Preparation method of expandable carbon nitride flame retardant epoxy resin

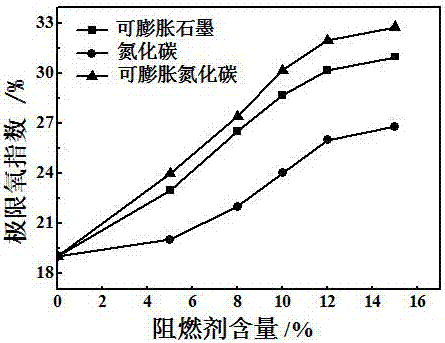

A technology of epoxy resin and carbon nitride, which is applied in the flame retardant field of flame retardant epoxy resin system, can solve the problem of destroying the layered structure, and achieve the effects of improving flame retardant performance, delaying decomposition, and increasing the value of oxygen index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

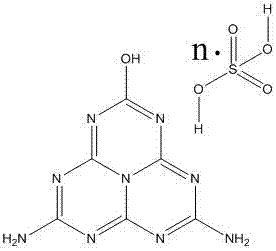

[0027] 1. Preparation of expanded carbon nitride:

[0028] 1. Add 30-50mL of concentrated sulfuric acid (preferably 10mL) to the flask, and add 10-12g (preferably 3g) of graphite-structured carbon nitride (g - C 3 N 4 ). Put it in a constant temperature water bath with a magnetic stirrer, turn on the magnetic stirrer, raise the temperature of the water bath to 60-80°C, stir until the carbon nitride dissolves, and obtain a carbon nitride-concentrated sulfuric acid solution.

[0029] 2. Put the carbon nitride-concentrated sulfuric acid solution into a low-temperature cold bath, and cool it to 8-10°C at a rate of 2-4°C / h. As the temperature decreases slowly, the solution begins to precipitate white expandable carbon nitride crystals. Finally, white expandable carbon nitride crystals were obtained.

[0030] 3. Transfer the white expandable carbon nitride crystals to a sand core funnel, filter under reduced pressure, take the solid phase and wash the precipitate with absolute et...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com