A kind of semi-automatic pickling method of low magnification test piece

A semi-automatic, test piece technology, applied in the preparation of test samples, etc., can solve the problems of high risk factor and high labor intensity, and achieve the effect of reducing labor intensity, improving surface quality, and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

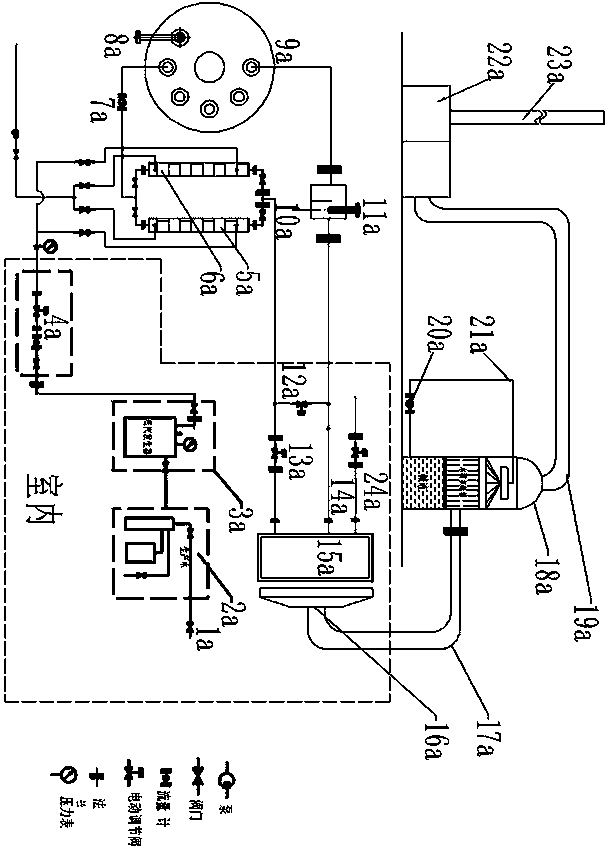

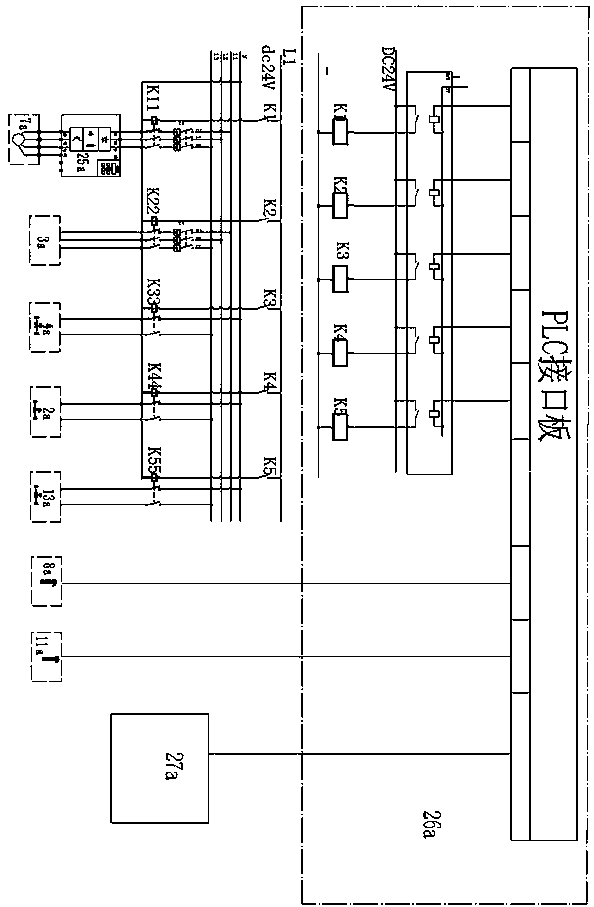

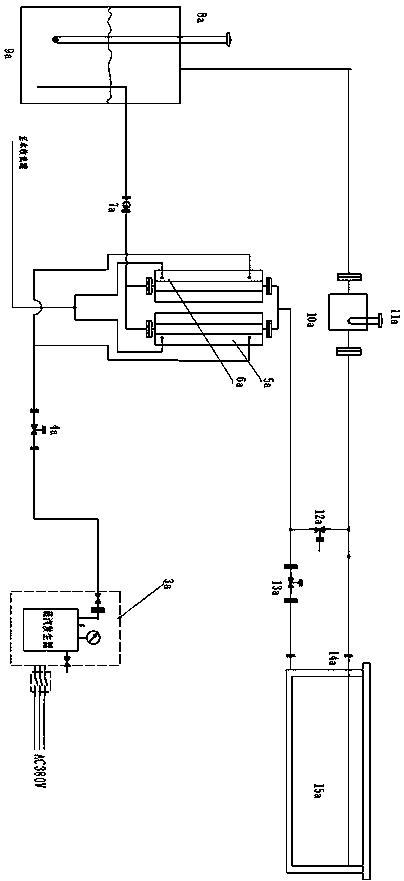

[0029] The semi-automatic pickling method for low-magnification test strips of the present invention will be further elaborated and illustrated below in conjunction with specific embodiments and accompanying drawings.

[0030] A semi-automatic pickling method for a low-magnification test piece, the method comprises the steps of:

[0031] Step 1: Make an appointment to heat the acid solution in the automatic pickling pool, and set the temperature and corrosion time;

[0032]The method for preheating the acid liquid in the step 1 is as follows: when the preheating mode is started, the system automatically starts the hot acid circulation pump and the steam generator, at this time the acid inlet valve of the acid pool is automatically closed, the bypass valve is automatically opened, and the acid The liquid is extracted from the hot acid tank, enters the sedimentation tank through the first graphite exchanger or the second graphite exchanger and returns to the hot acid tank; the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com