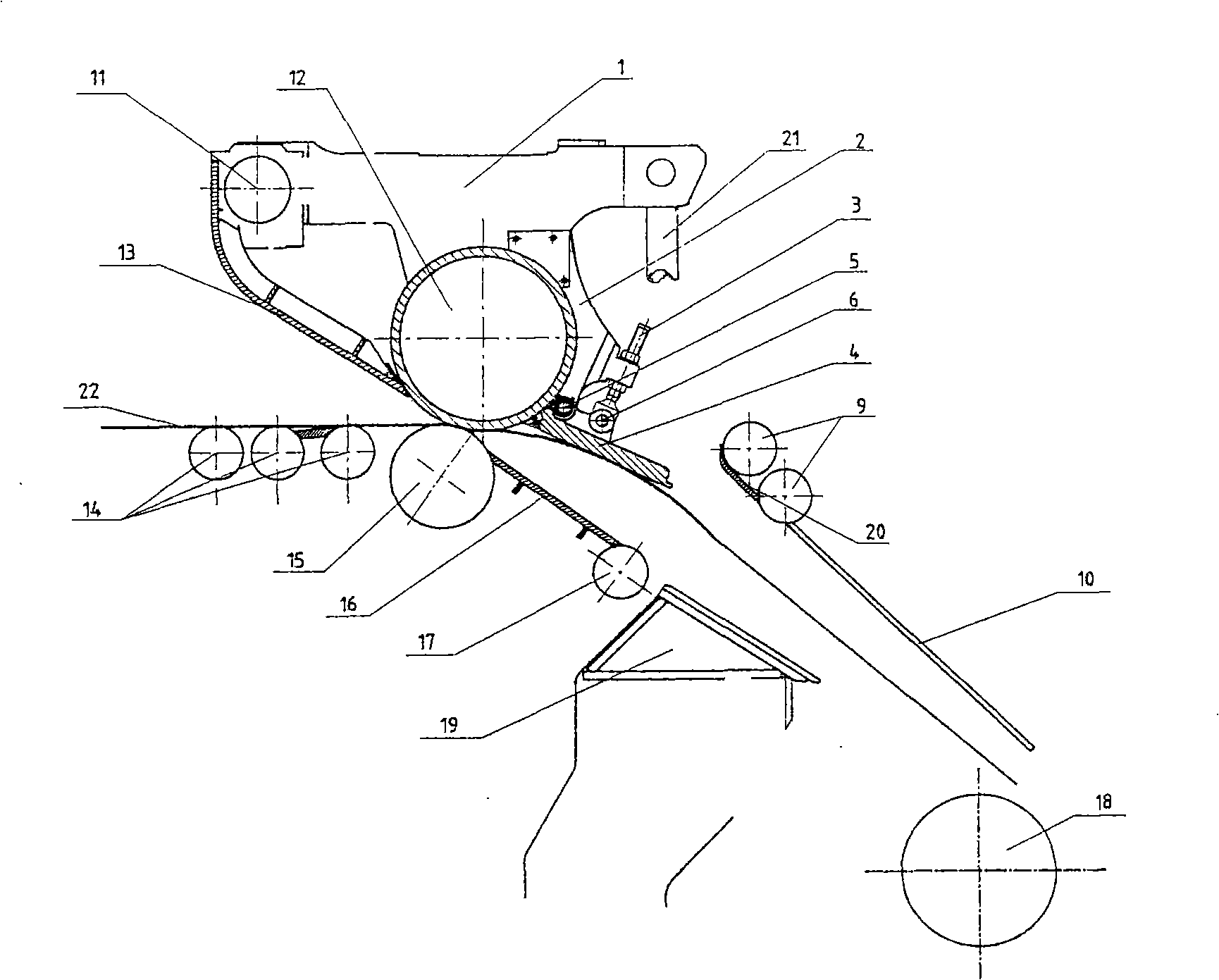

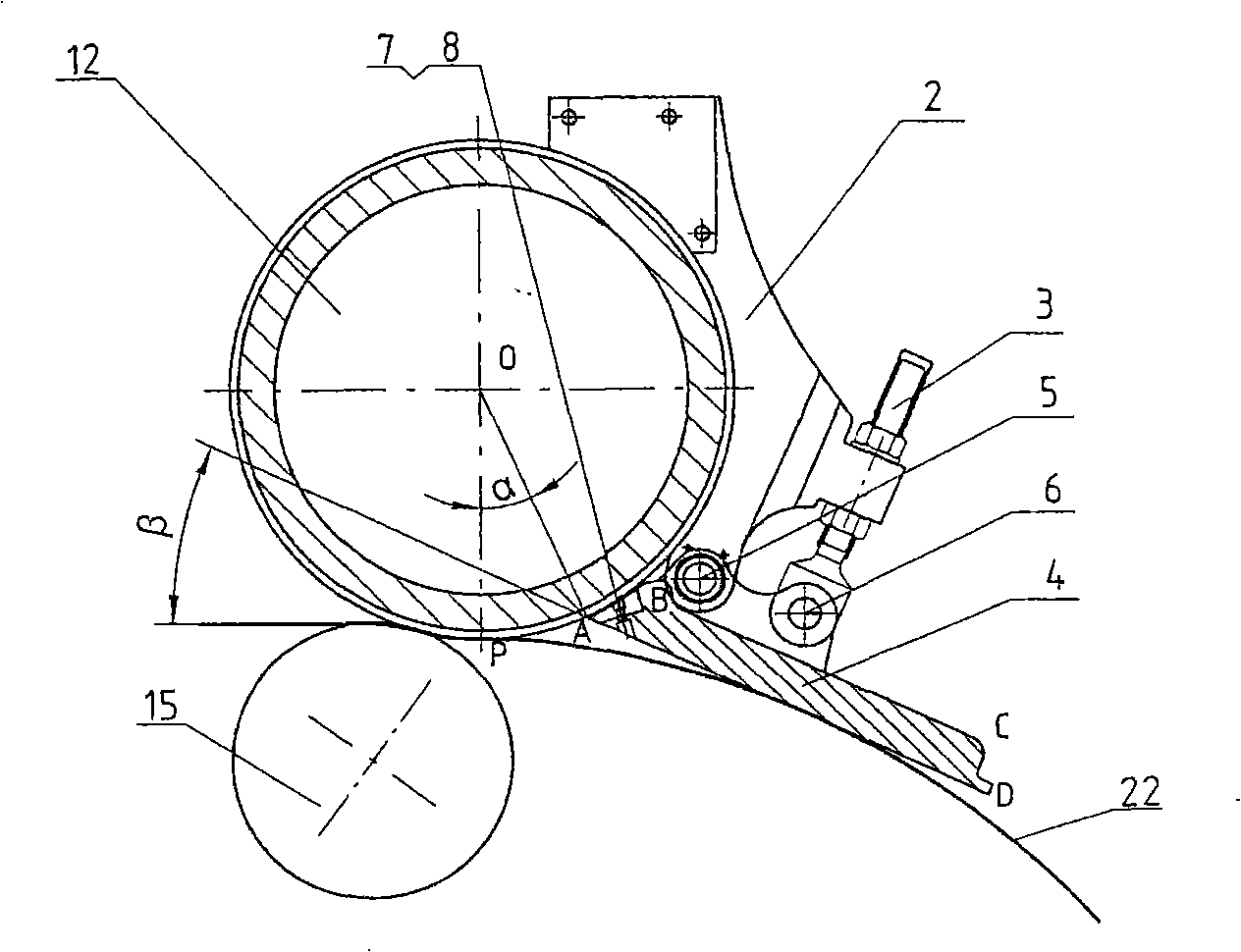

[0015] figure 1 It is a cross-sectional view of the device of the present invention. In the figure, the strip steel 22 is in the form of a single line. The upper pinch roll 12, the lower pinch roll 15, the switch roll 9, the frame roll 14, and the lower switch roll 17 that the strip passes through are all represented by circles, and the guide plate 4 is represented by ABCD The enclosed figure shows that the upper part of the guide plate 4 is connected to the plane by a cylindrical concave arc surface 7, which is represented by arcs AB and BC, and the bottom of the guide plate 4 is a plane, which is represented by AD. The bite line between the strip 22 and the upper pinch roller 12 is represented by the tangent point P between the line segment and the circle, and the gap between the front end of the guide plate 4 and the upper pinch roller 12 is represented by A, then ∠AOP is the back shift angle α , The angle between the bottom surface AD of the guide plate 4 and the rolling l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com