Linear actuator

A technology of linear actuators and outer tubes, applied in the direction of electric components, transmission devices, and control of mechanical energy, can solve problems such as inconvenient assembly, complex structure, and increased cost of linear actuators 90

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to enable your examiners to further understand the structure, features and other purposes of the present invention, the following preferred embodiments are attached to the accompanying drawings for detailed description, but the examples illustrated in the illustrations are for illustration purposes, not for patent application on the limit.

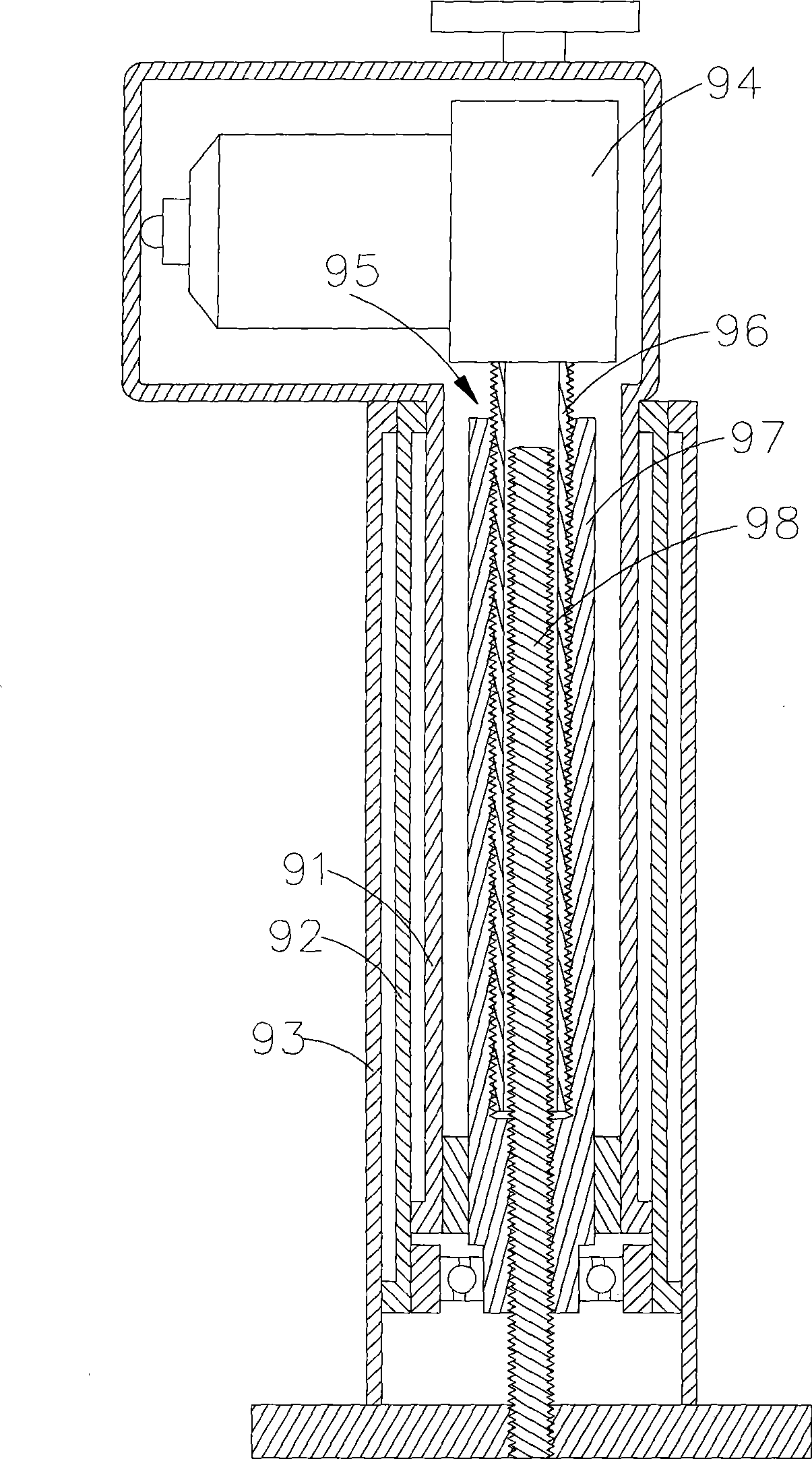

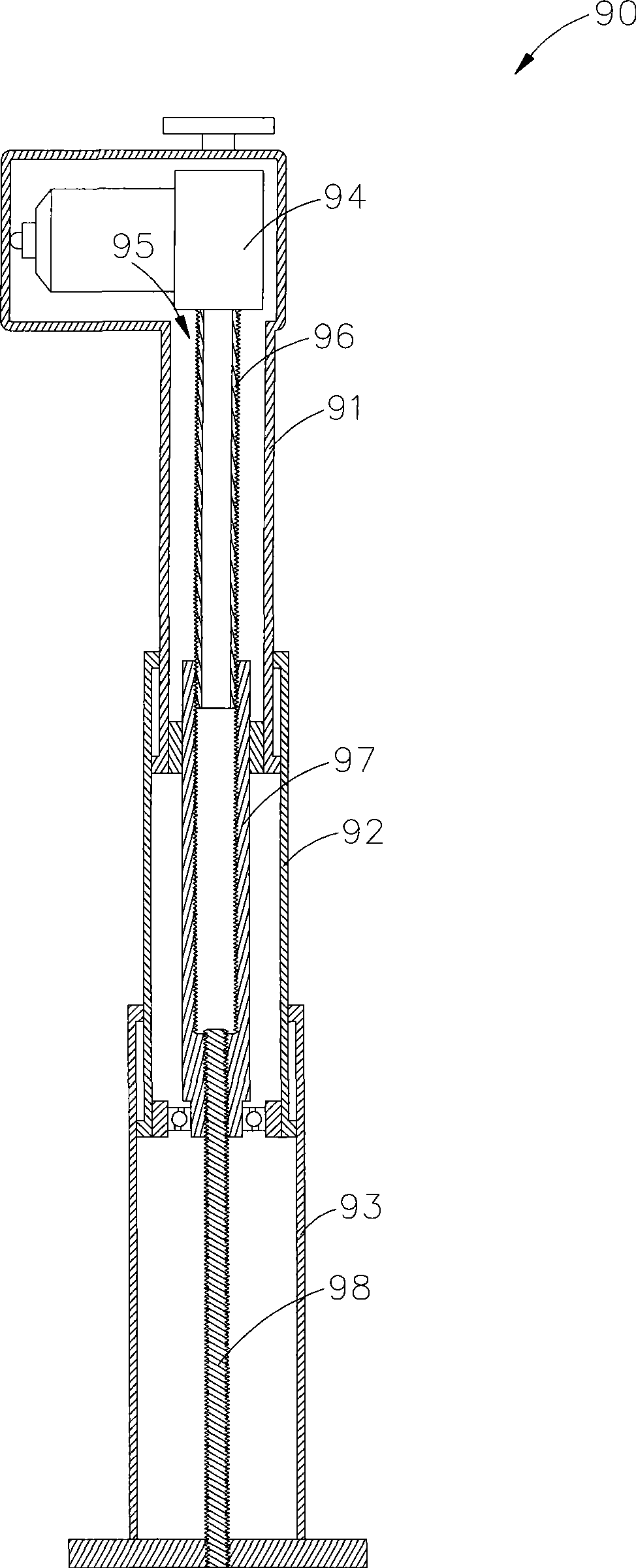

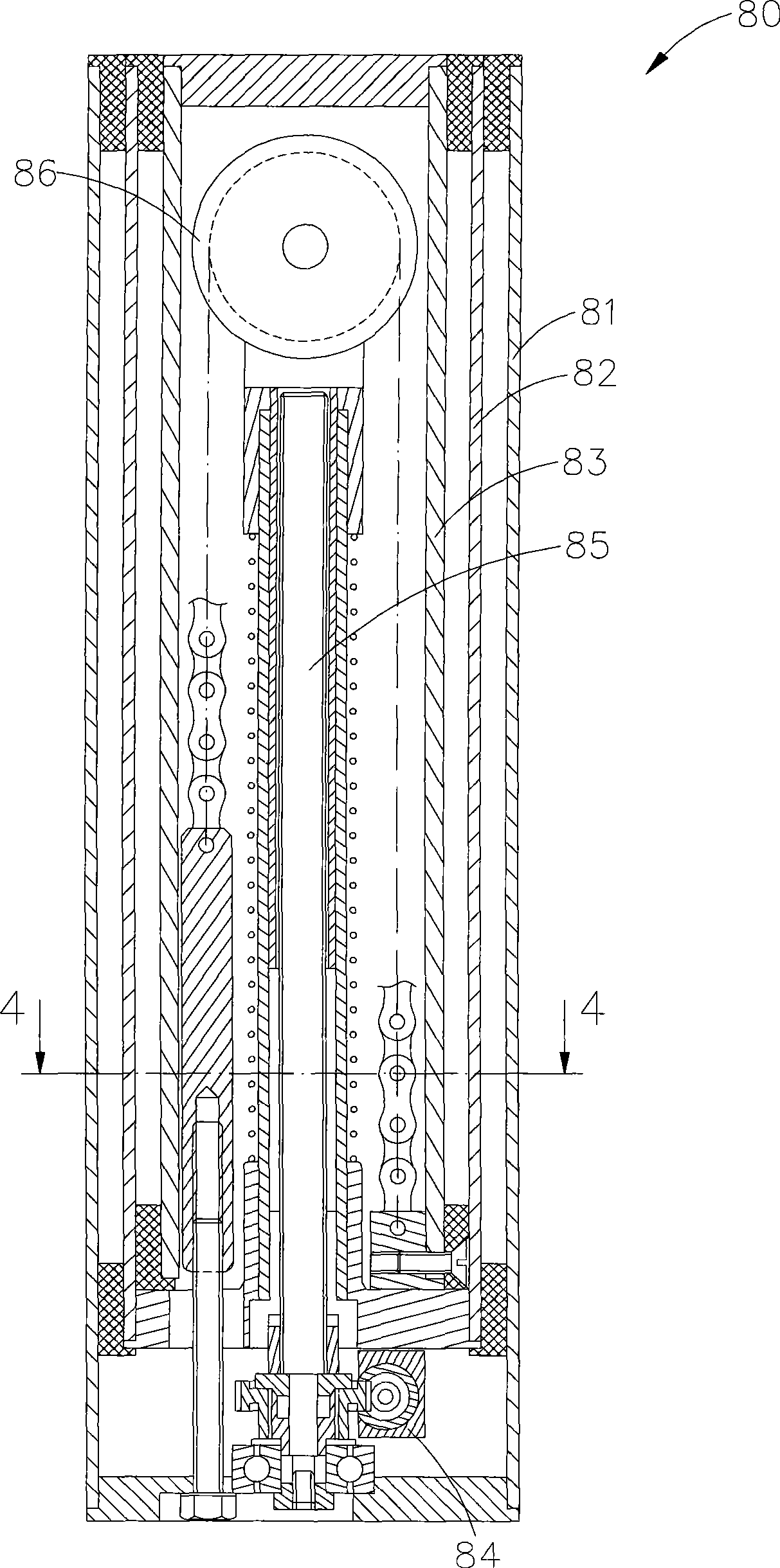

[0034] Please refer to Figure 5 , Figure 6 , Figure 7 A kind of linear actuator shown, it comprises the outer tube 10 of a hollow polygonal tubular form, and this outer tube 10 is for a middle tube 20 and an inner tube 30 of the same shape as the outer tube to pass through, and this outer tube 10 1. The polygonal tube shape of the middle tube 20 and the inner tube 30 can mutually expand and contract in the axial direction and the radial direction is limited to each other, which can maintain the stability of the telescopic action, and the polygonal tubes 10, 20, 30 The shape can be hollow triangle, quadrangular or pent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com