All-carbon flue gas denitrification system and method

A flue gas and denitrification technology, which is applied in the full-carbon flue gas denitrification system and the denitrification field, can solve the problems of high biological toxicity in the ecological environment, air preheater blockage, ammonia secondary pollution, etc., and achieves convenient preparation, avoiding consumption, and high efficiency. The effect of removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

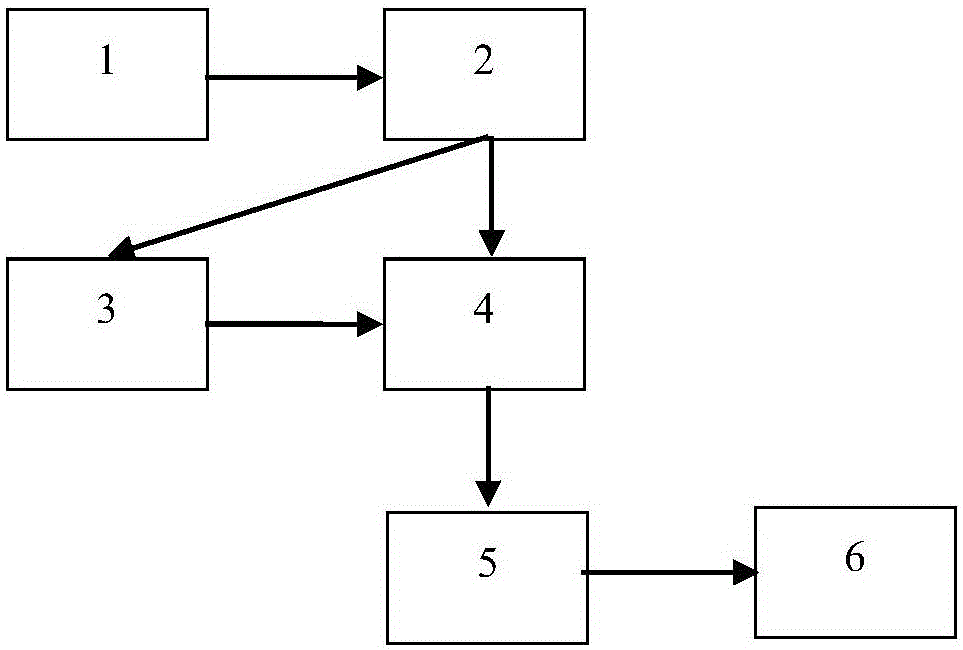

Image

Examples

Embodiment 1

[0040] The reaction device 4 is a moving bed reactor.

[0041] A method for all-carbon flue gas denitrification, comprising the steps of:

[0042]1. The inlet flue gas detection device 1 monitors and learns that the oxygen content in the flue gas is 0.8%, and the hypoxic mode is turned on at this time;

[0043] 2. The flue gas and carbon monoxide (the amount of carbon monoxide is three times the amount of nitrogen oxides in the flue gas and the sum of the oxygen in the flue gas) are mixed, and they enter the moving bed reactor together for reaction. The reaction temperature is 150 ° C. The reaction The air speed ratio in the device is 4000h -1 .

[0044] The moving bed is loaded with carbon carrier catalyst particles, and the carbon carrier catalyst includes carrier active coke and active metal copper supported on the active coke. The active metal copper is loaded on the active coke carrier by impregnation method.

Embodiment 2

[0046] The reaction device 4 is a circulating fluidized bed.

[0047] A method for all-carbon flue gas denitrification, comprising the steps of:

[0048] 1. The entrance flue gas detection device 1 monitors and learns that the oxygen content in the flue gas is 2%, and at this time, the high oxygen mode is turned on;

[0049] 2. Flue gas and carbon monoxide (the amount of carbon monoxide is five times the amount of nitrogen oxides in the flue gas) respectively enter different zones in the circulating fluidized bed for reaction, the reaction temperature is 300 ° C, after 0.5 min of reaction. The circulating fluidized bed is divided into two areas, the ascending zone and the descending zone. The catalyst bed material is loaded in the bed, and the bed material circulates in the ascending zone and the descending zone. The circulation rate of the bed material is determined by the reaction time. The flue gas enters the descending zone, and the carbon monoxide enters the ascending zo...

Embodiment 3

[0052] The reaction device 4 is a double-chamber reactor.

[0053] A method for all-carbon flue gas denitrification, comprising the steps of:

[0054] 1. The entrance flue gas detection device 1 monitors and learns that the oxygen content in the flue gas is 5%, and at this time the high oxygen mode is turned on;

[0055] 2. The flue gas and carbon monoxide (the amount of carbon monoxide is three times the amount of nitrogen oxides in the flue gas) respectively enter different reaction chambers in the double-chamber reactor for reaction. The reaction temperature is 100 ° C. Every 5 minutes, the flue gas The input direction of gas and carbon monoxide is switched, and they start to be input into the reaction zone of the other party for reaction. The nitrogen oxides in the flue gas react and adsorb to the surface of the catalyst to form nitrogen-containing compounds, and the reactions of carbon monoxide and nitrogen-containing compounds to form nitrogen gas.

[0056] A carbon-sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com