Linear guideway assembly

A technology of linear guide rails and components, applied in the direction of metal processing machinery parts, large fixed members, metal processing equipment, etc., can solve problems such as large frictional resistance, difficult installation, and affecting the straightness of sliding bars, so as to reduce frictional resistance and ensure The effect of straightness and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing, describe the specific embodiment of the present invention in detail:

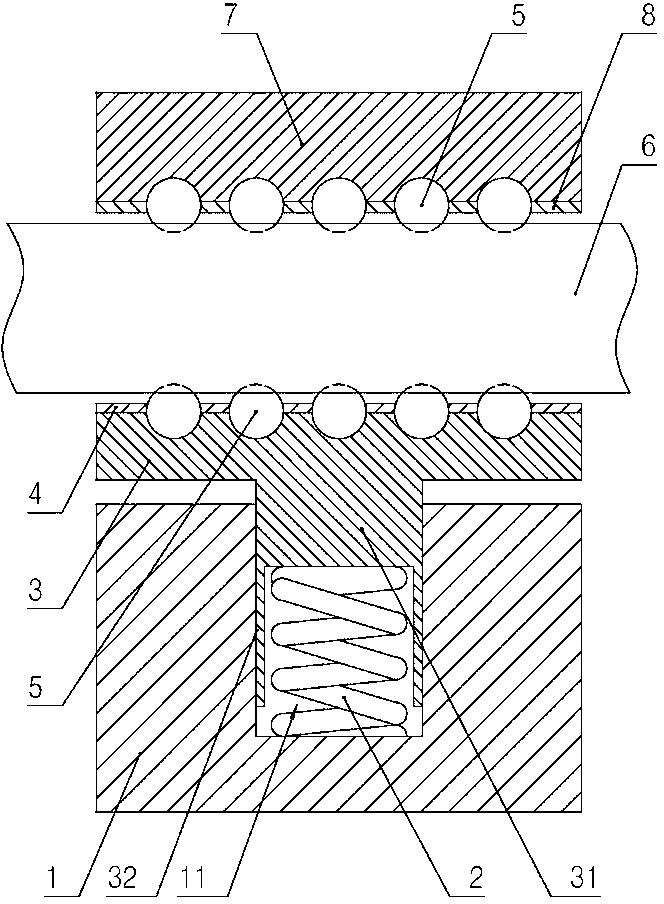

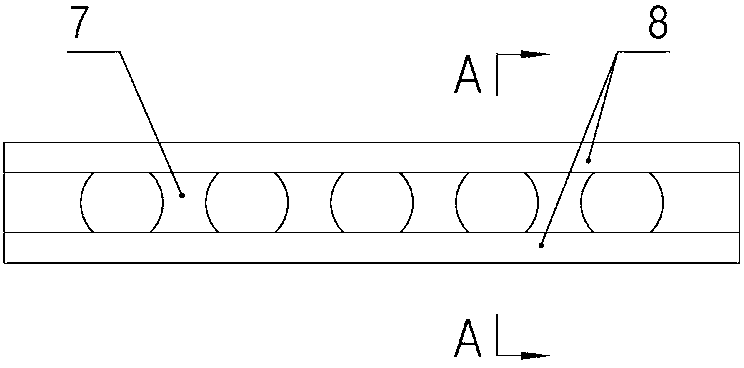

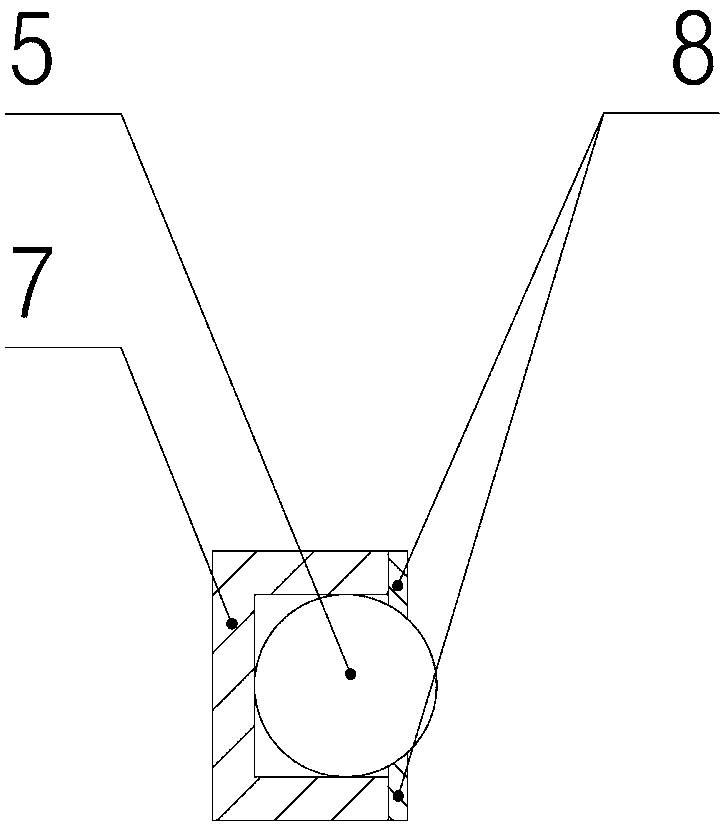

[0014] Such as figure 1 As shown, the linear guide rail assembly of the present invention includes: a sliding bar 6, one side of the sliding bar 6 is provided with a fixed guide body 7, and the other side of the sliding bar 6 is provided with a guide seat 1 and is arranged in the guide seat 1 The movable guide body 3, the top of the guide seat 1 is provided with a guide hole 11, the bottom of the movable guide body 3 is provided with a guide post 31 matching with the guide hole 11, the guide post 31 is arranged in the guide hole 11, and the guide hole In 11, a pre-tension spring 2 is also provided between the guide post 31 and the bottom wall of the guide hole 11, and the guide surfaces of the fixed guide body 7 and the movable guide body 3 are respectively provided with several placement holes, and the placement holes A steel ball 5 is placed in it, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com