Carburetor with air channel

An air channel and carburetor technology, applied in carburetors, machines/engines, engine components, etc., can solve the problems of reduced engine output power, increased muffler volume, mixed gas discharge, etc., to achieve fuel consumption reduction, Overcome the effect of narrowing the space and reducing the intake air volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

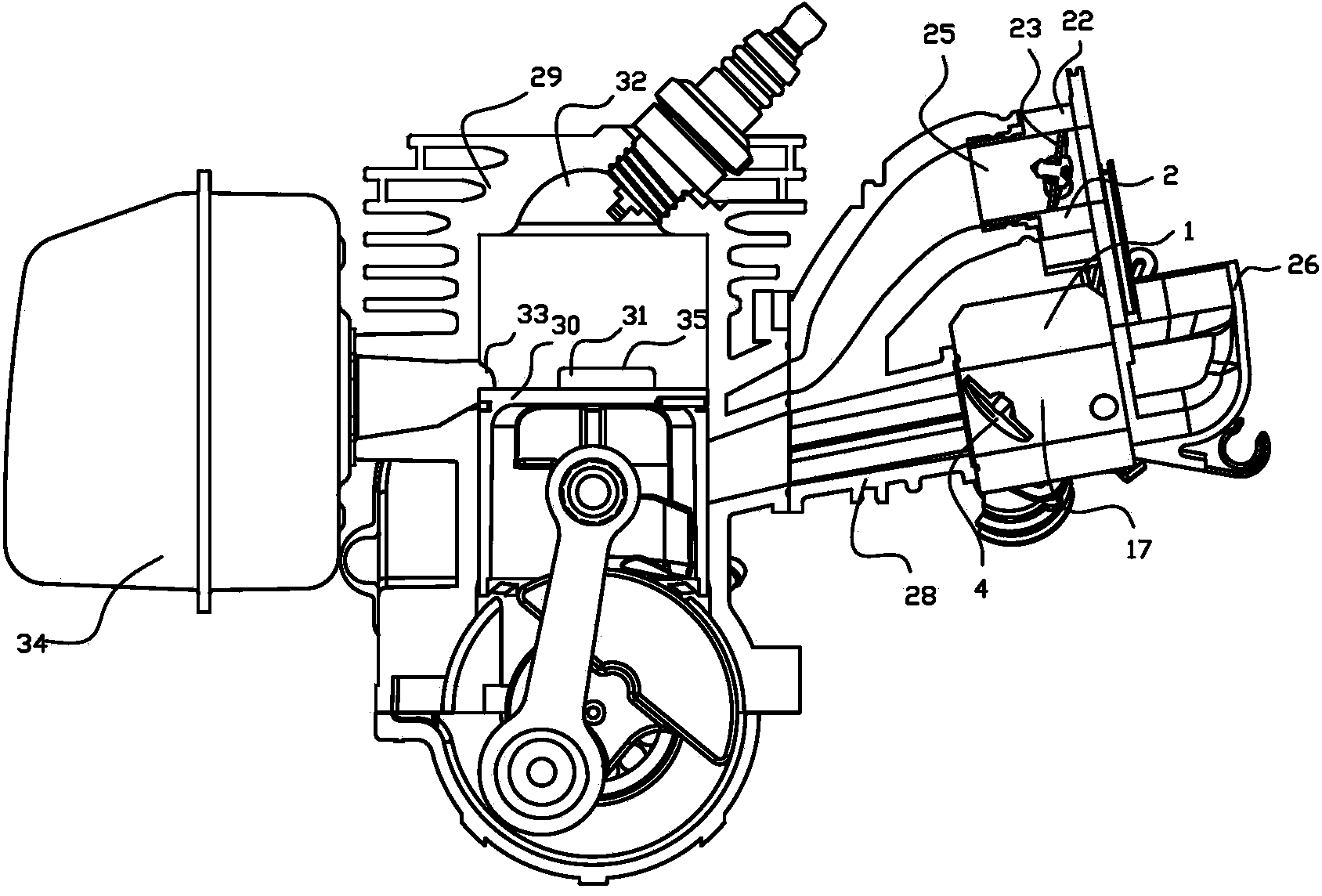

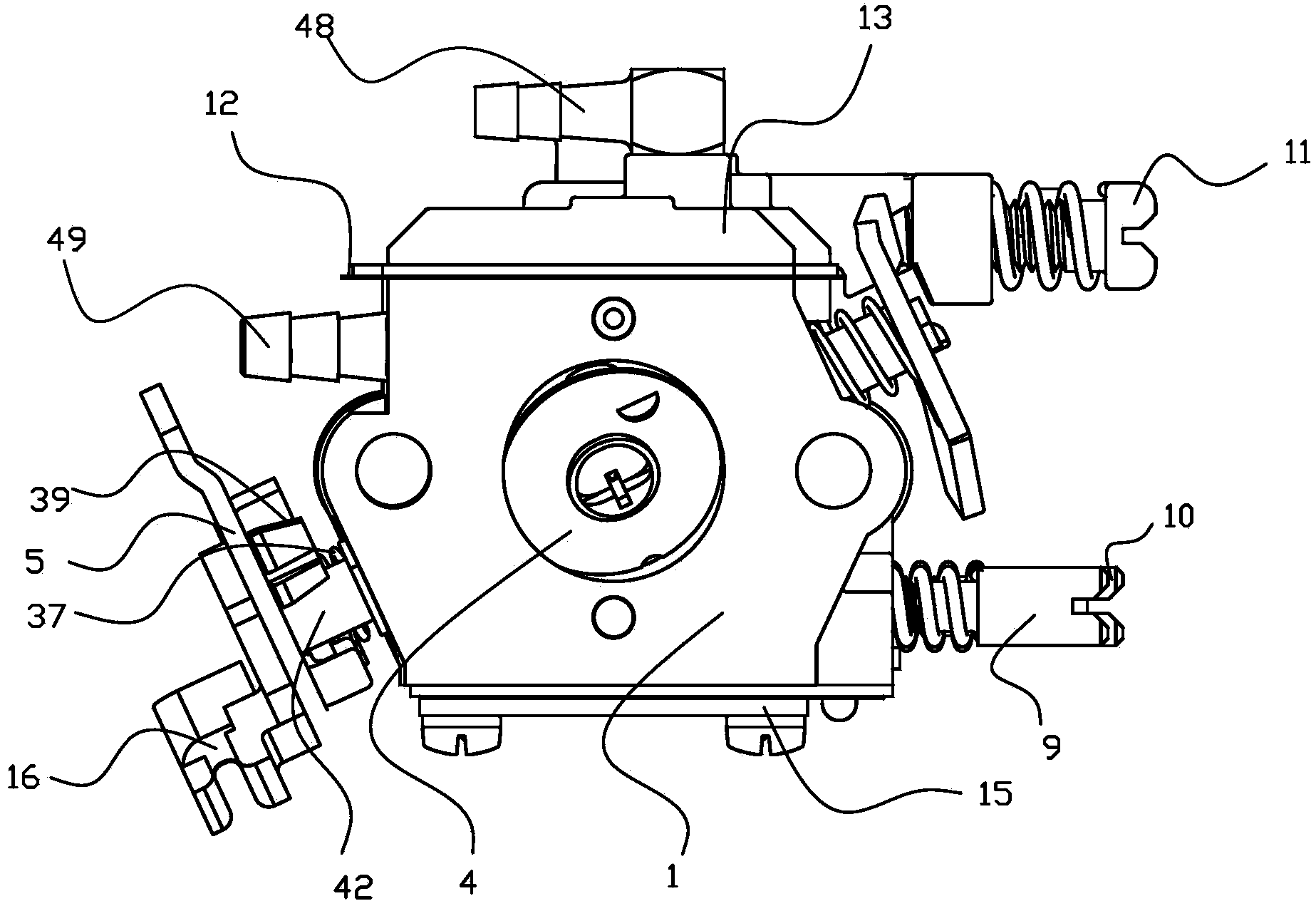

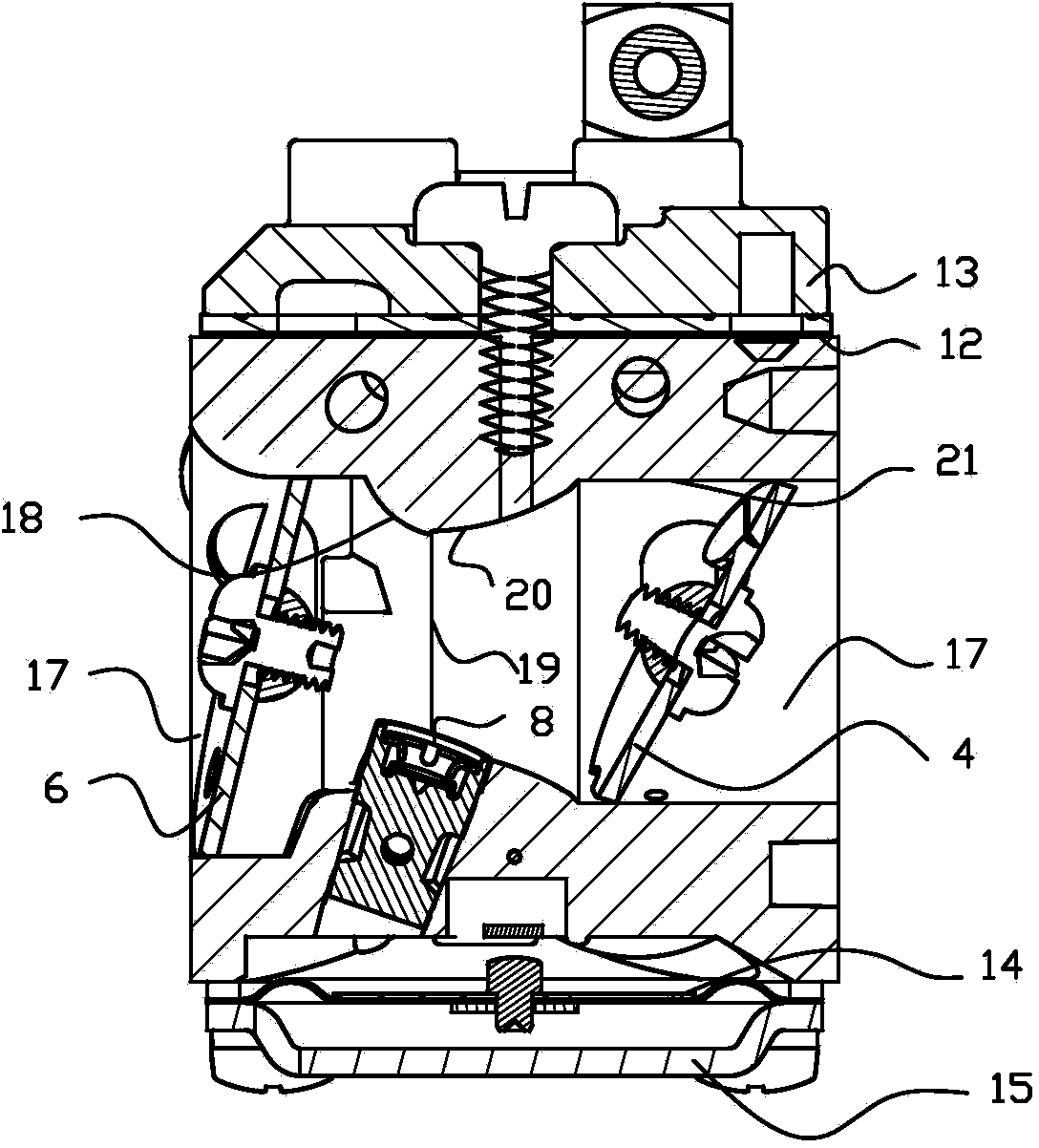

[0035] Such as Figure 1 to Figure 8 As shown, it is a carburetor with an air channel disclosed by the present invention, which includes a carburetor body 1, a carburetor main channel 17 that runs through the front and rear side walls of the carburetor body 1, and the carburetor body 1 The front side of the intake elbow 26 is fixed with an air intake elbow 26, the air channel 25 of the air channel device 2 communicating with the through hole 3 is installed on the intake elbow 26, and the lower side of the intake elbow 26 is provided with a right-angle turning channel 47. The right-angle turning channel 47 communicates with the main channel 17 of the carburetor. The air channel device is connected with the throttle rocker arm 5 through the linkage rod 27. When the throttle rocker arm 5 rotates, the opening and closing of the air channel device is driven by the linkage rod 27 . The invention can be used in small two-stroke engines on garden tools such as chain saws and brush cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com