Power panel box and washing machine

A power board and washing machine technology, which is applied to other washing machines, washing devices, electrical components, etc., can solve the problems of safety hazards of filters and power boards, complex production and installation processes, and high production costs of washing machines, so as to save raw materials and simple structure , The effect of shortening the length of the wire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

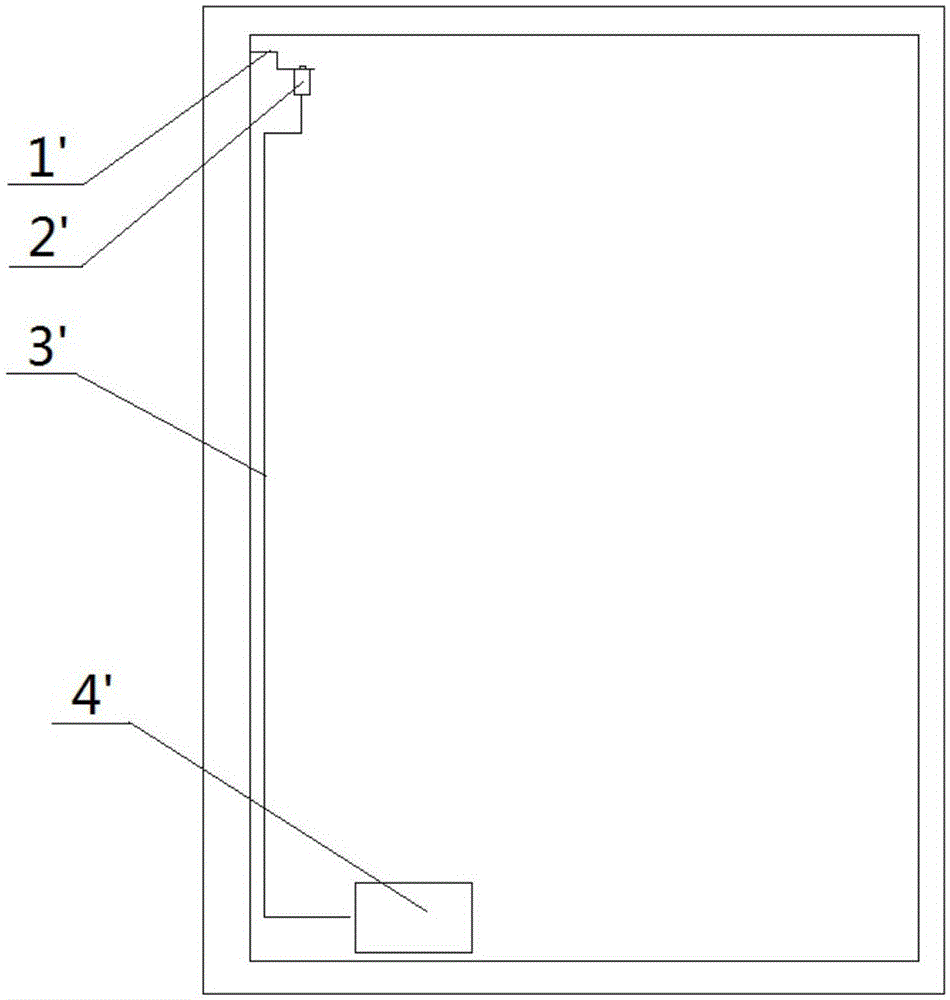

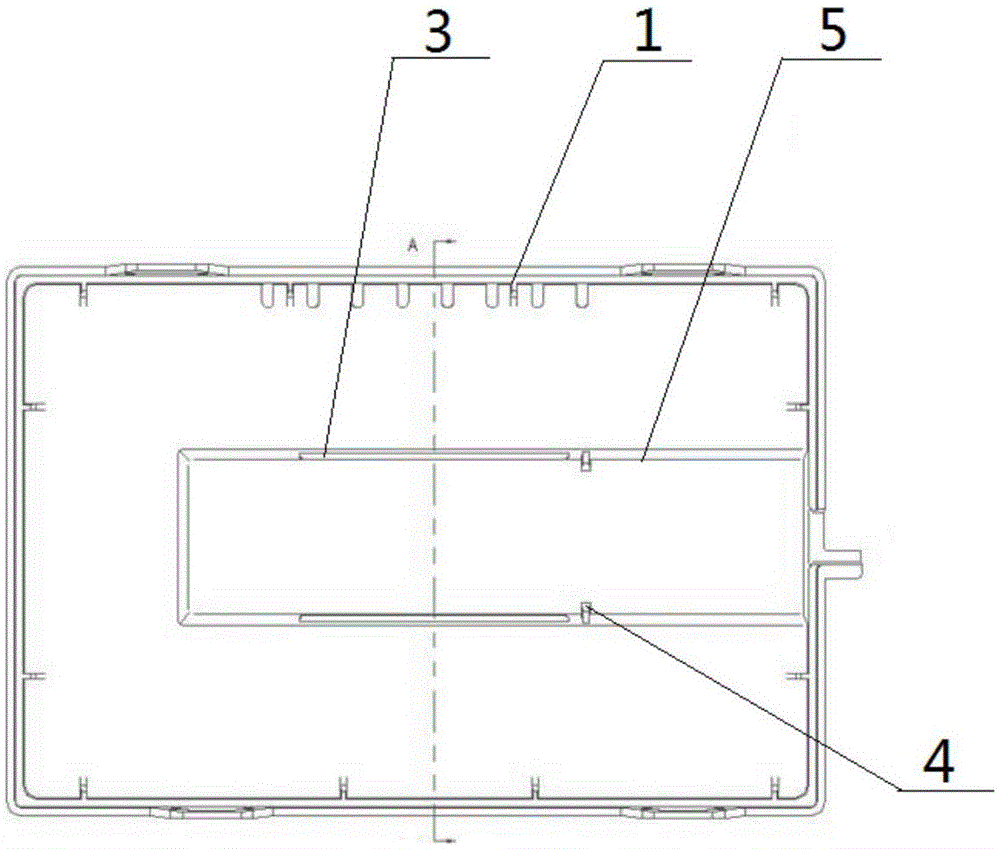

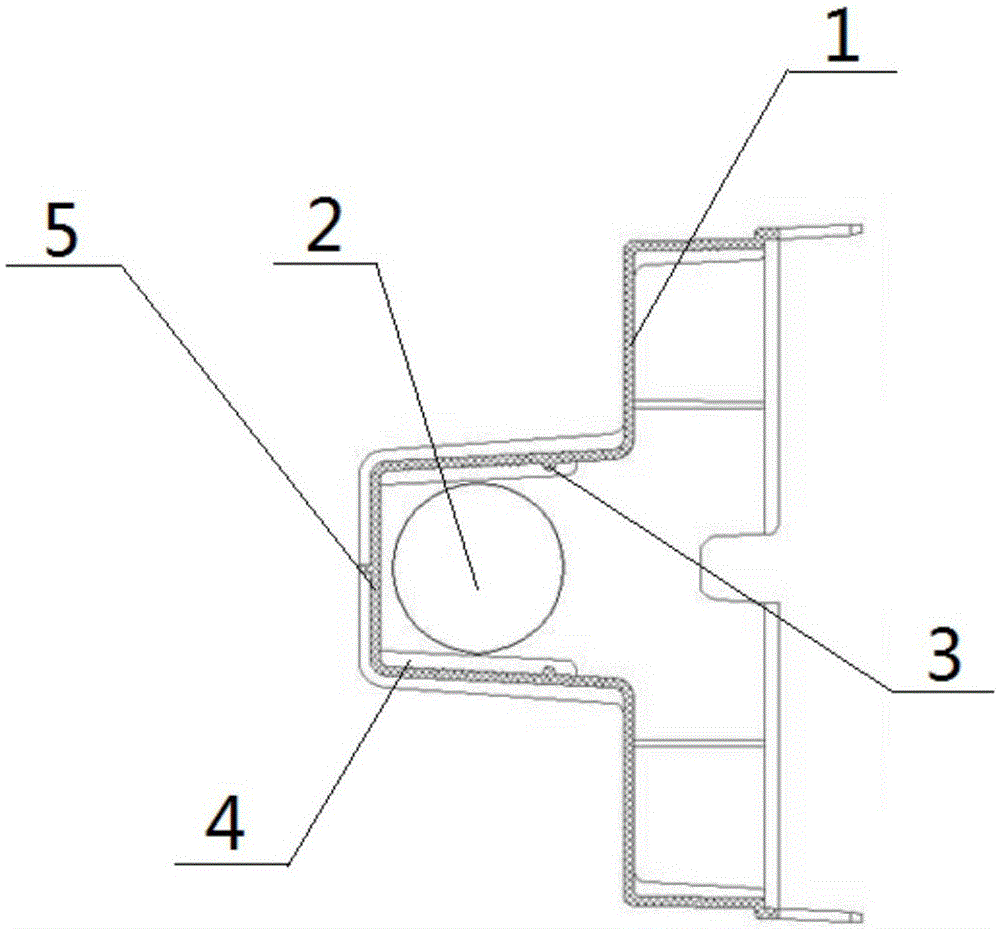

[0034] Such as figure 2 , image 3 As shown, it is a power board box disclosed by the present invention, which includes a box body 1, and the inside of the box body 1 has an accommodating cavity for placing the filter 2, and the accommodating cavity 5 is provided with a The limiting structure of the position of the filter 2 is described. As a preferred embodiment, the position-limiting structure is fixed on the inner wall of the accommodating cavity 5 by screwing or pasting.

[0035] Since the filter 2 is installed inside the power board box, the distance between the filter 2 and the power board is shortened, and the length of wires required to connect the two becomes shorter, saving raw materials, and better economic benefits for the manufacturer.

[0036] As a further embodiment, the limiting structure includes a first limiting rib 3 provided on at least one of the inner walls on the left and right sides of the accommodating cavity 5, and the first limiting rib 3 is used ...

Embodiment 2

[0044] This embodiment discloses a drum washing machine, which is provided with the power board box structure as described in the first embodiment.

[0045] The washing machine disclosed in the present invention is provided with the above-mentioned power supply board box, so the filter of the washing machine is installed inside the power supply board box, and the structure of the sheet metal bracket and bolts for fixing the filter is omitted, thus reducing the overall cost of the washing machine. The production cost of the machine is reduced, the manufacturing and installation process is simplified, and the product is more competitive in the market.

[0046] Since the drum washing machine in this embodiment is provided with the above-mentioned power board box structure, on the one hand, the cost of the washing machine in this embodiment is reduced, and the economic benefit is better; on the other hand, the safety of the washing machine in this embodiment is improved. Well, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com