Method and device for controlling NOx concentration in smoke gas of cement kiln

A technology of control device and central controller, applied in separation methods, chemical instruments and methods, and separation of dispersed particles, can solve problems affecting the long-term stable operation of cement kiln production lines, threats to normal operation of induced draft fans, and blockage of catalyst pores, etc., to achieve Reduced denitrification costs, reduced tail ammonia escape, and strong adaptability to load fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

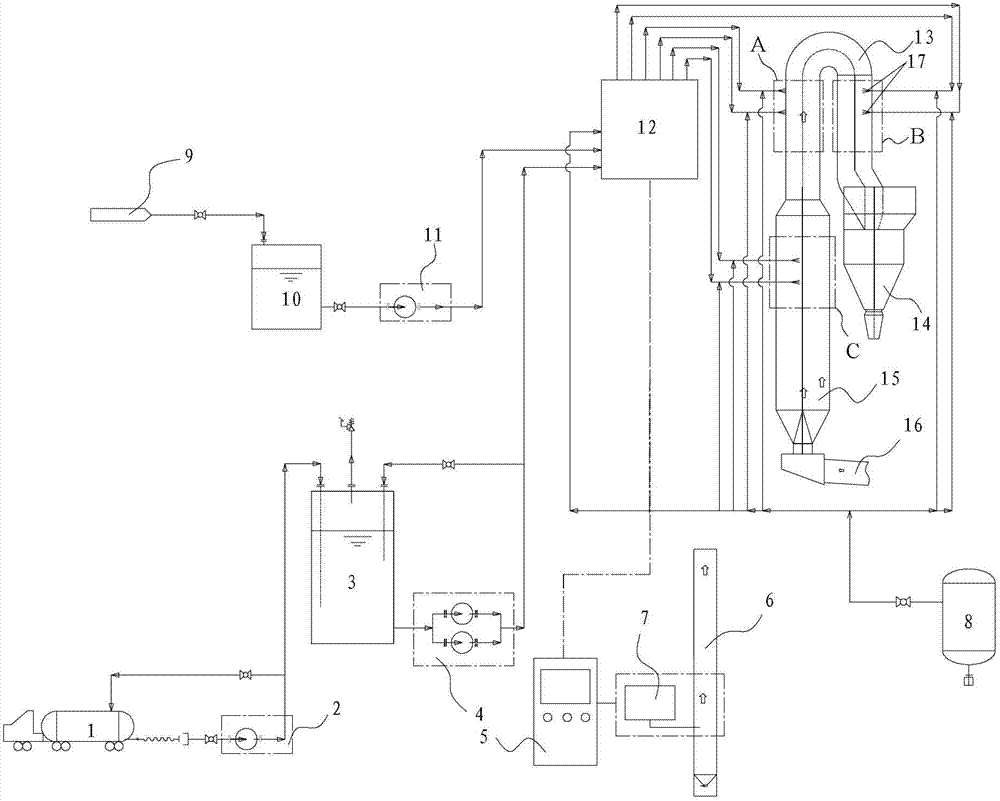

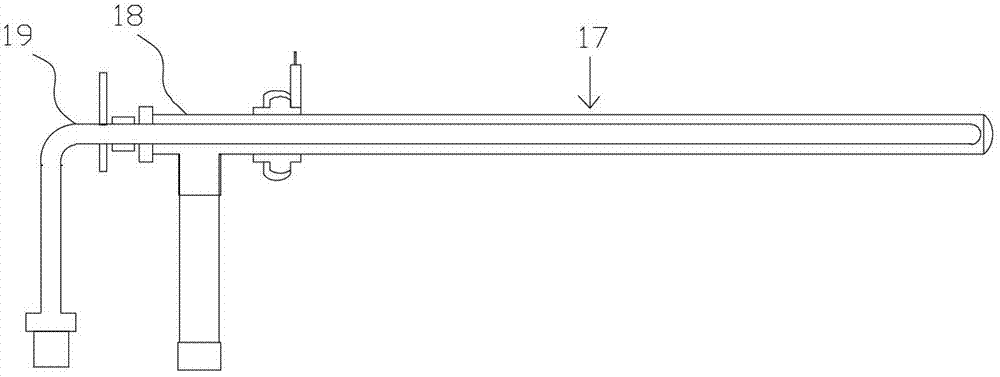

[0046] The spray gun is installed on the outlet flue ( figure 1 Injection module 1 shown in the dotted box in A). According to the CFD simulation results, the injection points are divided into three layers, each layer has 2 nozzles, and they are distributed on the circular flue. All injection points fall within the temperature range of 800-950°C. There are spray guns installed at the three layers of the system, and each spray gun is numbered A1, A2, B1, B2, C1, C2, and the system is put into automatic operation. X Concentration, flow and other parameter feedback (temperature changes, the system selects the appropriate temperature window according to the temperature parameter feedback, that is, changes the injection point level; flow changes, what needs to be changed is the size of the ammonia injection amount of the system, and the change of NSR mainly depends on the NOx concentration Change and change), the system automatically selects the point, A1, A2, B1, B2, C1, C2 can ...

Embodiment 2

[0053] According to the CFD simulation results, the spray gun is installed in the upper part of the decomposition kiln body ( figure 1 Injection module 3) and outlet flue ( figure 1 Injection module 2 shown in the dotted line box in middle B), the injection points are divided into two layers, each layer has 3 pieces (A1, A2, A3, B1, B2, B3). All injection points fall within the temperature range of 800-950°C. According to the temperature, concentration, flow and other parameter feedback of the system, the system automatically selects the point, and 3-6 spray guns can be selected from A1, A2, A3, B1, B2, B3, which are the spray gun points actually put into operation.

[0054] The flue gas treatment capacity of the denitrification system is 3.0×10 5 N m 3 / h, NOx content 700mg / Nm 3 , adjust NSR=1.8, kiln tail chimney NO X The concentration is reduced to about 150mg / Nm 3 , the denitrification rate fluctuates around 78%.

[0055] Adjust NSR=1.7, kiln tail chimney NO X The ...

Embodiment 3

[0060] According to the CFD simulation results, it is determined that the outlet flue is vertically upward on the flue gas pipeline ( figure 1 Injection module 2 shown in the dotted line box in middle A), the injection point is a layer, with a total of 8 spray guns (A1, A2, A3, A4, A5, A6, A7, A8). All injection points fall within the temperature range of 800-950°C. The spraying points of the system are all equipped with spray guns, and the system is put into automatic operation. According to the feedback of parameters such as system temperature, concentration, and flow rate, the system automatically selects the point. A1, A2, A3, A4, A5, A6, A7, and A8 can be selected Select 4-8 spray guns as the actual spray gun points that are put into operation.

[0061] The system automatically selects the point as the spray gun point actually put into operation.

[0062] The flue gas treatment capacity of the denitrification system is 6.0×10 5 N m 3 / h, NOx content 1000mg / Nm 3 , adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com