Built-in sealed continuous ink supply system with pressure dynamic compensation function

A dynamic compensation and sealing technology, applied in printing and other directions, to achieve the effect of reducing the possibility, reducing the phenomenon of head resistance, and solving the phenomenon of air resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

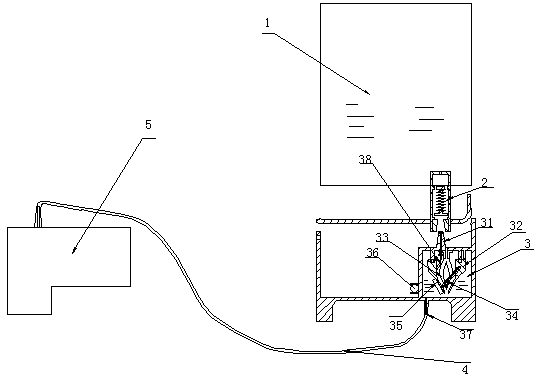

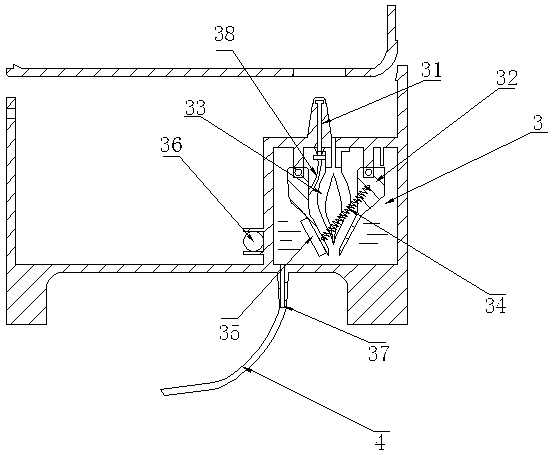

[0017] A built-in sealed pressure dynamic compensation continuous ink supply system, which includes an ink soft bag 1, a pressure dynamic compensation device and a print head 5, the ink soft bag 1 is located above the pressure dynamic compensation device, connected to the The ink inlet 31 of the pressure dynamic compensation device is connected, and an elastic air bag 33 is arranged in the pressure dynamic compensation device. The ink outlet 37 below the pressure dynamic compensation device is connected with the print head 5 through the ink supply tube 4. When the ink port 37 supplies ink, the pressure dynamic compensation device is in a sealed state.

[0018] The pressure dynamic compensation device comprises a pressure dynamic compensation container 3, an ink inlet 31, an air bag clip 32, an elastic air bag 33, a spring 34, a magnetic material 35, an intelligent switch 36, an ink outlet 37 and an ink inlet connecting rod 38, and the pressure dynamics An ink inlet 31 is arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com