Synthetic method and synthetic device of propyl propionate

A propyl propionate and synthesis device technology, which is applied in the field of high-purity propyl propionate synthesis, can solve the problems of unsatisfactory propyl propionate, low conversion rate of propyl propionate, long reaction time, etc., and facilitates industrial production , high selectivity and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

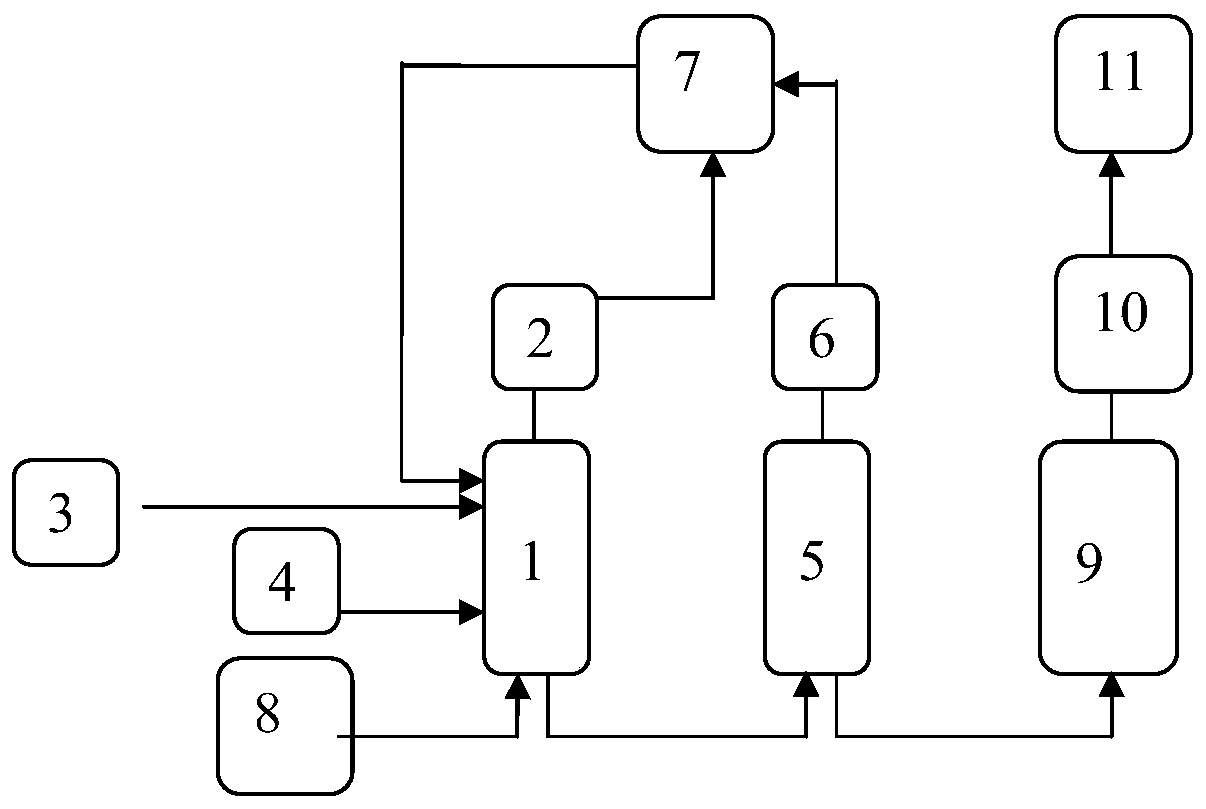

[0026] The present embodiment provides a kind of synthetic device of propyl propionate, comprises catalytic reaction rectification tower 1, the first condenser 2, n-propanol feed inlet 3, propionic acid feed inlet 4, fractionation tower 5, the second condenser Device 6, phase separator 7, reboiler 8, purification tower 9, the third condenser 10 and propyl propionate collection tank 11;

[0027] The catalytic reaction rectification tower 1 has a diameter of 300 mm, and a packing layer of a reaction section and a packing layer of a stripping section are arranged inside, and the packing layer of the reaction section is located above the packing layer of the stripping section; the packing layer of the reaction section is a catalyst layer, and the catalyst adopts p-toluene Sulfonic acid has a diameter of 1mm and a height of 1m; the packing layer of the stripping section is a packing layer of stainless steel mesh packing, and the height of the packing layer of stainless steel mesh is...

Embodiment 2

[0033] Same as the device in Example 1, the difference is that the catalyst in the device adopts p-toluenesulfonic acid, its diameter is 1mm, and its height is 3m; the packing layer of the stripping section is a packing layer of stainless steel mesh packing, and the height of the packing layer of stainless steel mesh is 2m .

[0034] Present embodiment also provides the method for synthesizing propyl propionate by above-mentioned synthetic device, specifically as follows:

[0035] Propionic acid and propanol are taken by weighing according to the mol ratio of 0.8:1, and add propionic acid and n-propanol in catalytic reaction rectification column 1 by propionic acid feed port 3 and n-propanol feed port 4, catalyzer and propanol The mass ratio of the acid is 0.1:1, and the heating power of the tower kettle reboiler 8 is adjusted to control the temperature of the kettle liquid at about 250°C. The n-propanol-propyl propionate-water azeotrope obtained after the overhead steam of t...

Embodiment 3

[0037]Same as the device in Example 1, the difference is that the diameter of the catalytic rectification tower 1 is 800 mm, and the catalyst in the device is p-benzenesulfonic acid, with a diameter of 5 mm and a height of 4 m; the packing layer of the stripping section is a stainless steel wire mesh packing Filling layer, the height of the stainless steel wire mesh packing layer is 3m.

[0038] Present embodiment also provides the method for synthesizing propyl propionate by above-mentioned synthetic device, specifically as follows:

[0039] Propionic acid and propanol are taken according to the mol ratio with 2:1, and add propionic acid and n-propanol in catalytic reaction rectification column 1 by propionic acid feed port 3 and n-propanol feed port 4, catalyzer and propanol The mass ratio of the acid is 0.3:1, and the heating power of the tower kettle reboiler 8 is adjusted to control the temperature of the kettle liquid at about 250°C. The n-propanol-propyl propionate-wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com