Piston

A piston and piston ring groove technology, which is applied in the direction of pistons, engine components, machines/engines, etc., can solve the problems of shortening the service life of pistons and cylinder liners, and preventing metal wear debris from washing away, so as to prevent cylinder scuffing and reduce friction work Loss, the effect of reducing fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

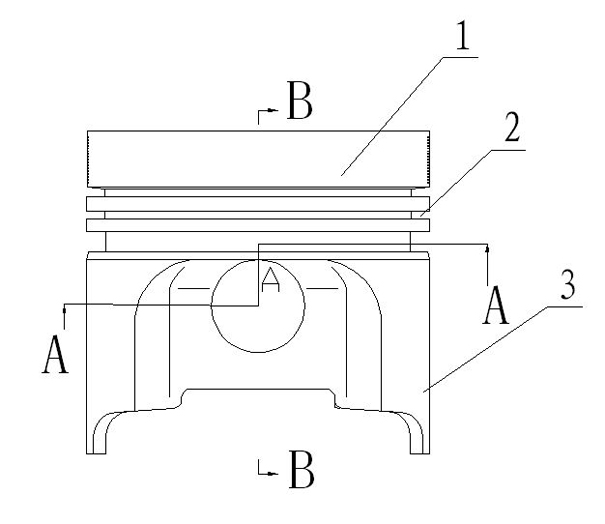

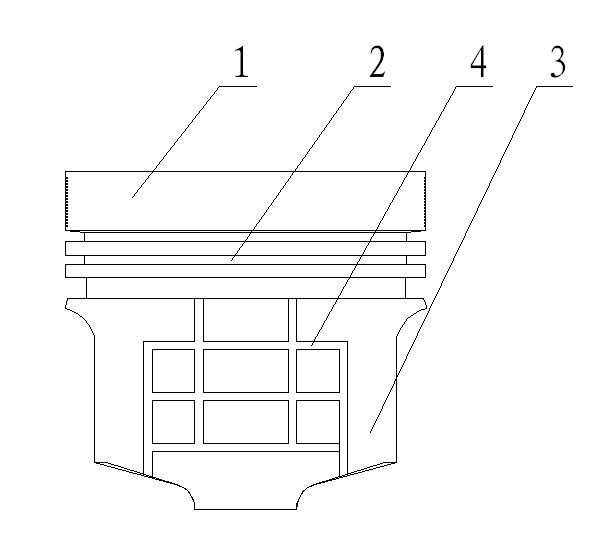

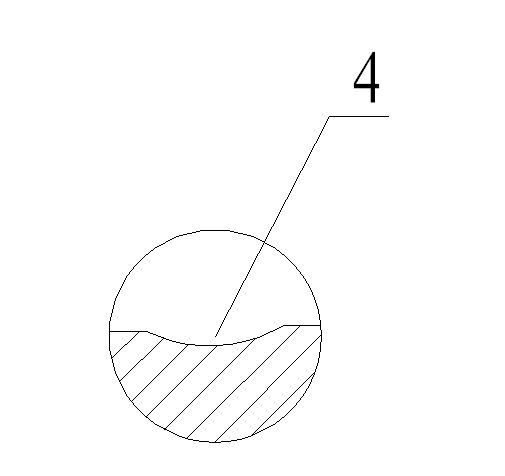

[0013] Referring to the accompanying drawings, this piston has a body 1 with a piston ring groove 2 and a skirt 3, the inside of the body 1 is an oil return hole 5, and the outer surface of the skirt 3 is provided with a labyrinth. The groove 4 makes the outer circular surface of the skirt 3 form a plurality of curved surfaces; in this embodiment, the labyrinth-like groove 4 divides the outer circular surface of the skirt 3 into fields; the cross section of the groove 4 is arc-shaped After the cross-section of the groove 3 is made into an arc shape, the lubricating oil can flow more quickly, and an oil film can be formed between the piston and the cylinder liner during the mutual movement. The depth of the groove is preferably between 0.3-0.5 mm, and the width is preferably between 2-2.5 mm. The outer circular surface of the skirt is divided into fields, that is, multiple curved surfaces. The area of each curved surface is not less than 225 mm. There must be no sharp co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com