Patents

Literature

30results about How to "Avoid contact opportunities" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

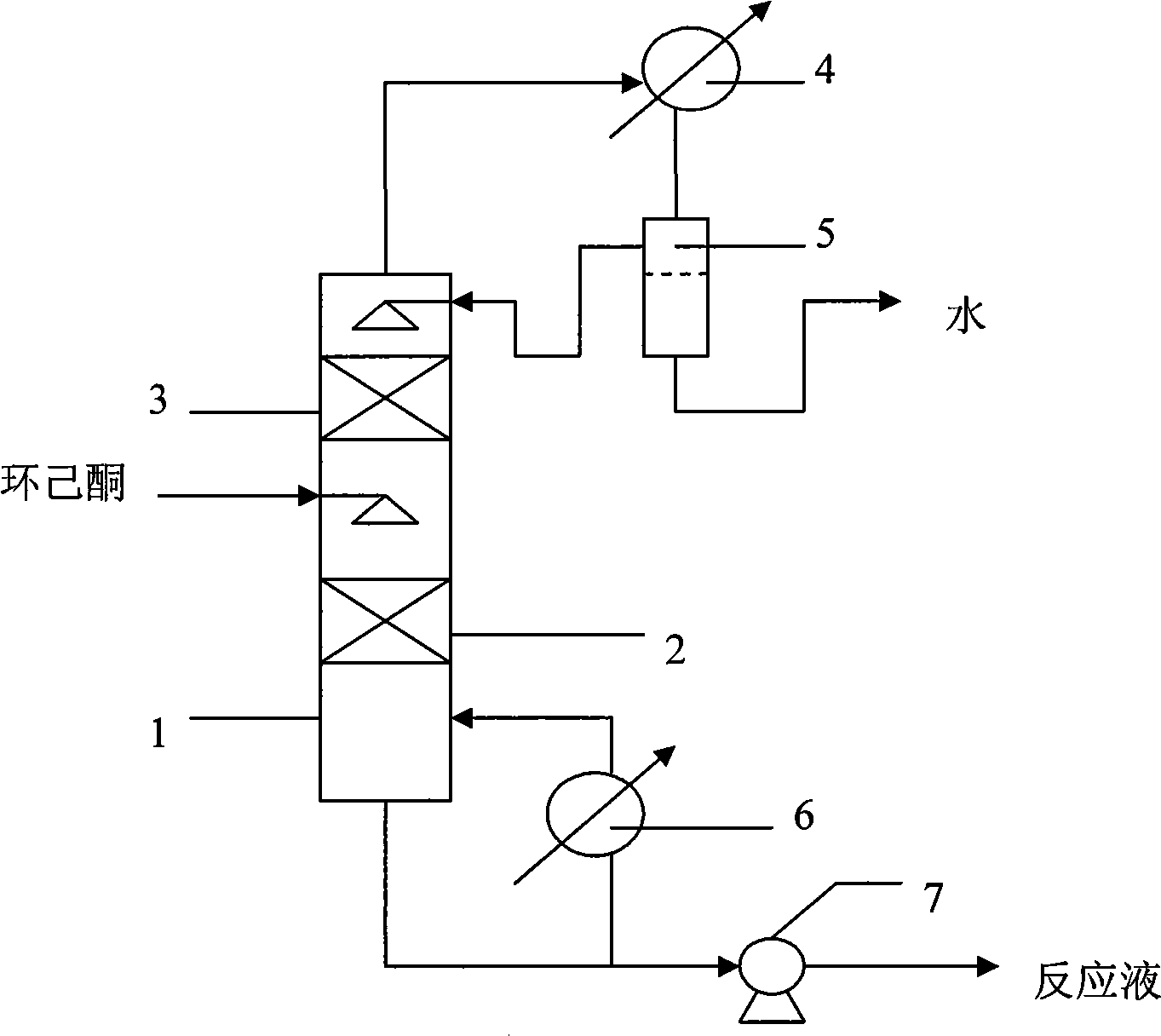

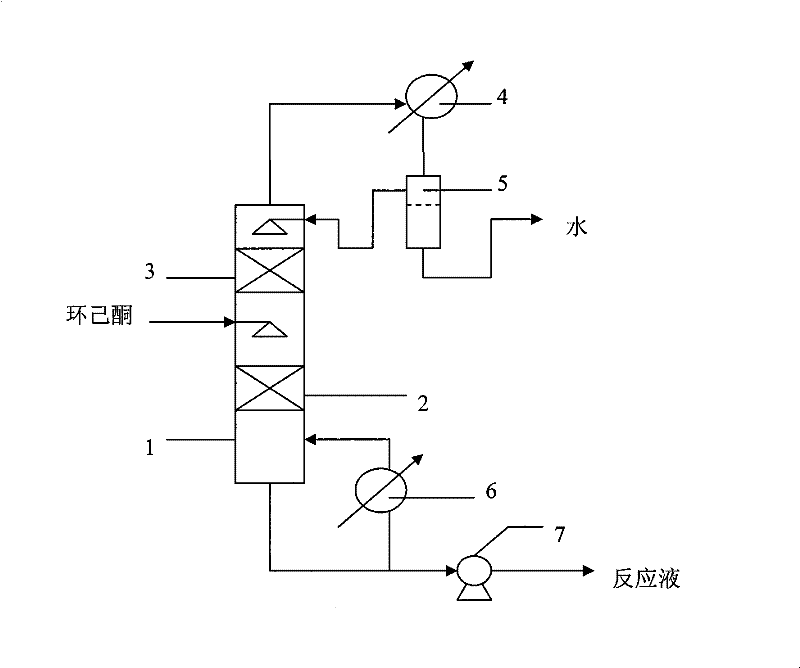

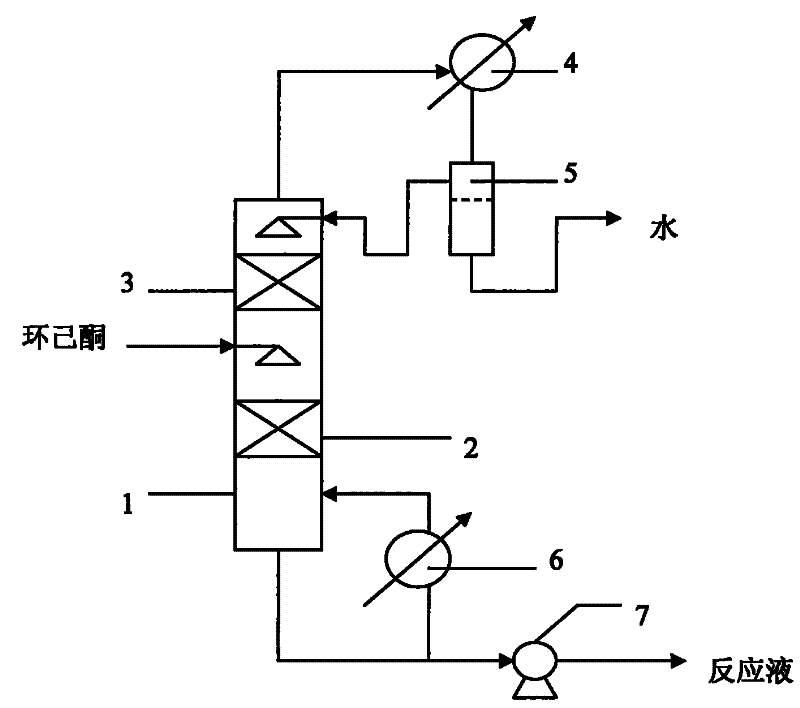

Method for synthesizing cyclohexanone dimer by continuous catalytic reaction and distillation

InactiveCN101544553AHigh selectivityAvoid contact opportunitiesPhysical/chemical process catalystsOrganic compound preparationCyclohexanoneReaction field

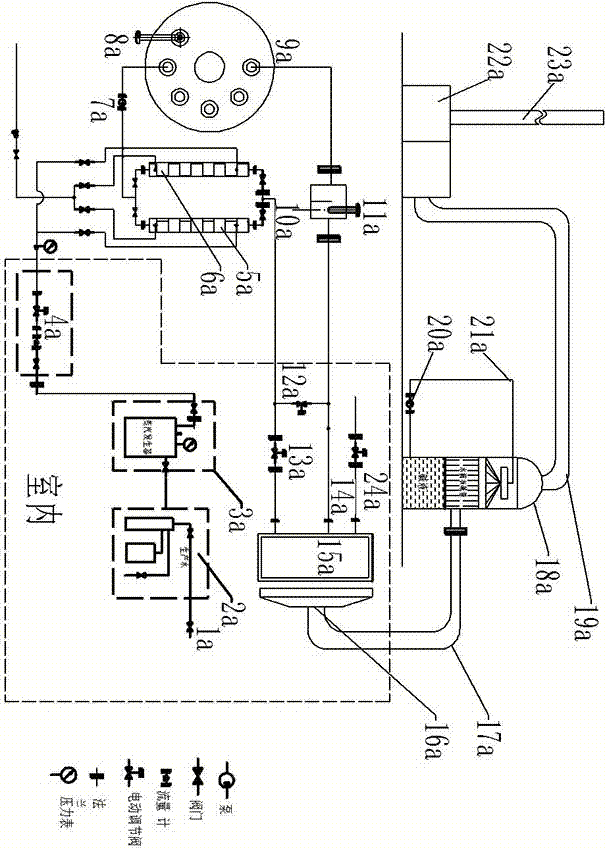

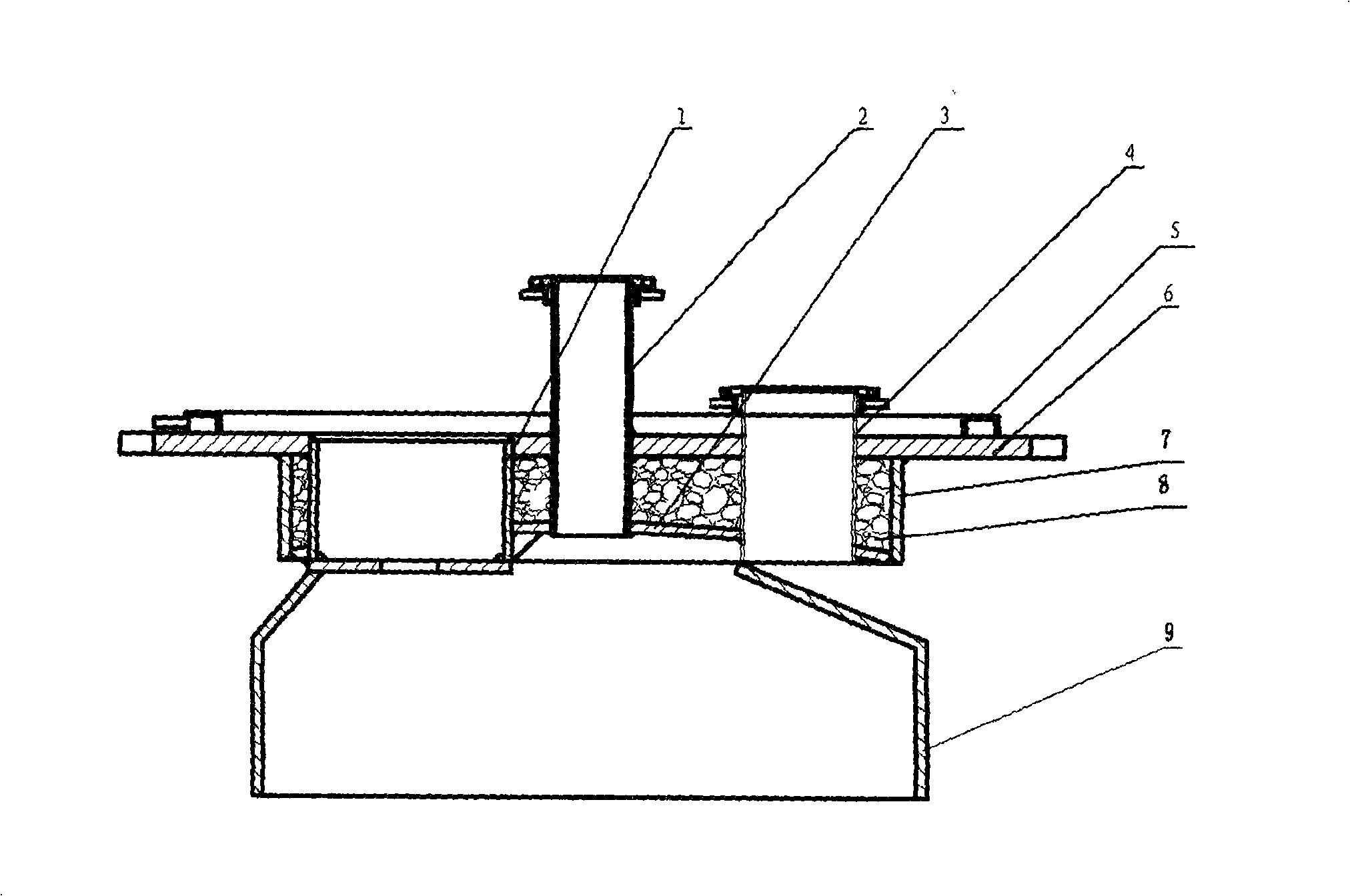

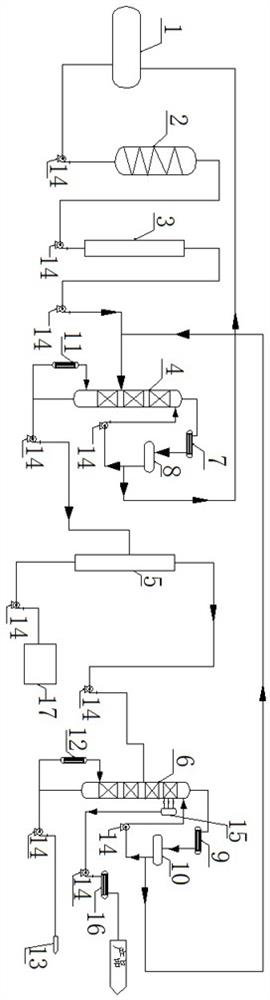

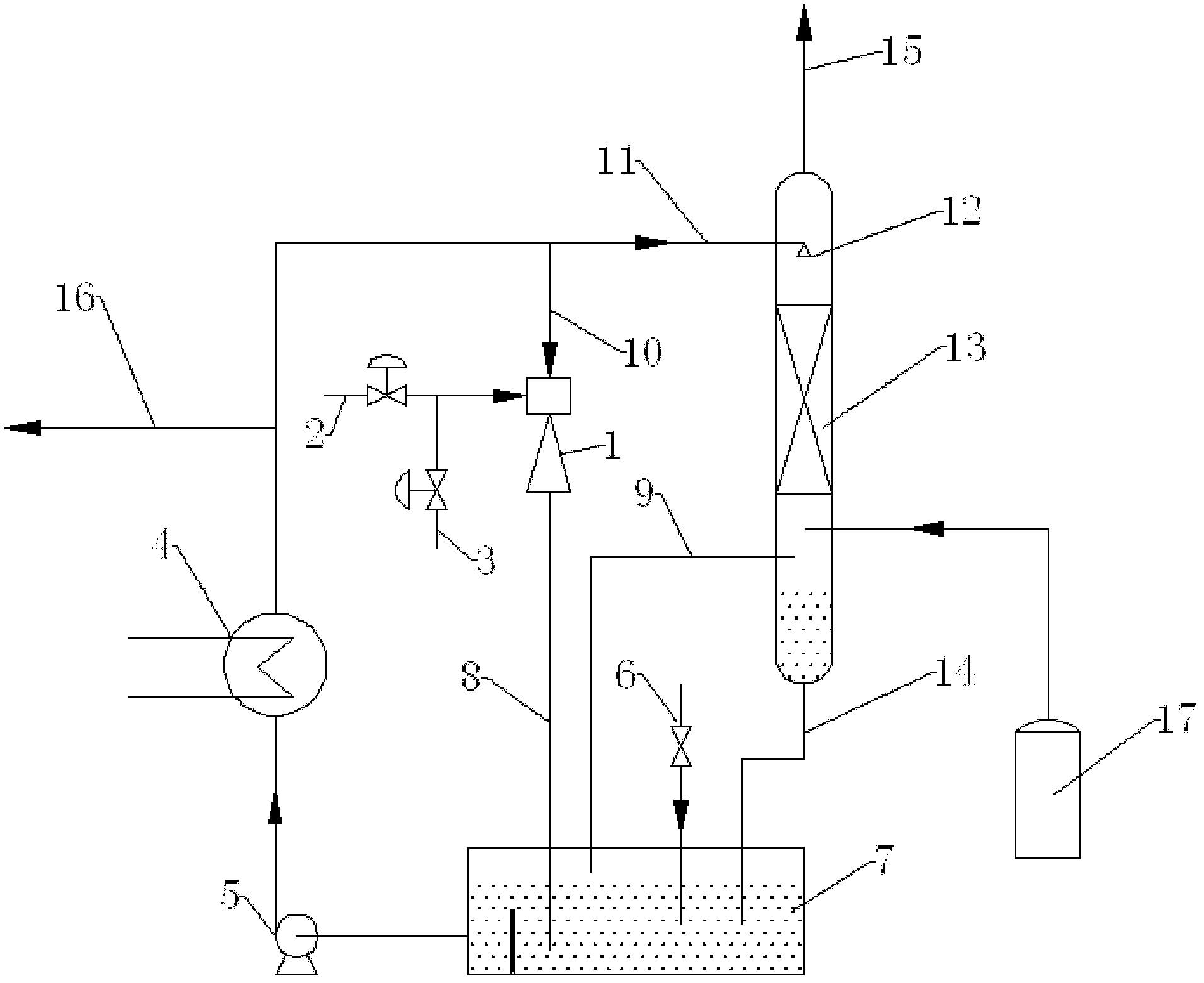

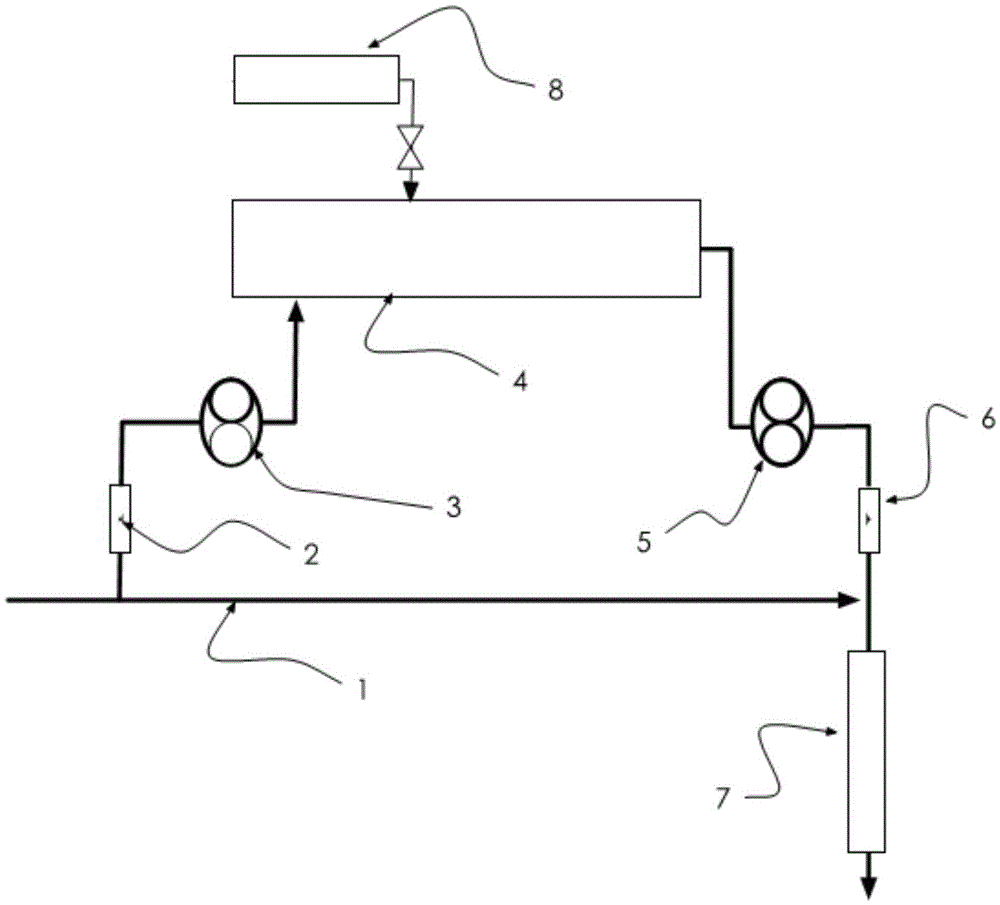

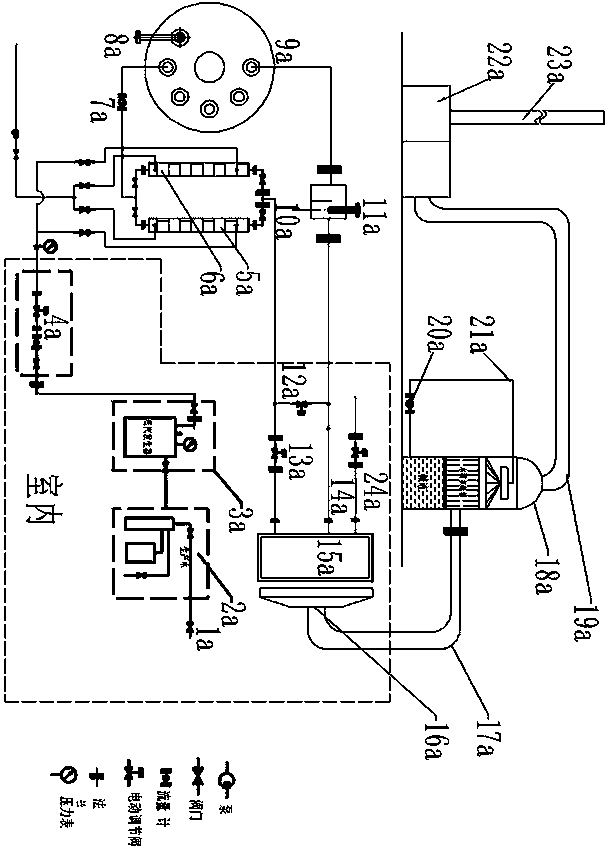

The invention discloses a method for synthesizing cyclohexanone dimer by continuous catalytic reaction and distillation. The method comprises the following steps that: a catalytic reaction and distillation device shown in a figure is adopted, and cyclohexanone enters the a tower from the middle part of the tower; a cyclohexanone dimer and water azeotropic mixture obtained by the condensation of overhead vapor is subjected to continuous low layer resultant water separation in a water knockout vessel, and the upper layer cyclohexanone flows into the top of the tower; and tower bottom residue is heated by a reboiler, the temperature of the residue is controlled to be 250 to 280 DEG C, and 60 to 90 mass percent cyclohexanone dimer can be obtained from liquid discharged from the bottom of the tower. The method adopts continuous catalytic reaction and distillation technology and removes water in products away from a reaction field in time, thereby promoting a reaction to move toward the direction of the formation of the cyclohexanone dimer; meanwhile, the method separates the products of the reaction from a stripping section at the lower part to further eliminate the opportunity for the products of the reaction to contact a catalyst, thereby improving the selectivity of the cyclohexanone dimer, ensuring continuous reaction, high production efficiency and high selectivity of the cyclohexanone dimer, and facilitating industrial production.

Owner:ZHEJIANG UNIV +1

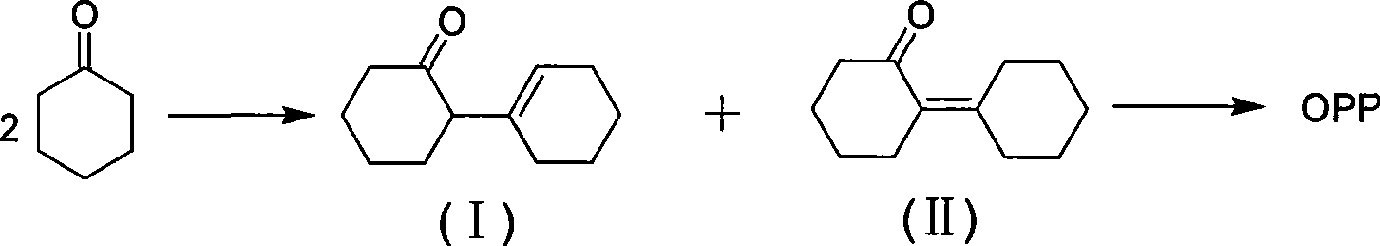

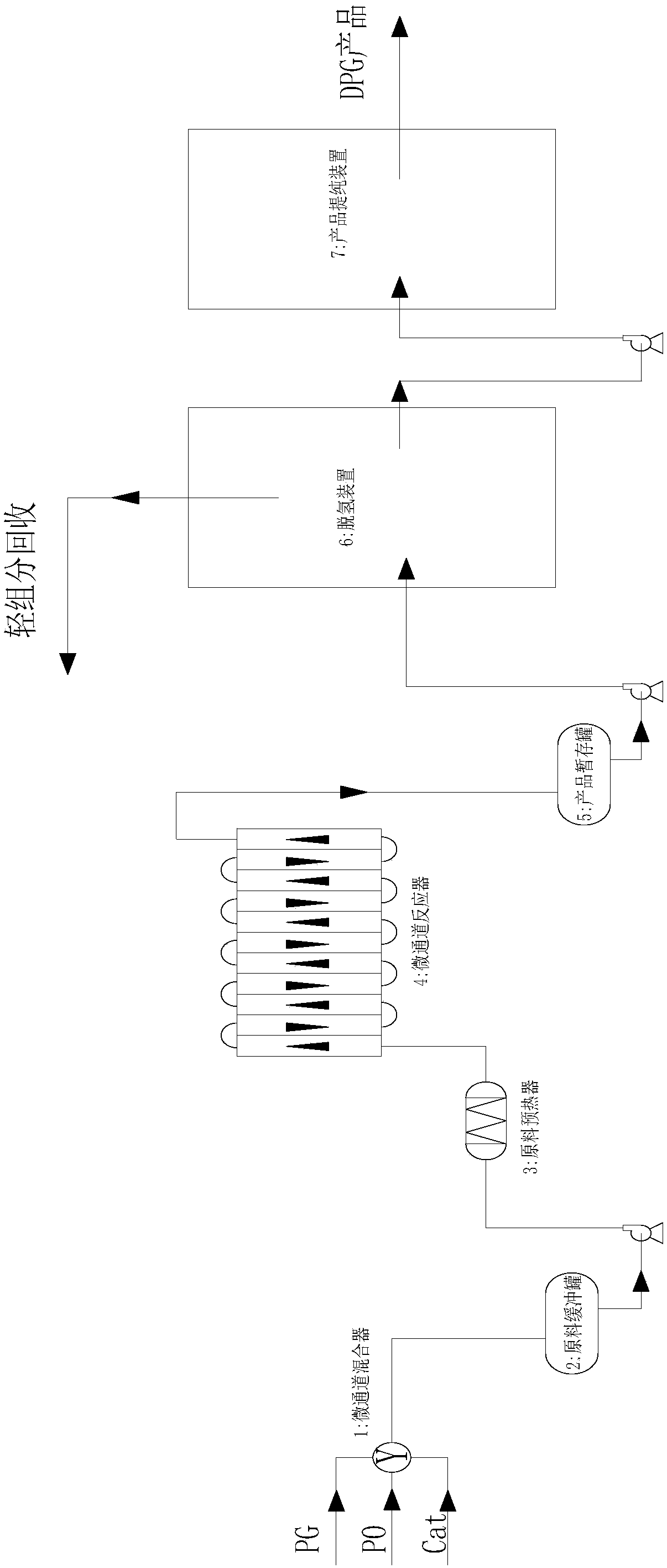

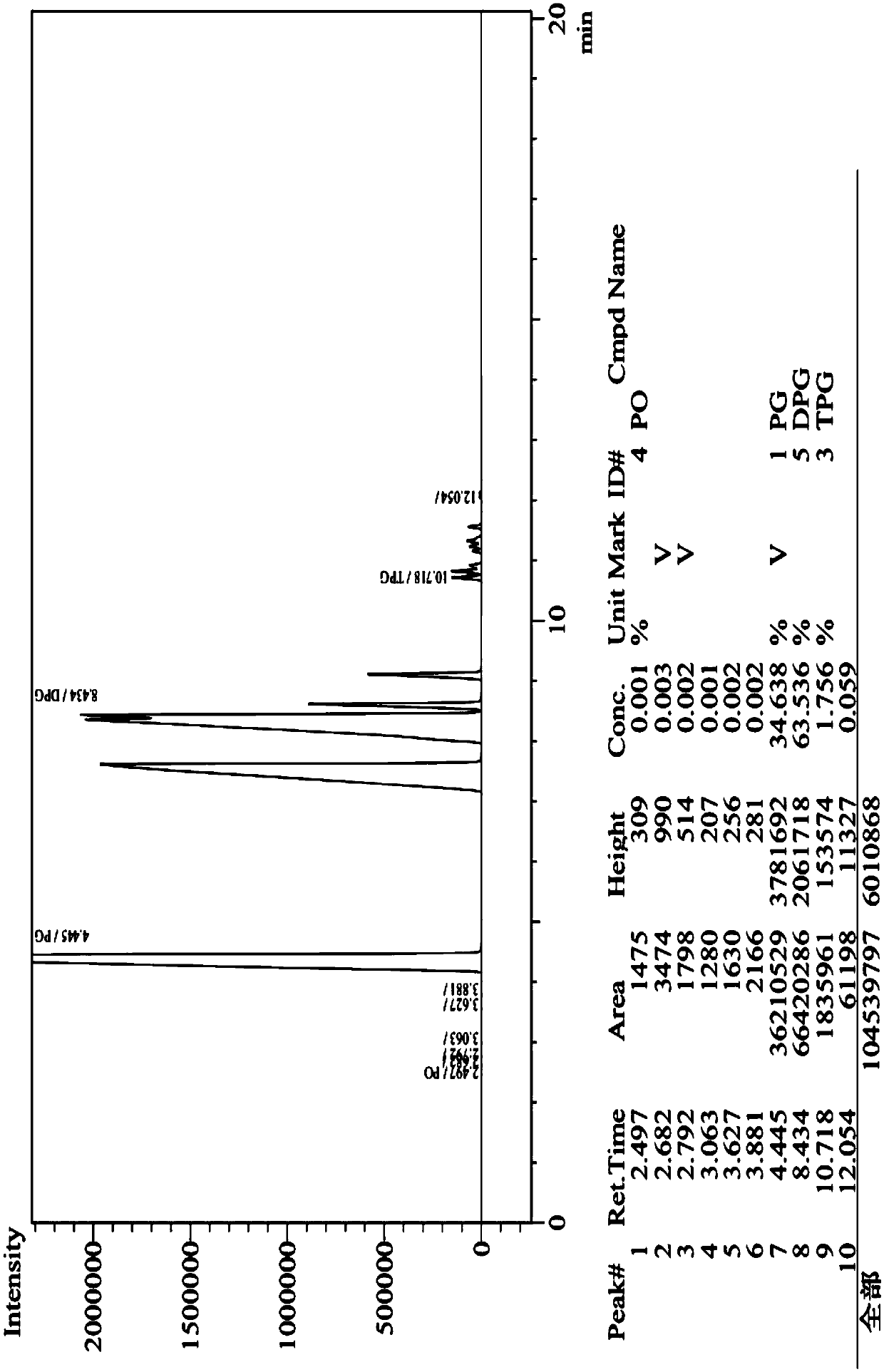

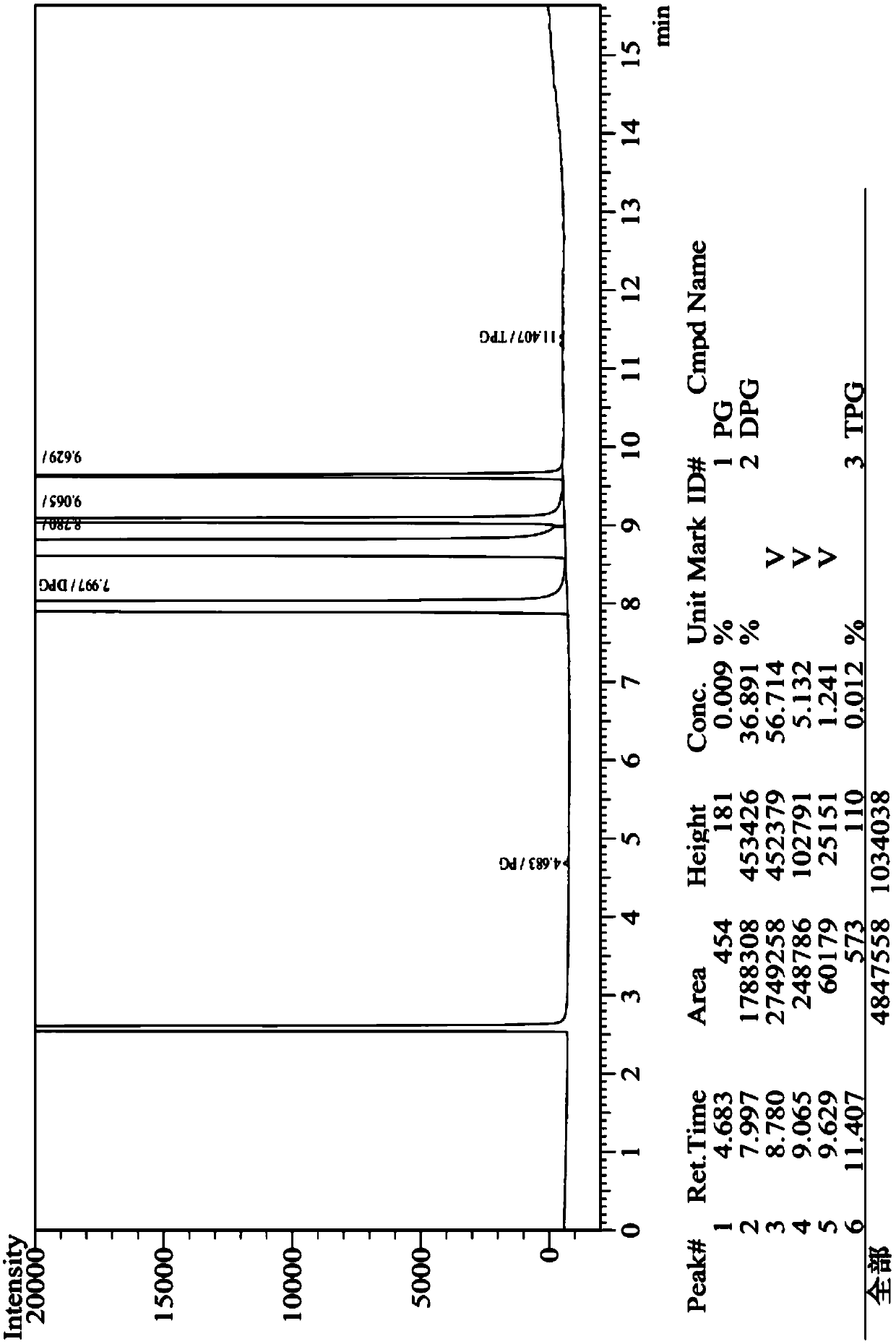

Method and system for high-selectivity preparation of dipropylene glycol

InactiveCN110655454AHigh selectivityHigh yieldEther separation/purificationEther preparation from oxiranesPropylene glycolMaterials science

The invention provides a dipropylene glycol preparation method, which comprises: mixing propylene oxide and propylene glycol to obtain a mixed raw material; and carrying out a condensation reaction onthe mixed raw material obtained in the previous step in a micro-channel reactor to obtain dipropylene glycol. According to the invention, based on the fluid mechanics of the reaction process, particularly the micro-channel reactor is used as the reaction place, and has the characteristic of low channel diameter, so that the raw material is in a laminar flow state in the channel so as to reduce the back-mixing phenomenon, avoid the chance of the contact of the dipropylene glycol and the raw materials 1,2-propylene glycol and propylene oxide, and reduce the occurrence of the cascade reaction, such that the selectivity of the dipropylene glycol in the product is effectively improved; and the preparation method can further effectively reduce the reaction time and improve the yield of the dipropylene glycol product, and is simple in process, mild in condition, easy to control and suitable for industrial mass production.

Owner:DONGYING HI TECH SPRING CHEM IND

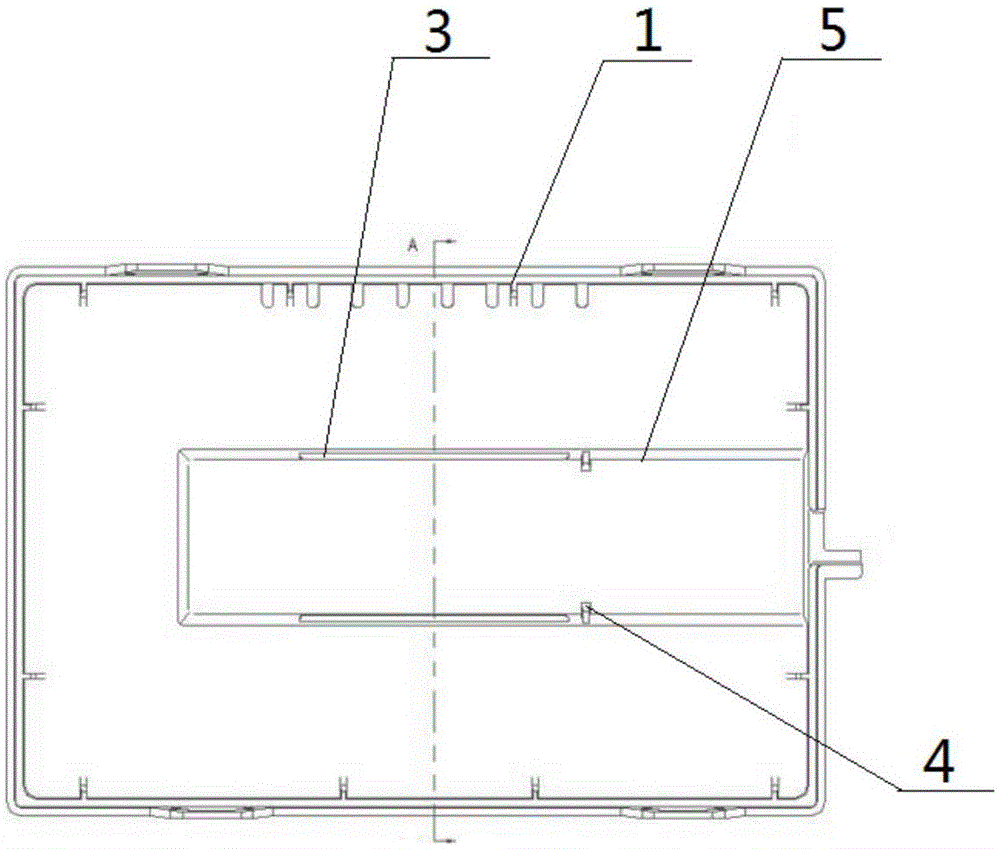

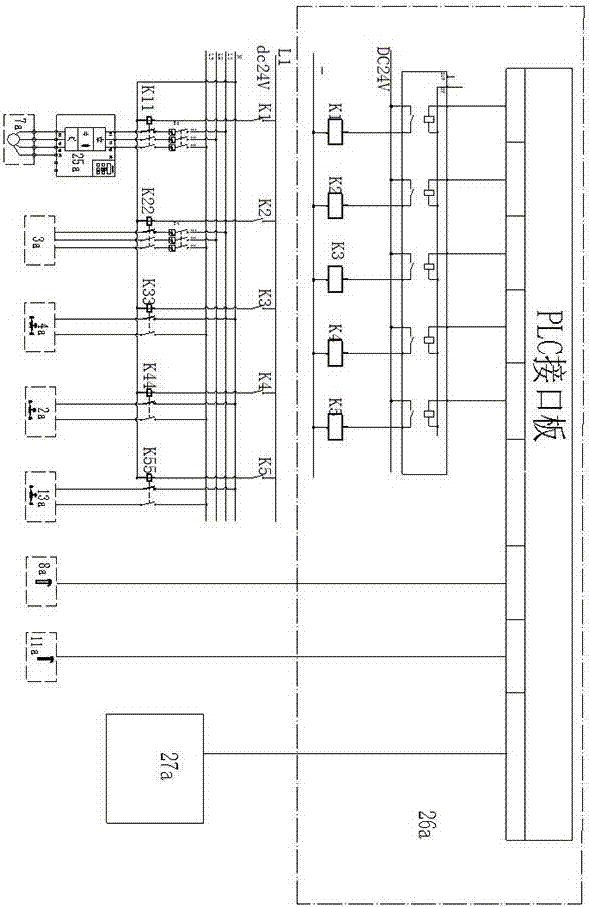

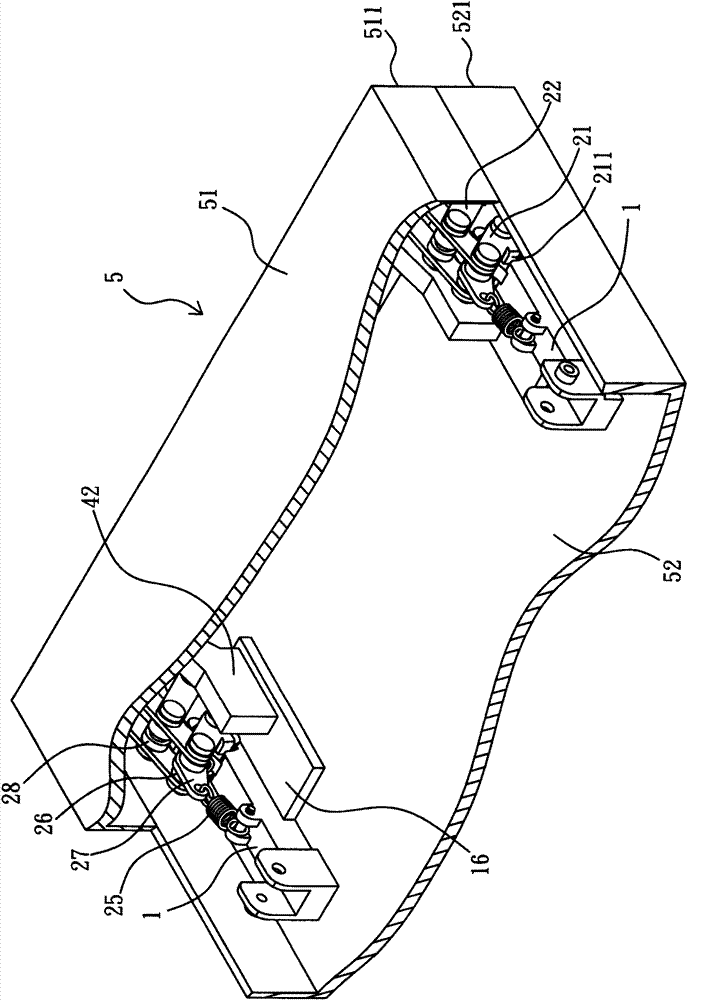

Power panel box and washing machine

InactiveCN106550590AReduce manufacturing costSmall structureMagnetic/electric field screeningOther washing machinesMetallic materialsElectrical and Electronics engineering

The invention discloses a power panel box and a washing machine and relates to the field of washing machines. The power panel box comprises a box body, wherein an accommodating cavity for placing a filter is arranged in the box body; and a limiting structure for limiting the position of the filter is arranged in the accommodating cavity. According to the power panel box and the washing machine disclosed by the invention, the filter is arranged in the power panel box and a sheet metal bracket and bolt structure for fixing the filter is omitted, so that the production cost of the whole washing machine is reduced, the manufacturing and installing processes are simplified and a product has higher market competitiveness. Meanwhile, the filter and a power panel are arranged in the power panel box, so that the contact opportunity of the filter and the power panel and a liquid is completely eradicated and a potential safety hazard is avoided; and on the other hand, the power panel box is made of a metal material, so that the flame retardant property is good and a plug terminal of the filter is safer.

Owner:QINGDAO HAIER DRUM WASHING MACHINE

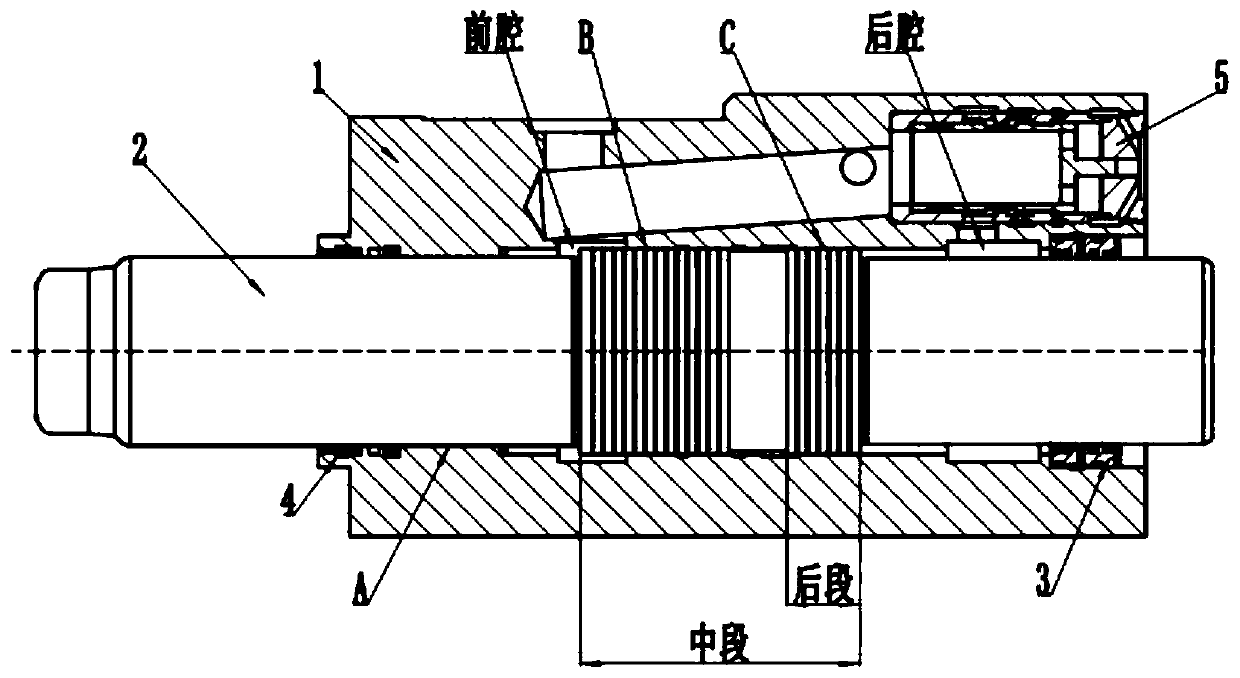

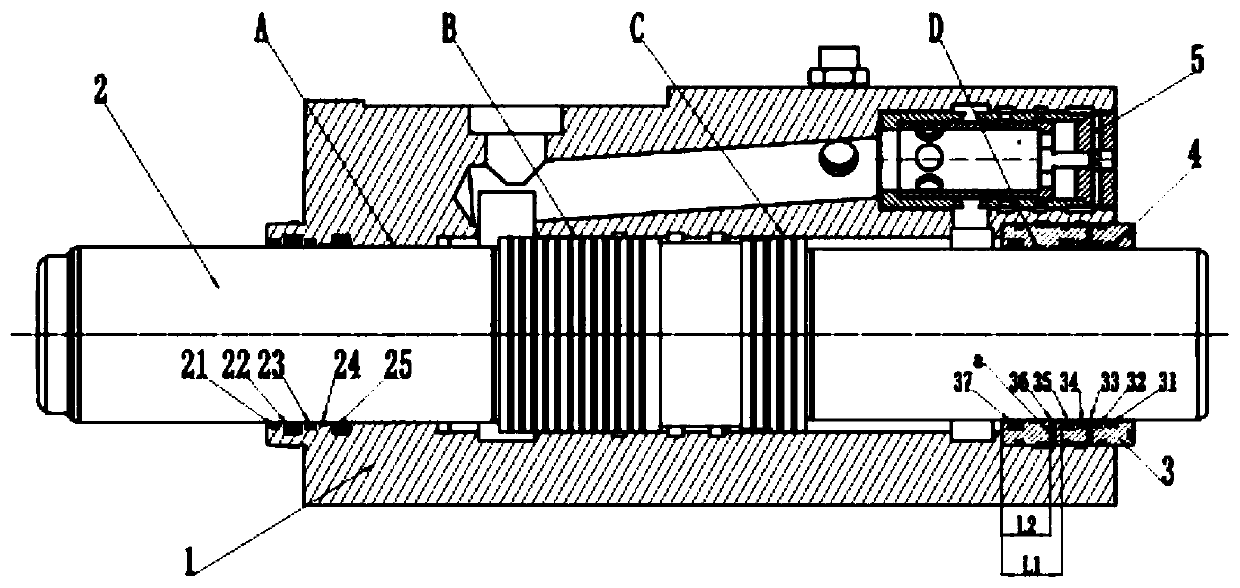

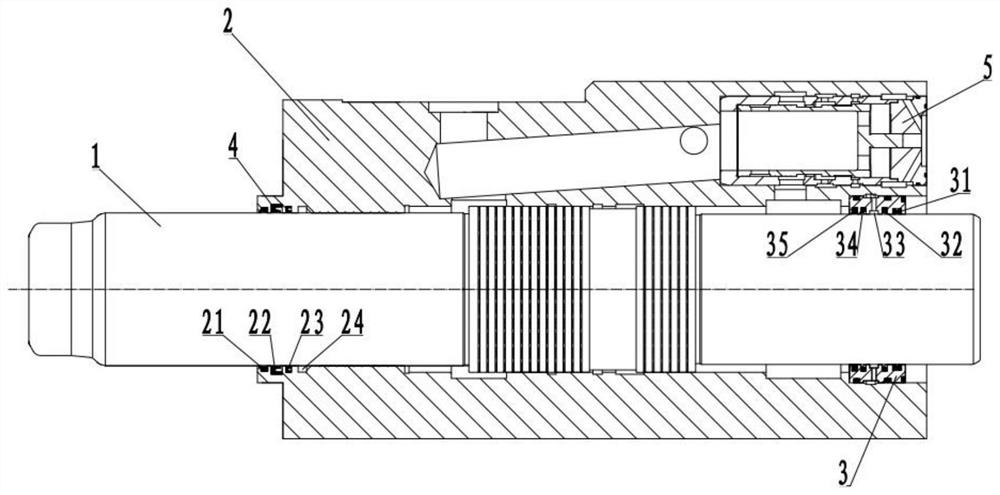

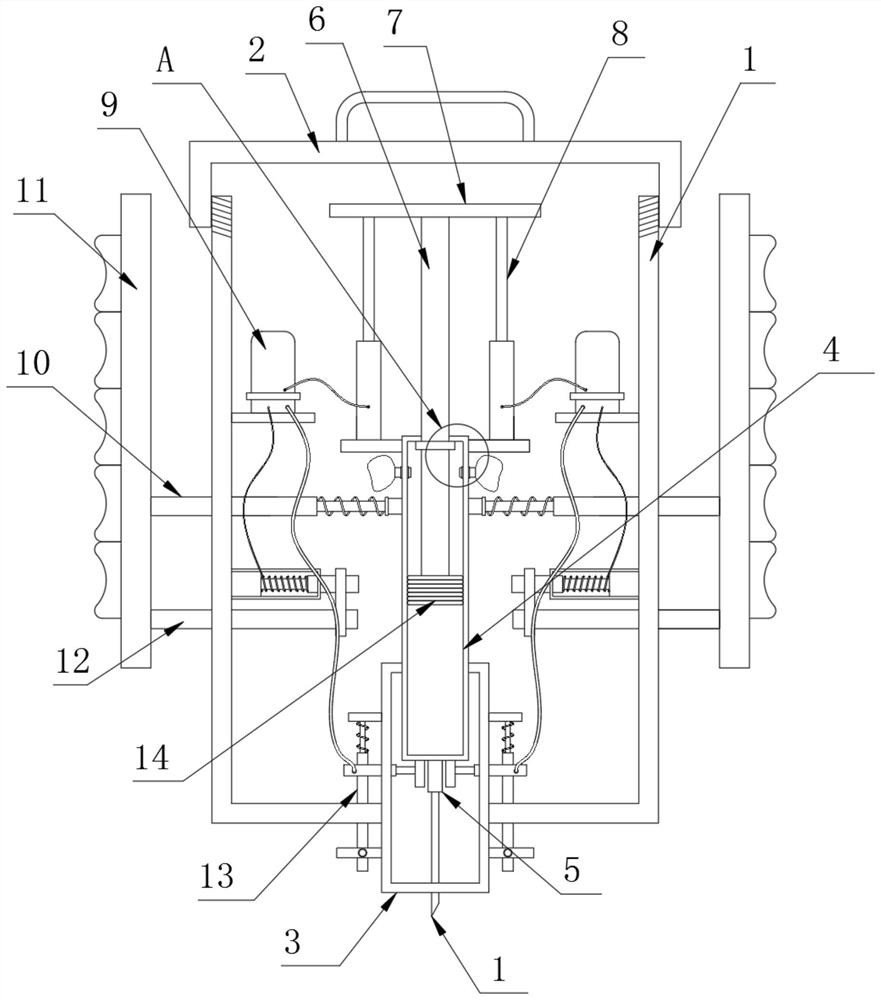

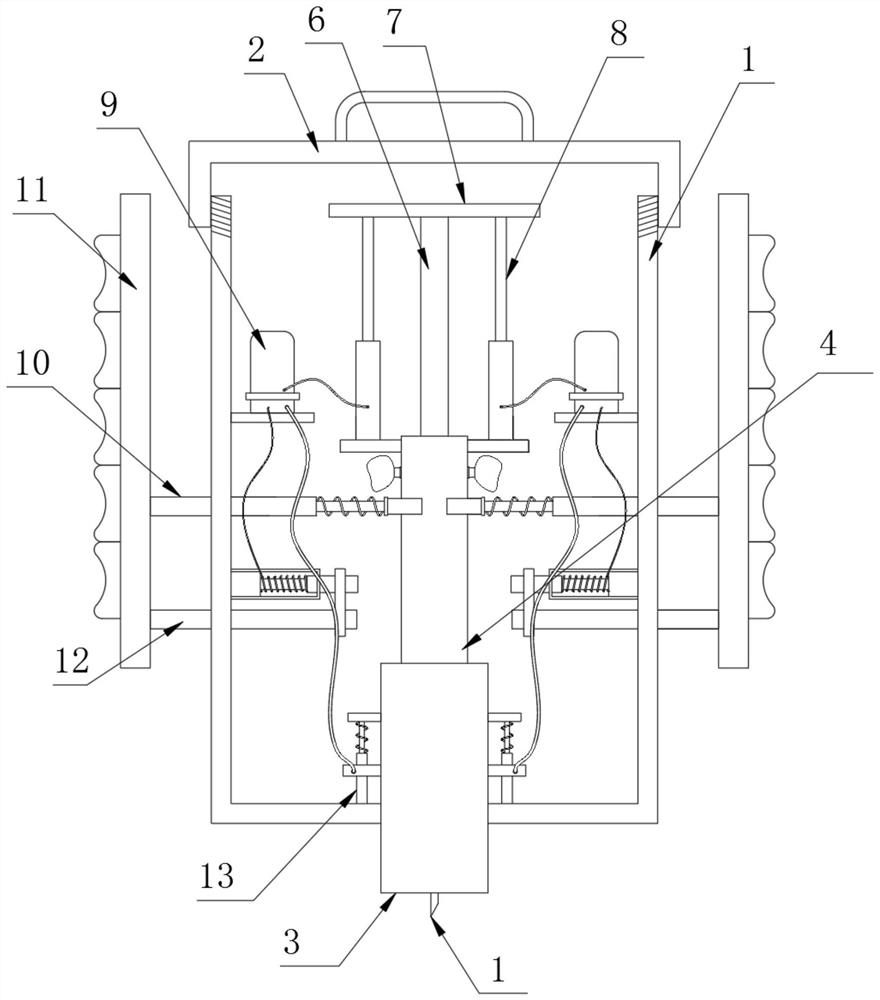

Hydraulic hammer cylinder part

PendingCN110067277AStable supportFit closelySoil-shifting machines/dredgersFluid-pressure actuatorsAxial compressionPiston ring

The invention discloses a hydraulic hammer cylinder part. The hydraulic hammer cylinder part comprises a cylinder body, a piston, a piston ring, sealing parts and a reversing valve. According to the hydraulic hammer cylinder part, a left side piston ring cylindrical section of a leftmost sealing part groove of a piston ring inner hole is lengthened by L1, meanwhile, an oil feeding groove is additionally formed in the lengthened part, and a gap sealing section D is formed on the left side of the oil feeding groove, or one or two sealing part grooves are additionally formed in the left side of the oil feeding groove; and in the working process, high-pressure oil is always introduced into the gap sealing section D or the added sealing part grooves, so that the sealing parts in the sealing part grooves are simultaneously subjected to axial compression force and radial compression force under the action of the high-pressure oil, the sealing parts in the grooves are more tightly matched witha to-be-sealed surface, the great supporting effect is achieved on a postmedian section in the piston, so that the severe loss caused by scoring of the piston and the inner hole due to contact of thepiston and the inner hole of the cylinder is effectively avoided.

Owner:MAANSHAN KAMET HYDRAULIC MASCH MFG CO LTD

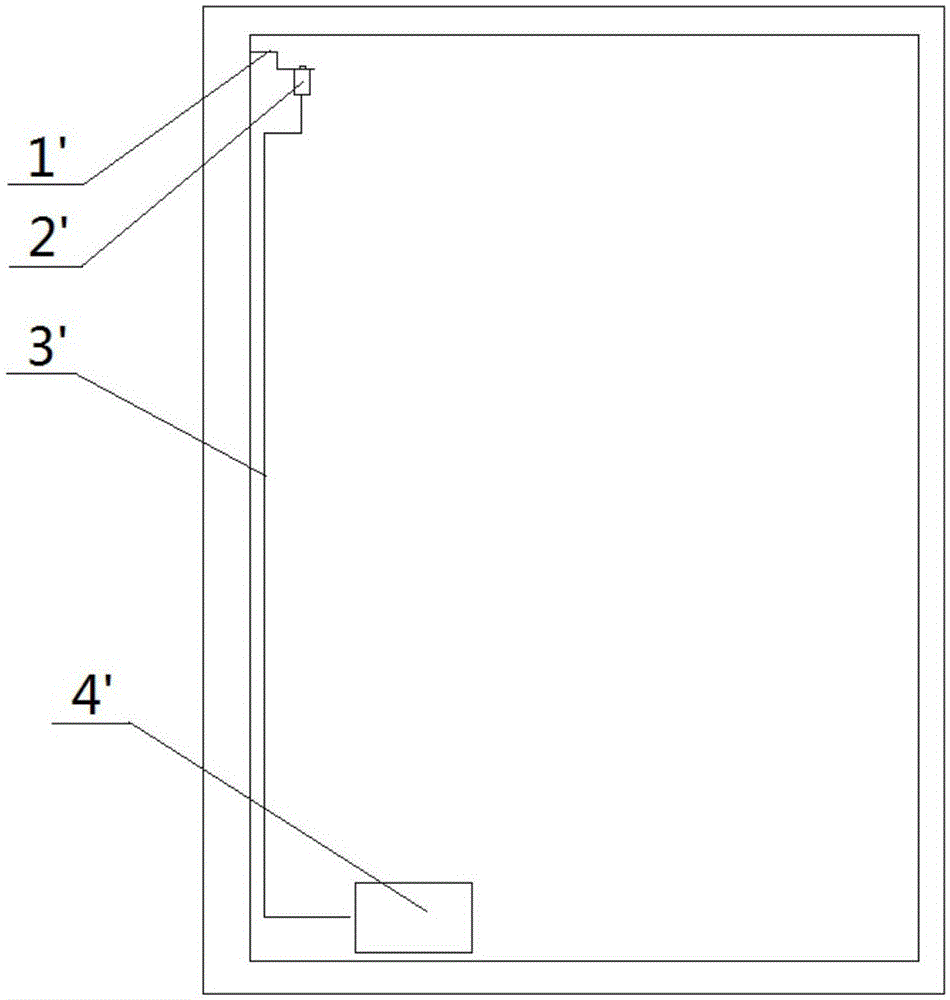

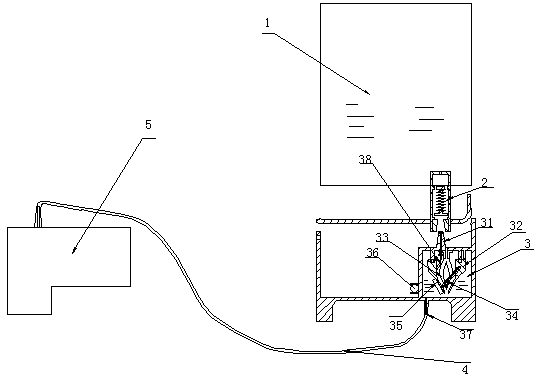

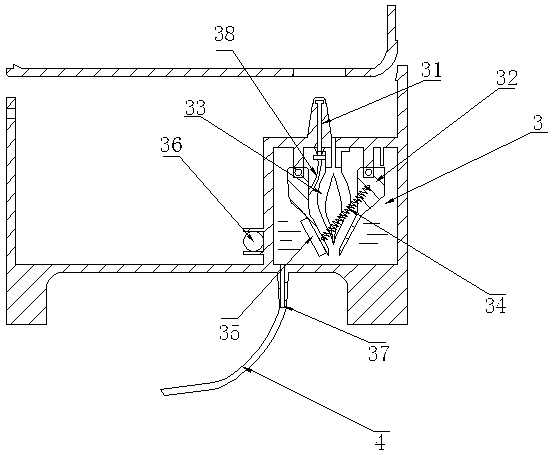

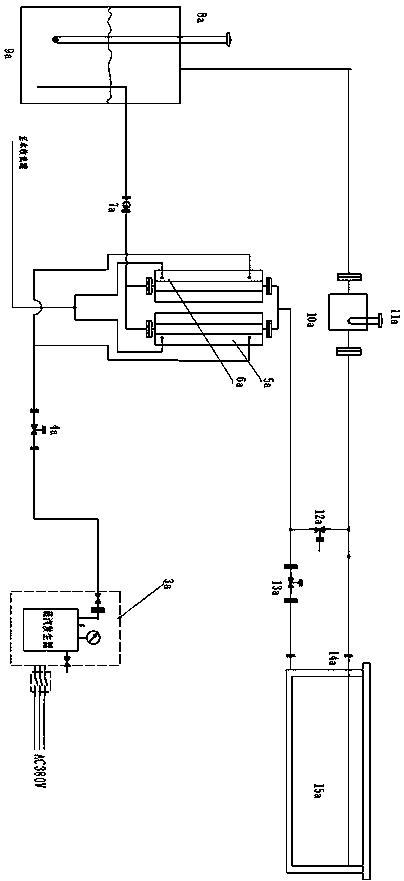

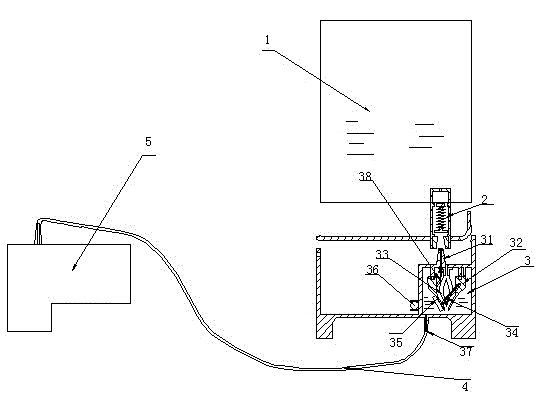

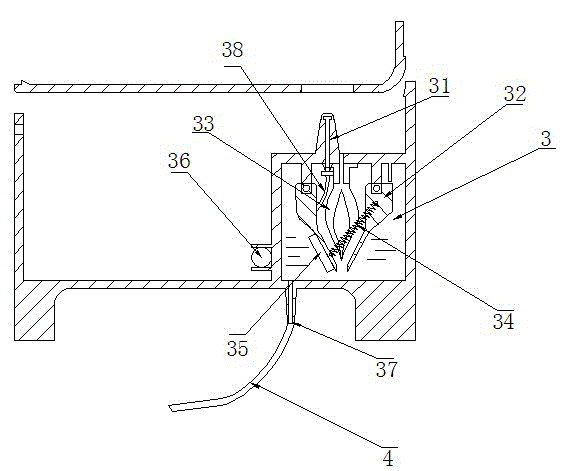

Built-in sealed continuous ink supply system with pressure dynamic compensation function

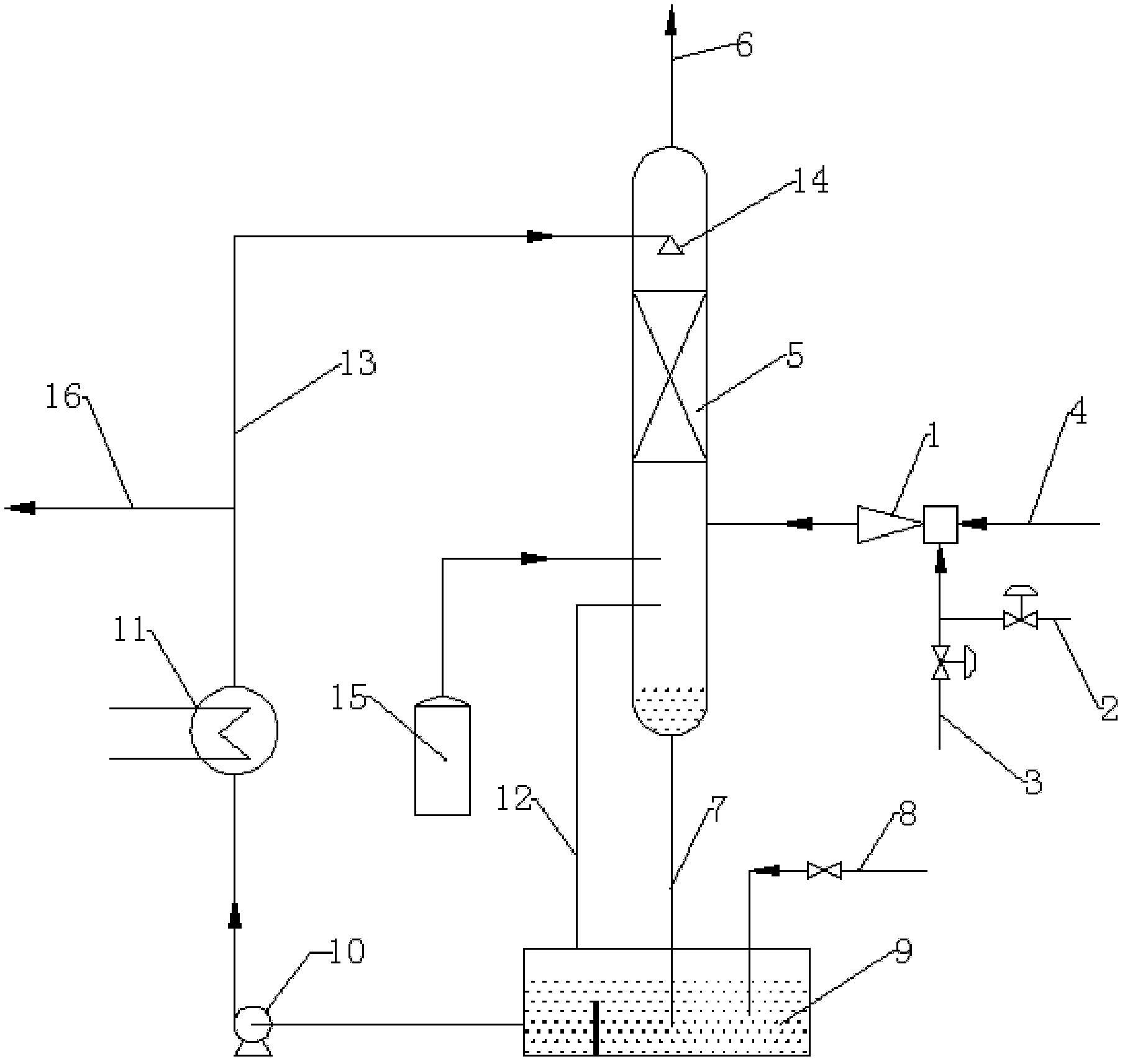

The invention relates to a built-in sealed continuous ink supply system with a pressure dynamic compensation function. The built-in sealed continuous ink supply system comprises an ink soft bag (1), a pressure dynamic compensation device and a printing head (5). The ink soft bag (1) is positioned above the pressure dynamic compensation device and is connected with an ink inlet (31) of the pressure dynamic compensation device by a soft bag connecting tube (2), an elastic air bag (33) is arranged in the pressure dynamic compensation device, an ink outlet (37) on the lower side of the pressure dynamic compensation device is connected with the printing head (5) by an ink supply tube (4), and the pressure dynamic compensation device is in a sealed state when ink is supplied by the ink inlet (31) and the ink outlet (37). The built-in sealed continuous ink supply system has the advantages that the ink is completely prevented from being in contact with external air, the probability of oxidation, evaporation and crystallization of the ink is reduced, and a phenomenon of head blockage is decreased; problems of air resistance, backflow, misting, overflow and the like can be effectively solved, and the built-in sealed continuous ink supply system is provided with a warning device with functions of ink deficiency voice prompting, corresponding indicator lamp prompting and the like.

Owner:抚州市新智铨科技有限公司

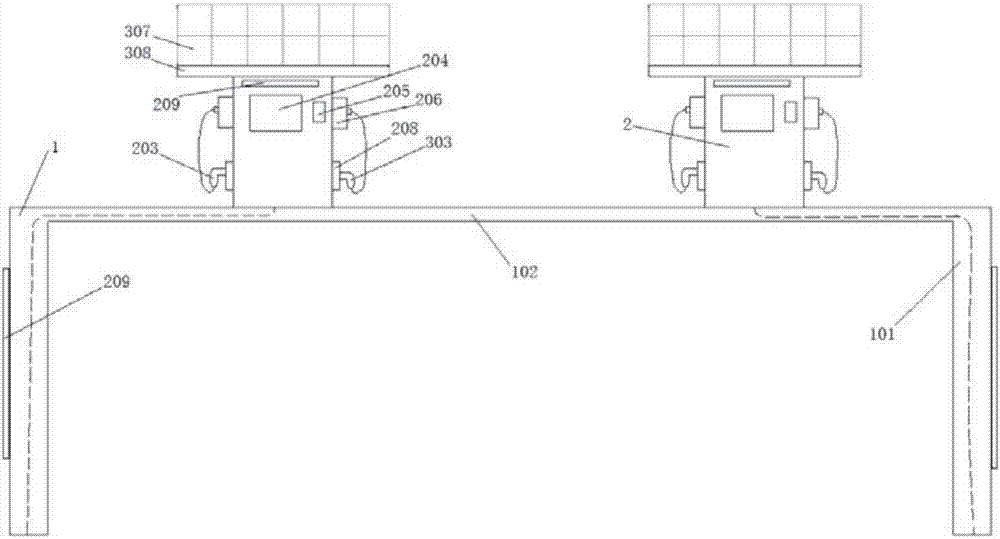

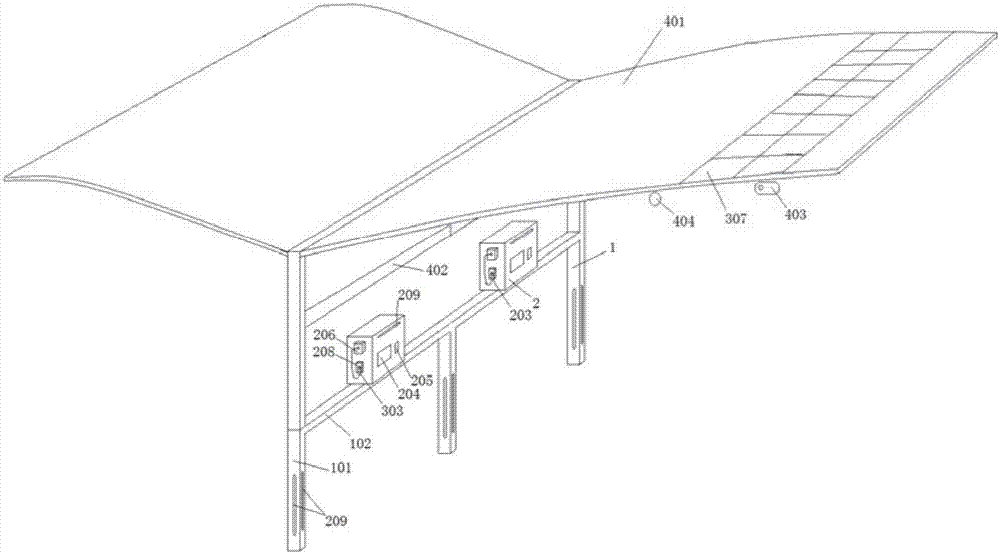

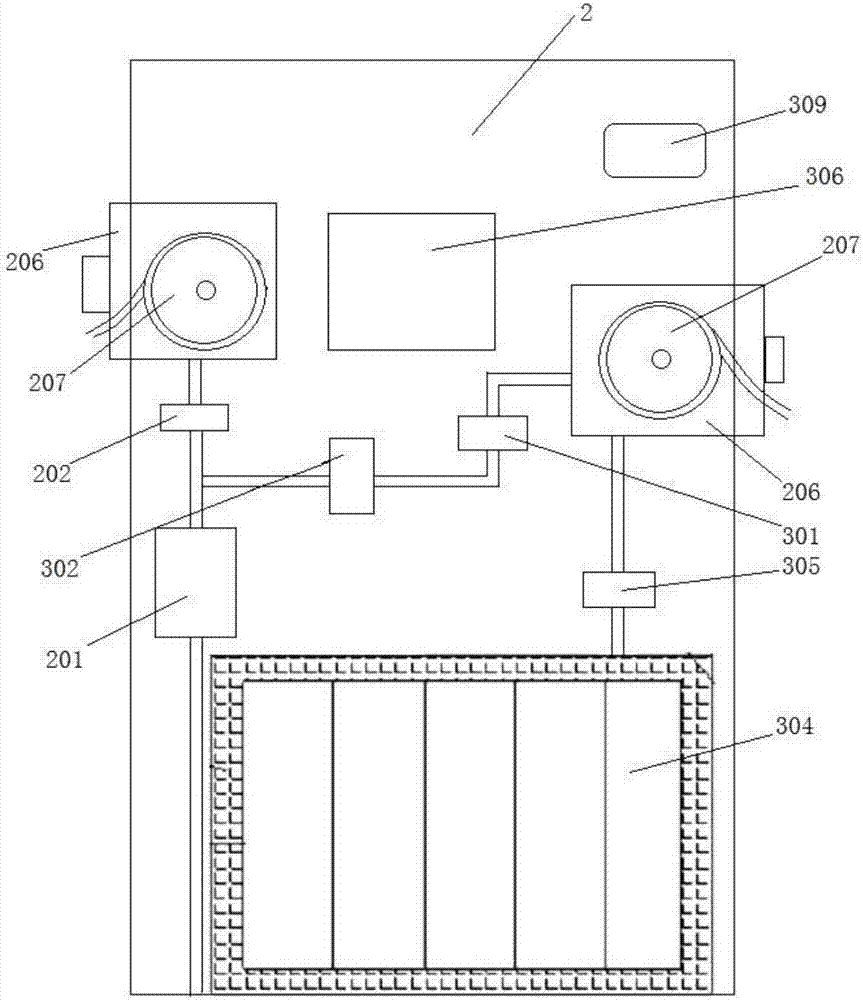

Non-floor type charging pile

PendingCN107128208ANovel structureSmall footprintCharging stationsSafety/protection battery circuitsDriver/operatorElectric vehicle

The invention provides a non-floor type charging pile. The non-floor type charging pile is characterized by comprising a gantry column, wherein the gantry column comprises two hollow support columns and a transverse beam; the transverse beam is used for communicating the two hollow support columns; a plurality of charging pile bodies are erected on the transverse beam; each charging pile body is a direct current charging pile, an alternating current charging pile or a direct current and alternating current integrated charging pile. The non-flooring type charging pile has the advantages that the structure is novel, the charging pile is disengaged from a floor, and the land occupation is small; the charging operation is performed at a height and position which can be conveniently operated by an adult and easily watched by a driver; a miniature automobile can safely pass through under the gantry column, so that the possibility of contact with children is avoided, the risk is avoided, and the utilization rate of a land area is greatly improved; an electric automobile can be charged by direct current or alternating current, and the electricity utilization requirements of different electric vehicles are met; by using a photovoltaic power generation assembly as an auxiliary power source, the all-weather and all-time charging operation can be realized, and the energy-saving and environment-friendly effects are truly realized.

Owner:ANHUI YI WEISS NEW ENERGY TECH

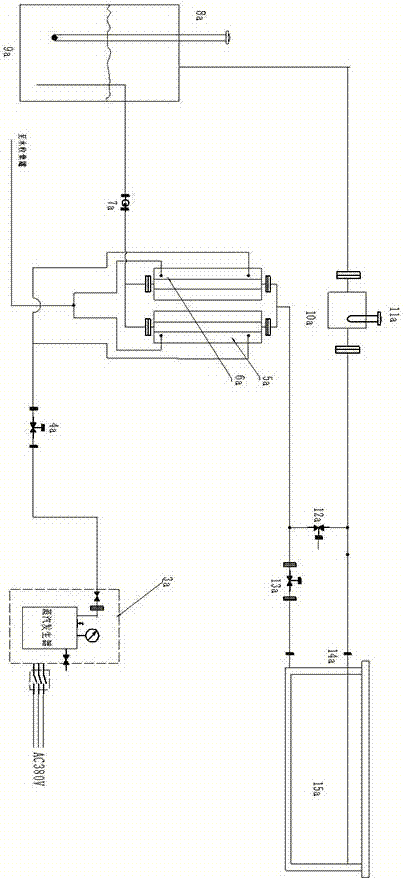

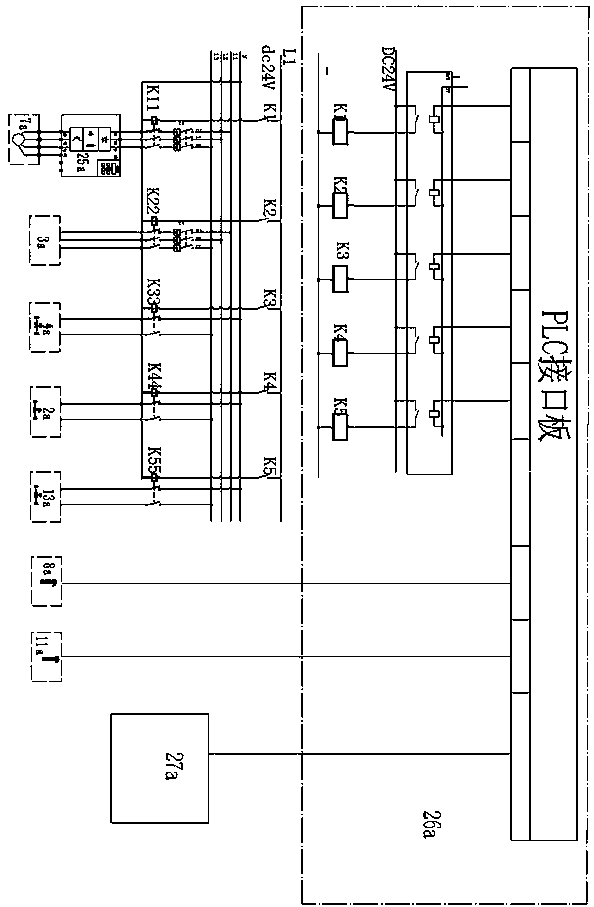

Low power test block semi-automatic pickling method

ActiveCN106978600AReduce labor intensityEliminate the chance of acid contactPreparing sample for investigationSemi automaticPower test

The invention belongs to the field of detection of metallographic low power test blocks, and particularly relates to a low power test block semi-automatic pickling method. The method comprises the following steps that firstly, acid liquid is preheated in an automatic pickling bath, and temperature and etching time are set; secondly, test blocks are put into the pickling bath according to the etching degrees; thirdly, the test blocks are subjected to automatic pickling is conducted according to the set temperature and time, after the set picking time is reached, the automatic pickling bath discharges acid automatically, a fan operates at a rated maximum rotation speed, and after acid mist in the bath disappears, a pickling bath cover is automatically opened for lifting-out operation on a pallet; fourthly, the test block pallet is lifted into a cleaning pool, and test block automatic cleaning is conducted by operating a cleaning trolley travelling button; and fifthly, the test block pallet is lifted out, enters a drying device with set drying temperature and reaches a detection zone until detection is completed. The low power test block semi-automatic pickling method is capable of relieving the labor intensity, ensuring the safety of operators and improving and increasing the surface quality of the test blocks after pickling.

Owner:HENAN ZHONGYUAN SPECIAL STEEL EQUIP MFG CO LTD

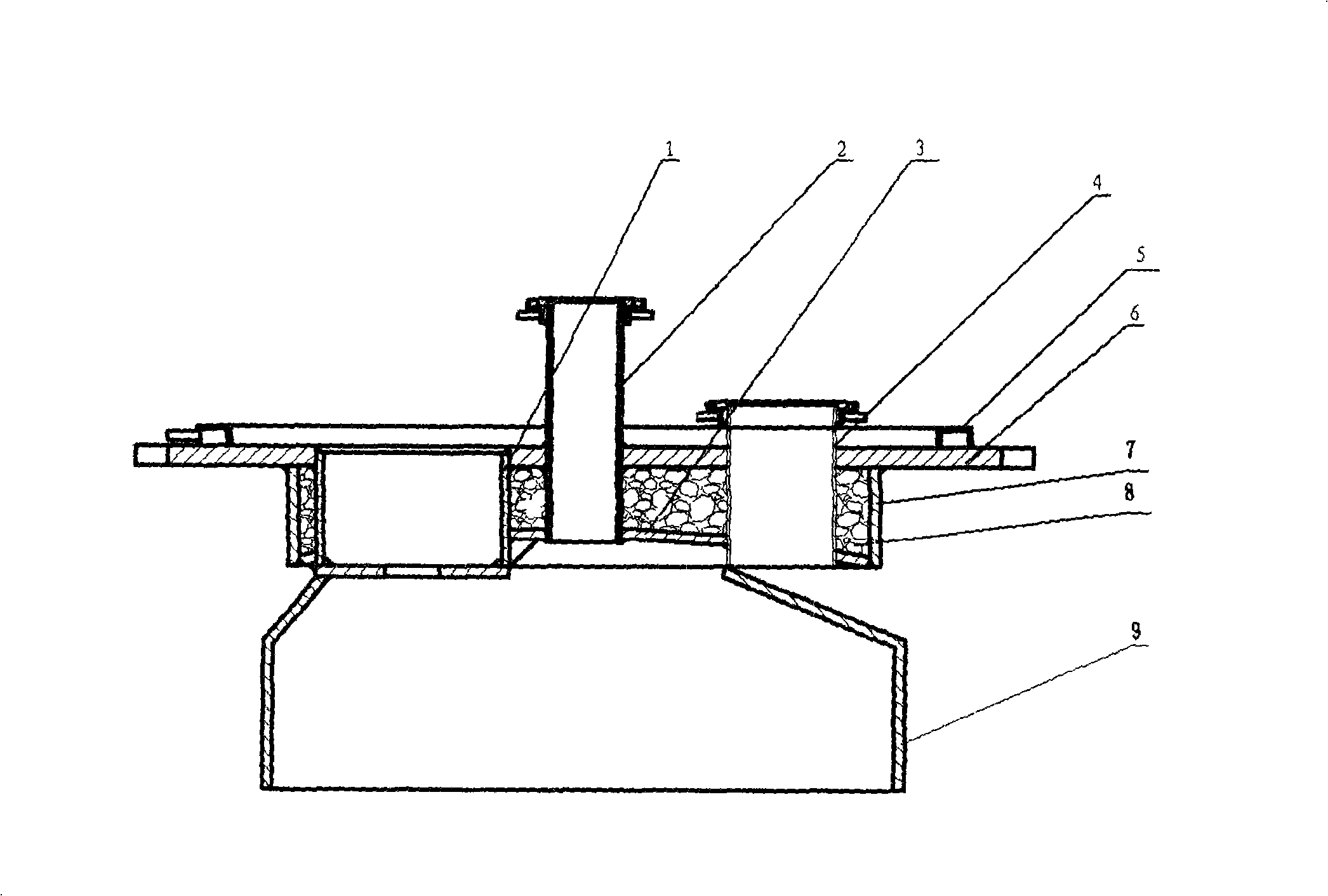

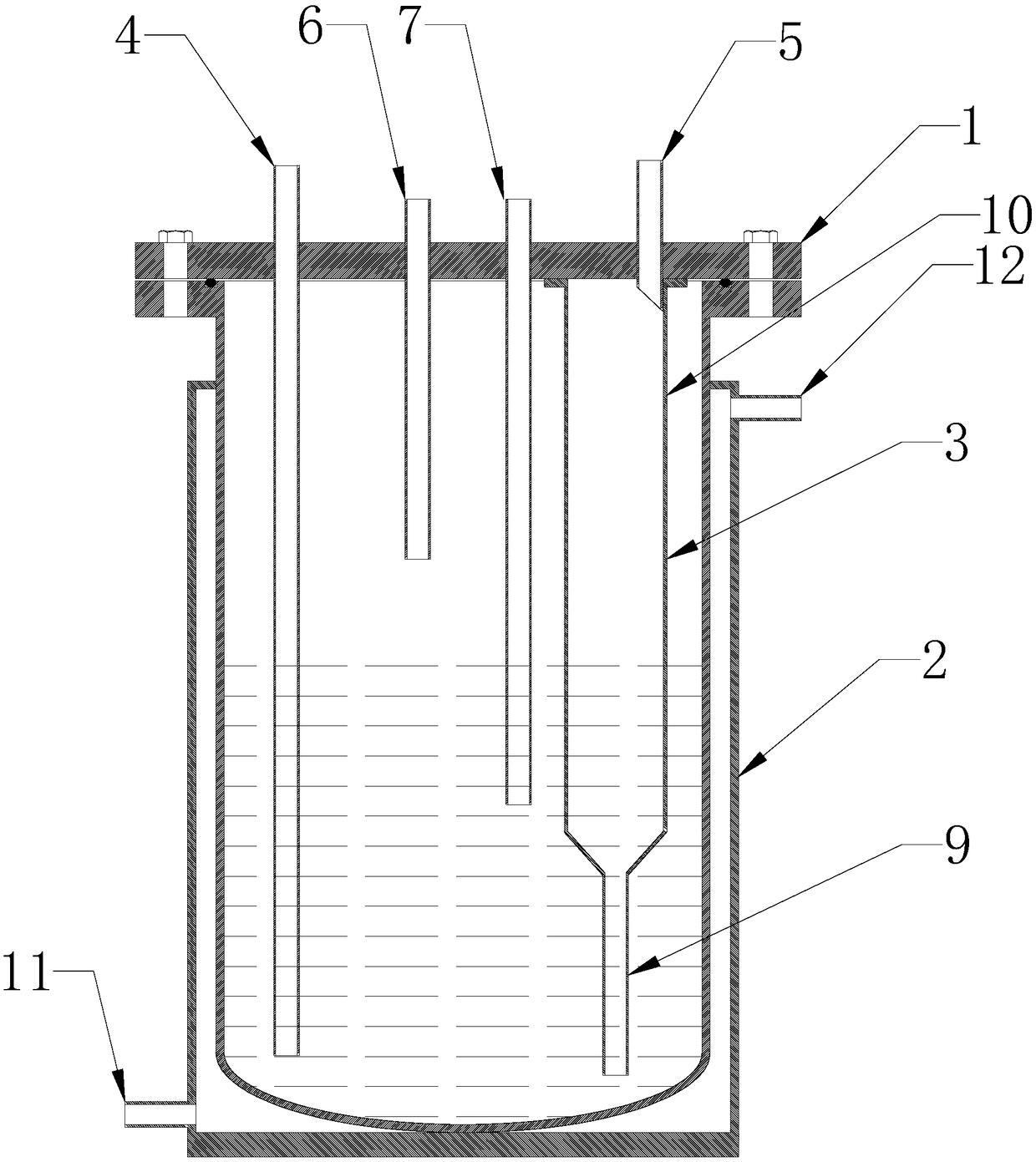

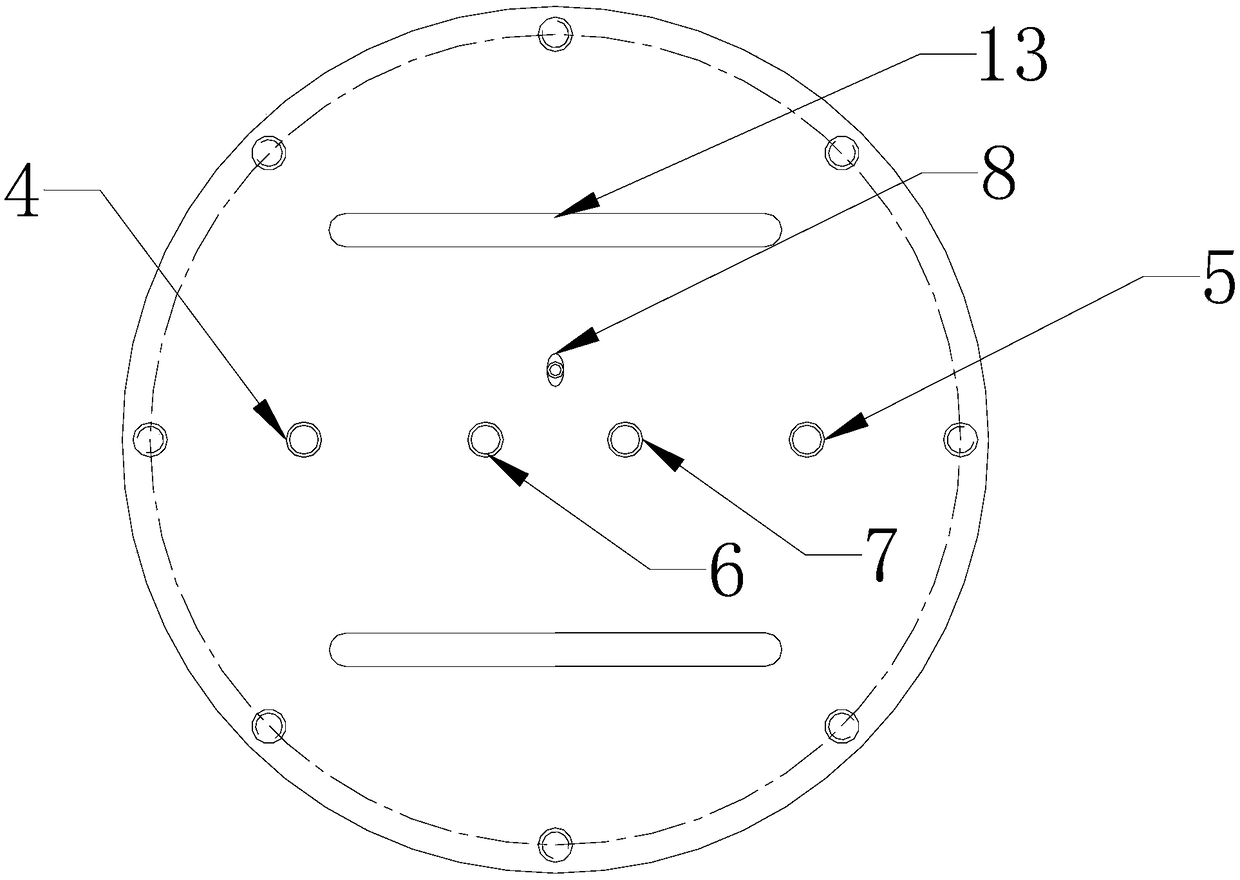

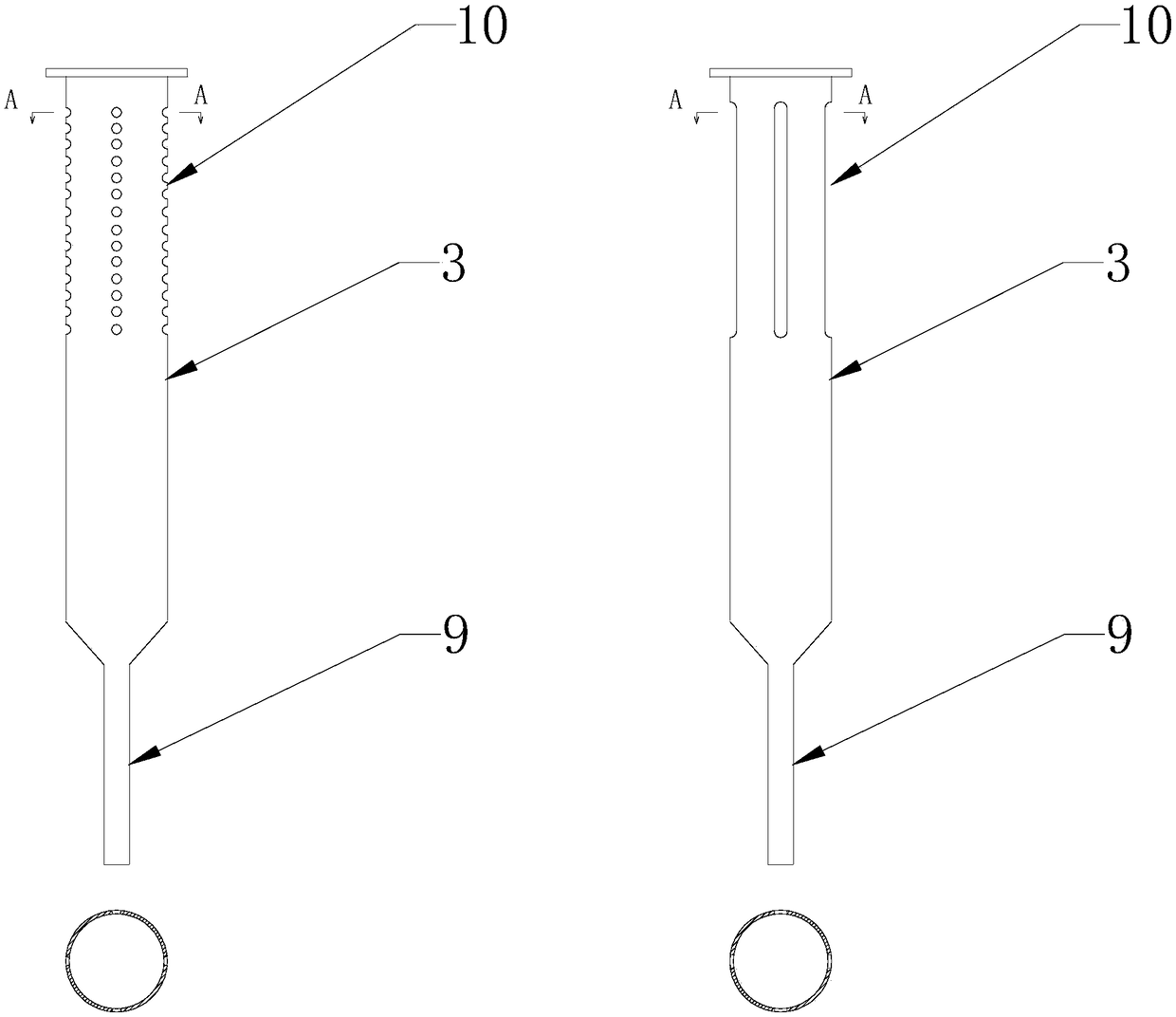

Furnace lid for manufacturing titanium sponge

The invention discloses a furnace cover for producing sponge titanium, which comprises a cylinder, a panel arranged on the cylinder, and a bottom plate under the cylinder, wherein, the furnace cover is provided with an aisle bushing, a feeder bushing and a vacuum pipeline bushing. The furnace cover is characterized in that: a sleeve is arranged below the bottom plate of the furnace cover to ensure that the aisle bushing and the feeder bushing are arranged inside the sleeve, the vacuum pipeline bushing is positioned outside the sleeve, the bottom plate of the furnace cover is of an upward vaulted spherical shape, and a heat insulating material, namely sayla cotton containing zirconium is filled in a cavity enclosed by the panel, the bottom plate and the cylinder. The furnace cover can effectively prevent distilled materials from being directly pumped by a vacuum unit, and does not affect the production of reduction reaction at the same time; the vaulted bottom plate has large anti-deformation ability, which solves the problems of furnace cover deformation, threatening weld craters, short service life and so on. The furnace cover has universal interchange function, avoids distillates from contacting the air to be polluted, and assures the steady operation of the production.

Owner:CITIC JINZHOU METAL

Reactor cap for manufacturing titanium sponge

The invention provides a cover of a reactor used for producing sponge titanium. The cover comprises a barrel, a panel arranged on the upper part of the barrel, a bottom plate arranged on the lower part of the barrel; and a channel sleeve, a feeder sleeve and a vacuum piping sleeve are arranged on the cover of the reactor. The cover is characterized in that a cavity enclosed by the panel, the bottom plate and the barrel is filled with a heat insulating material-serra cotton containing zirconium, the bottom plate of the cover of the reactor is arched spherical, a sleeve barrel is arranged below the bottom plate of the reactor cover, the channel sleeve and the feeder sleeve are arranged inside the sleeve barrel, the vacuum piping sleeve is arranged outside the sleeve barrel. The reactor cover has the advantages of simple structure, easy manufacturing, light weight, safety and reliability and hard deformation, and can effectively avoid distilled materials from being directly pumped out by a vacuumizer and simultaneously does not affect the completion of the reduction reaction. The reactor cover has the functions of universal interchangeability, and can ensure the normal operation of production, and the product quality is not threatened, so that the main equipment problem of producing the sponge titanium by the combined method is radically solved.

Owner:CITIC JINZHOU METAL

Optical fiber coating paint tank

PendingCN108975257AStable supplyReduce air bubble contentLiquid transferring devicesWater jacketLiquid level sensor

The invention discloses an optical fiber coating paint tank. The optical fiber coating paint tank comprises a paint tank main container and a water jacket container, wherein the paint tank main container is embedded inside the water jacket container, the upper end surface of the paint tank main container is provided with a paint tank handle, and the paint tank main container is sequentially provided with a liquid inlet, a low-level sensor mouthpiece, a compressed air joint and a liquid outlet; the lower end of the liquid inlet is provided with a buffer pipe, the lower end of the buffer pipe isprovided with a guide pipe, and the upper end of the buffer pipe is provided with a breathing port; the upper end surface of the paint tank main container I also provided with the compressed air joint. The optical fiber coating paint tank can avoid being influenced by external paint feeding speed and guide paint to flow into the paint tank main container along the inner and outer walls of the buffer pipe to avoid bubbles due to impact of fluid dropping onto liquid surface; meanwhile, the optical fiber coating paint tank can achieve release of tiny bubbles inside the paint during a flow guiding process to ensure stable paint supply and reduce bubble content.

Owner:PNC PROCESS SYSTEMS CO LTD

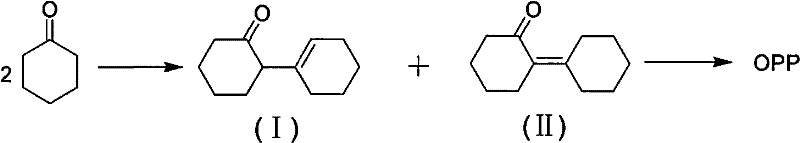

Synthetic method and synthetic device of propyl propionate

PendingCN110483283AHigh selectivityReasonable structureOrganic compound preparationCarboxylic acid esters preparationPropionatePropanoic acid

The invention provides a synthetic device of propyl propionate, which comprises a catalytic reaction rectifying tower, a first condenser, a n-propyl alcohol feeding hole, a propionic acid feeding hole, a fractionating tower, a second condenser, a phase splitter, a reboiler, a purification tower, a third condenser and a propyl propionate collection tank. The invention further provides a method forsynthesizing propyl propionate through the device. The synthesis device is reasonable in structure and convenient to use, wherein water in a product can be moved away from the reaction section in time by adopting a catalytic reaction rectification technology, so that the reaction is facilitated to move towards the direction of forming propyl propionate; meanwhile, a reaction product is separatedthrough a stripping section at the lower part, so that the chance of further contact with the catalyst is avoided, and the selectivity of propyl propionate is improved. According to the invention, theprocess from reaction to product refining can be continuously carried out, the production efficiency is high, the propyl propionate selectivity is high, and industrial production is facilitated.

Owner:许兆石

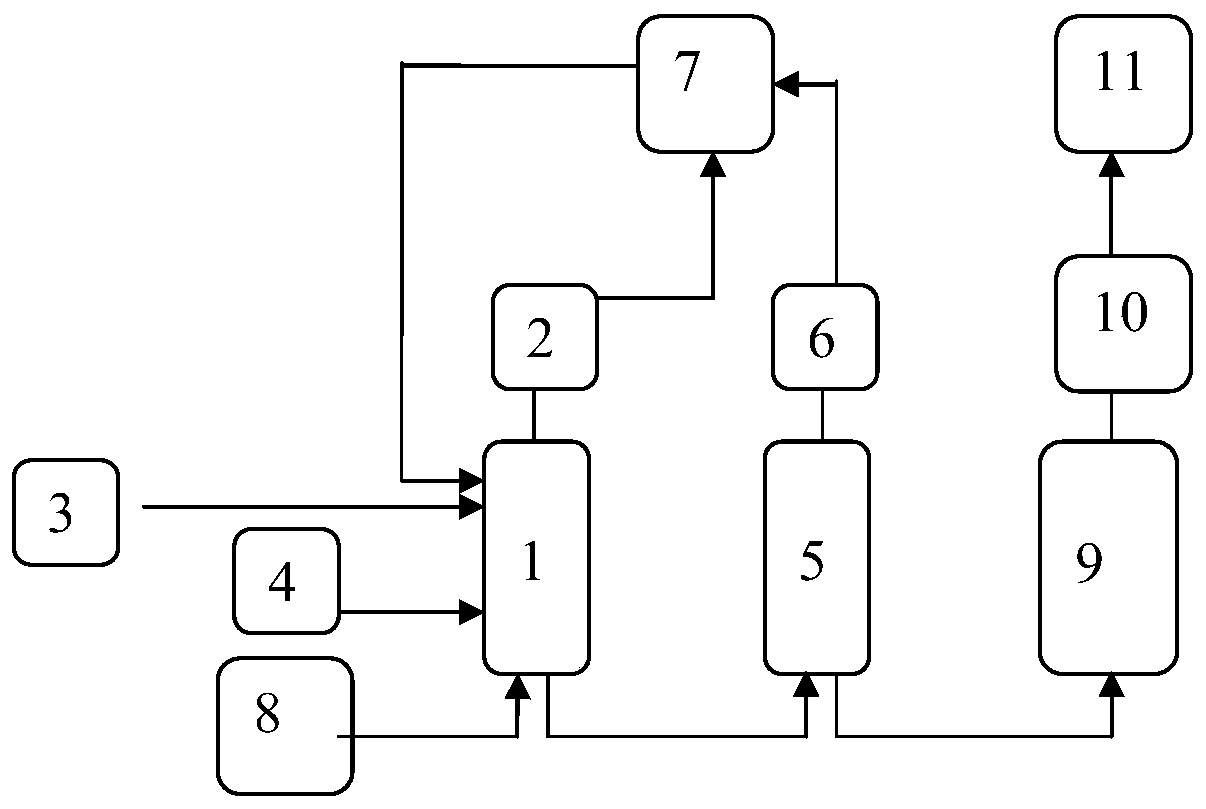

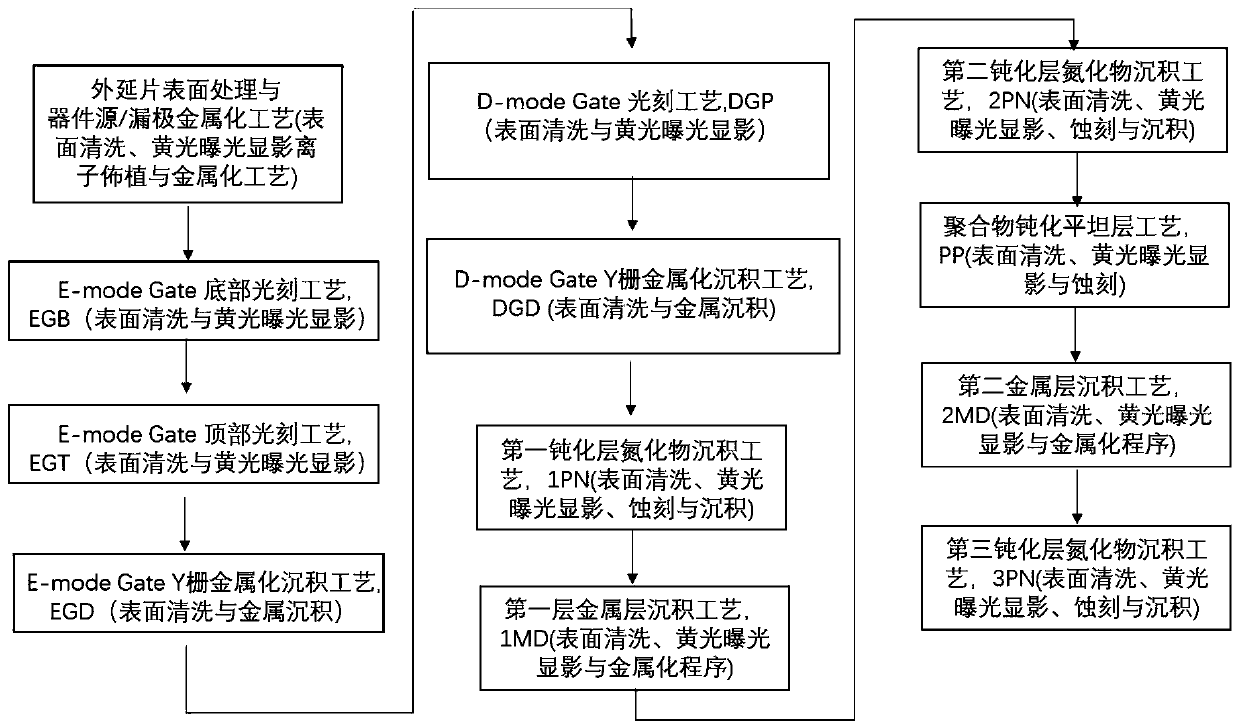

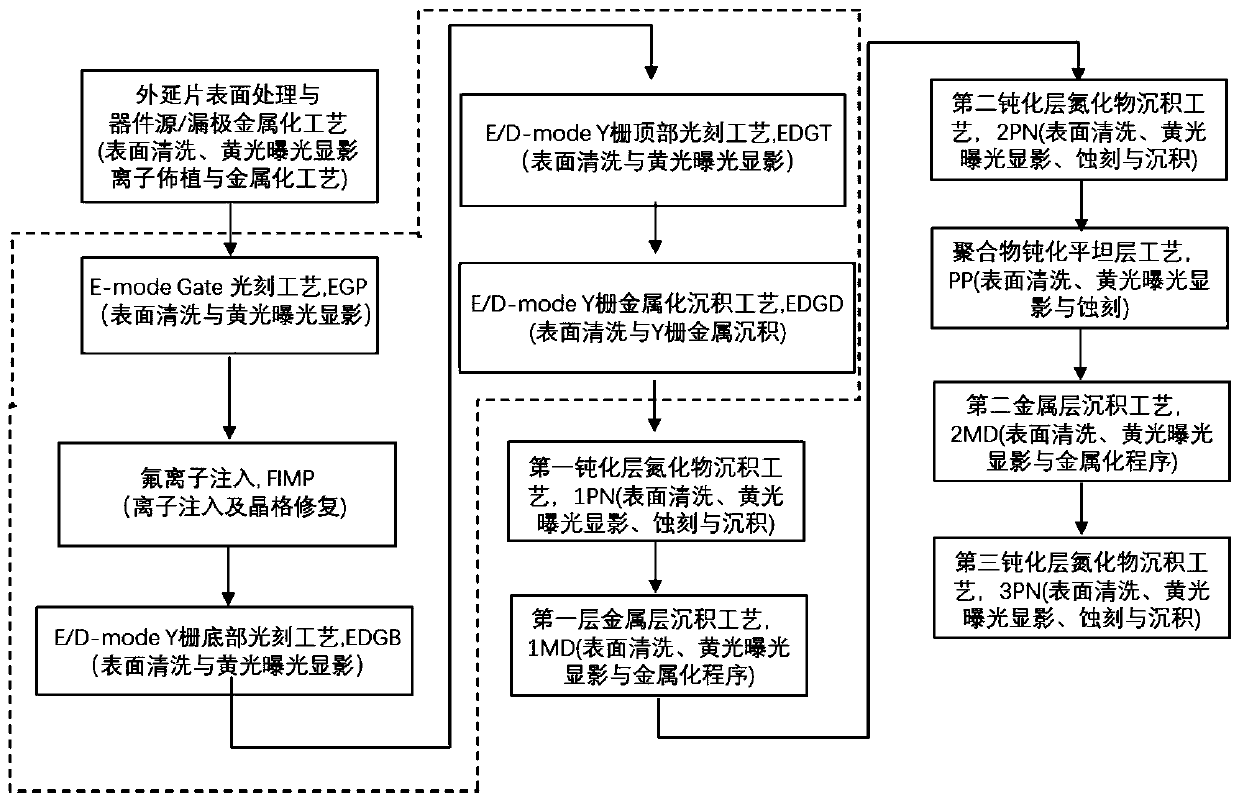

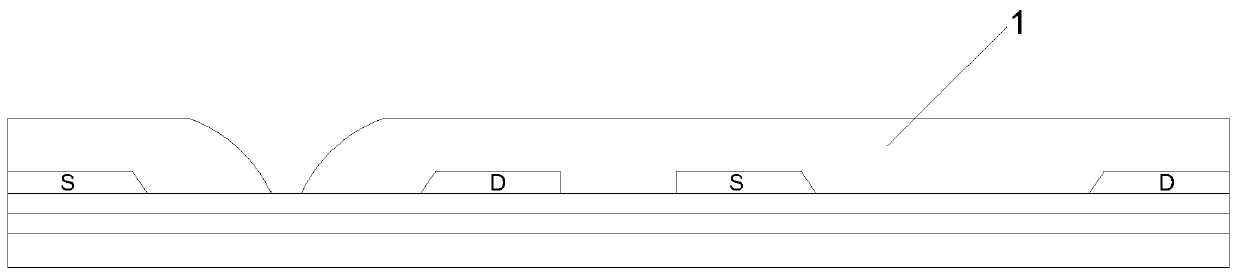

Method for simultaneously preparing enhanced and depletion gate devices and device

InactiveCN110112131AAvoid contact opportunitiesAvoid timeTransistorSolid-state devicesPhotoresistIon implantation

The invention discloses a method for simultaneously preparing enhanced and depletion gate devices and a device. The method comprises the following steps: a source metal and a drain metal are preparedon an epitaxial wafer; a first photoresist is coated and an opening is arranged on the gate bottom of the enhanced device; fluoride ion injection and heat treatment are performed on the bottom of theenhanced device to repair the lattice; the first photoresist is removed, a second photoresist is coated and an opening of which the upper part is wide and the lower part is narrow is arranged on the enhanced gate bottom and the depletion gate bottom; a third photoresist is coated and an opening of which the upper part is narrow and the lower part is wide is arranged on the enhanced gate bottom andthe depletion gate bottom; metal deposition is performed so that the metal is deposited on the enhanced gate bottom and the depletion gate bottom to form the enhanced gate metal and the depletion gate metal; and the second photoresist and the third photoresist are removed. The metal evaporation process of the enhanced gate and the depletion gate is simultaneously performed so as to reduce the primary metal evaporation, save the cost and improve the performance.

Owner:福建省福联集成电路有限公司

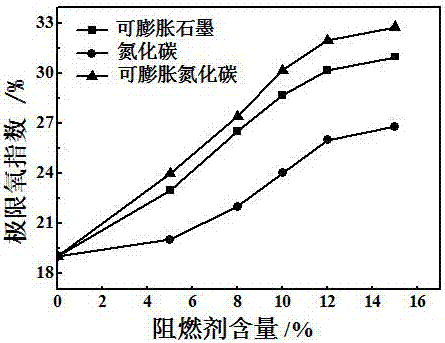

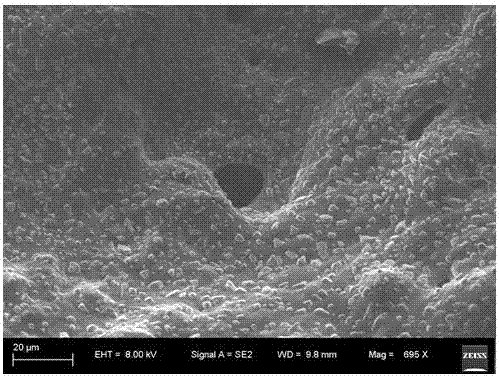

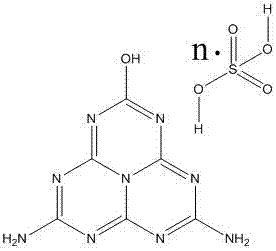

Preparation method of expandable carbon nitride flame retardant epoxy resin

The invention discloses a preparation method of expandable carbon nitride flame retardant epoxy resin, which relates to the flame retardant technical field of flame retardant epoxy resin system. The expandable carbon nitride is used as the flame retardant, the epoxy resin is used as the matrix, and the curing agent is used for curing. Synergistic preparation of flame retardant epoxy resin composites. The limiting oxygen index and scanning electron microscope analysis methods are used for testing and characterization. Compared with expandable graphite, expandable carbon nitride has better compatibility. After thermal expansion, a denser carbon layer is formed, which can be well developed To heat insulation and oxygen insulation, delay or inhibit the combustion of the system. The invention successfully prepares a new generation of high-performance flame-retardant material that is halogen-free, highly efficient, non-toxic and low-smoke.

Owner:YANGZHOU UNIV

Preparation method of electronic grade propylene glycol monomethyl ether and product obtained by preparation method

ActiveCN111807934AAvoid contact opportunitiesReduce generationEther separation/purificationOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystMonomethyl ether

The invention discloses a preparation method of electronic grade propylene glycol monomethyl ether and a product obtained by the preparation method, and belongs to the technical field of preparation of fine chemicals. The method comprises the following steps of: 1) mixing methanol, propylene oxide and a basic ionic liquid catalyst, and carrying out reaction in a micro-channel reactor to obtain a reaction solution; 2) removing light components from the reaction solution to obtain a light component removed reaction solution; and 3) evaporating the light component removed reaction solution obtained in step 2), and performing negative pressure rectification on the obtained steam to obtain the electronic grade propylene glycol monomethyl ether. The preparation method of the electronic grade propylene glycol monomethyl ether provided by the invention are mild in reaction conditions, the purity of the prepared product is high, the yield is high, and the activity and selectivity of the catalyst are high.

Owner:HAIKE GRP RES INST OF INNOVATION & TECH

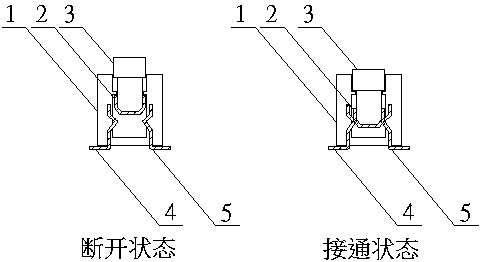

Physical disconnection network switch

InactiveCN109698811AReduce contact timeEliminate contact opportunitiesSubstation remote connection/disconnectionContact timeInput/output

The invention relates to a physical disconnection network switch. The physical disconnection network switch comprises the following parts: a network signal input / output interface, a signal interruption switching structure and a interruption control switch; the interruption switching structure capable of being controlled by the switch is added in the electronic device network signal connection line, when network connection is not needed, a user can conveniently connect network signals of the electronic device through the interruption control switch, thorough physical disconnection is conducted,and information safety of the electronic device is guaranteed. The network signal connection is disconnected in a physical mode, the basic conditions of hacker infringement and network virus damage are cut off, effective isolation of network intrusion and virus propagation is achieved, the contact time of the electronic device and the network signal is shortened, and the opportunity exposed in front of network harmful information is reduced.

Owner:钟志刚

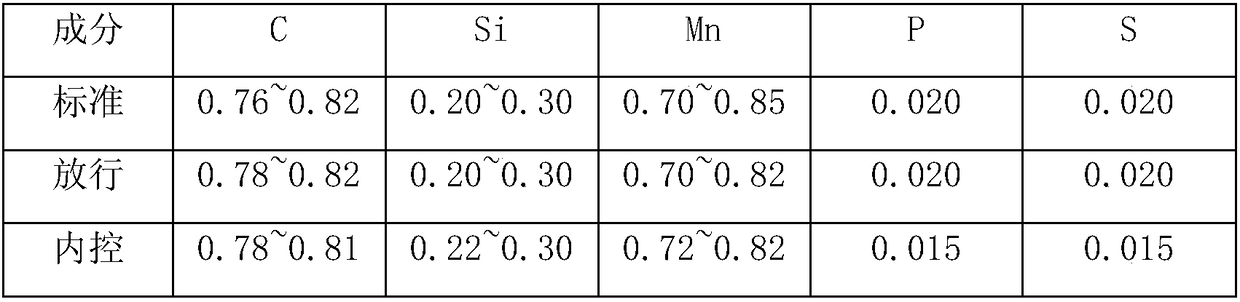

Nitrogen control technology for stranded wire steel series steel grade

InactiveCN108913844AReduce nitrogen contentOpportunity to avoid contactProcess efficiency improvementLow nitrogenSmelting process

The invention provides a nitrogen control technology for a stranded wire steel series steel grade. The technology comprises the working procedures of selection of low-nitrogen accessories for smelting, LF furnace port positive pressure operation, LF submerged arc refining, continues casting protection casting and steelmaking full-process argon blowing, and the nitrogen content in steel is controlled to be 60ppm or below; and the nitrogen content in the accessories does not exceed 40ppm. The nitrogen increasing phenomenon in the smelting process is effectively restrained, the TiN content in thesteel is sharply decreased, and therefore production of the low-nitrogen steel grade with the nitrogen content being 60ppm or below is achieved.

Owner:BENGANG STEEL PLATES +1

Sample dilution tube and sampling kit using same

PendingCN114459819AMaintain an anaerobic environmentImprove the efficiency of isolation and cultureWithdrawing sample devicesPreparing sample for investigationPhysicsSample dilution

The invention provides a sample dilution tube and a sampling kit using the same. The sample dilution tube comprises: a tube body; the sealing piston is sleeved on the inner side of the pipe body in a free sliding manner; the sealing cover covers the upper part of the tube body, and a sample introduction channel is formed on the sealing cover; wherein a diluent space is defined by the tube body, the sealing piston and the sealing cover, and when a sample is squeezed into diluent from the sample injection channel, the sealing piston can automatically slide to increase the volume of the diluent space. The opportunity that the sample and the diluent are in contact with the outside air is minimized, the anaerobic environment is kept, and the separation culture efficiency of anaerobic and facultative anaerobic microorganisms in the excrement sample is improved.

Owner:ACADEMY OF MILITARY MEDICAL SCI +1

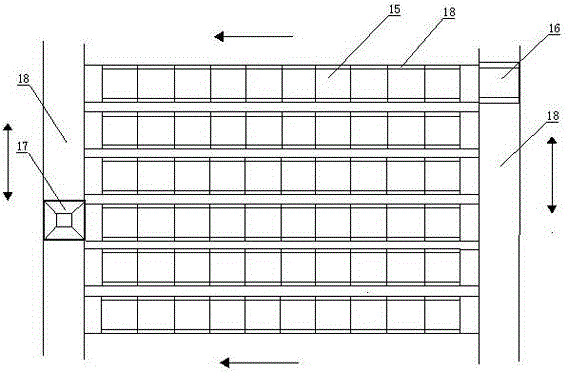

A method for automatic typesetting of plywood laminates

InactiveCN108214731BAvoid contact opportunitiesKeep healthyWood veneer joiningSingle plateMechanical engineering

The invention discloses a plywood laminate automatic composing method. A composing procedure of a single laminate layout unit is set at a control module first, coordinate positioning of a composing working plane is initialized, and the composing procedure of the single laminate layout unit is started. According to the composing procedure of the single laminate layout unit, a positioning dischargemechanism picks a raw material veneer of specified specifications in a raw material holding area. The positioning discharge mechanism moves the picked raw material veneer onto an induction panel of ameasuring and calculating mechanism, the induction panel conducts image acquisition, and the length and width of the raw material veneer and the position of the center point of a sucker are calculated. The relative position of the center point of the sucker during discharge of the raw material veneer is calculated, and the raw material veneer is moved to the relative position in a to-be-composed area. Through the plywood laminate automatic composing method, veneers of different specifications can be arranged into an appropriate laminate layout automatically according to laminate arranging requirements, and the characteristics of automatic composing, little labor investment and low production cost are achieved.

Owner:WUZHOU UNIV

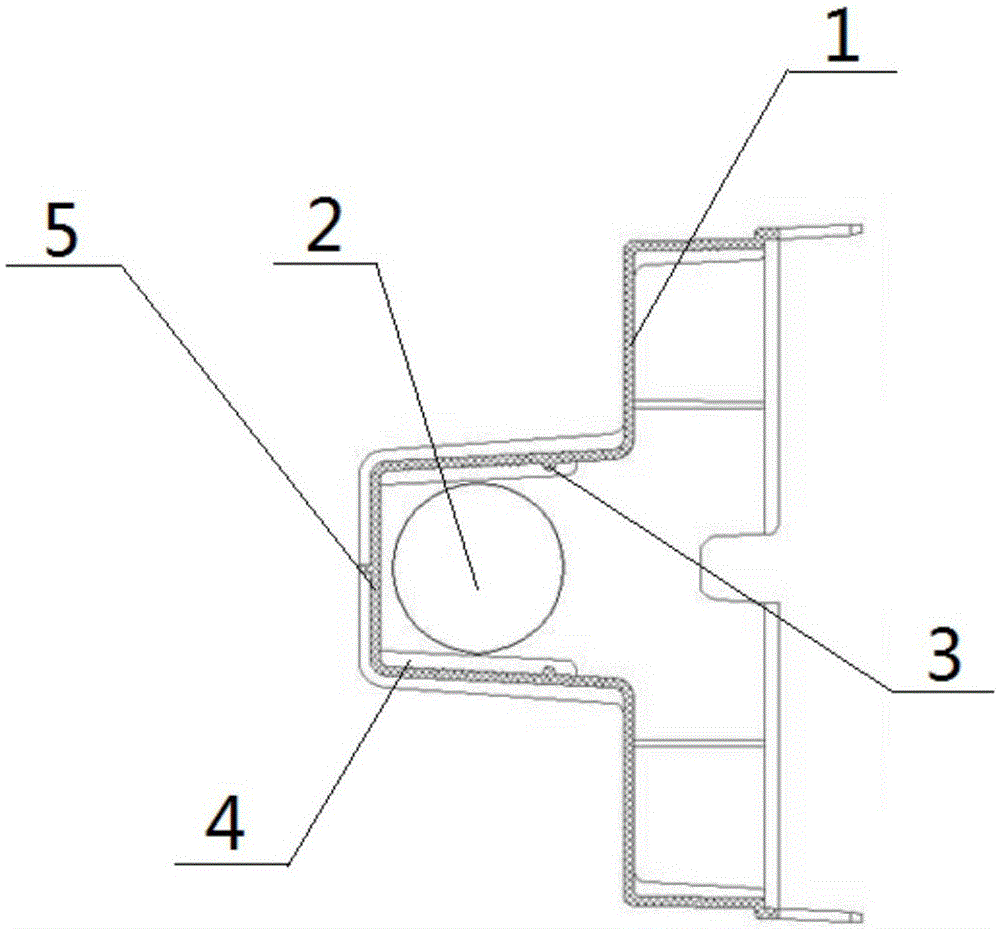

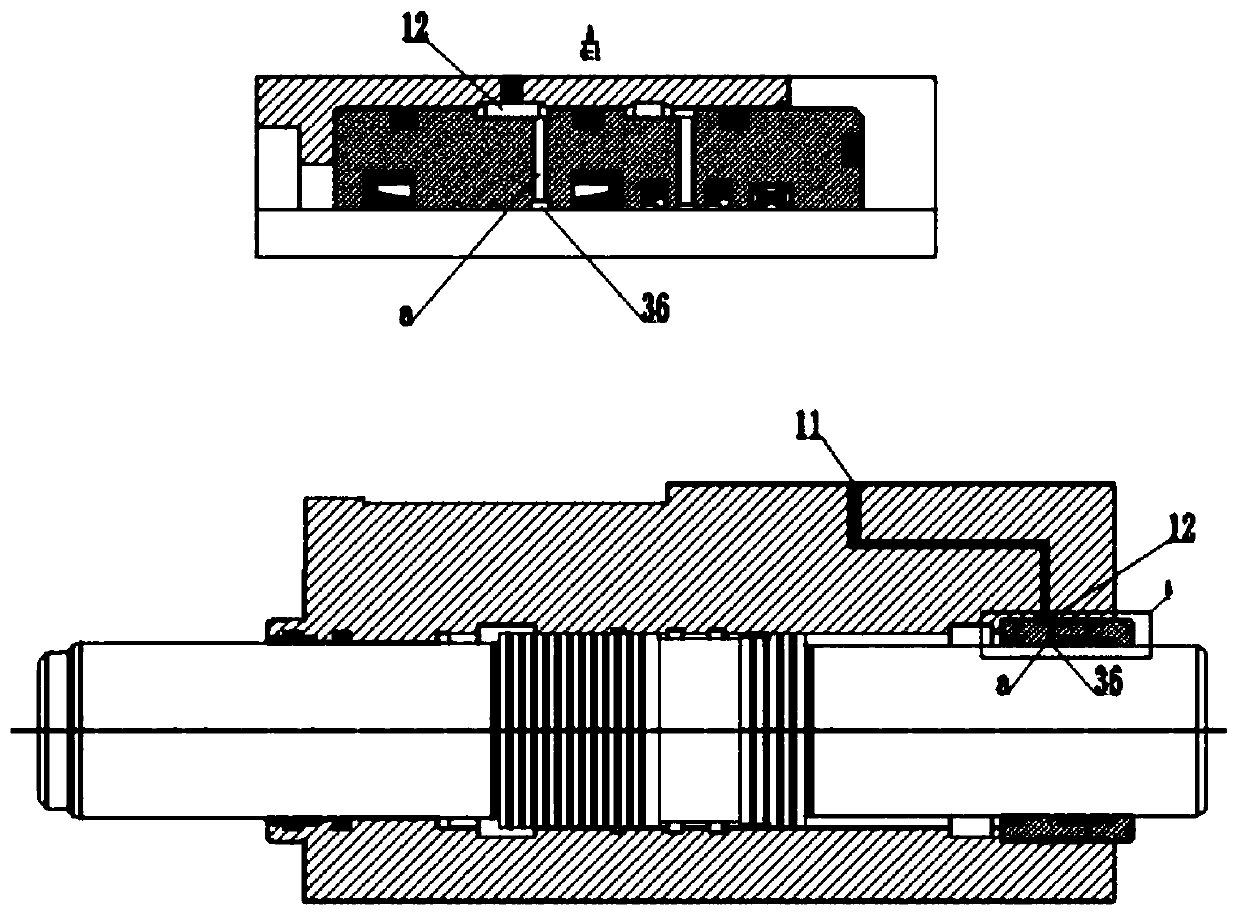

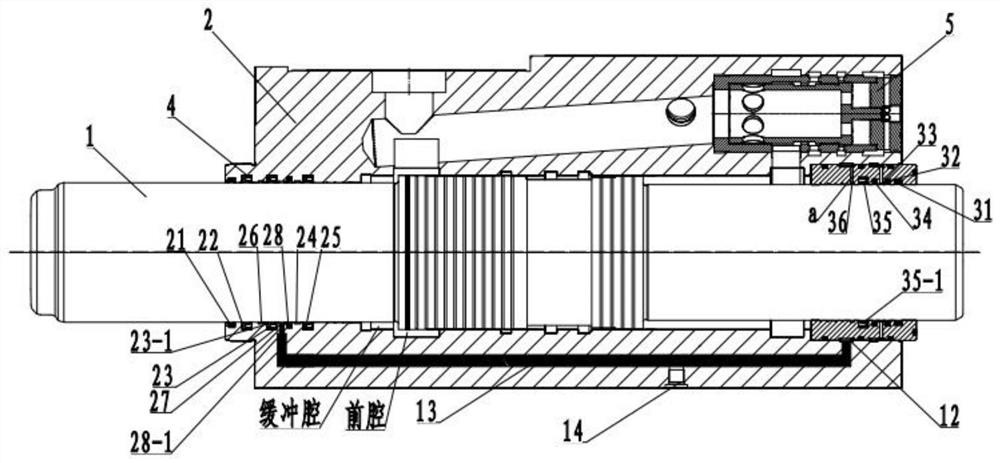

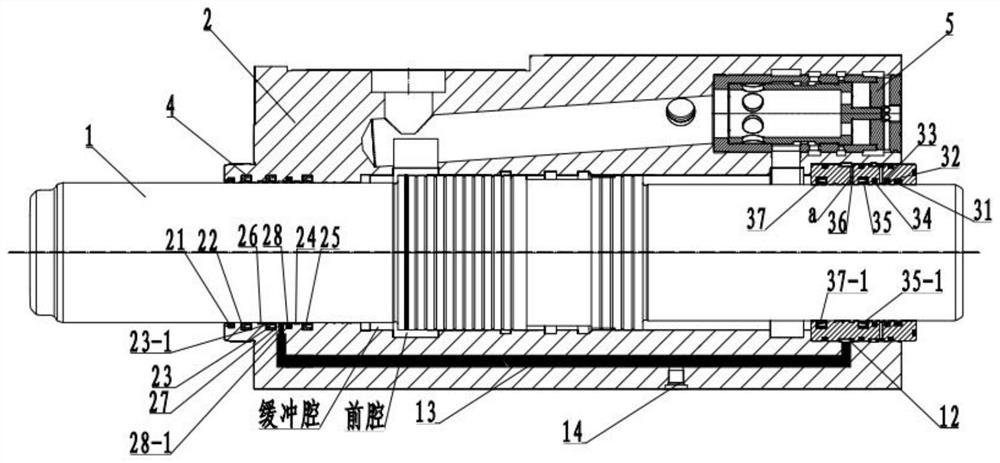

Middle cylinder component of hydraulic breaking hammer

PendingCN112983927ASolve the strainPrevent oil spillsEngine sealsMechanical machines/dredgersPiston ringCylinder block

The invention discloses a middle cylinder component of a hydraulic breaking hammer. The middle cylinder component of the hydraulic breaking hammer comprises a piston 1, a middle cylinder body 2, a piston ring 3, a sealing piece 4 and a reversing valve 5; a fifth piston rod sealing piece groove 25, a second oil return groove 26, a high-pressure oil groove 27 and a sixth piston rod sealing piece groove 28 are additionally arranged on an original sealing structure which is matched with a piston head in an inner hole of the middle cylinder body 2; an oil feeding groove 36 is additionally formed in an original inner hole sealing structure of the piston ring 3; a radial through hole a is formed in the oil feeding groove 36 and communicated with an oil inlet groove 12 formed in the piston ring; an oil way 13 is arranged on the middle cylinder body 2 and communicated with the high-pressure oil groove 27 and the oil inlet groove 12; and meanwhile the oil way 13 is externally connected with a high-pressure oil supply port 14. According to the invention, the high-pressure oil supporting effect of the front section and the rear section of the piston is enhanced, so that the problems that the piston and the cylinder body are prone to strain, oil leakage and the like in the initial working stage of the breaking hammer are effectively solved.

Owner:MAANSHAN KAMET HYDRAULIC MASCH MFG CO LTD

Method for synthesizing cyclohexanone dimer by continuous catalytic reaction and distillation

InactiveCN101544553BHigh selectivityAvoid contact opportunitiesPhysical/chemical process catalystsOrganic compound preparationReaction fieldCyclohexanone

The invention discloses a method for synthesizing cyclohexanone dimer by continuous catalytic reaction and distillation. The method comprises the following steps that: a catalytic reaction and distillation device shown in a figure is adopted, and cyclohexanone enters the a tower from the middle part of the tower; a cyclohexanone dimer and water azeotropic mixture obtained by the condensation of overhead vapor is subjected to continuous low layer resultant water separation in a water knockout vessel, and the upper layer cyclohexanone flows into the top of the tower; and tower bottom residue isheated by a reboiler, the temperature of the residue is controlled to be 250 to 280 DEG C, and 60 to 90 mass percent cyclohexanone dimer can be obtained from liquid discharged from the bottom of the tower. The method adopts continuous catalytic reaction and distillation technology and removes water in products away from a reaction field in time, thereby promoting a reaction to move toward the direction of the formation of the cyclohexanone dimer; meanwhile, the method separates the products of the reaction from a stripping section at the lower part to further eliminate the opportunity for theproducts of the reaction to contact a catalyst, thereby improving the selectivity of the cyclohexanone dimer, ensuring continuous reaction, high production efficiency and high selectivity of the cyclohexanone dimer, and facilitating industrial production.

Owner:ZHEJIANG UNIV +1

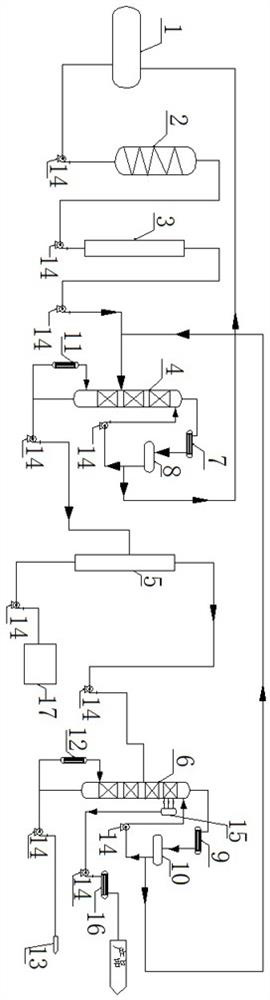

Method and device for processing off-gases in productive process of polyester or copolyester

ActiveCN102585190BGuaranteed uptimeAvoid contact opportunitiesDispersed particle separationPositive pressureCopolyester

The invention discloses a method and device for processing off-gases in the productive process of polyester or copolyester. The method comprises the following steps of: firstly leading the vacuum off-gases containing tetrahydrofuran to be in contact with circulating water and absorbed through a water jet pump, and sending the vacuum off-gases not being absorbed by water to a spray absorber for carrying out spraying absorption once again; and directly sending the ordinary pressure or positive pressure off-gases containing tetrahydrofuran to the spray absorber for spraying absorption. The method and device provided by the invention can be used for processing industrial off-gases generated by different devices in the productive process of polyester or copolyester in a differentiation manner;and as more than one automatic regulating valves are arranged in a pipeline by which the vacuum tail gases are communicated to the water jet pump, the automatic regulating valves can lead the pressures of the vacuum off-gases under different operating conditions to be kept in a constant working range so that a system can operate in a more stable condition. The device provided by the invention canavoid the probability to the maximum degree that inflammable and explosive objects are in contact with open fire, thereby the corresponding potential safety hazard is eliminated fundamentally.

Owner:KINGFA SCI & TECH CO LTD +1

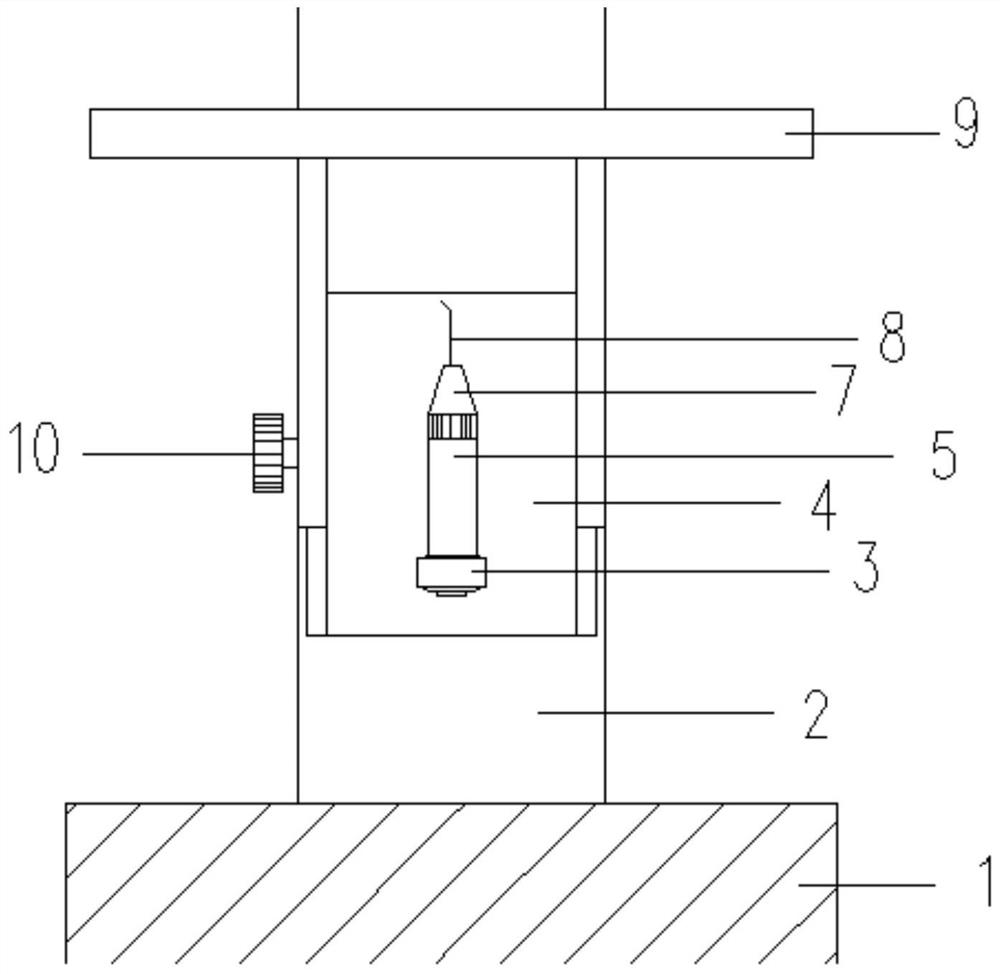

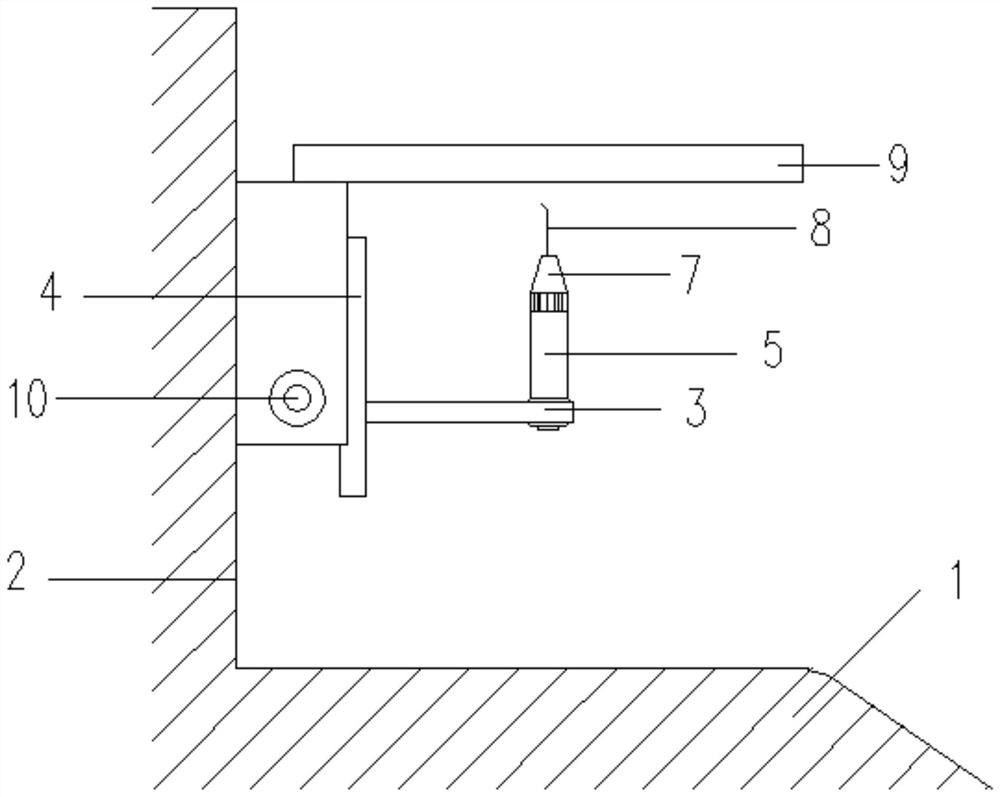

Single spore separation device, single spore separation microscope and single spore separation method

ActiveCN110923121BGuaranteed accuracyAvoid misuseBioreactor/fermenter combinationsBiological substance pretreatmentsSporeEngineering

The invention discloses a single spore separation device, a single spore separation microscope and a single spore separation method. The single spore separation device of the present invention comprises a lifting regulator, a connecting rod, a needle-shaped object fastener and a separation needle; the lifting regulator is installed at the position of the condenser lifting regulator on the microscope mirror arm; Control the rise or fall of the lifting regulator; one end of the connecting rod is connected to the lifting regulator, and the other end of the connecting rod is connected to the needle-shaped object fastener; one end of the separation needle is locked Inside the pin object fastener. The invention has the advantages of ensuring the accuracy of single spore separation; the height of the separation needle can be adjusted; the separation needle is not easy to break; frequent focusing is not required; and the operation process is simple.

Owner:HUAZHONG AGRI UNIV

Polyester melt direct spinning method and system with online addition of functional modifier

ActiveCN104264244BSolve for uniformityAvoid contact opportunitiesArtificial thread manufacturing machinesMelt spinning methodsPolyesterStatic mixer

The invention provides a polyester melt direct spinning method by online adding functional modifiers. The melt with 5%-10%wt of conveying capacity is taken out on a melt main pipeline and enters a dynamic mixer, the functional modifiers are added, a functional melt is generated and returns to the melt main pipeline, and the functional melt and other melts on the main pipeline enter an efficient static mixer on the melt main pipeline and are mixed again to obtain the functional melt for spinning. The invention further discloses a polyester melt direct spinning system by online adding the functional modifiers. The melt with 5%-10% of the conveying capacity is taken out on the polyester melt main pipeline, so that production of the functional melt and production of polyester are relatively independent, the basic performance of the melt is consistent with that of a melt produced by large-scale polyester, the problem of poor uniformity of the functional melt is solved by mixing twice, a re-cooling and pelleting process of the melt is omitted, machining cost is greatly reduced, the heating capacity of the melt entering the dynamic mixer is reduced, and energy consumption is low.

Owner:JIANGSU JIANGNAN HIGH POLYMER FIBER

Method and device for processing off-gases in productive process of polyester or copolyester

ActiveCN102585189BGuaranteed uptimeAvoid contact opportunitiesDispersed particle separationPositive pressureWater vapor

The invention discloses a method and device for processing off-gases in the productive process of polyester or copolyester. The method comprises the following steps of: firstly leading the vacuum off-gases containing tetrahydrofuran to be in contact with water vapor and absorbed through a water vapor injection pump, then sending a mixture of the vacuum off-gases and the water vapor to a spray absorber for carrying out spraying absorption once again; and directly sending the ordinary pressure or positive pressure off-gases containing tetrahydrofuran to the spray absorber for spraying absorption. The method and device provided by the invention can be used for processing the industrial off-gases generated by different devices in the productive process of polyester or copolyester in a differentiation manner; as one or more than two automatic regulating valves are arranged in a pipeline by which the vacuum tail gases are communicated to the water vapor injection pump, the automatic regulating valves can lead the pressures of the vacuum off-gases under different operating conditions to be kept in a constant working range so that a system can operate in a more stable condition. The device provided by the invention can avoid the probability to the maximum degree that inflammable and explosive objects are in contact with open fire, thereby the corresponding potential safety hazard is eliminated fundamentally.

Owner:KINGFA SCI & TECH CO LTD +1

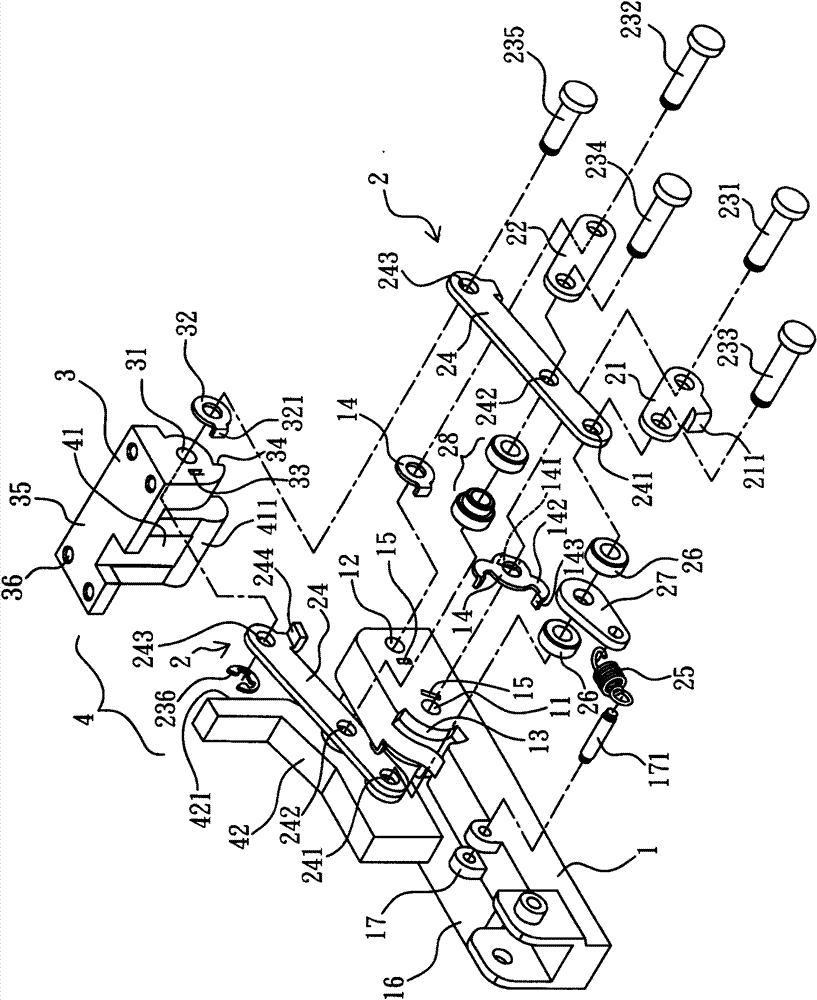

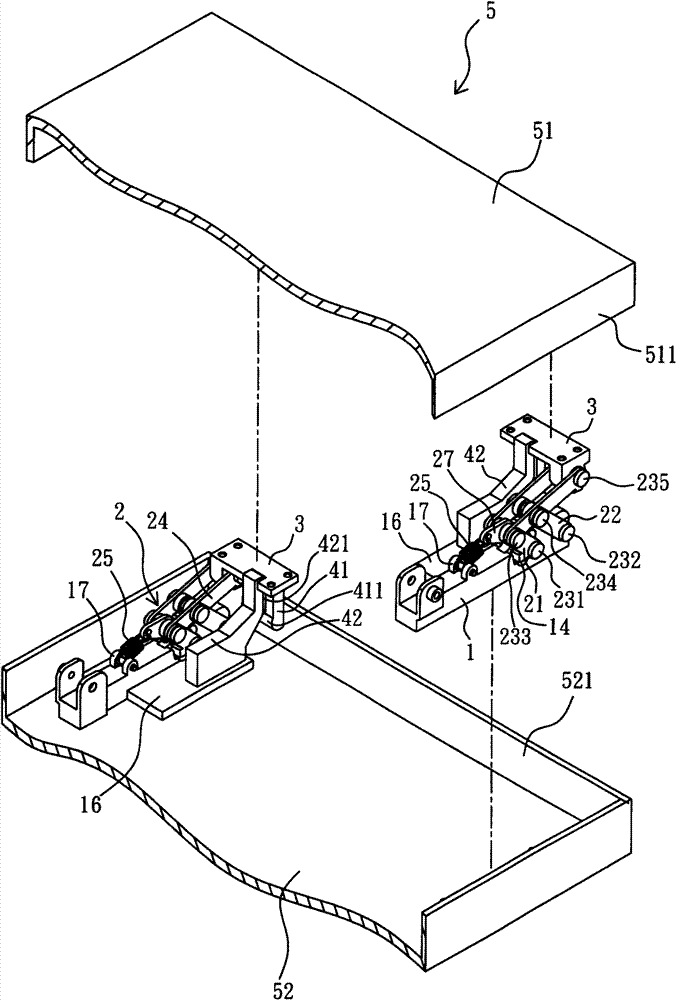

Hinge structure

The invention relates to a hinge structure which is composed of a base, at least a linkage mechanism, a shaft connecting seat and a guide mechanism. When the shaft connecting seat performs upwards opened rotation moving relative to the base, a guide piece of the guide mechanism moves upwards along the guide wall of a fixing piece to move the shaft connecting seat outwards; and simultaneously, a non-parallel four-bar mechanism composed of a first shaft bar, a second shaft bar, a third shaft bar of the linkage mechanism and the base produces a linkage action to enable the shaft connecting seat to rotate and simultaneously move upwards and outwards. According to the hinge structure, the side wall bottom edge of a front cover of a casing can not collide the side wall bottom edge of a back cover when the hinge structure is opened or closed, and the opening or the closing can be smoothly achieved.

Owner:JARLLYTEC CO LTD

Preparation method of electronic grade propylene glycol monomethyl ether and product thereof

ActiveCN111807934BAvoid contact opportunitiesReduce generationEther separation/purificationOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystMonomethyl ether

The invention discloses a preparation method of electronic grade propylene glycol monomethyl ether and a product obtained by the preparation method, and belongs to the technical field of preparation of fine chemicals. The method comprises the following steps of: 1) mixing methanol, propylene oxide and a basic ionic liquid catalyst, and carrying out reaction in a micro-channel reactor to obtain a reaction solution; 2) removing light components from the reaction solution to obtain a light component removed reaction solution; and 3) evaporating the light component removed reaction solution obtained in step 2), and performing negative pressure rectification on the obtained steam to obtain the electronic grade propylene glycol monomethyl ether. The preparation method of the electronic grade propylene glycol monomethyl ether provided by the invention are mild in reaction conditions, the purity of the prepared product is high, the yield is high, and the activity and selectivity of the catalyst are high.

Owner:HAIKE GRP RES INST OF INNOVATION & TECH

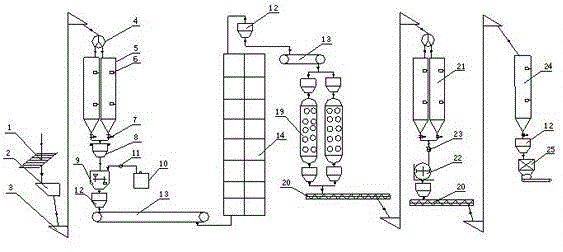

Production device and method for producing feed soybean meal by utilizing anaerobe fermentation

ActiveCN102972854BAvoid contactAvoid contact opportunitiesFeeding-stuffAnimal feeding stuffEngineeringDistributor

The invention provides a production device and a method for producing feed soybean meal by utilizing anaerobe fermentation. The production device comprises a feeding device, a material distributing and mixing device, a fermentation device, a drying device, a shattering device and a baling device; the feeding device comprises a filter, a discharging pit and a lifter; the material distributing and mixing device comprises a mixing cabin, a distributor, a mixer and a conveyor, which are sequentially connected with one another from top to bottom; the fermentation device adopts a matrix-type solid fermentation system; and the shattering device comprises a shattered material cabin and a pulverizer. The production process is reasonable in design, the matrix-type solid fermentation system is used for fermenting the material, the feeding and discharging systems are equipped, so that the pollution can be effectively controlled, the produced fermentation soybean meal is safe and reliable, and the production device and the method have the advantages of easiness in popularization and application.

Owner:菏泽海鼎饲料科技有限公司

A kind of semi-automatic pickling method of low magnification test piece

ActiveCN106978600BReduce labor intensityEliminate the chance of acid contactPreparing sample for investigationSemi automaticMagnification

The invention belongs to the field of detection of metallographic low power test blocks, and particularly relates to a low power test block semi-automatic pickling method. The method comprises the following steps that firstly, acid liquid is preheated in an automatic pickling bath, and temperature and etching time are set; secondly, test blocks are put into the pickling bath according to the etching degrees; thirdly, the test blocks are subjected to automatic pickling is conducted according to the set temperature and time, after the set picking time is reached, the automatic pickling bath discharges acid automatically, a fan operates at a rated maximum rotation speed, and after acid mist in the bath disappears, a pickling bath cover is automatically opened for lifting-out operation on a pallet; fourthly, the test block pallet is lifted into a cleaning pool, and test block automatic cleaning is conducted by operating a cleaning trolley travelling button; and fifthly, the test block pallet is lifted out, enters a drying device with set drying temperature and reaches a detection zone until detection is completed. The low power test block semi-automatic pickling method is capable of relieving the labor intensity, ensuring the safety of operators and improving and increasing the surface quality of the test blocks after pickling.

Owner:HENAN ZHONGYUAN SPECIAL STEEL EQUIP MFG CO LTD

Surgical injection equipment for child treatment

InactiveCN112516416AAutomate the processImprove practicalityInfusion syringesIntravenous devicesCopper wireInjection equipment

The invention discloses surgical injection equipment for child treatment, and particularly relates to the field of injection equipment. The surgical injection equipment comprises an outer cylinder, wherein a top cover is arranged at the top of the outer cylinder in a threaded sleeving mode, a bottom cylinder is fixedly mounted at the bottom of the outer cylinder, a needle cylinder is movably arranged at the top of the bottom cylinder in a sleeving manner, and a needle opening pipe is fixedly mounted at the bottom of the needle cylinder; and a push rod is movably arranged at the top of the needle cylinder in a sleeving manner, a piston block is fixedly mounted at the bottom extending into the needle cylinder, of the push rod, and the outer part of the piston block is attached to the inner wall of the needle cylinder. By holding holding rods, at the moment, a power generation assembly drives a corresponding transverse rod to move, and each transverse rod drives a corresponding linkage sleeve to move transversely, so that each linkage sleeve drives a corresponding magnet pipe to move transversely, namely, a magnetic induction line generated by each magnet pipe is cut by a corresponding copper wire, and at the moment, current is generated in each copper wire and fed into a corresponding storage battery through a wire. Therefore, the drive of the surgical injection equipment provides electric power, further the automation process of the surgical injection equipment is realized, and the practicability of the surgical injection equipment is improved.

Owner:沈丽萍

Built-in sealed continuous ink supply system with pressure dynamic compensation function

The invention relates to a built-in sealed continuous ink supply system with a pressure dynamic compensation function. The built-in sealed continuous ink supply system comprises an ink soft bag (1), a pressure dynamic compensation device and a printing head (5). The ink soft bag (1) is positioned above the pressure dynamic compensation device and is connected with an ink inlet (31) of the pressure dynamic compensation device by a soft bag connecting tube (2), an elastic air bag (33) is arranged in the pressure dynamic compensation device, an ink outlet (37) on the lower side of the pressure dynamic compensation device is connected with the printing head (5) by an ink supply tube (4), and the pressure dynamic compensation device is in a sealed state when ink is supplied by the ink inlet (31) and the ink outlet (37). The built-in sealed continuous ink supply system has the advantages that the ink is completely prevented from being in contact with external air, the probability of oxidation, evaporation and crystallization of the ink is reduced, and a phenomenon of head blockage is decreased; problems of air resistance, backflow, misting, overflow and the like can be effectively solved, and the built-in sealed continuous ink supply system is provided with a warning device with functions of ink deficiency voice prompting, corresponding indicator lamp prompting and the like.

Owner:抚州市新智铨科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com