Preparation method and application of starch and poly(butylene succinate) thermoplastic blend

A polybutylene succinate and thermoplastic technology, which is applied in the field of environmental protection, can solve the problems that natural starch does not have thermoplastic processing properties, etc., to overcome the difficulty of controlling the dosage of carbon sources, reduce the cost of denitrification, and strong adaptability effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

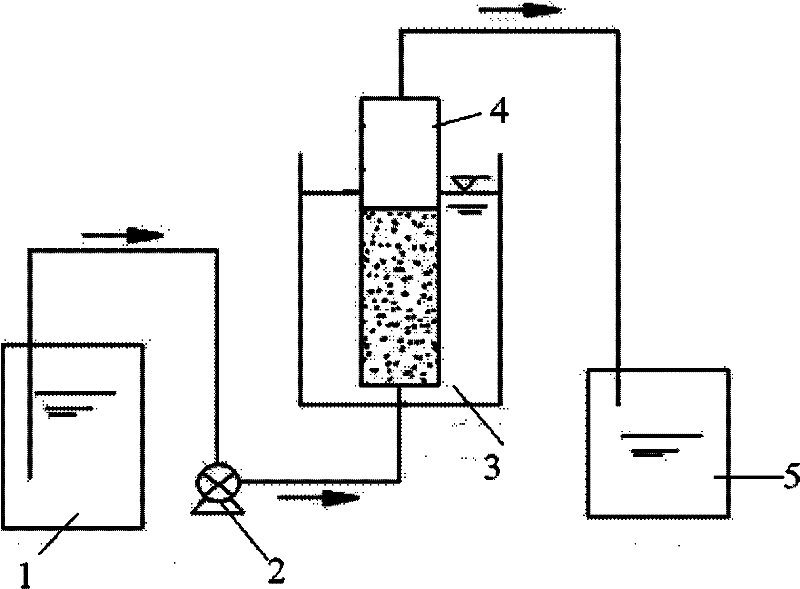

Method used

Image

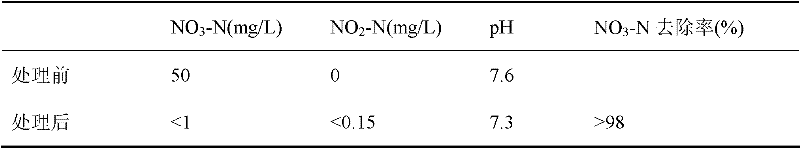

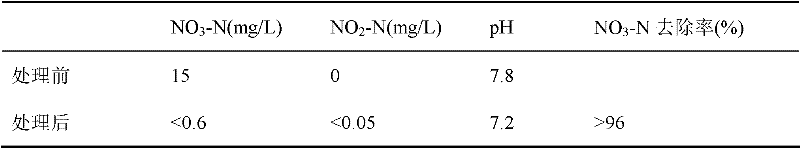

Examples

Embodiment 1

[0019] The preparation method of thermoplastic blend of starch and polybutylene succinate, after stirring 50g cornstarch, 30gPBS (molecular weight 90000), 15g water and 5g wood powder, in a twin-screw extruder at 140~180 ℃ extrusion granulation.

Embodiment 2

[0021] The preparation method of starch and polybutylene succinate thermoplastic blend, after stirring 52g cornstarch, 30gPBS (molecular weight 90000), 13g water and 5g wood powder, extrude at 160 ℃ in twin-screw extruder out of granulation.

Embodiment 3

[0023] The preparation method of starch and polybutylene succinate thermoplastic blend, after 55g tapioca starch, 33gPBS (molecular weight 100000), 10g water and 2g KH-560 silane coupling agent are stirred, in twin-screw extruder Extrude and granulate at 140-180°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com