Method and device for processing off-gases in productive process of polyester or copolyester

A production process and tail gas technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve problems such as easy explosion, danger, waste of tetrahydrofuran, etc., to eliminate potential safety hazards, reduce investment and operating costs, avoid Effects of contact with open flames

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

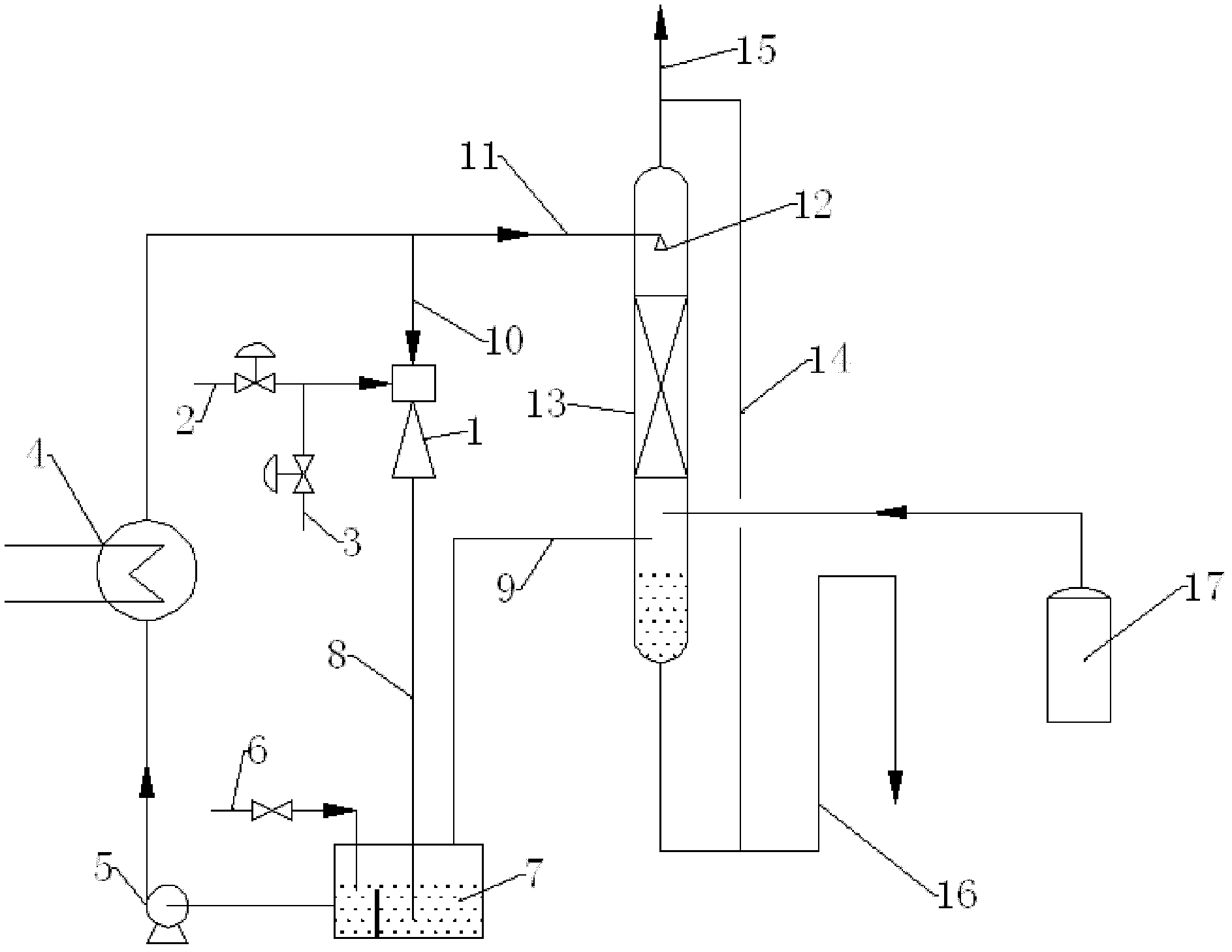

[0034] A device for treating tail gas in the production process of polyester or copolyester, such as figure 1 shown. The vacuum tail gas containing tetrahydrofuran discharged from the gas phase tube of the liquid ring vacuum pump and the high-concentration vacuum tail gas condensed by the top condenser of the butanediol separation tower enter the water jet pump 1 through the pipeline 2 and the pipeline 3 respectively. The water jet pump 1 communicates with the circulating water storage tank 7 through the tail pipe 8. After the two vacuum tail gases in the water jet pump 1 are absorbed by the high-pressure water generated by the circulating water pump 5, they enter into the circulating water through the tail pipe 8 of the water jet pump together. In the storage tank 7, gas-liquid separation is carried out in the circulating water storage tank 7.

[0035] Since the pressure of the butanediol separation tower in the PBT unit is usually controlled within the range of 40-60KPa, an...

Embodiment 2

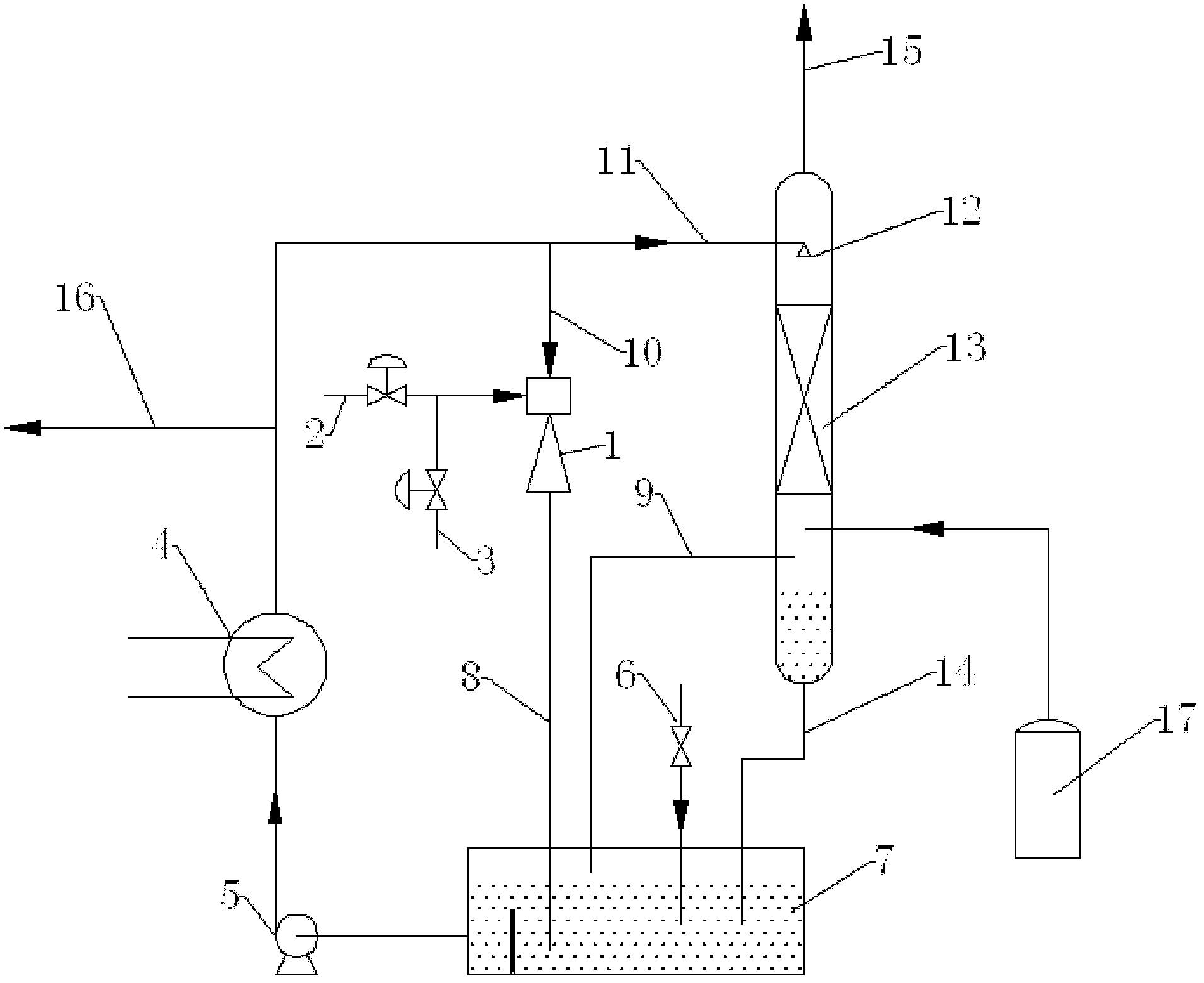

[0041] A device for treating tail gas in the production process of polyester or copolyester, such as figure 2 As shown, it differs from the device in Example 1 in that the tetrahydrofuran recovery liquid is automatically discharged, that is, the bottom of the spray absorption tower 13 of the device in this embodiment is connected to the circulating water storage tank 7 through a pipeline 14, and the spray absorption tower 13 absorbs The aqueous solution containing tetrahydrofuran flows into the circulating water storage tank 7; in addition, after the pipeline passes through the heat exchanger 4, there is another way (ie, the pipeline 16) to transport the circulating water to the tetrahydrofuran recovery unit for recovery.

[0042] The structure, connection relationship and working principle of other parts of the device of this embodiment are the same as those of the device of embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com