Dedusting and denitration system for thermal power plant fire coal smoke

A technology for coal-fired flue gas and thermal power plants, applied in the field of flue gas dedusting and denitrification systems, can solve problems such as catalyst wear, pore blockage, and high concentration of fly ash, and achieve the effects of reducing denitrification costs, stabilizing catalytic performance, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

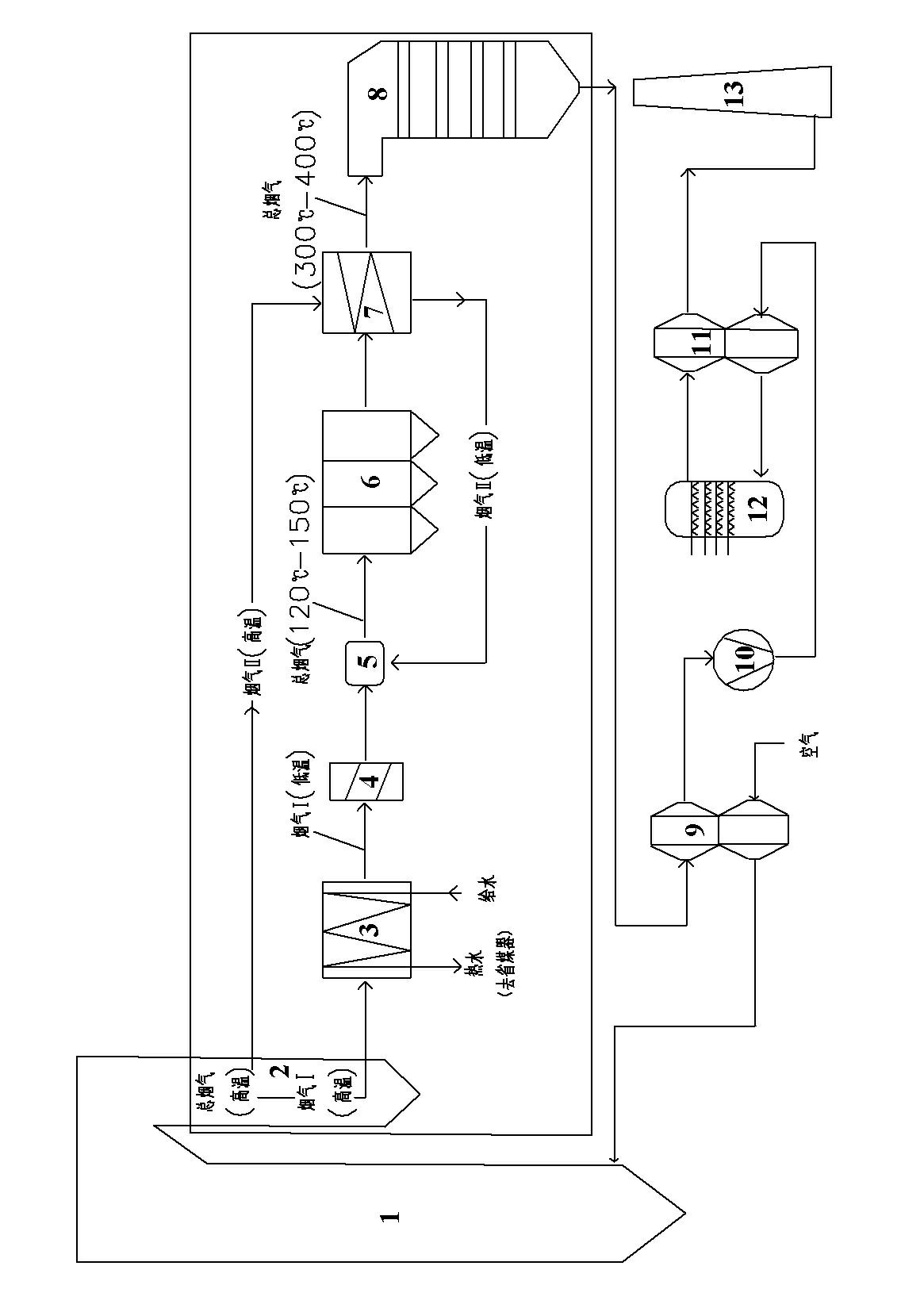

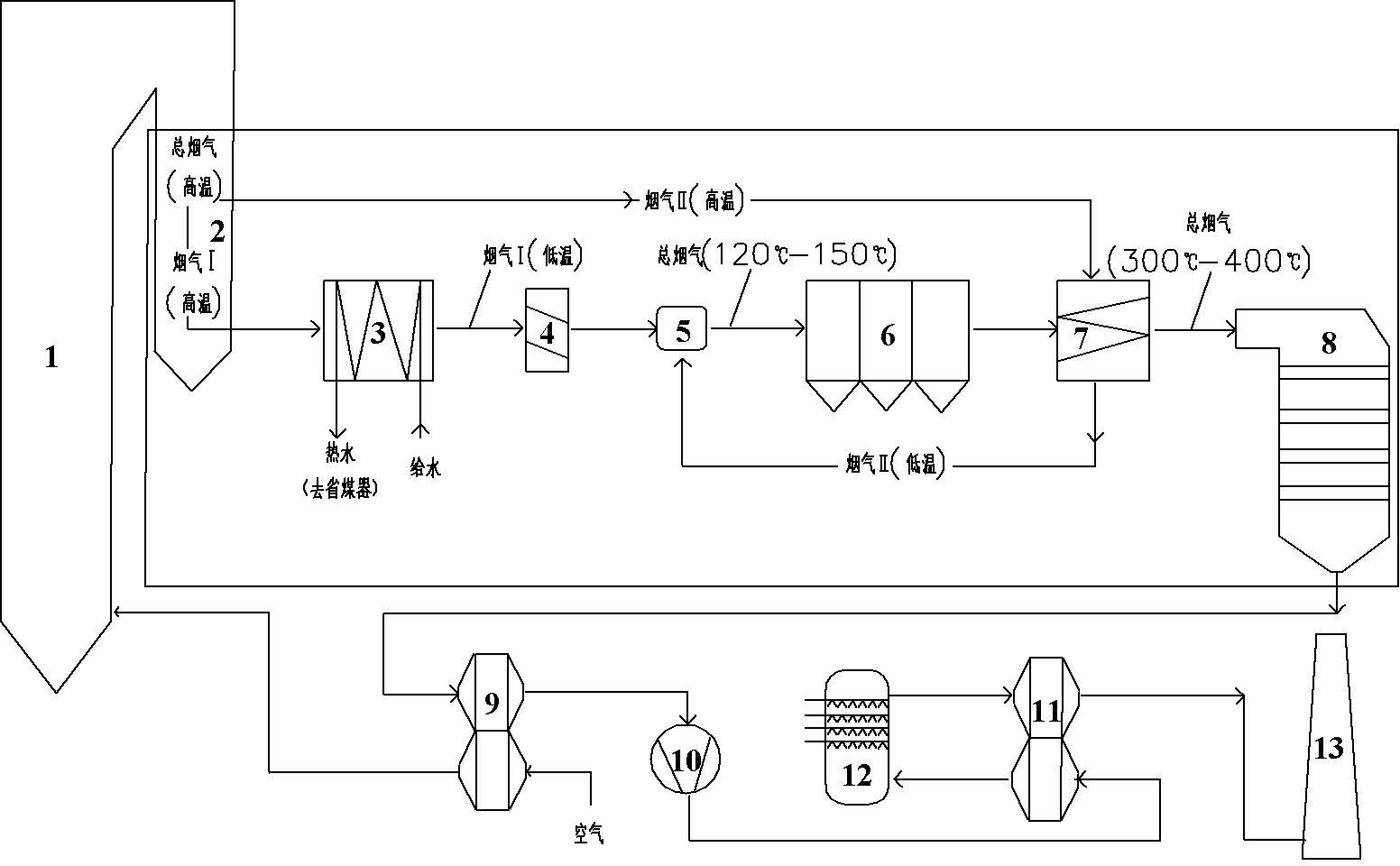

[0014] See figure 1 , which includes a coal-fired boiler 1, an economizer 2, a heat exchanger, an SCR reactor 8, and an air preheater 9. The flue gas of the coal-fired boiler 1 leads to the inlet of the economizer 2, and the heat exchanger includes a heat exchanger Heat exchanger Ⅰ3, heat exchanger Ⅱ7, heat exchanger Ⅰ3 adopts a liquid-gas heat exchanger, heat exchanger Ⅱ7 adopts a gas-gas heat exchanger, the low-temperature inlet to the low-temperature outlet of heat exchanger Ⅰ is water, and the water flow direction of the low-temperature outlet Economizer 2, economizer 2 has two flue gas outlets, one of which leads to the high temperature inlet of heat exchanger Ⅰ3, and the other flue gas outlet leads to the high temperature inlet of heat exchanger Ⅱ7, the heat exchanger The high temperature outlet of Ⅰ3 is connected to the inlet of the flue gas flow regulating valve 4, the outlet of the flue gas flow regulating valve 4 is connected to one inlet of the flue gas mixer 5, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com