A Highly Compact "Micro Differential" Closed Servo Mechanism with Single Rod

A servo mechanism and compact technology, applied in the direction of servo motors, mechanical equipment, fluid pressure actuators, etc., can solve the problems of complex control of the consistency of expansion and contraction characteristics, huge energy demand in the direction of extension, etc., to achieve increased compactness and resistance Interference ability, improving energy utilization efficiency, and avoiding the effect of cylinder scuffing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following describes the one provided by the present invention with reference to the accompanying drawings and embodiments:

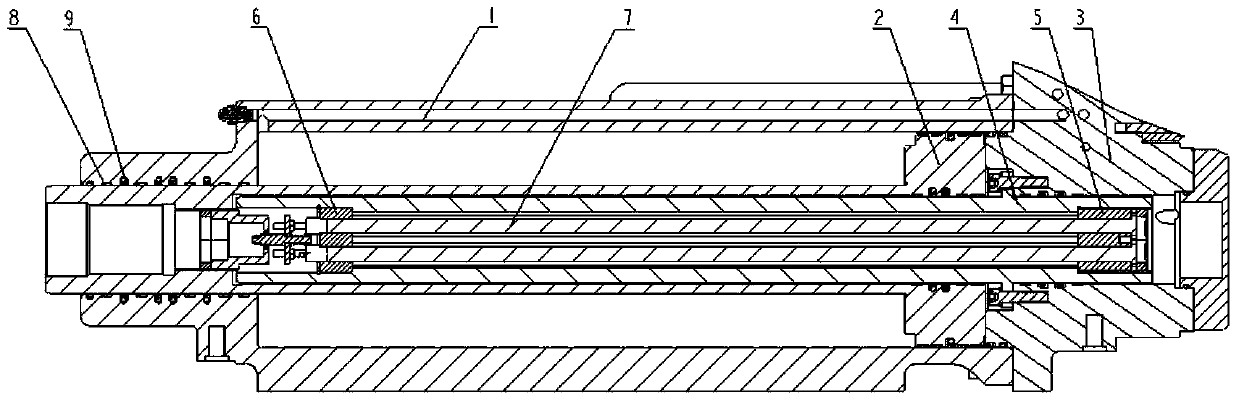

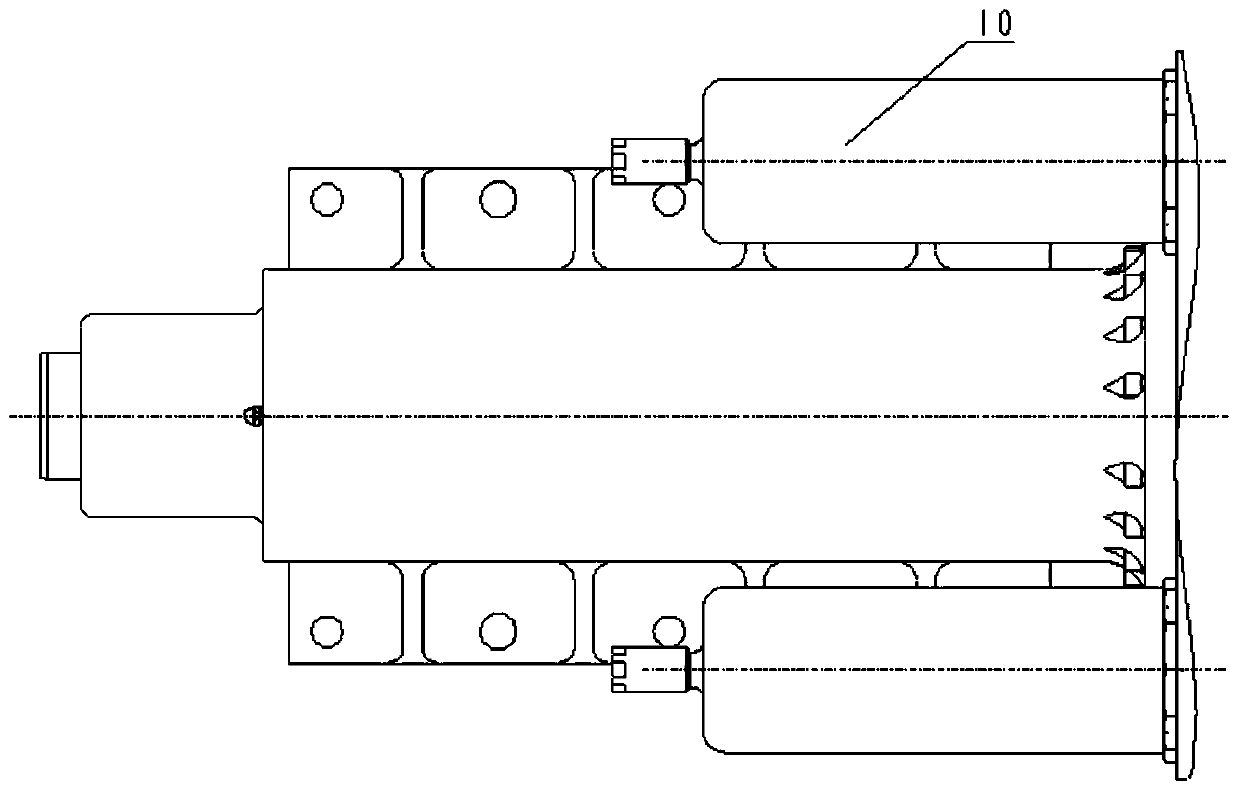

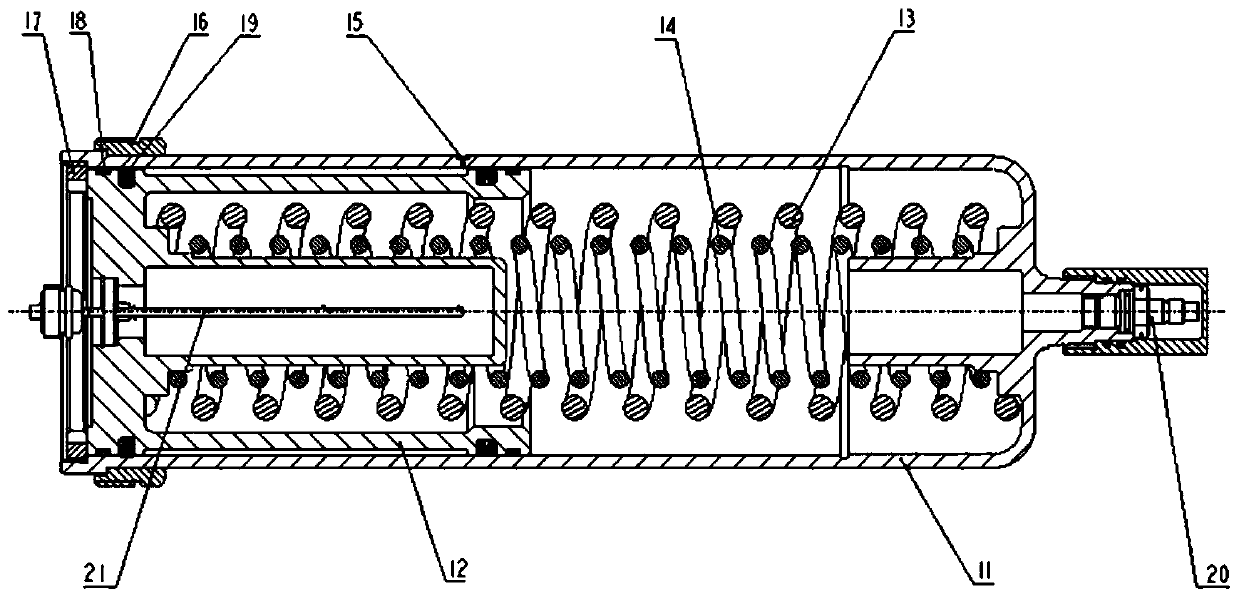

[0019] A single-rod high compact "micro-differential" closed-type servo mechanism, comprising a servo mechanism main body and two mechanical springs and air pressure double-acting self-pressurizing oil tanks 10. The servo mechanism main body includes: an actuator 1, Piston rod 2, housing 3, support rod 4, rear support 5, front support 6, displacement sensor 7, support ring A8 and combined seal A9; the short end of support rod 4 is inserted into the main hole of housing 3 through the flange Fixed on the housing 3, the long end of the support rod 4 is installed in the piston rod 2, a support ring A8 and a combined seal A9 are arranged between the support rod 4 and the piston rod 2, and the two ends of the displacement sensor 7 are installed through the front support 6 and the rear support 5. In the support rod 4, the rod end of the displacement sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com