Method and system for high-selectivity preparation of dipropylene glycol

A technology for reducing dipropylene glycol and propylene glycol, which is applied in the field of 1,2-propanediol synthesis, which can solve the problems of unsuitable automatic control, low price of crude products, and inability to achieve high selectivity, etc., and achieve easy control, mild conditions, and improved selectivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

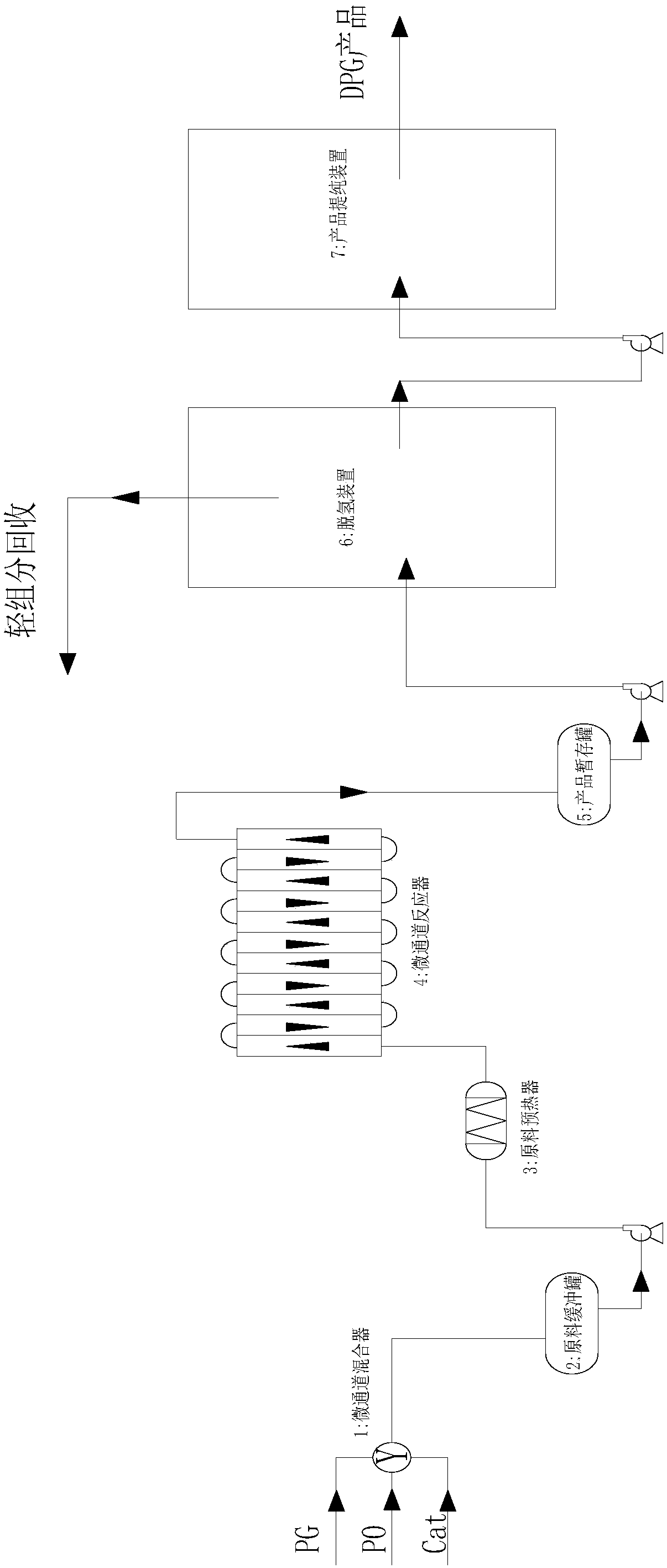

preparation example Construction

[0060] The invention provides a kind of preparation method of dipropylene glycol, comprises the following steps:

[0061] 1) After mixing propylene oxide and propylene glycol, a mixed raw material is obtained;

[0062] 2) After carrying out the condensation reaction in the microchannel reactor with the mixed raw material that above-mentioned steps obtains, obtain dipropylene glycol.

[0063] The present invention firstly mixes propylene oxide and propylene glycol to obtain mixed raw materials.

[0064] The present invention has no special limitation on the addition ratio of the propylene oxide and propylene glycol, and the conventional addition ratio well known to those skilled in the art can be used, and those skilled in the art can select and adjust according to actual production conditions, raw material conditions and product requirements, The molar ratio of propylene glycol to propylene oxide in the present invention is preferably (1-10):1, more preferably (3-9):1, more p...

Embodiment 1

[0104] First, inject propylene oxide, 1.2-propanediol and benzenesulfonic acid catalysts into the microchannel mixer through the metering pump respectively, and the multi-strand raw materials are mixed by the microchannel mixer and then enter the raw material buffer tank, and the materials in the raw material buffer tank pass through the preheater After preheating to 80°C, enter the microchannel reactor for full reaction. Control the temperature in the microchannel reactor to 110°C, the pressure to 0.3MPa, and the residence time of the material to be 10 minutes. / h, 1.2-propanediol feed rate 152Kg / h, benzenesulfonic acid 0.5Kg / h.

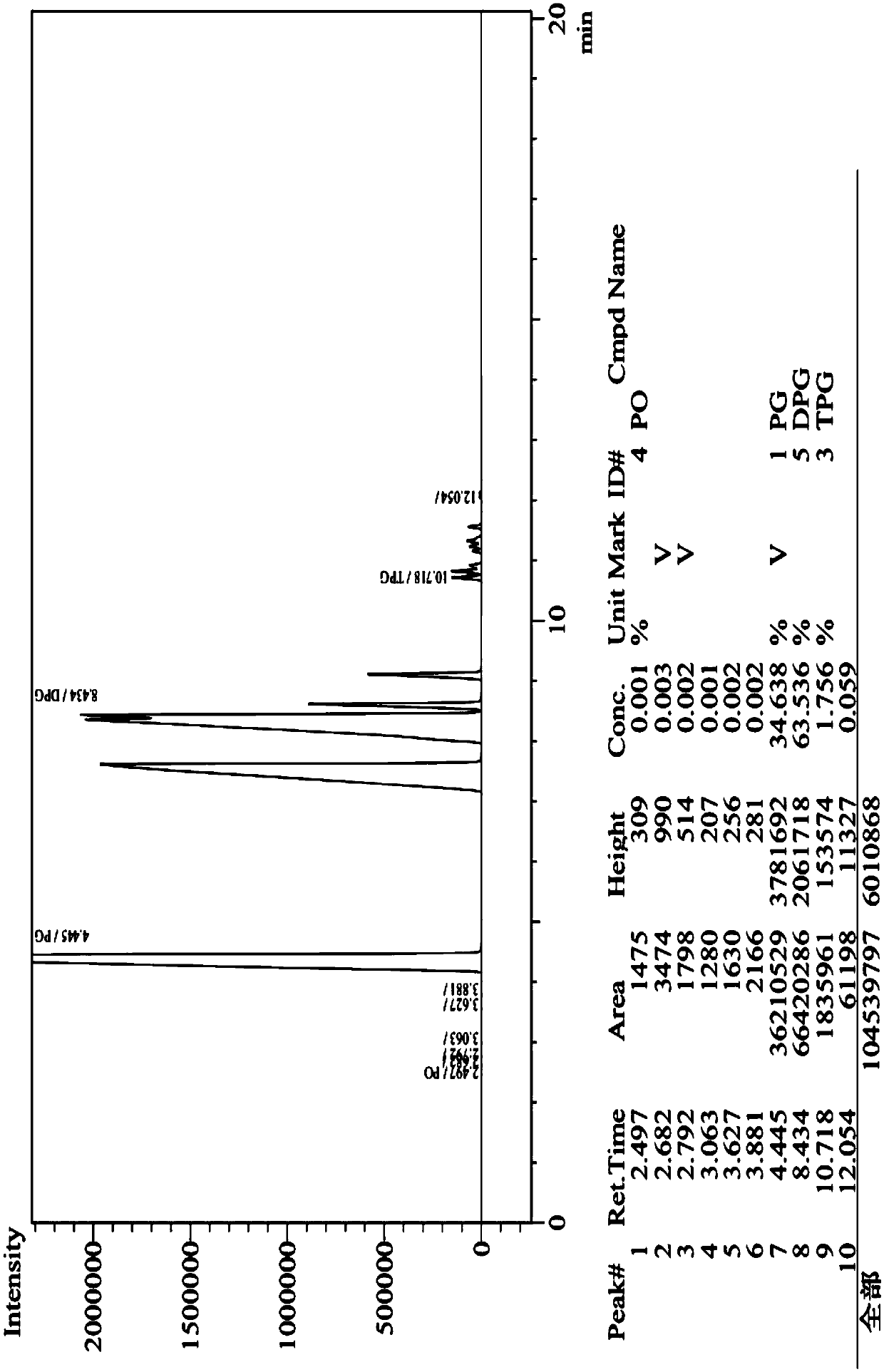

[0105] The crude product after the reaction of Example 1 of the present invention was detected and analyzed.

[0106] see figure 2 , figure 2 It is the gas chromatogram of the crude product after the reaction of Example 1 of the present invention.

[0107] Referring to Table 1, Table 1 shows the specific composition of the crude product after t...

Embodiment 2

[0116] Firstly, propylene oxide, 1.2-propylene glycol and sodium bicarbonate catalyst are respectively injected into the microchannel mixer through the metering pump, and the multi-strand raw materials are mixed by the microchannel mixer and then enter the raw material buffer tank, and the materials in the raw material buffer tank pass through the preheater After preheating to 50°C, enter the microchannel reactor for full reaction. Control the temperature in the microchannel reactor to 120°C, the pressure to 0.2MPa, and the residence time of the material to be 2 minutes. / h, 1.2-propanediol feed rate 304Kg / h, sodium methoxide 0.5Kg / h.

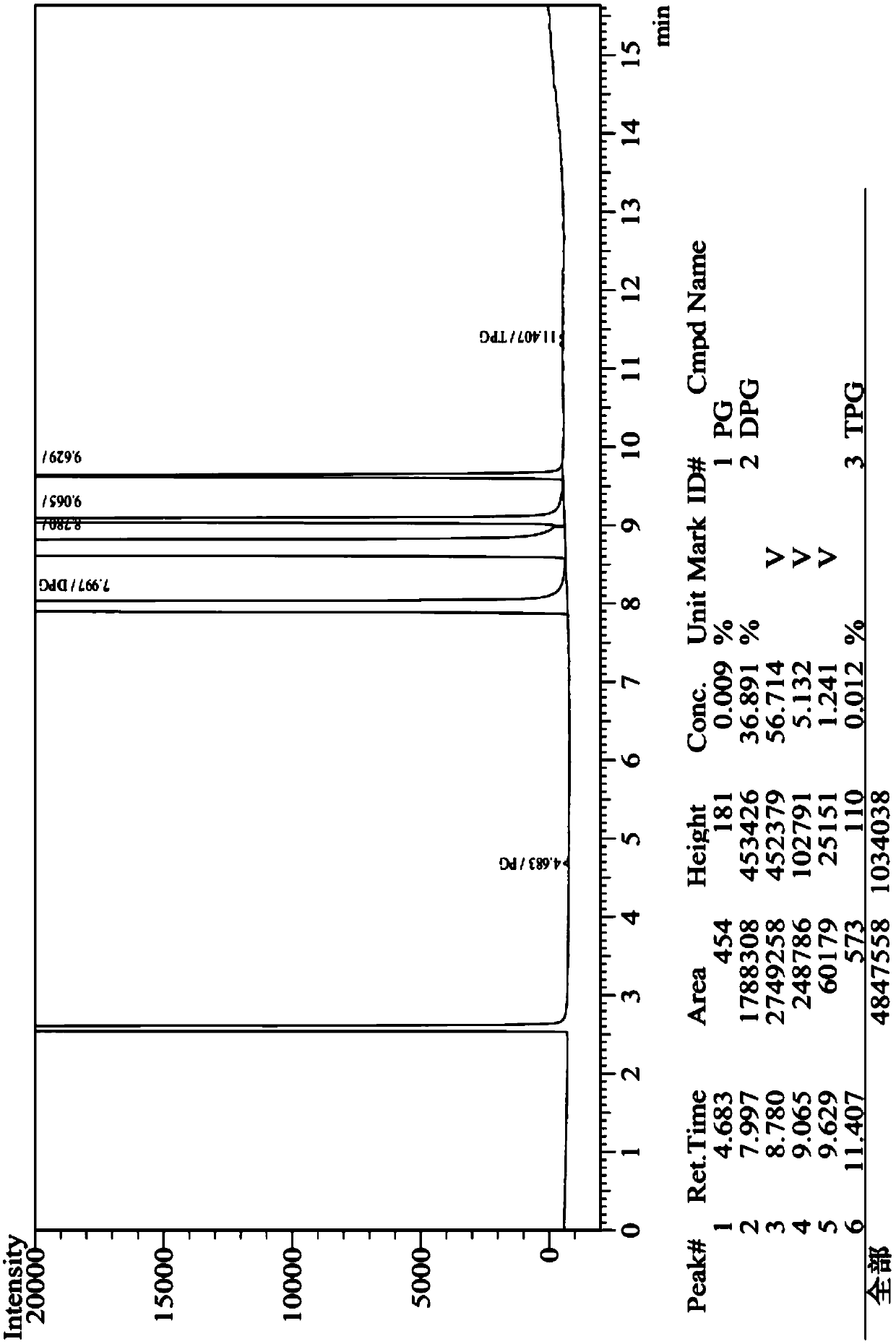

[0117] The crude product after the reaction in Example 2 of the present invention was detected and analyzed, the content of dipropylene glycol in the crude product was 37%, and the selectivity of dipropylene glycol in the product was 98%.

[0118] Then the crude product is separated by rectification. Firstly, it is delightened by the first rect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com