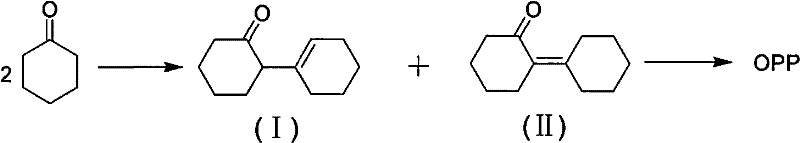

Method for synthesizing cyclohexanone dimer by continuous catalytic reaction and distillation

A cyclohexanone dimer, catalytic reaction technology, applied in chemical instruments and methods, preparation of organic compounds, separation/purification of carbonyl compounds, etc., can solve the problems of catalyst deactivation, slow reaction, easy deactivation, etc. , to achieve the effect of facilitating industrial production, high production efficiency and improving selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

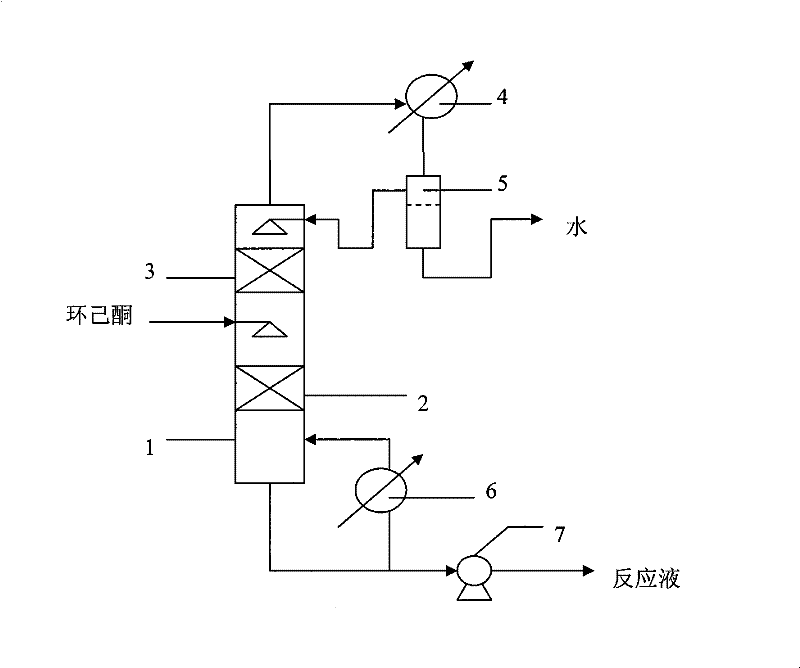

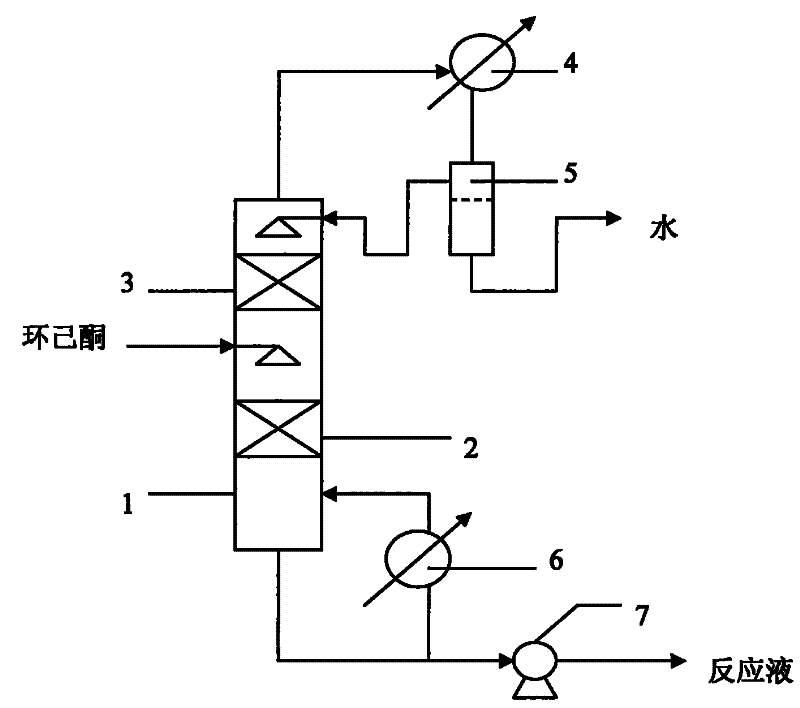

[0015] In the stainless steel catalytic reaction rectification device with a diameter of 300 mm as shown in the accompanying drawing, the rectification section is filled with γ-Al with a diameter of 2 mm 2 o 3 The catalyst has a height of 1m, and the stripping section is filled with stainless steel wire mesh packing with a height of 1m. Pump cyclohexanone into the tower at a speed of 50kg / h, adjust the heating power of the reboiler of the tower kettle, and control the temperature of the kettle liquid at about 250°C. At this time, the rate of separating water from the lower layer of the water separator at the top of the tower is 2.8kg / h, and the unreacted cyclohexanone in the upper layer is then refluxed into the top of the tower to contact and react with the catalyst layer, and the speed of discharging the still liquid at the bottom of the tower is 47.2kg / h . The results of gas chromatography analysis showed that the content of cyclohexanone dimer in the bottom discharge liq...

Embodiment 2

[0017] In the stainless steel catalytic reaction rectification device with a diameter of 300 mm as shown in the accompanying drawing, the rectification section is filled with γ-Al with a diameter of 3 mm 2 o 3 The catalyst has a height of 3m, and the stripping section is filled with stainless steel wire mesh packing with a height of 2m. Pump cyclohexanone into the tower at a speed of 100kg / h, adjust the heating power of the reboiler in the tower kettle, and control the temperature of the kettle liquid at about 270°C. At this time, the rate of separating water from the lower layer of the water separator at the top of the tower is 7.6kg / h, and the unreacted cyclohexanone in the upper layer is refluxed into the top of the tower to contact and react with the catalyst layer, and the speed of discharging the still liquid at the bottom of the tower is 92.4kg / h . The gas chromatographic analysis results showed that the content of cyclohexanone dimer in the bottom discharge liquid wa...

Embodiment 3

[0019] In the stainless steel catalytic reaction rectification device with a diameter of 300 mm as shown in the accompanying drawing, the rectification section is filled with γ-Al with a diameter of 4 mm 2 o 3 The catalyst has a height of 4m, and the stripping section is filled with stainless steel mesh packing with a height of 3m. Pump cyclohexanone into the tower at a rate of 200kg / h, adjust the heating power of the reboiler of the tower kettle, and control the temperature of the kettle liquid at about 275°C. At this time, the rate of separating water from the lower layer of the water separator at the top of the tower is 15.1kg / h, and the unreacted cyclohexanone in the upper layer is refluxed into the top of the tower to contact and react with the catalyst layer, and the speed of discharging the still liquid at the bottom of the tower is 184.9kg / h . The gas chromatographic analysis results showed that the content of cyclohexanone dimer in the bottom discharge liquid was 82...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com