Preparation method of electronic grade propylene glycol monomethyl ether and product thereof

A propylene glycol monomethyl ether, electronic grade technology is applied in the preparation field of electronic grade propylene glycol monomethyl ether, can solve the problems of high catalyst activity and selectivity, low catalyst activity and selectivity, harsh reaction conditions, etc. By-products, beneficial to activation and ring opening, and the effect of stable reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

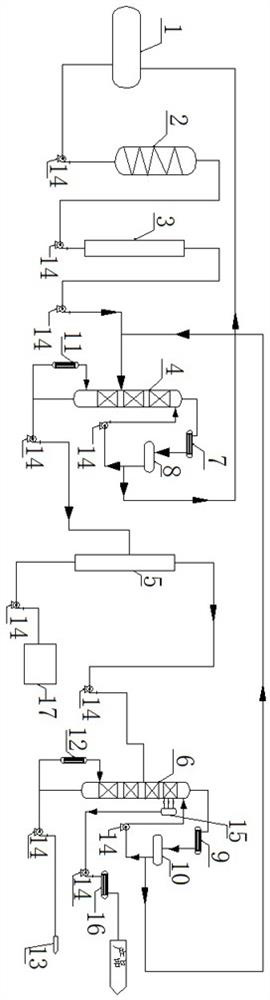

Image

Examples

preparation example Construction

[0024] The invention provides a kind of preparation method of electronic grade propylene glycol monomethyl ether, comprises the steps:

[0025] 1) Mix methanol, propylene oxide and alkaline ionic liquid catalyst, and react in a microchannel reactor to obtain a reaction liquid;

[0026] 2) Delighting the reaction solution in step 1) to obtain a delightening reaction solution;

[0027] 3) Evaporate the light-removing reaction solution in step 2), and perform negative pressure distillation on the obtained steam to obtain electronic grade propylene glycol monomethyl ether.

[0028] The invention mixes methanol, propylene oxide and alkaline ionic liquid catalyst, and reacts in a microchannel reactor to obtain a reaction liquid. In the present invention, the molar ratio of methanol to propylene oxide is preferably (2-11):1, more preferably 5:1. In the present invention, the cation of the basic ionic liquid catalyst is preferably 1,3-dialkylimidazolium cation, alkylimidazolium cati...

Embodiment 1

[0050] Inject propylene oxide, methanol and alkaline ionic liquid catalyst (1-butyl-3 methylimidazolium bicarbonate) into the raw material mixer through a metering pump (the feed rate of propylene oxide is 14Kg / h, the feed rate of methanol 23Kg / h, the amount of alkaline ionic liquid catalyst added is 0.5% of the mass of the raw material), multiple raw materials are mixed by the raw material mixer and then enter the raw material preheater, and the raw material preheater preheats the material to 50°C before entering the microchannel reaction The reaction is carried out in the reactor (control the temperature in the microchannel reactor at 100°C, the pressure is 0.3MPa, and the material residence time is 6min), and the gas chromatograph is used to detect and analyze the reaction solution (under the selected chromatographic conditions, the sample gasifies and passes through the chromatographic column , to separate the components therein. Detect with a hydrogen flame detector, calcu...

Embodiment 2

[0059] Propylene oxide, methanol and alkaline ionic liquid catalyst (1-butyl-3 methylimidazole hydroxide) are respectively injected into the raw material mixer through a metering pump (the feed rate of propylene oxide is 14Kg / h, and the feed rate of methanol is 30Kg / h, the amount of alkaline ionic liquid catalyst added is 1.5% of the mass of the raw material), multiple raw materials are mixed by the raw material mixer and then enter the raw material preheater, and the raw material preheater preheats the material to 50 °C before entering the microchannel reactor Fully react within the microchannel reactor (control the temperature in the microchannel reactor at 120°C, the pressure at 0.2MPa, and the material residence time for 3 minutes), and use a gas chromatograph to detect and analyze the reaction solution. The PO conversion rate is greater than 99%, and the isomer selectivity is greater than 98%. .

[0060] Transfer the obtained reaction liquid to the dealcoholization tower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com