Hydraulic hammer cylinder part

A technology of hydraulic breaker and components, which is applied in fluid pressure actuating devices, earth movers/excavators, construction, etc. It can solve problems such as piston return wear and pull piston full support balance, and achieve Great support and tight fit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

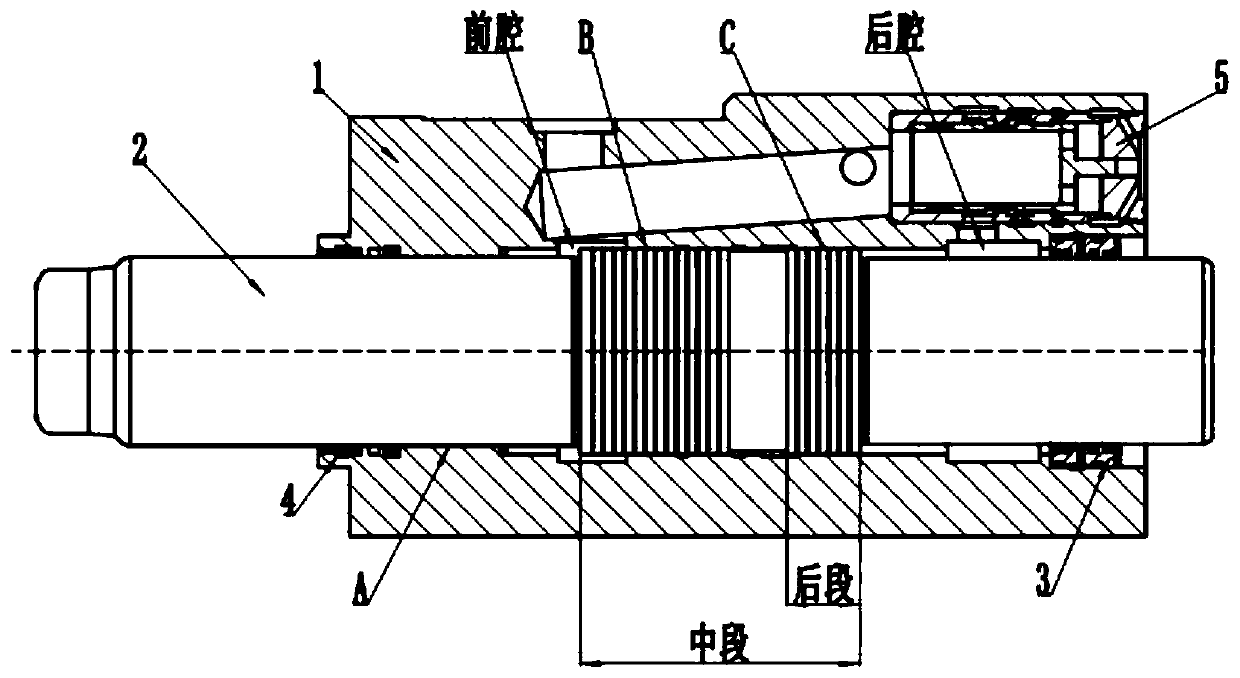

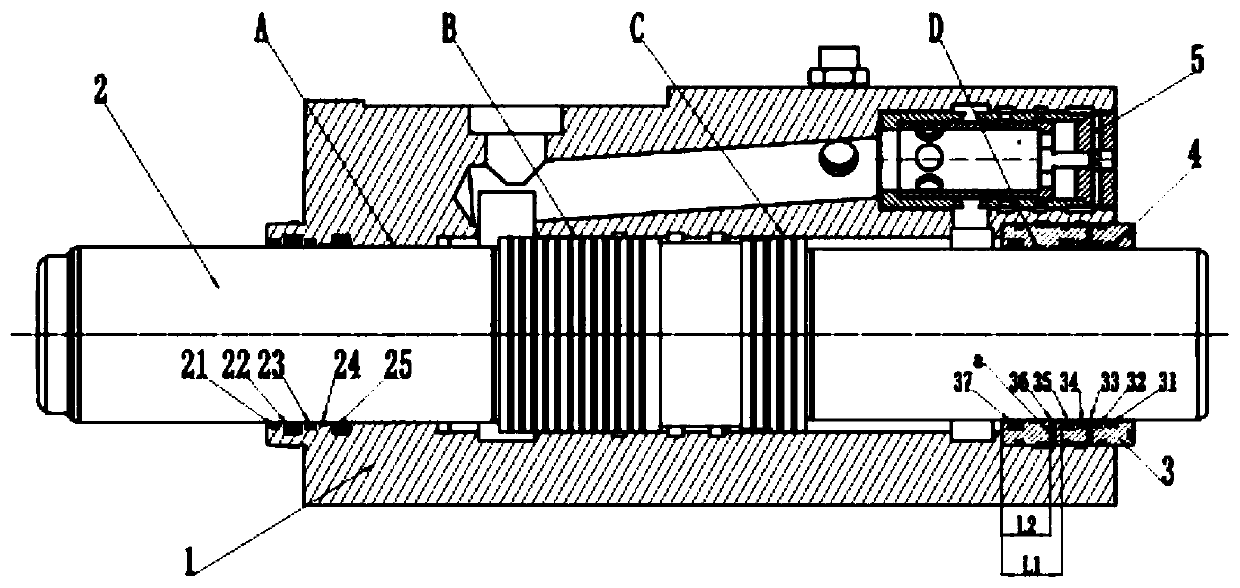

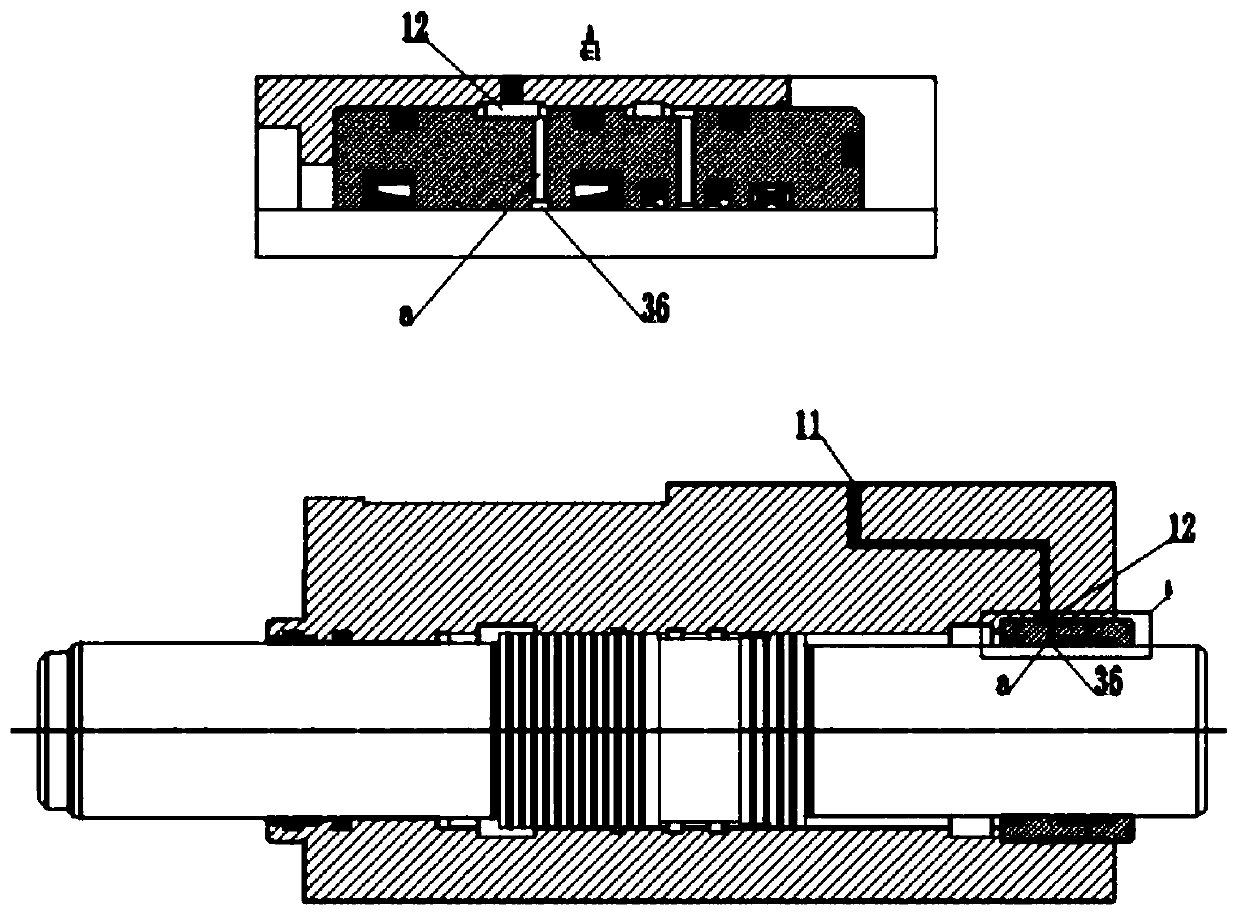

[0036] Example 1: Combining figure 2 , image 3 and Figure 4 Explain the technical solutions of claims 1, 2 and 7 of the invention;

[0037] An embodiment of the present invention is a middle cylinder part of a hydraulic breaker, the middle cylinder part (see figure 2 ) includes: a middle cylinder body 1, a piston 2, a piston ring 3, a seal 4 and a reversing valve 5, and the inner hole structure of the piston ring 3 (see Figure 4 ) includes from right to left: air seal groove 31, oil seal groove 32, oil return groove 33, seal grooves 34 and 35; the technical solution of this embodiment is: the piston ring on the left side of the seal groove 35 3 The cylindrical section is lengthened to L1, and an oil supply groove 36 is added at the same time. A radial through hole a is arranged in the oil supply groove 36. The distance between the center line of the through hole a and the left end face is L2, and the through hole a and the middle cylinder body The high-pressure oil in...

Embodiment 2

[0038] Example 2: Combining figure 2 , Figure 5 Explain the technical solutions of invention claims 3, 4, and 6:

[0039] An embodiment of the present invention is a middle cylinder part of a hydraulic breaker, the middle cylinder part (see figure 2 ) includes: a middle cylinder body 1, a piston 2, a piston ring 3, a seal 4 and a reversing valve 5, and the inner hole structure of the piston ring 3 (see Figure 5 ) includes from right to left: air seal groove 31, oil seal groove 32, oil return groove 33, seal grooves 34 and 35; the technical solution of this embodiment is: the piston ring on the left side of the seal groove 35 3. The cylindrical section is lengthened to L1, and an oil supply groove 36 is added at the same time. A radial through hole a is arranged in the oil supply groove 36. The distance between the through hole a and the left end face is L2. The high-pressure oil inlet is connected, and the high-pressure oil is always passed through the oil supply groove...

Embodiment 3

[0040] Example 3: Binding figure 2 , Figure 6 Explanation of the technical solutions of invention claims 3 and 5:

[0041] An embodiment of the present invention is a middle cylinder part of a hydraulic breaker, the middle cylinder part (see figure 2 ) includes: a middle cylinder body 1, a piston 2, a piston ring 3, a seal 4 and a reversing valve 5, and the inner hole structure of the piston ring 3 (see Figure 5 ) includes from right to left: air seal groove 31, oil seal groove 32, oil return groove 33, seal grooves 34 and 35; the technical solution of this embodiment is: the piston ring on the left side of the seal groove 35 3. The cylindrical section is lengthened to L1, and an oil supply groove 36 is added at the same time. A radial through hole a is arranged in the oil supply groove 36. The distance between the through hole a and the left end face is L2. The high-pressure oil inlet port of the high-pressure oil is connected, and the high-pressure oil is always connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com