Polyester melt direct spinning method and system with online addition of functional modifier

A polyester melt and functional technology, applied in the field of synthetic fiber production, can solve the problems of low uniformity of fiber products, complicated implementation process and high processing cost, and achieve the effects of reducing processing cost, low energy consumption and improving effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

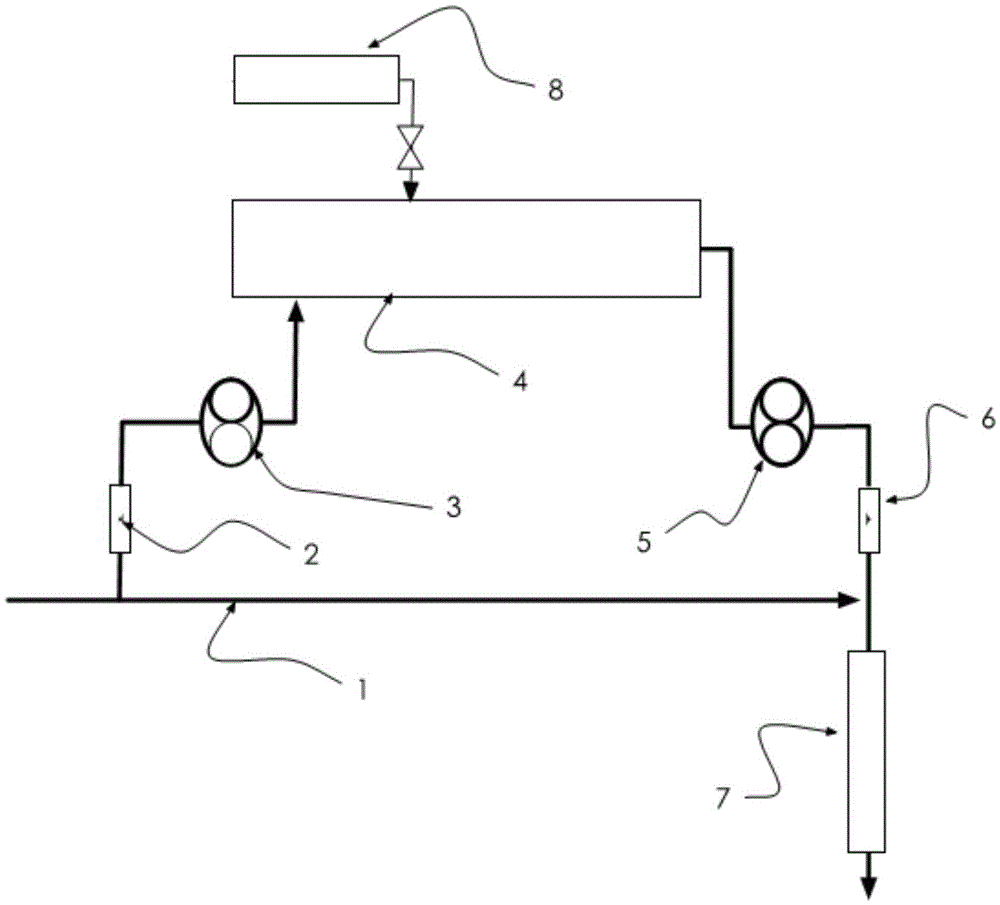

[0019] Example 1 Adding the polyester melt direct spinning system of functional modifier on-line

[0020] The polyester melt direct spinning system with online addition of functional modifiers includes polyester melt main line and melt branch line;

[0021] Described polyester melt main line comprises polyester melt main line 1 and static mixer 7;

[0022] The melt branch pipeline includes a melt branch pipe stop valve 2, a metering pump 3, a dynamic twin-screw mixer 4, a discharge metering pump 5, and a functional melt stop valve 6 connected in sequence. The cut-off valve 2 is connected to the main line of polyester melt, and the connection position is located after the outlet of the polyester final polymerization tank. After the functional melt stop valve 6 is connected to the main line of polyester melt 1, it is connected to the static mixer 7 The position where the functional melt stop valve 6 is connected to the polyester melt main line 1 is located after the position wh...

Embodiment 2

[0023] Embodiment 2 The polyester melt direct spinning method of adding functional modifier on-line produces anti-ultraviolet polyester staple fiber

[0024] The intrinsic viscosity IV of the melt at the exit of the polyester final polymerization kettle is 0.670dl / g, the content of the anti-ultraviolet additive in the target polyester staple fiber is 3.0wt%, and quasi-nanometer rutile type (RutilR type) titanium dioxide is used, with an average particle size of 200nm.

[0025] The melt delivery volume of the polyester melt main line 1 is 100 tons / day, the melt temperature is 288°C, the melt pipe pressure is 10MPa, the melt branch pipe stop valve 2 is opened, the inlet pressure of the metering pump 3 is 9.8MPa, and the discharge The amount is 8 tons / day, the heating temperature (electric heating) of the dynamic twin-screw mixer 4 is 286°C, the injection amount of the additive metering device 8 with a syringe is 3 tons / day, the injection pressure is 10MPa, and the output metering...

Embodiment 3

[0035] The steps and the amount of raw materials added in this embodiment are consistent with those in Example 2, the difference being that the output of the metering pump 3 is 5 tons / day, the injection amount of additives is 2.5 tons / day, and the finally measured defect content is 0.3mg / 100g .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com